A mountain rail transport device for loading and unloading goods conveniently

A rail transportation and mountain technology, applied in the field of mountain rail transportation devices, can solve the problems of high cost of transportation roads, manpower transportation, impracticality of ordinary farmers, etc., and achieve the effect of convenient up and down transportation and smooth and efficient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

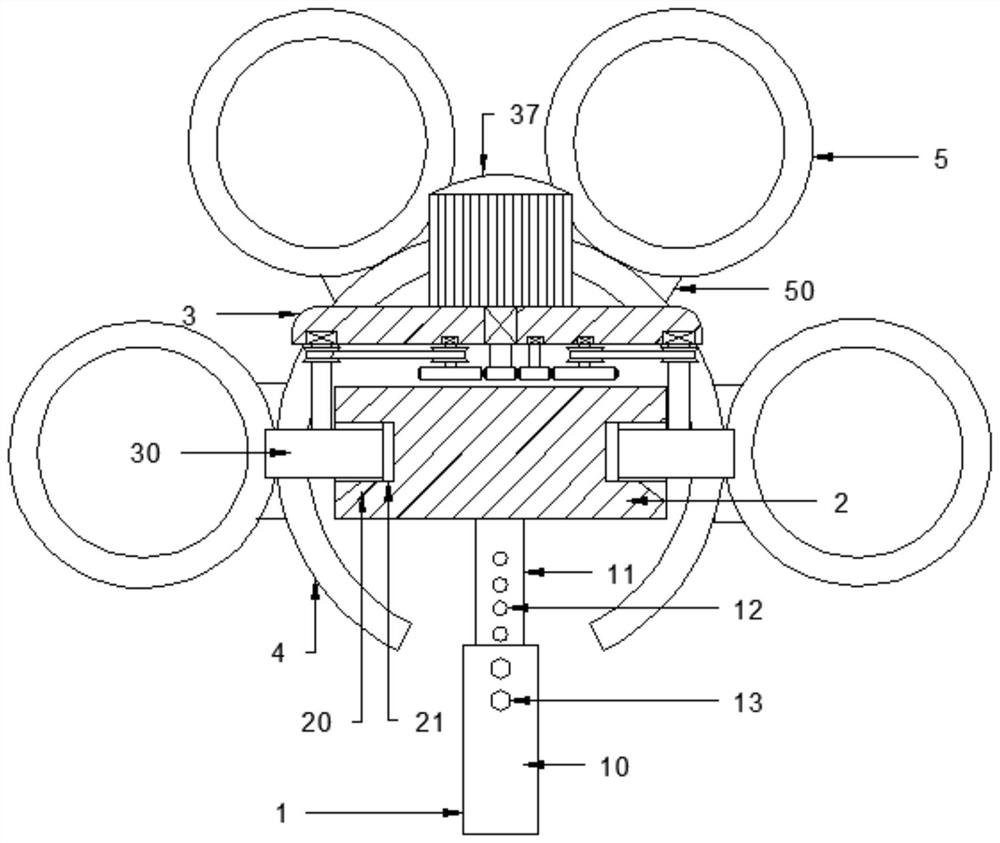

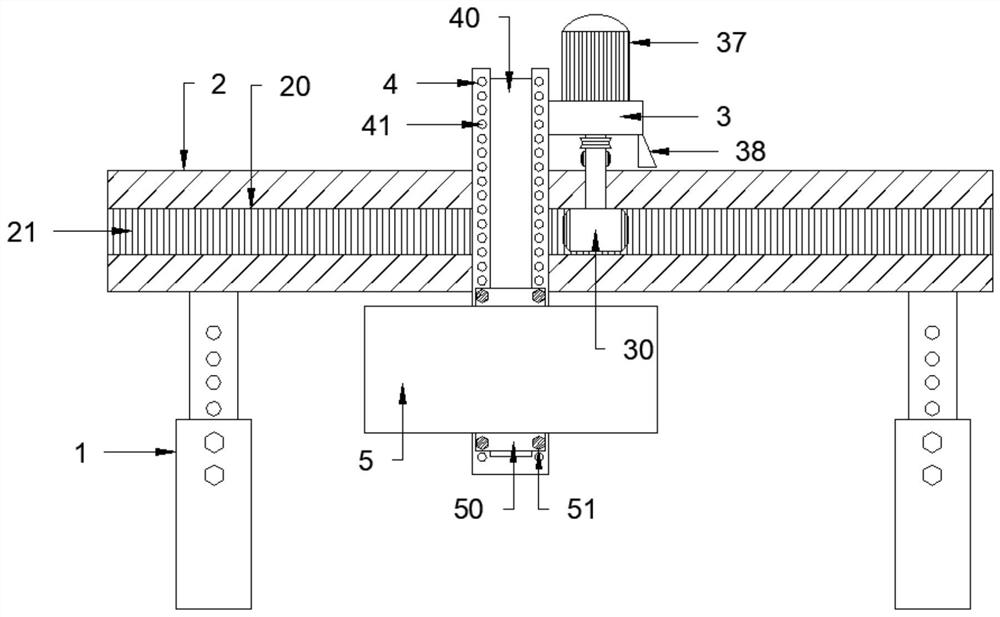

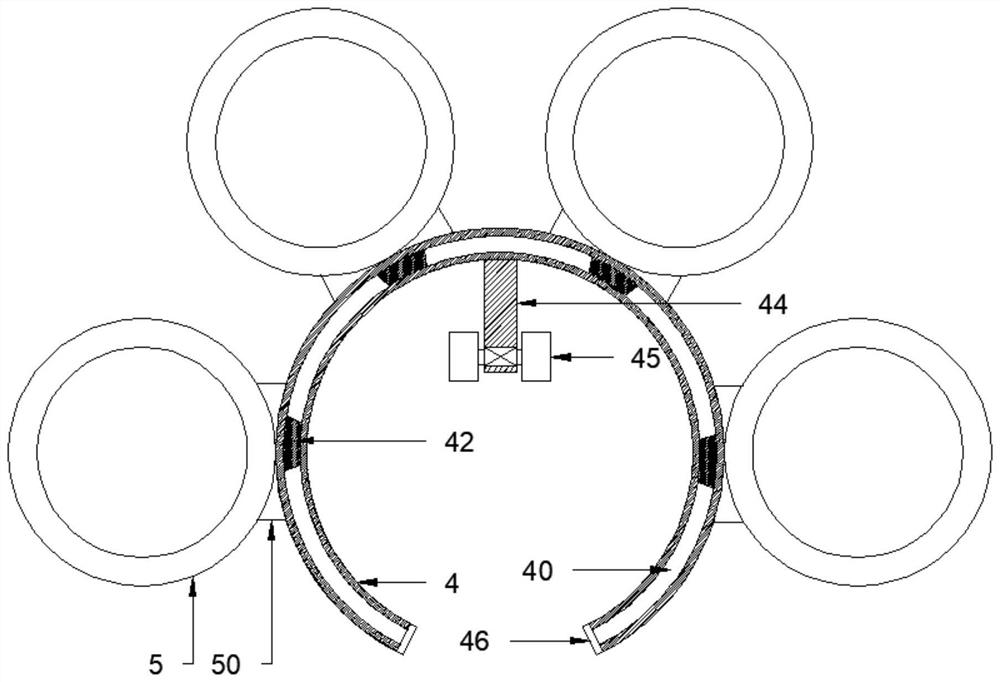

[0023] see Figure 1~6 , in the embodiment of the present invention, a kind of mountain track transportation device that is convenient for loading and unloading goods, comprises guide rail frame 1, guide rail platform 2, driving platform 3, sliding material rack 4 and material box 5, and the bottom of described guide rail platform 2 is made of a plurality of The vertically fixed guide rail frame 1 is erected and fixed between the mountains, the top of the guide rail platform 2 is provided with a drive platform 3, and a gear drive mechanism is arranged between the drive platform 3 and the guide rail platform 2, and the drive platform 3 The rear panel of the sliding material rack 4 is fixed, and a plurality of feed boxes 5 are installed on the sliding material rack 4. The sliding material rack 4 is an annular support with a gap at the bottom, and the sliding material rack 4 is set on the The outer ring of the guide rail table 2, the sliding material rack 4 and the driving table ...

Embodiment 2

[0029] The difference between this embodiment and embodiment 1 is:

[0030] The lowest part of the rack chute 40 is provided with an opening for sliding out the rack slider 42 , and a movable baffle plate 46 for slot opening is fixed by bolts on the opening.

[0031] A cleaning plate 38 for removing foreign matters on the top surface of the guide rail platform 2 is provided in the forward direction of the driving platform 3 .

[0032] Described guide rail frame 1 is arranged as telescopic adjustment structure, and described guide rail frame 1 comprises casing rod 10 and telescoping rod 11, and described telescoping rod 11 is sleeved in casing rod 10, and described telescoping rod 11 and casing rod The vertical surface of 10 is provided with a plurality of rod screw holes 12, and the rod screw holes 12 between the casing rod 10 and the telescopic rod 11 are fixedly connected by rod bolts 13 threads.

[0033] Working principle of the present invention: the groove opening movabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com