A kind of automatic feeding control method of food processing machine

A food processing machine, automatic feeding technology, applied in the directions of transportation and packaging, packaging, loading/unloading, etc., can solve the problems of material bonding, material moldy, complex structure, etc., to achieve the effect of simple control and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

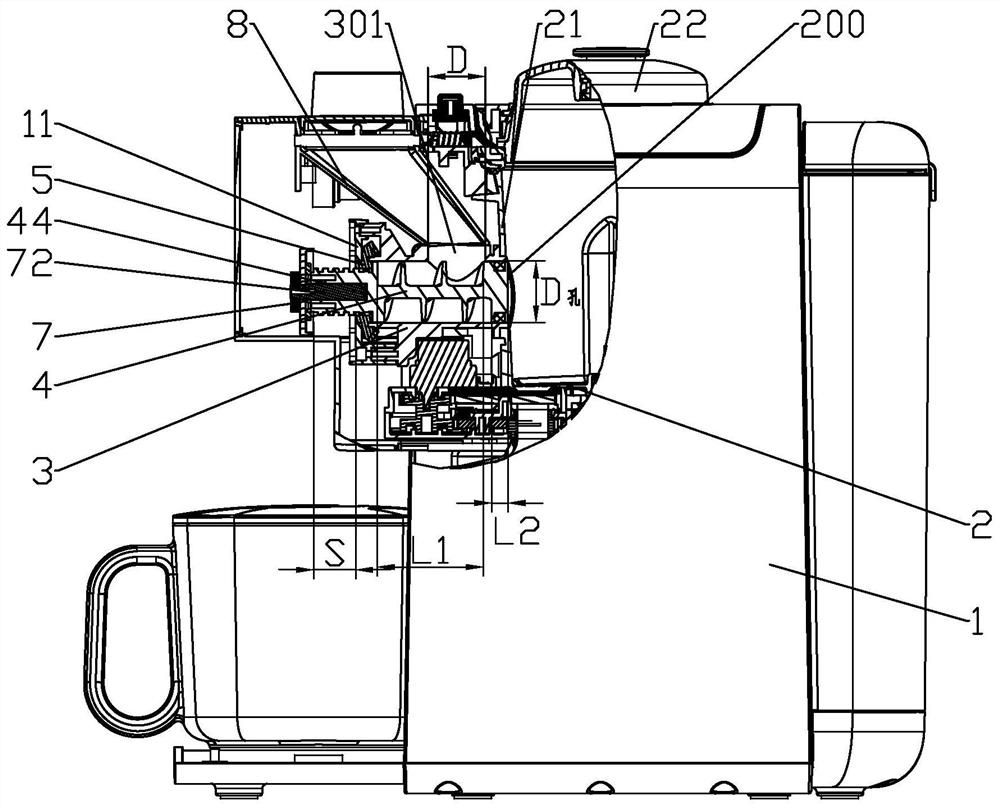

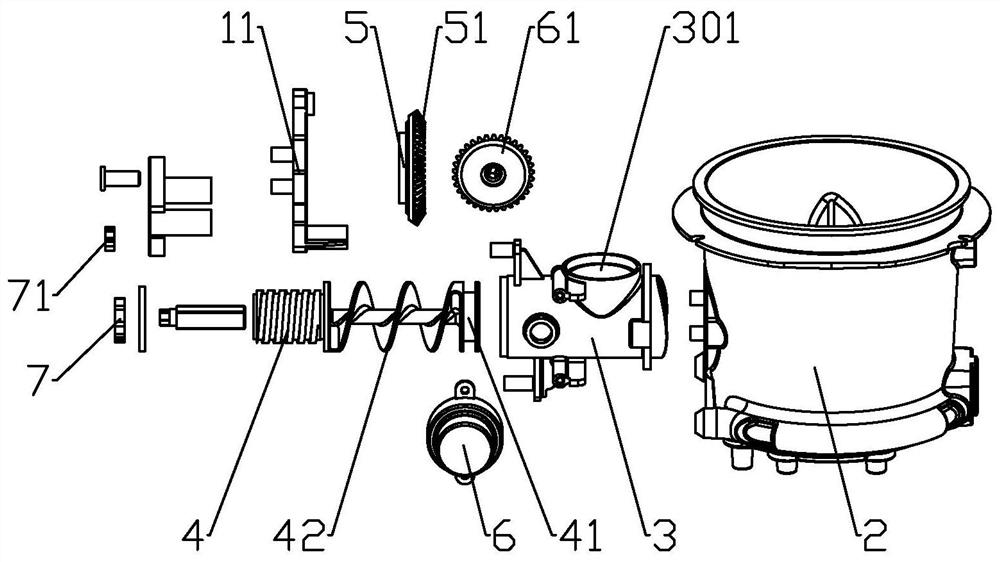

[0023] The invention provides a method for automatic feed control of a food processing machine. The structure of the food processing machine is as follows: figure 1 As shown, it includes a machine body 1, a processing cup 2 arranged on the machine body 1, a feeding cylinder 3 and a feeding screw 4. The front end of the feeding cylinder 3 communicates with the feeding hole 200 of the processing cup 2, and the feeding screw 4 is in the initial position. , the feeding screw 4 closes the feeding hole 200 of the processing cup 2, and when the feeding screw 4 is in the feeding position, the feeding screw 4 opens the feeding hole 200 of the processing cup 2, and the diameter D of the feeding hole 200 is 孔 5 ~ 60mm, automatic feeding control methods include the following:

[0024] (1) The feed screw 4 rotates forwardly at the initial position to transport the material to the feed hole 200;

[0025] (2) The feeding screw 4 moves from the initial position to the feeding position;

[0...

Embodiment 2

[0043] It can be understood that, in addition to adopting the ratchet 7 and the pawl 71, the feed screw 4 is reversely locked through the one-way bearing, the feed screw 4 is connected to the inner ring of the one-way bearing and fixed circumferentially, and the outer ring of the one-way bearing Relative to the feed cylinder 3 is fixed, the inner ring of the one-way bearing follows the forward rotation of the feed screw 4, and the one-way bearing is locked when the feed nut 5 is reversed so that the feed screw 4 cannot be reversed.

[0044] For other content not described in this embodiment, reference may be made to Embodiment 1.

Embodiment 3

[0046] It can be understood that, in addition to using a feeding motor to cooperate with the ratchet 7, the pawl 71 or the one-way bearing, it is also possible to add a reverse motor that drives the feeding screw 4 to reverse and retreat to close the feeding hole 200.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com