Epidermal thermal activation coating device

A coating device and thermal activation technology, applied in the direction of mechanical equipment, connecting components, etc., can solve the problems of affecting product quality, affecting the use effect, and weak coating force, so as to increase the pressure of air wrapping, avoid bulging of the foreskin, and improve The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

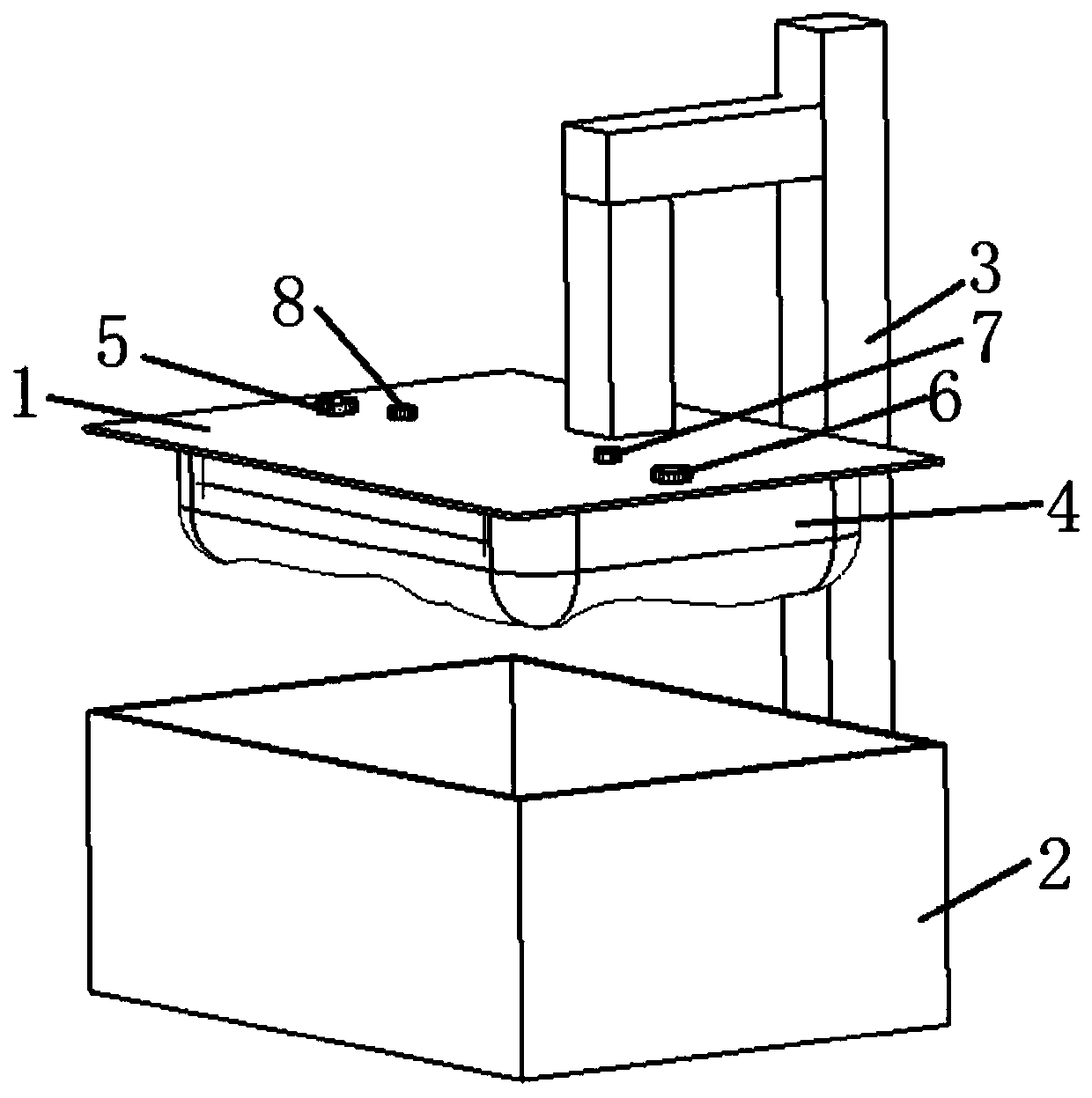

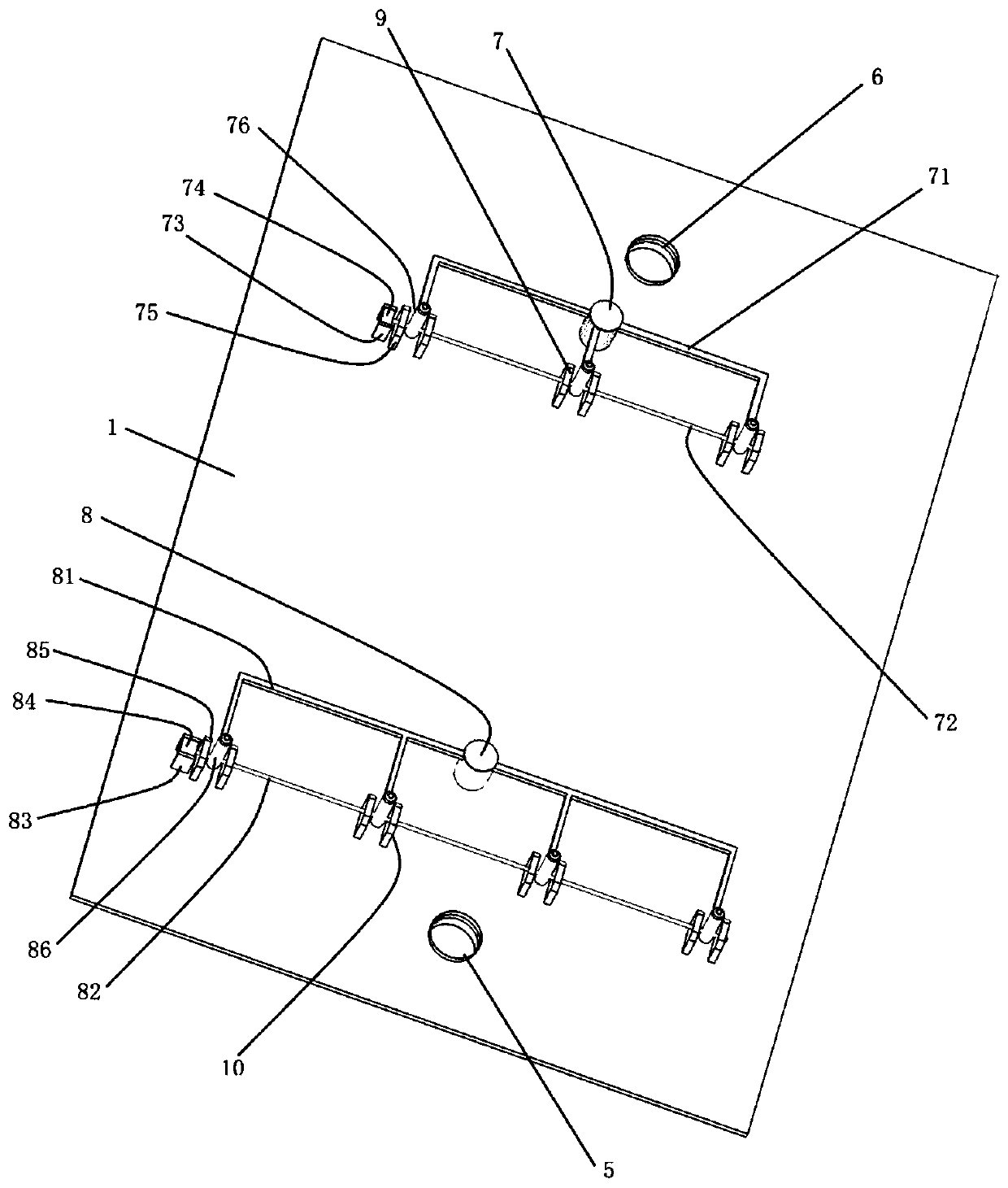

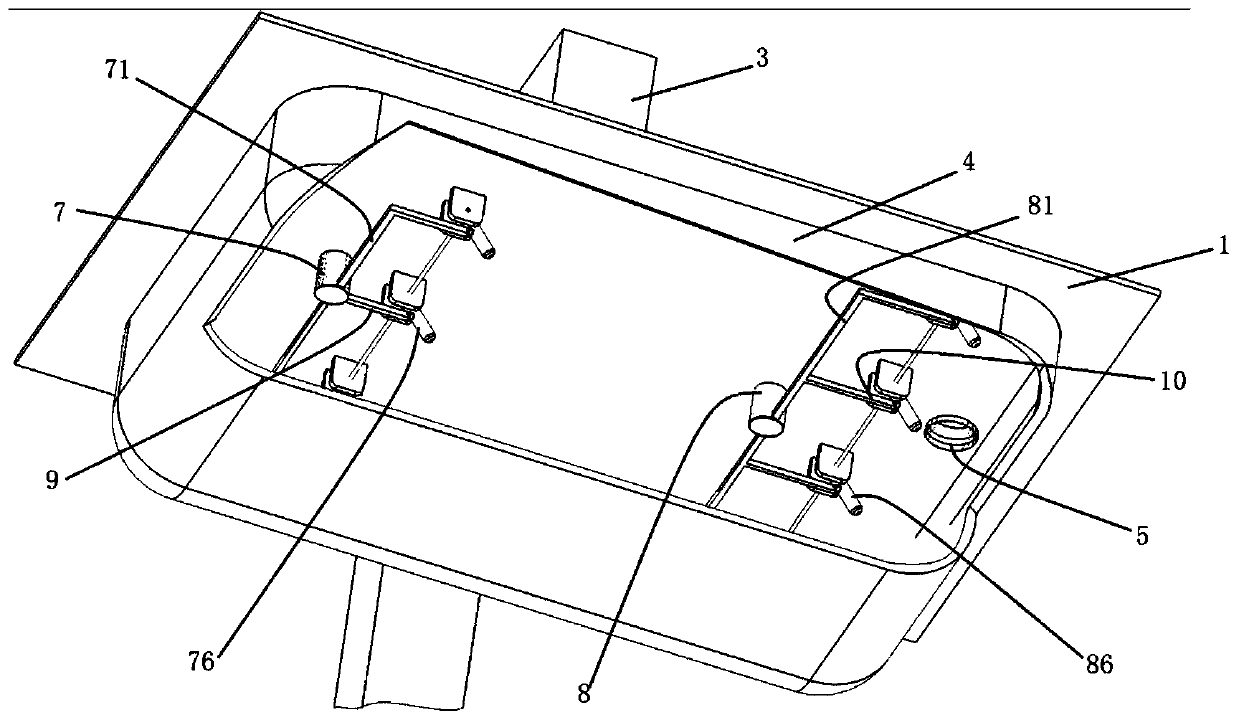

[0014] refer to Figure 1-5 , a skin heat activation coating device, including a lifting plate 1, a storage box 2, a lift 3, an air bag 4, an air inlet pipe 5, an air outlet pipe 6, a first high-pressure air inlet pipe 7, a second high-pressure air inlet pipe 8, a first The air injection mechanism 9 and the second air injection mechanism 10, the elevator 3 is connected to the lifting plate 1, the bottom of the lifting plate 1 is provided with an air bag 4, and the air inlet pipe 5, the air outlet pipe 6, and the first high pressure inlet pipe are arranged on the lifting plate 1. The air pipe 7 and the second high-pressure air intake pipe 8 communicate with the air bag 4, and the first air injection mechanism 9 and the second air injection mechanism 10 are symmetrically arranged in the bottom air bag 4 of the lifting plate 1, and the first air injection mechanism 9 and the first air injection mechanism The high-pressure intake pipe 7 communicates, the second air injection mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com