Square sleeve structure module of stage frame

A technology for structural modules and stages, applied in the field of stage stands, can solve the problems of environmental pollution, low use cost, short service life, etc., and achieve the effect of simplifying the processing process, saving materials, and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

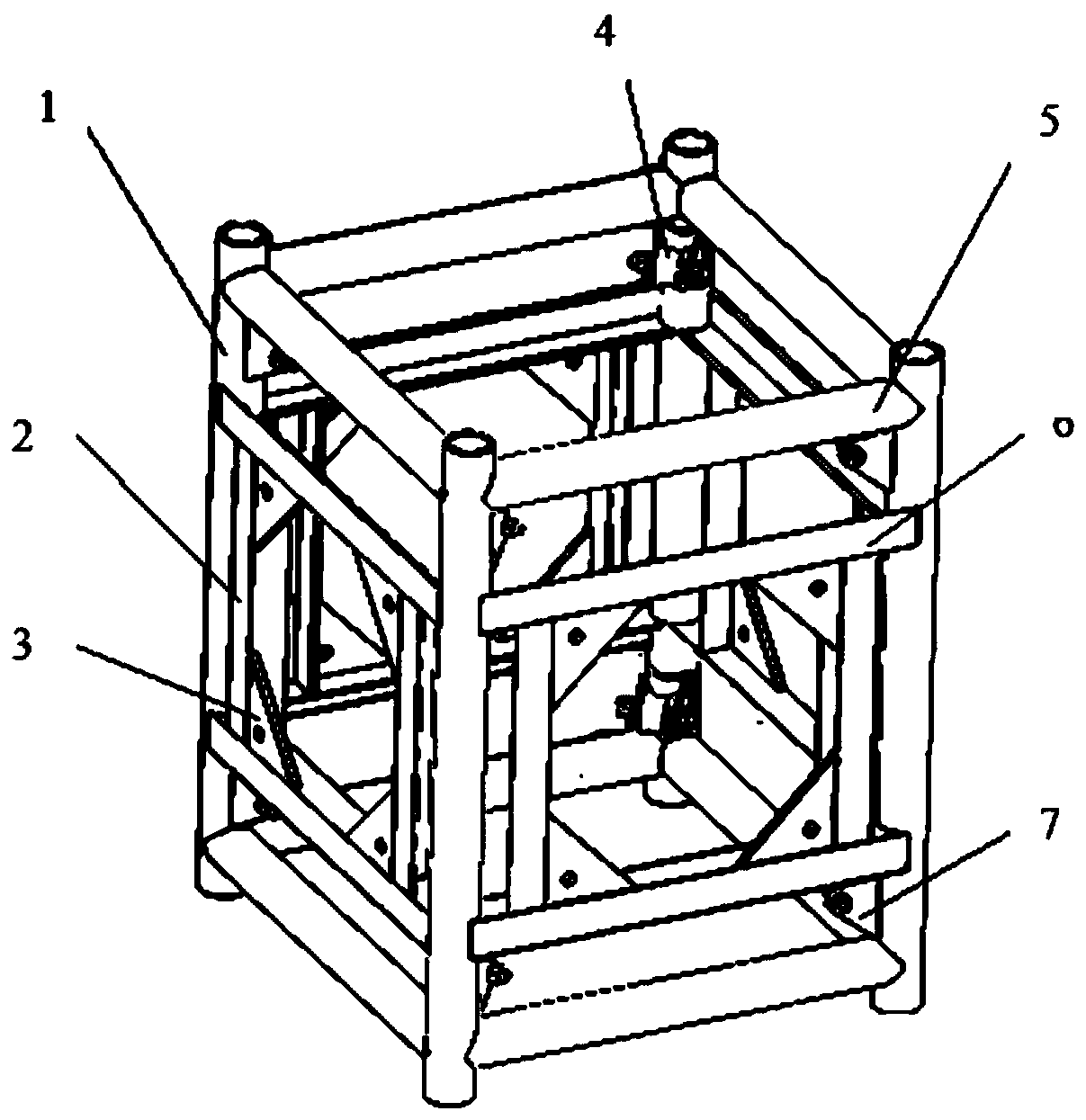

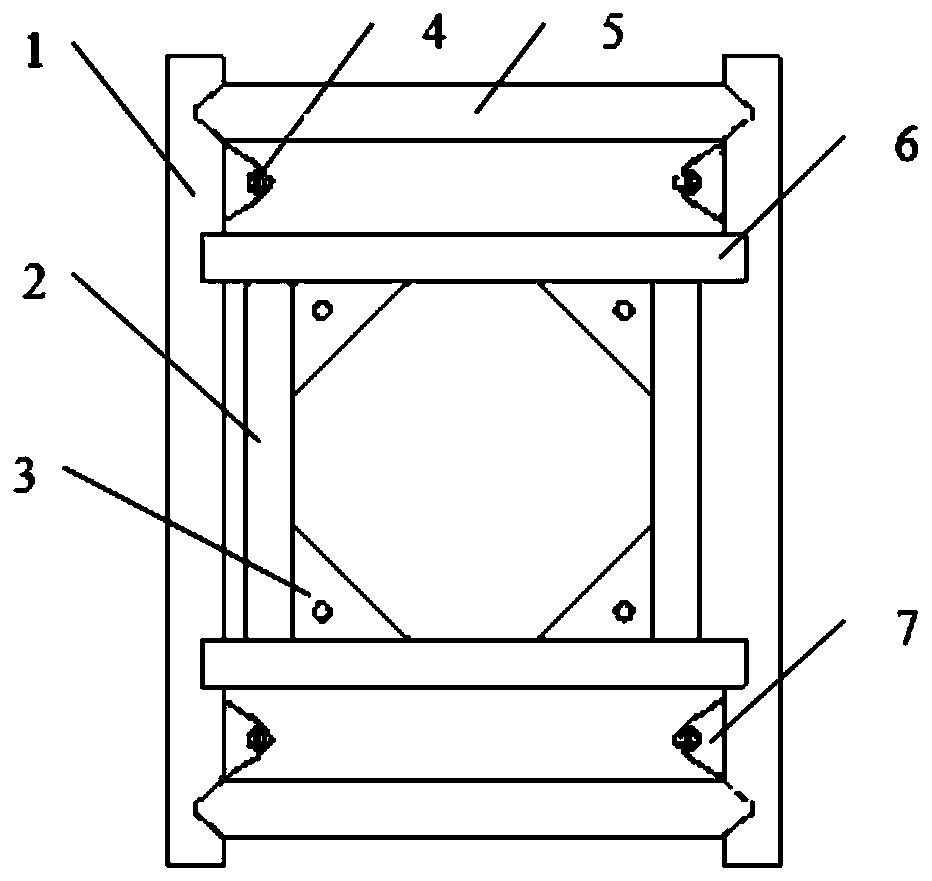

[0047] like figure 1 , figure 2 The square sleeve structure module of the stage frame shown is set on the truss, including a "cuboid"-shaped first frame composed of four columns 1 and eight beams 5 connecting the columns 1, and welded on the columns 1 close to The crawling module of the beam 5, the beam 5 has a curved surface 8 for fitting the column 1, the beam 5 and the column 1 are welded and fixed, and the cross section of the first frame is "square"; the crawling module includes a rubber tire 4 and a rubber tire fixing part 7, And a cylindrical connecting rod; the rubber tire 4 is hinged on the rubber tire fixing part 7, the rubber tire fixing part 7 has a curved surface 10 for fitting the column 1, and the rubber tire fixing part 7 is welded on the column 1; the rubber tire 4 It has a curved surface 11 for fitting the truss, and has a through hole in the axial direction with the rolling friction of the truss, and the rubber tire has a centrally symmetrical structure; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com