A flexible and stretchable hydrogel optical fiber sensor and its preparation and application

An optical fiber and hydrogel technology, applied in the directions of cladding fiber, optical waveguide light guide, fiber chemical characteristics, etc., can solve problems such as unfavorable use, instability, and easy water loss signal transmission, and achieve low production cost and optical transmission. The effect of stable signal and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation of lithium bromide aqueous solution in the embodiment:

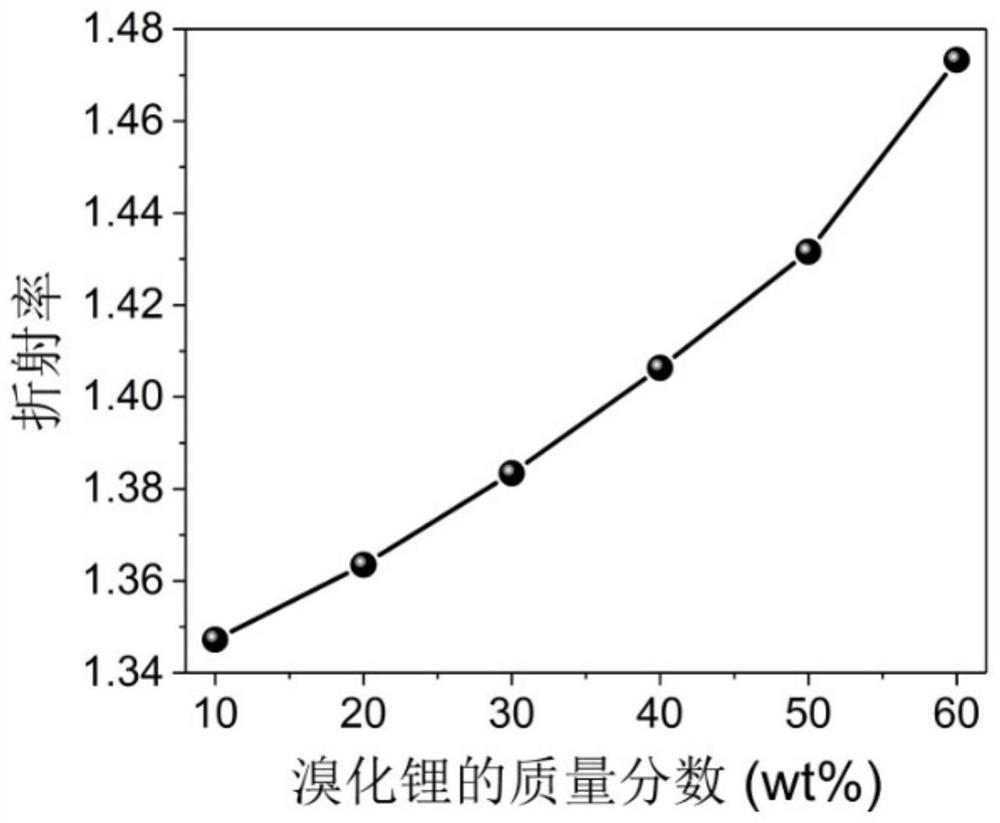

[0031] Move the weighed anhydrous lithium bromide into deionized water, shake to dissolve and then ultrasonically remove air bubbles. Such as figure 1 As shown, with the increase of lithium bromide concentration, the refractive index of lithium bromide aqueous solution also increases. Among them, the measurement of the refractive index uses a Japanese ATAGO PAL-RI digital display refractometer.

[0032] Preparation of acrylamide aqueous solution containing lithium bromide:

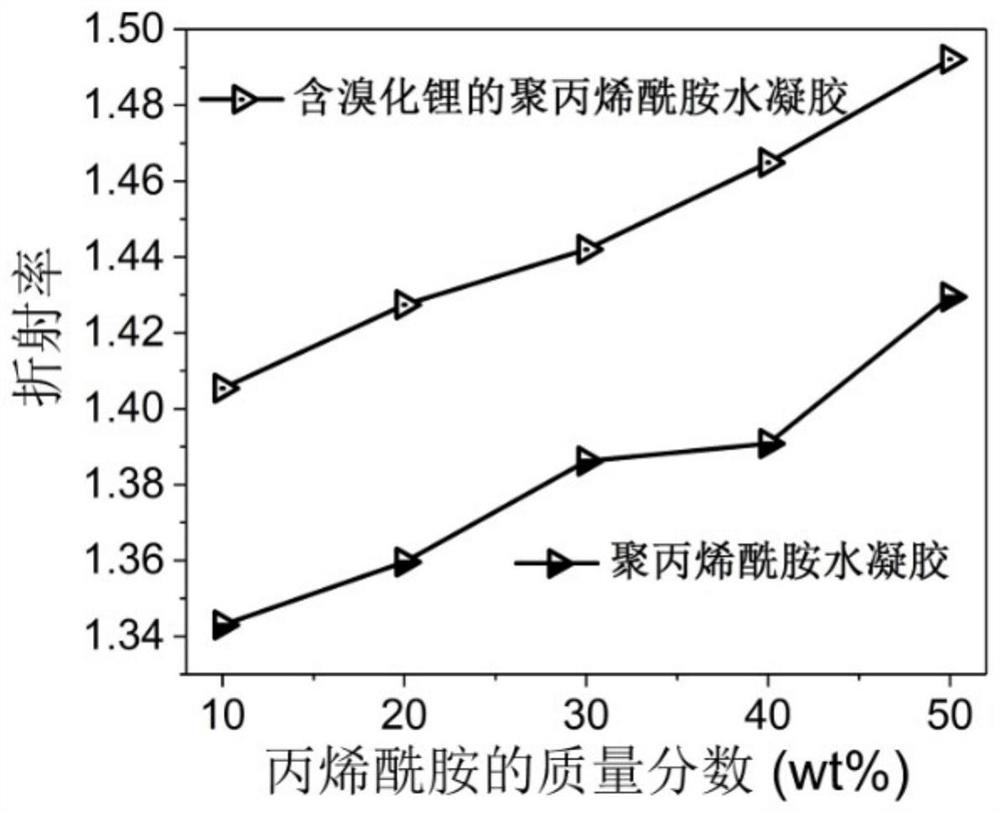

[0033] Transfer the weighed acrylamide monomer into lithium bromide aqueous solution, shake to dissolve, and then ultrasonically remove air bubbles. Such as figure 2 As shown, the refractive index of the hydrogel containing lithium bromide is higher, and all of them increase with the increase of the concentration.

Embodiment 1

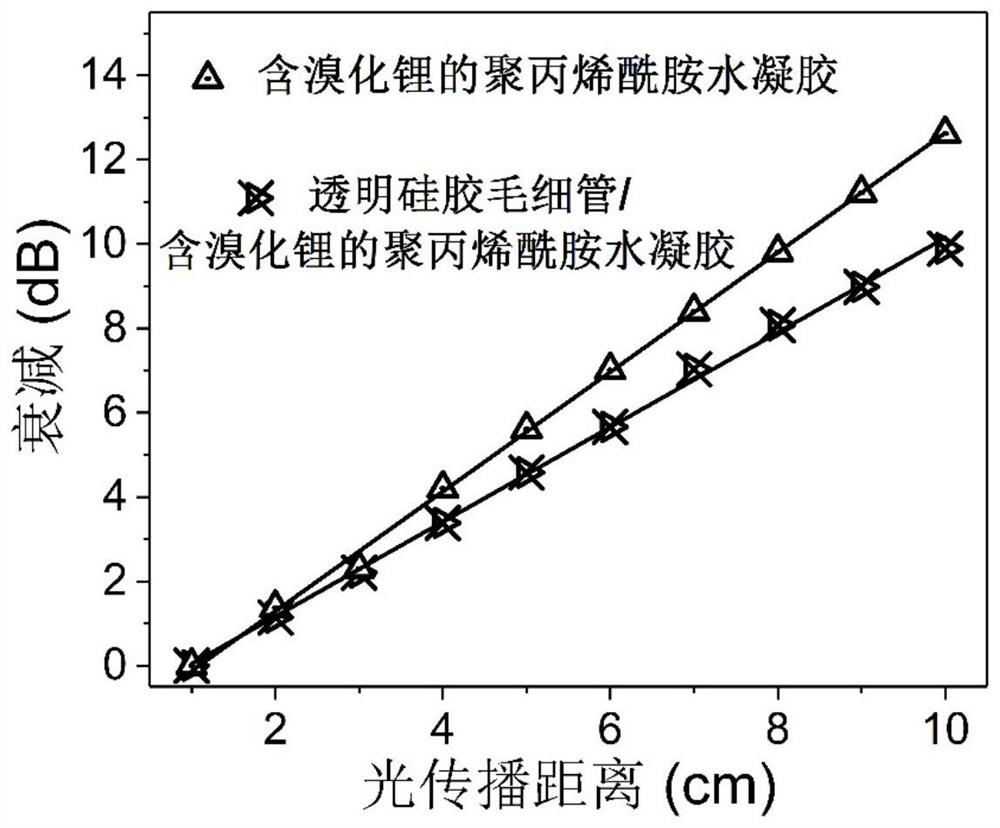

[0035] Prepare 7mL of 50wt% lithium bromide (refractive index 1.4316), (purchased from Titan Technology Company, product number is 01112263) mixed with 3g of acrylamide (purchased from Sigma Company, product number is V900845), and then add 0.0045g of Photoinitiator 2,2'-azobisisobutyramide hydrochloride (purchased from Sigma Company, product number is 440914) and 0.012g of cross-linking agent N,N'-methylenebisacrylamide (purchased from Sigma Company , item number 146072). Then the mixed solution was injected into a transparent silica gel capillary (purchased from Shanghai Shenhui Rubber and Plastic Products Factory), and cured by ultraviolet light for 2 minutes to obtain an optical fiber of transparent silica gel capillary / polyacrylamide hydrogel containing lithium bromide (refractive index 1.4221).

Embodiment 2

[0037] Prepare 7mL of 50wt% lithium bromide (refractive index 1.4320) and mix with 3g of acrylamide, then add 0.0045g of photoinitiator 2,2'-azobisisobutylamidine hydrochloride and 0.012g of Linking agent N, N'-methylenebisacrylamide. Then the mixed solution was poured into a transparent silica gel capillary, and cured by ultraviolet light for 2.5 minutes to obtain an optical fiber of transparent silica gel capillary / polyacrylamide hydrogel containing lithium bromide (refractive index 1.4233).

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com