Independent steering driving wheel based on hub motor

An in-wheel motor, independent steering technology, applied in electric steering mechanism, steering mechanism, power steering mechanism, etc., can solve problems such as instability, high noise, bumps, etc., achieve the effect of small size, small space, and avoid bumps and vibrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

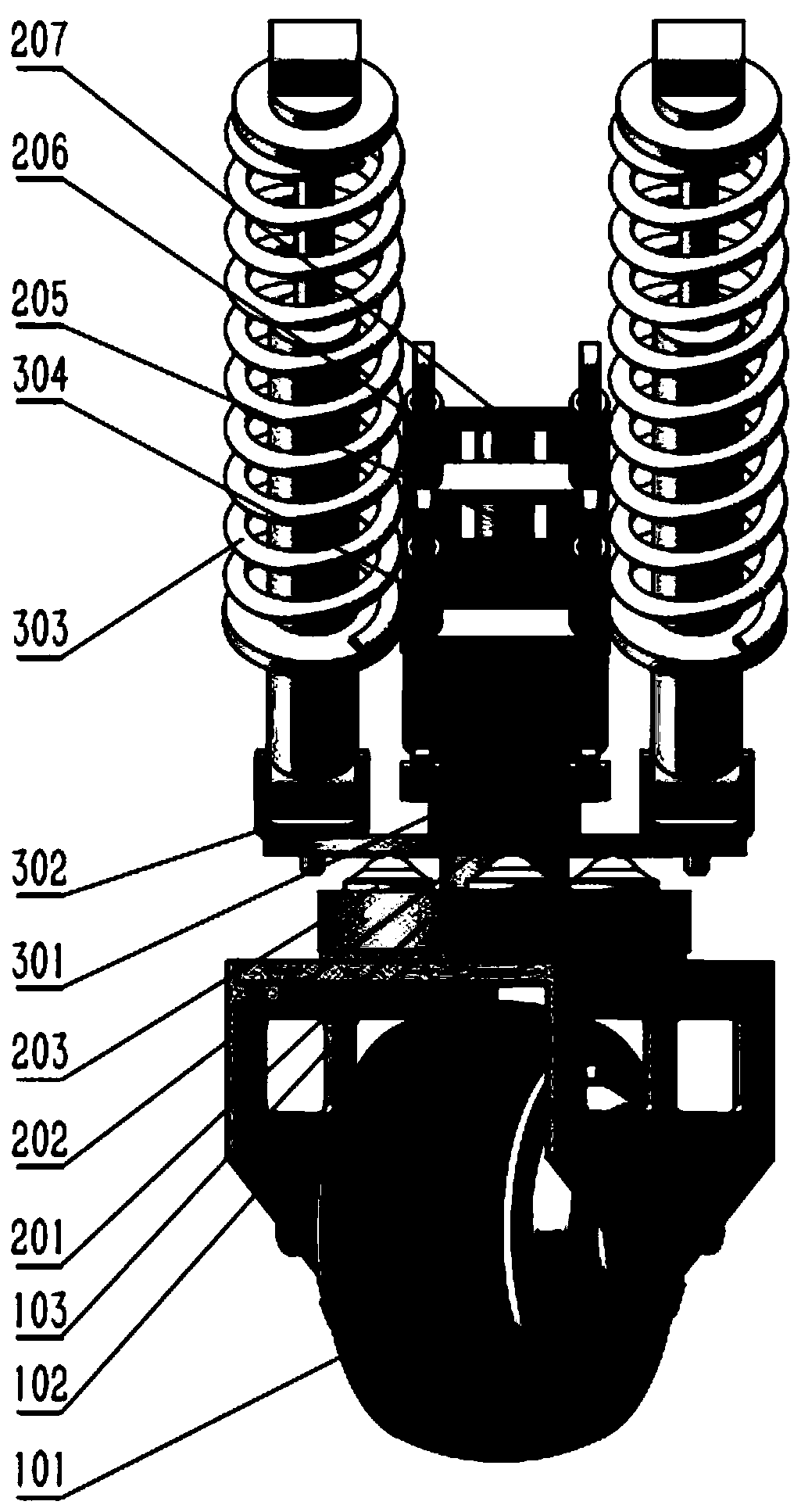

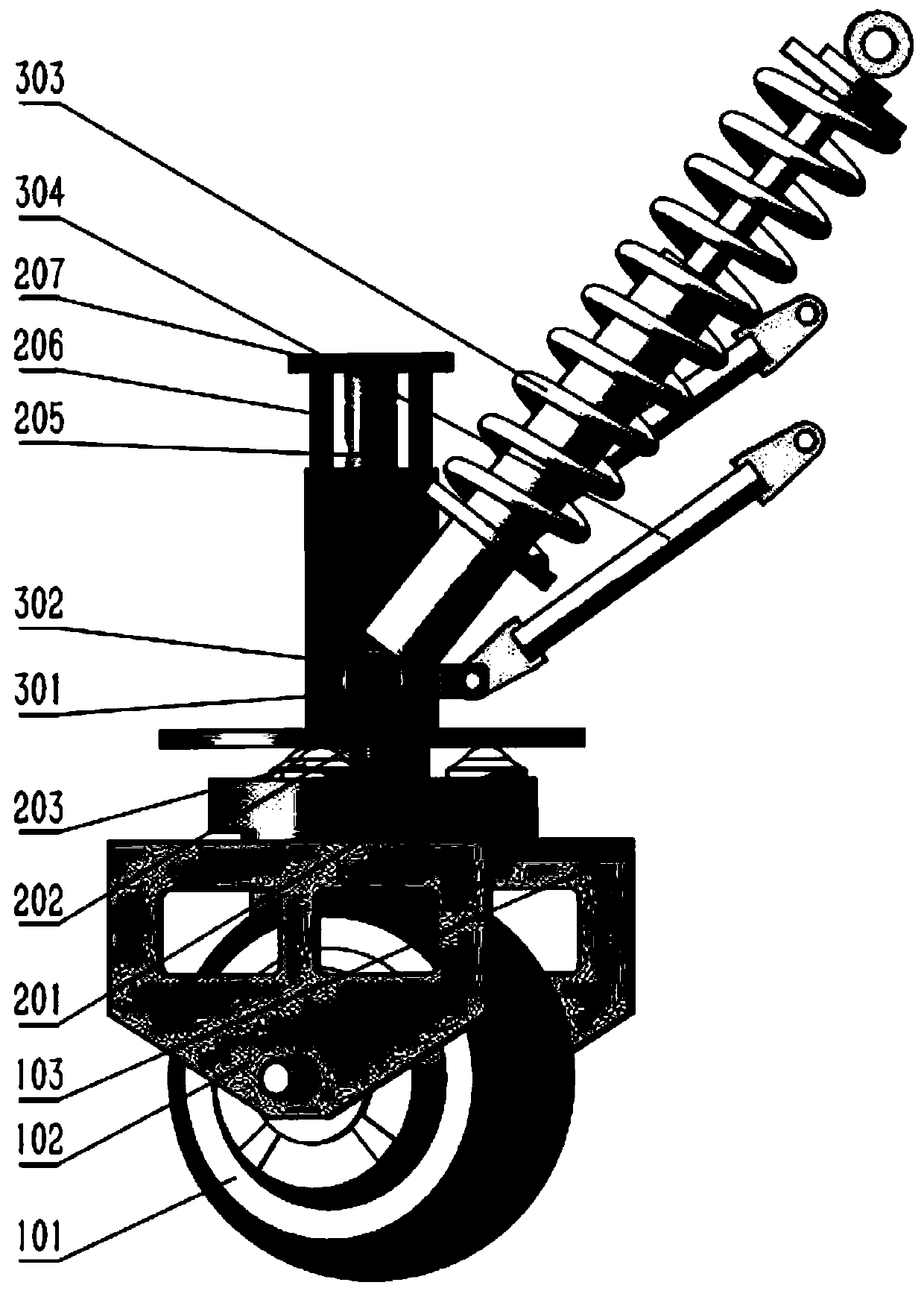

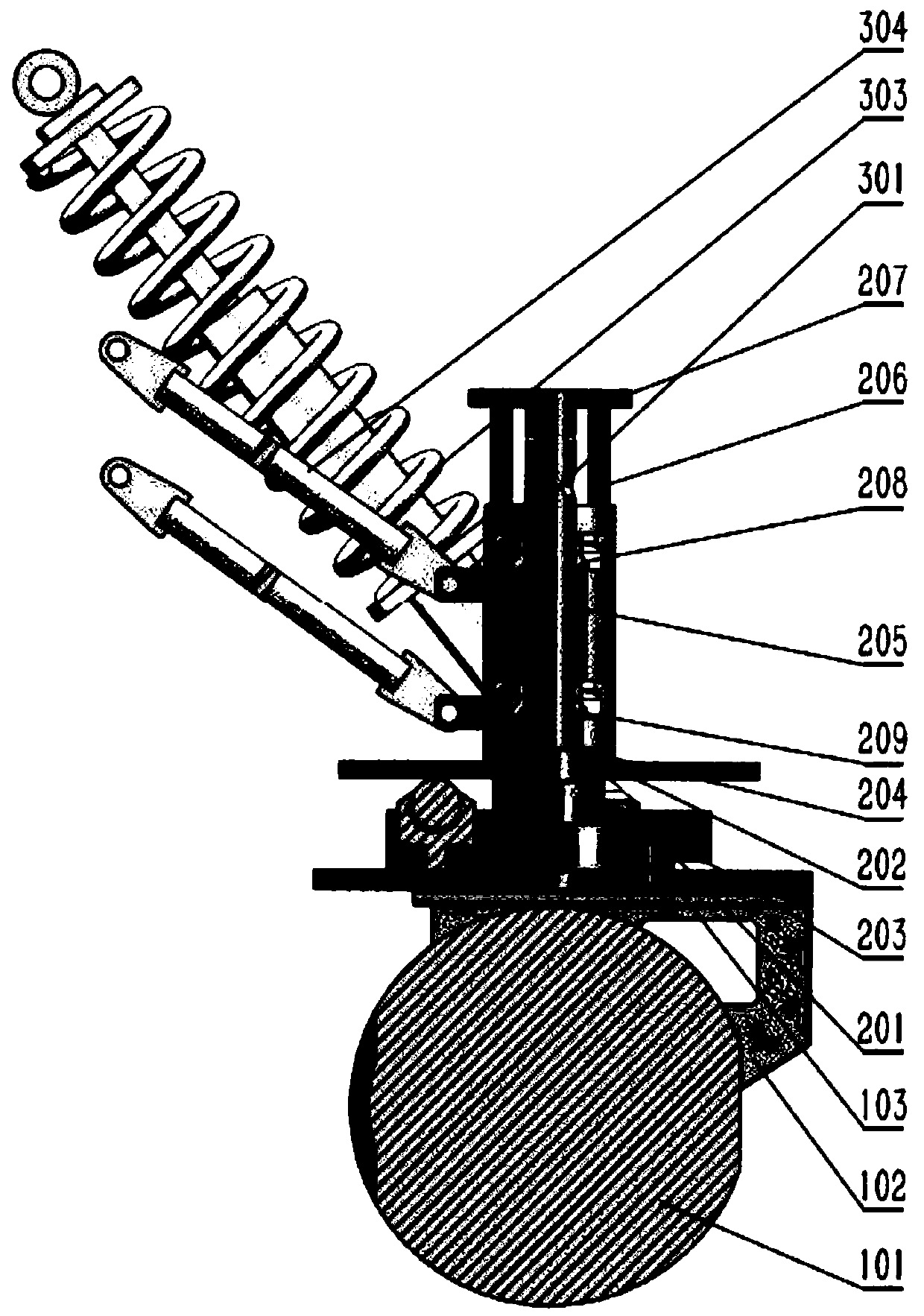

[0017] according to Figure 1-Figure 4 , the independently driven steering wheel applied to the omnidirectional mobile robot designed by the present invention is composed of 1 traveling mechanism, 2 force receiving mechanisms, and 3 shock absorbing mechanisms.

[0018] Among the above-mentioned mechanisms, the traveling mechanism includes 101 hub motor wheel, 102 hub frame A and 103 hub frame B; Optical shaft, 207 upper flanges, 208 upper contact bearings, 209 lower angular contact bearings; the damping mechanism includes 301 swing arm hinge connections, 302 shock absorber hinge connections, 303 shock absorbers, 304 swing arms.

[0019] The composition and connection relationship of each part is as follows: the 101 hub motor wheel is fixed on the motor frame composed of 102 hub frame A and 103 hub frame B through nuts. Screw fixed. There is a blind hole on the surface of the 201 pillow block and an internal thread, and the end of the 203 universal wheel is threaded, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com