Shaping and forming feeding device for viscous material

A feeding device and material technology, which is applied in the field of feeding device and viscous material shaping feeding device, can solve the problem that it is difficult to ensure the quality of feeding, automatic weighing and packaging. Automatic weighing, packaging, adhesion and friction Damage, difficult to meet the problem of direct weighing or packaging of viscous materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

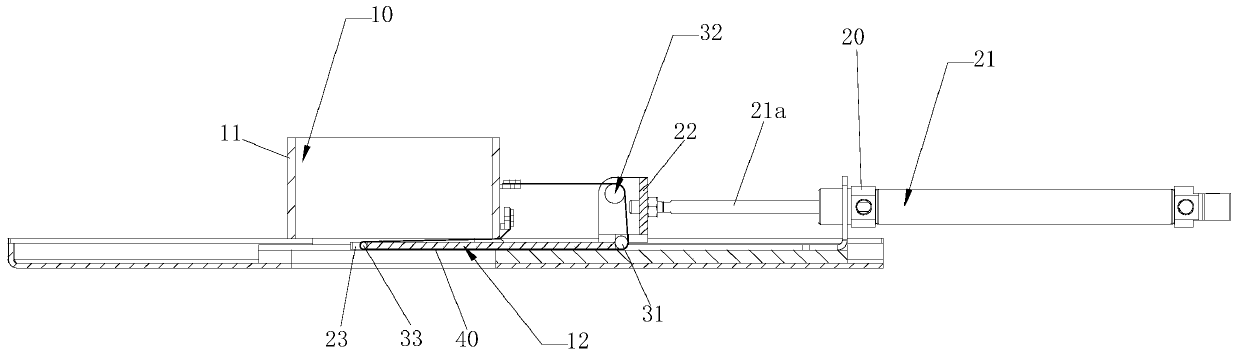

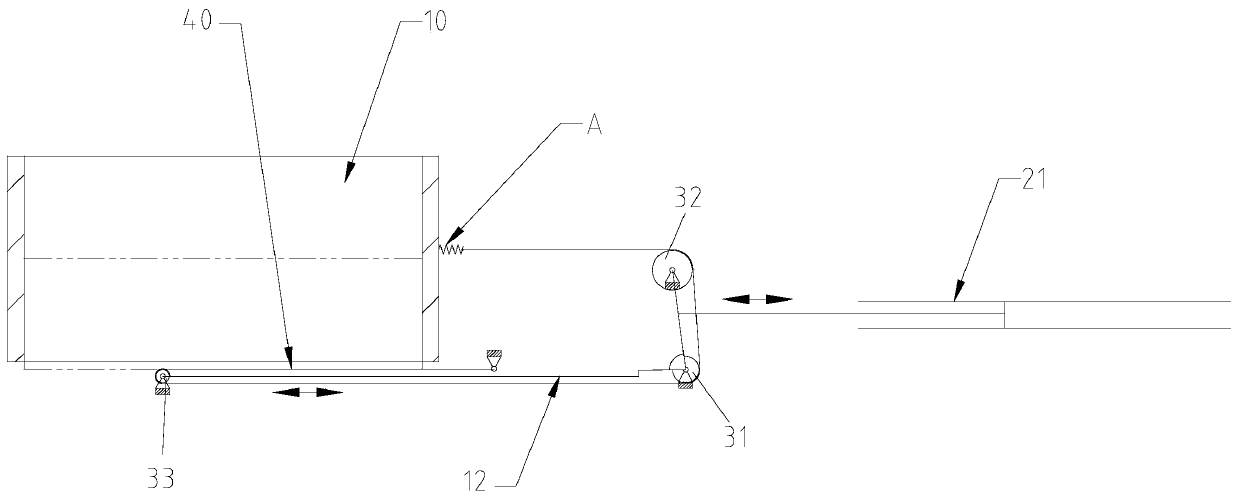

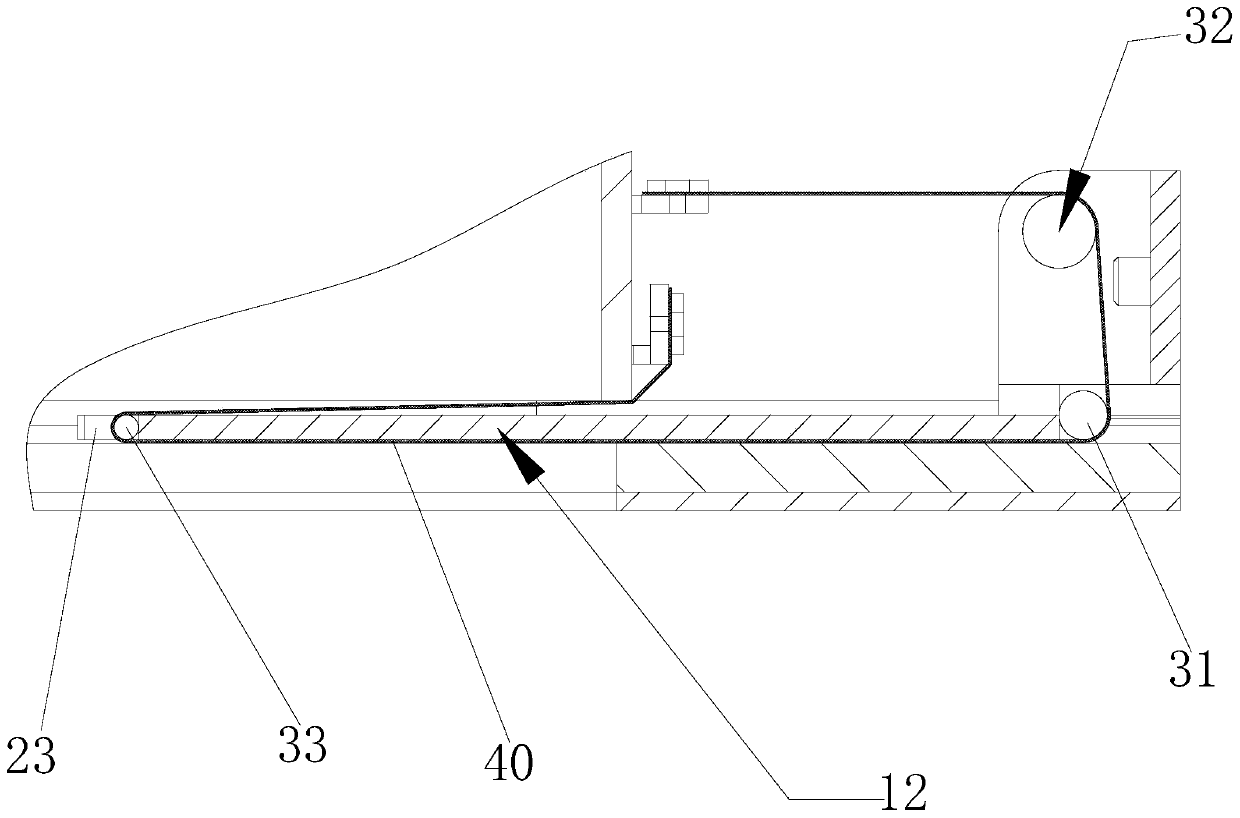

[0017] A fixed-shape feeding device for viscous materials, comprising a hopper 10 for flattening the viscous materials, the hopper 10 includes a forming cylinder 11 and a material receiving plate 12 arranged below the forming cylinder 11, the material receiving plate 12 The upper plate surface is arranged parallel to the lower mouth of the forming cylinder 11, and it is characterized in that: one side of the material receiving plate 12 is provided with a driving mechanism 20 that drives the material receiving plate 12 to move back and forth along the direction parallel to the lower mouth of the forming cylinder 11;

[0018] The drive mechanism 20 includes a cylinder 21 arranged along the moving direction of the receiving plate 12, the drive rod 21a end of the cylinder 21 is erected with a connecting frame 22, and one side of the lower shelf surface of the connecting frame 22 is fixedly provided with the receiving plate 12. Parallel translation plate 23, the side of described tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com