Building supporting steel plate cement remover

A technology for supporting steel plates and buildings, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problems of low mud removal efficiency, high labor intensity, and marks left by steel plates, etc. Mud efficiency, reduce labor intensity, facilitate the effect of loading and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

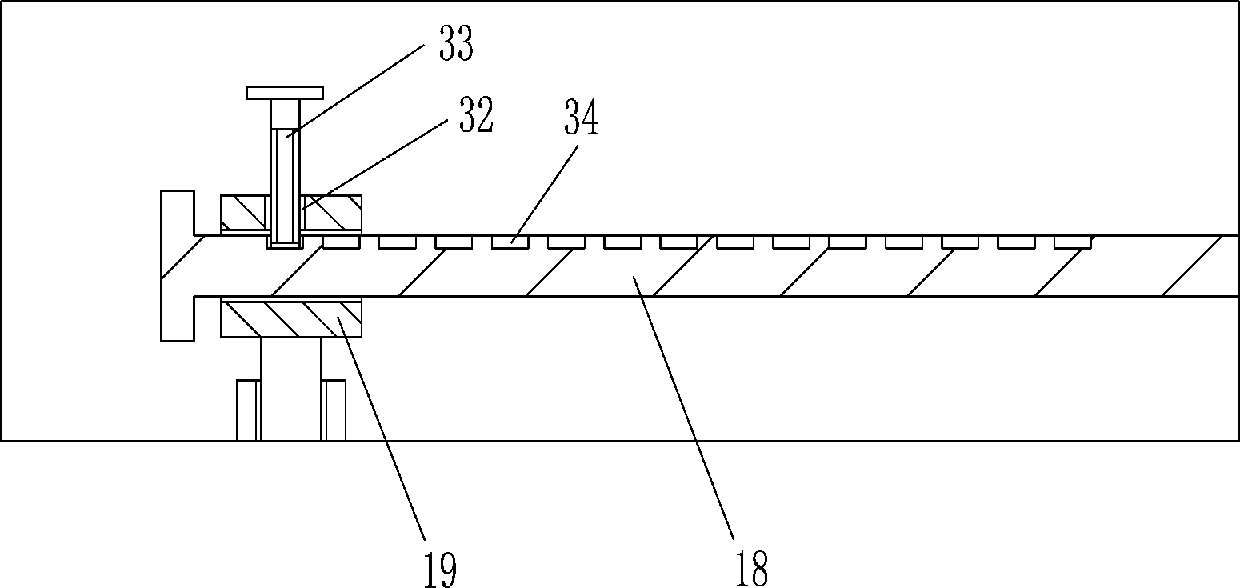

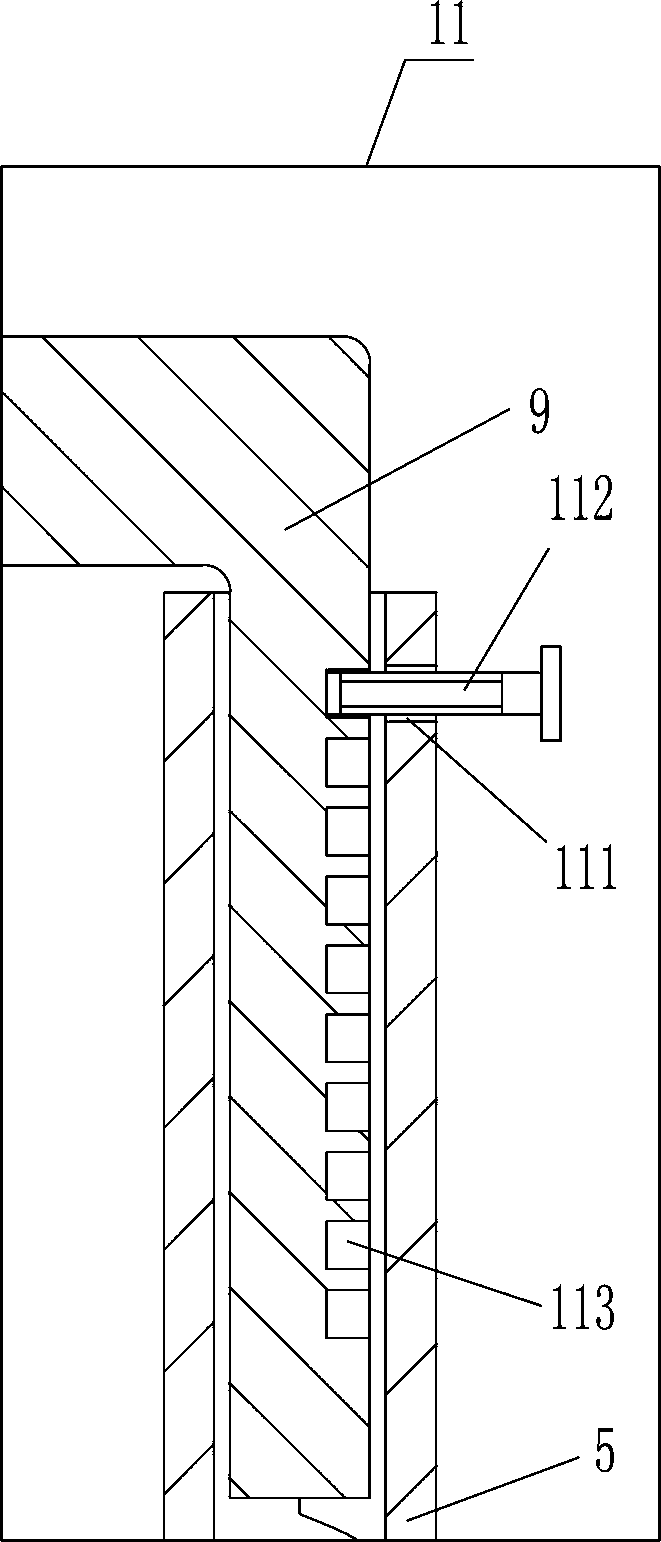

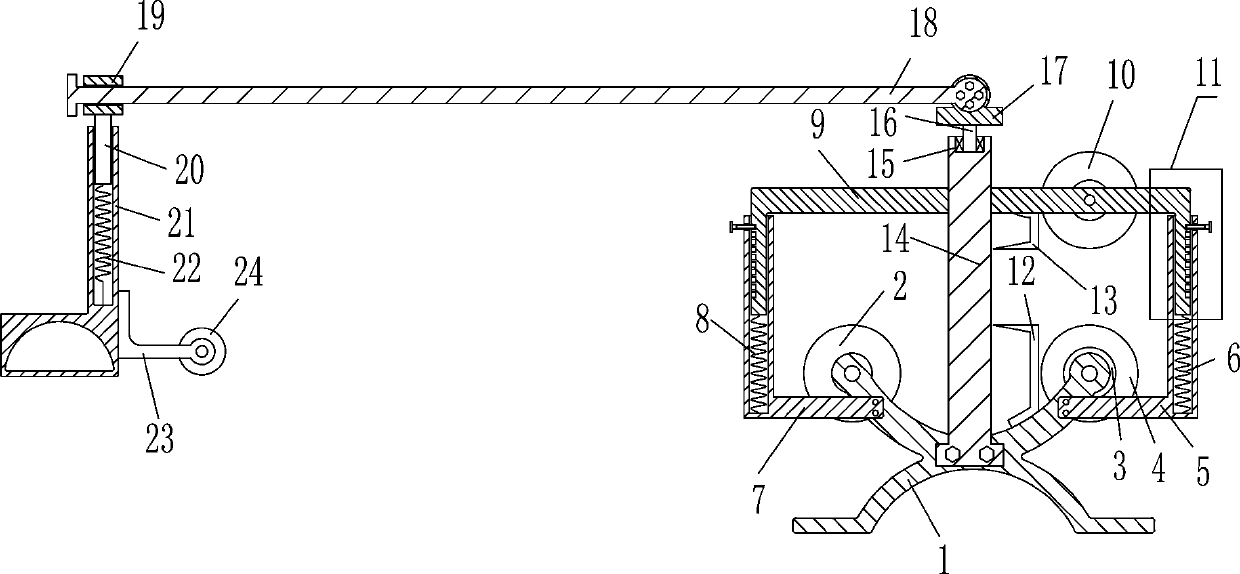

[0018] A building support steel plate desilter, such as Figure 1-2 As shown, it includes a support 1, a first roller 2, a motor 3, a first transmission wheel 4, a first sliding tube 5, a first spring 6, a second sliding tube 7, a second spring 8, and a first sliding rod 9 , the second transmission wheel 10, the fixing device 11, the first scraper 12, the second scraper 13, the bracket 14, the bearing 15, the rotating shaft 16, the fixed seat 17, the second sliding rod 18, the first sliding sleeve 19, the third Slide bar 20, the 3rd slide pipe 21, the 3rd spring 22, the first strut 23 and the second roller 24, the upper left side of bearing 1 rear side is equipped with the first roller 2, the right side of bearing 1 rear side The upper side is equipped with a motor 3 that can drive the first transmission wheel 4 to rotate. The support 1 is connected to the motor 3 through a bolt connection. The output shaft of the motor 3 is fixed with the first transmission wheel 4. The right...

Embodiment 2

[0020] A building support steel plate desilter, such as Figure 1-2 As shown, it includes a support 1, a first roller 2, a motor 3, a first transmission wheel 4, a first sliding tube 5, a first spring 6, a second sliding tube 7, a second spring 8, and a first sliding rod 9 , the second transmission wheel 10, the fixing device 11, the first scraper 12, the second scraper 13, the bracket 14, the bearing 15, the rotating shaft 16, the fixed seat 17, the second sliding rod 18, the first sliding sleeve 19, the third Slide bar 20, the 3rd slide pipe 21, the 3rd spring 22, the first strut 23 and the second roller 24, the upper left side of bearing 1 rear side is equipped with the first roller 2, the right side of bearing 1 rear side The upper side is equipped with a motor 3 that can drive the first transmission wheel 4 to rotate. The output shaft of the motor 3 is fixed with the first transmission wheel 4. The right part of the front side of the support 1 is fixed with the first slid...

Embodiment 3

[0023] A building support steel plate desilter, such as Figure 1-3As shown, it includes a support 1, a first roller 2, a motor 3, a first transmission wheel 4, a first sliding tube 5, a first spring 6, a second sliding tube 7, a second spring 8, and a first sliding rod 9 , the second transmission wheel 10, the fixing device 11, the first scraper 12, the second scraper 13, the bracket 14, the bearing 15, the rotating shaft 16, the fixed seat 17, the second sliding rod 18, the first sliding sleeve 19, the third Slide bar 20, the 3rd slide pipe 21, the 3rd spring 22, the first strut 23 and the second roller 24, the upper left side of bearing 1 rear side is equipped with the first roller 2, the right side of bearing 1 rear side The upper side is equipped with a motor 3 that can drive the first transmission wheel 4 to rotate. The output shaft of the motor 3 is fixed with the first transmission wheel 4. The right part of the front side of the support 1 is fixed with the first slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com