V-shaped rubber pile assembly and its stiffness design method and application

A technology of stiffness design and rubber stack, which is applied in the field of stiffness design of V-shaped rubber stack components, can solve the problems of low assembly efficiency of boom articulated suspension components, high deflection and torsional stiffness of ball joints, high production and maintenance costs, etc., to achieve Compact structure, reduced lateral rotation stiffness, convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

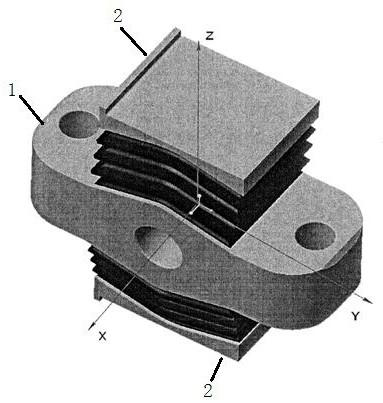

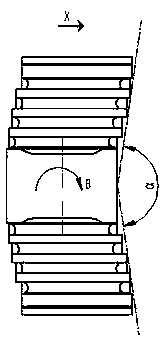

[0031] Combine below Figure 2 to Figure 6 The embodiments of the present invention will be described in detail.

[0032] The V-shaped rubber stack assembly includes a horizontal mounting plate 1, a rubber stack 2 that is vulcanized and bonded on the mounting plate 1. The rubber stack 2 includes a rubber layer 21, a partition 22 alternately laminated with the rubber layer 21, and the outermost The outer layer plate 23, the rubber layer 21, the partition 22 and the outer layer plate 23 are vulcanized and bonded into a whole, characterized in that the number of the rubber piles 2 is two, which are symmetrically arranged on the upper and lower sides of the mounting plate 1. , And glued to the middle position of the mounting plate 1, the rubber pile 2 is arranged obliquely to the longitudinal direction of the product, and the two rubber piles 2 form a V-shaped distribution with an angle α, 120°<α<180°.

[0033] as the picture shows, figure 2 The X direction is equivalent to the longi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com