Damping type current-carrying overall dropper

An overall, current-carrying technology, applied in the direction of power lines, overhead lines, transportation and packaging, etc., can solve the problems of high resistivity, loss of damping function of the device, loss of damping function, etc., to improve service life, reasonable and feasible structure, improve holistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the drawings and embodiments.

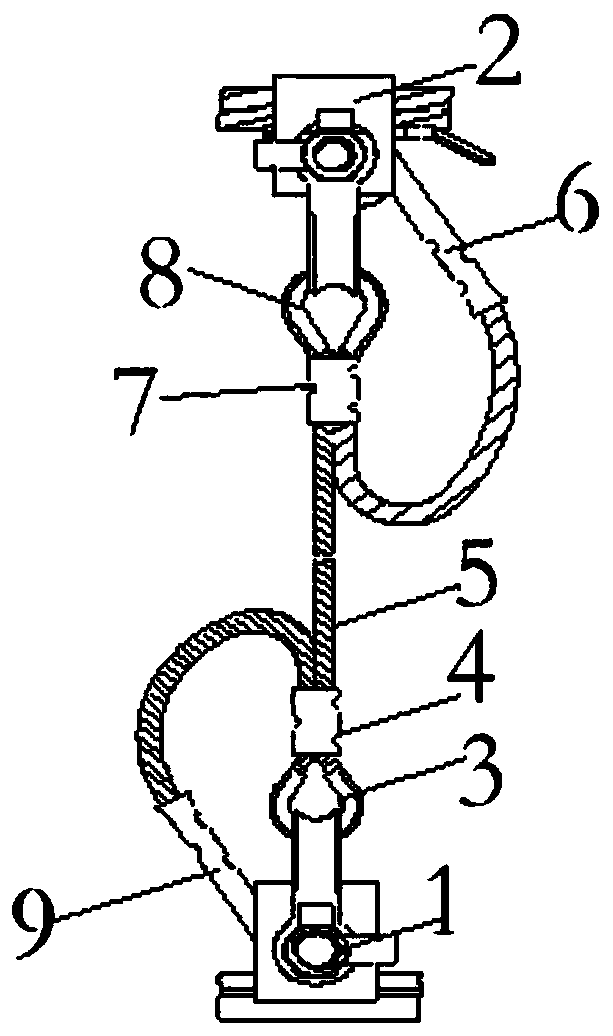

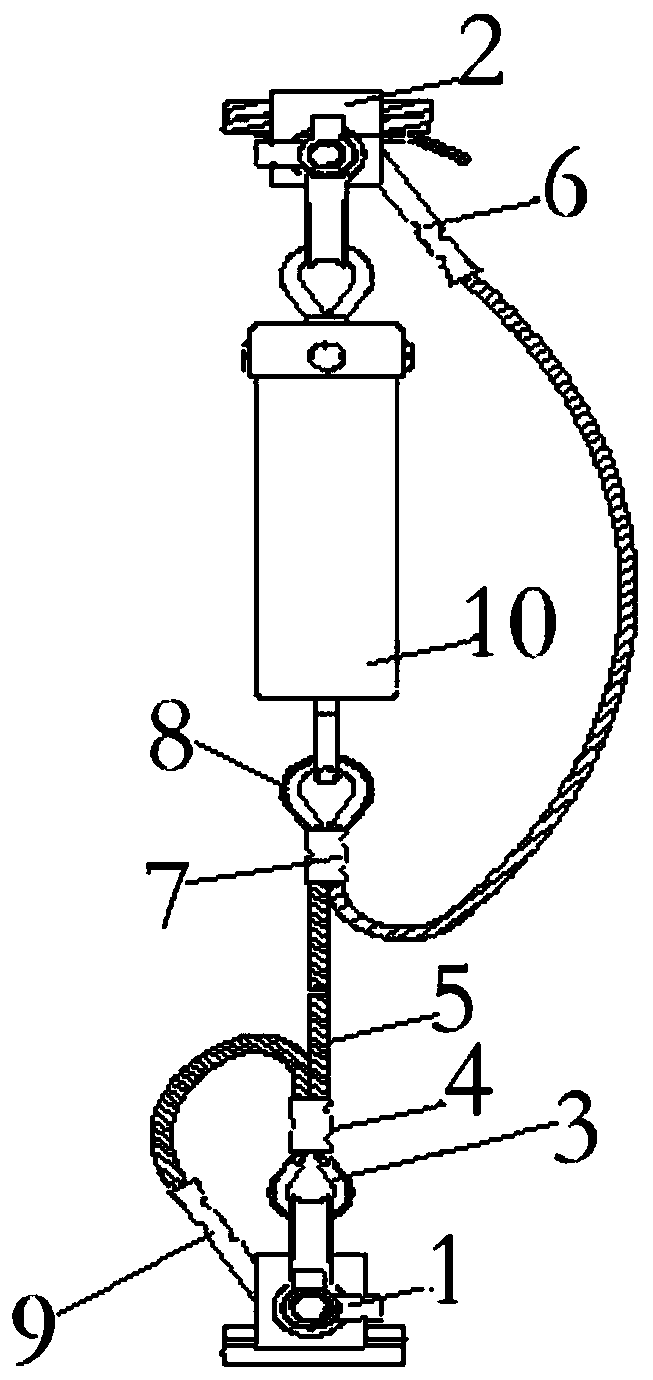

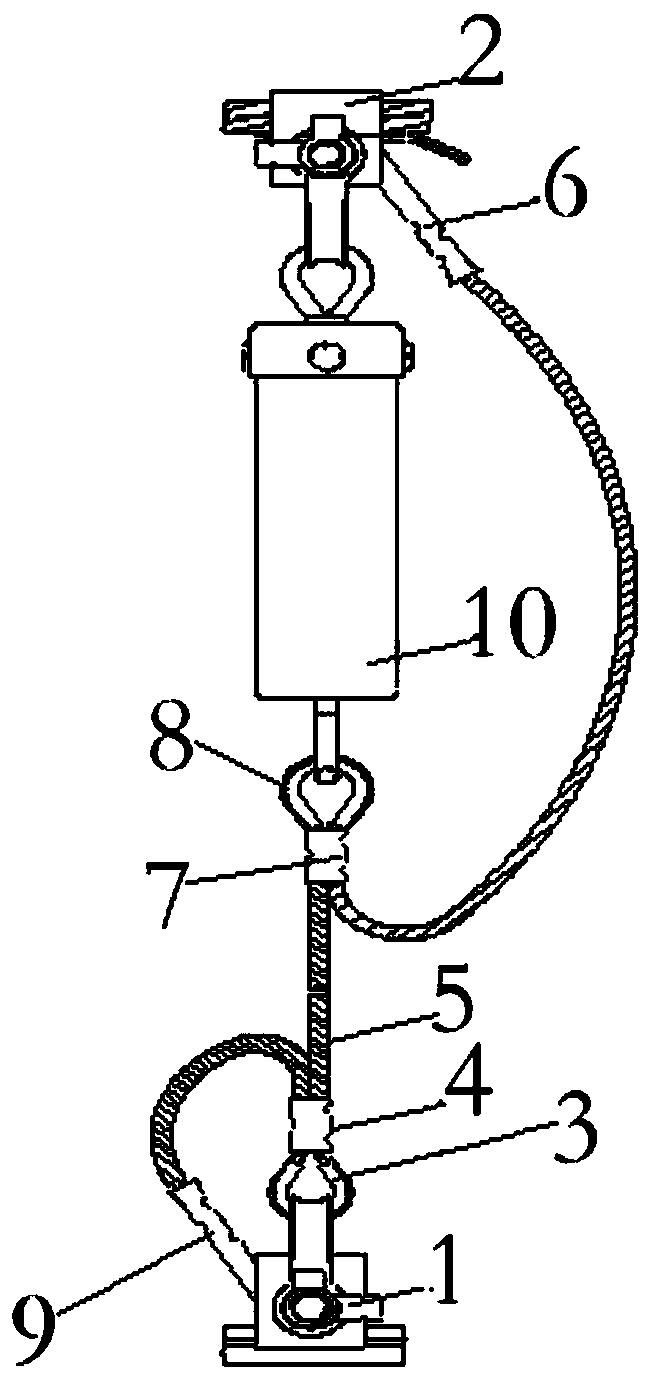

[0019] see figure 2 , a damping type current-carrying integral hanging string, including a lower contact wire hanging string clip 1 and an upper catenary cable hanging string clip 2; the contact wire hanging string clip 1 passes through a heart ring-3 and a crimping tube- 4 is connected with the lower part of the hanging string 5; the lower end of the hanging string 5 is connected with the terminal one 9; The tension cable hanging string clip 2 is connected; the upper end of the hanging string 5 is connected to the upper terminal 2 6; a damping device 10 is arranged between the dead cable hanging string clip and the heart ring two; the damping device The connecting earrings at the two ends are respectively connected with the suspension string clamp of the bearing cable and the heart ring two.

[0020] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com