Glass ceramic rear cover forming method and die

A technology of glass-ceramic and molding method, which is applied in glass molding, glass reshaping, glass manufacturing equipment, etc., can solve the problems of low yield rate and low molding efficiency, and achieve unbreakable, uniform force, and reduced The effect of the polishing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

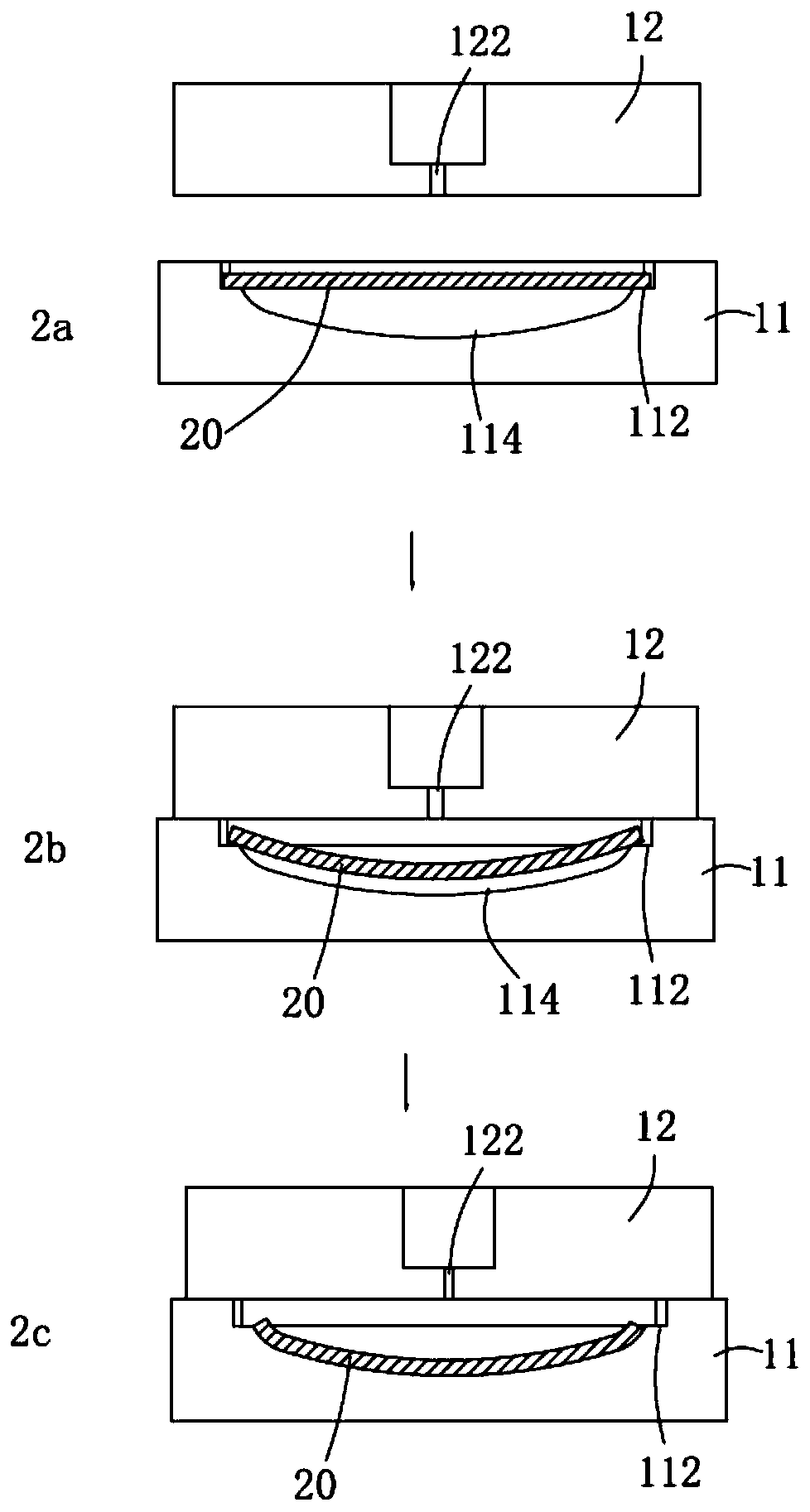

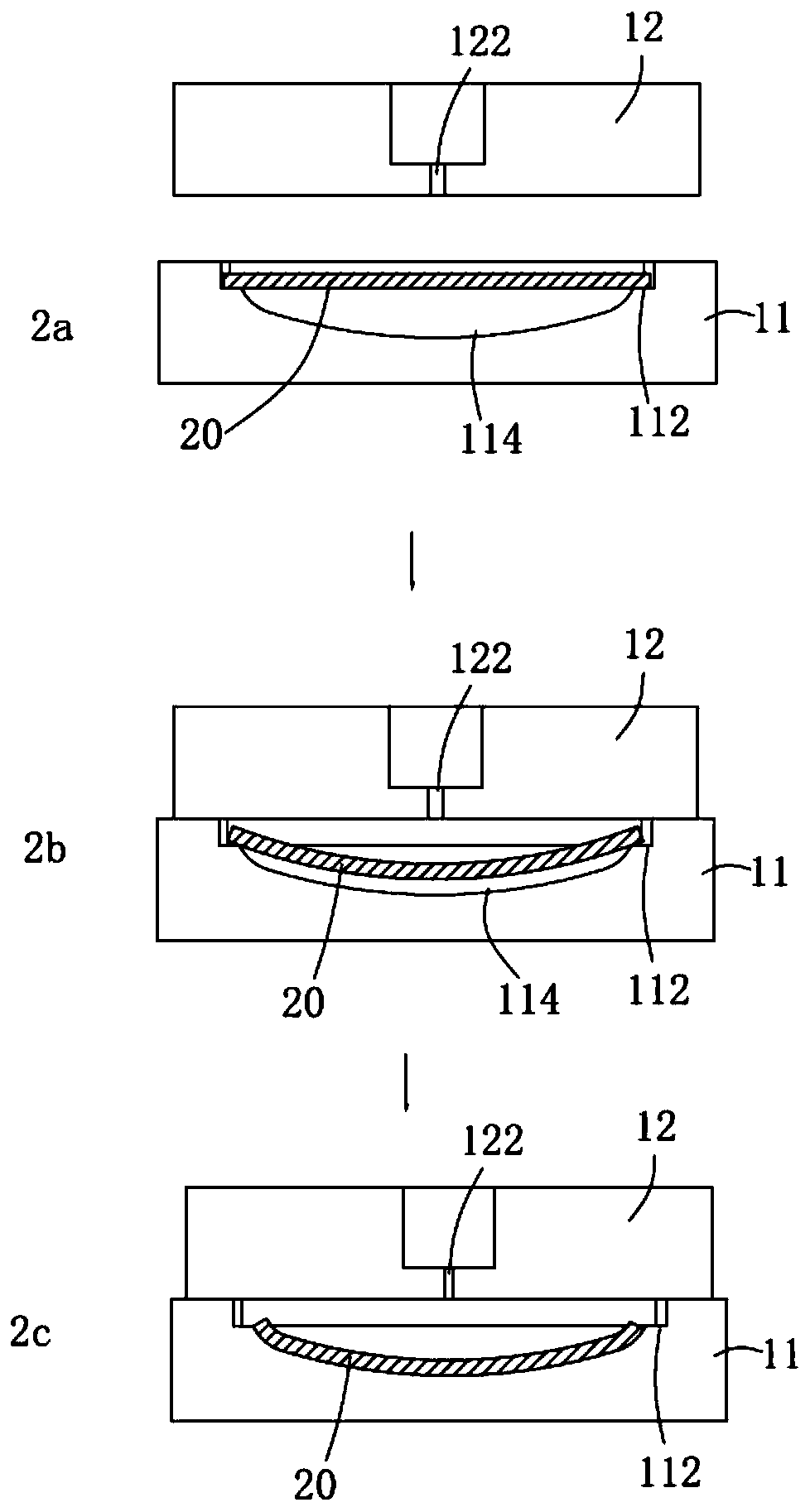

[0026] In order to make the purpose, technical solutions, and advantages of the present application clearer, the technical solutions of the present application will be described clearly and completely in conjunction with specific embodiments of the present application and the corresponding drawings.

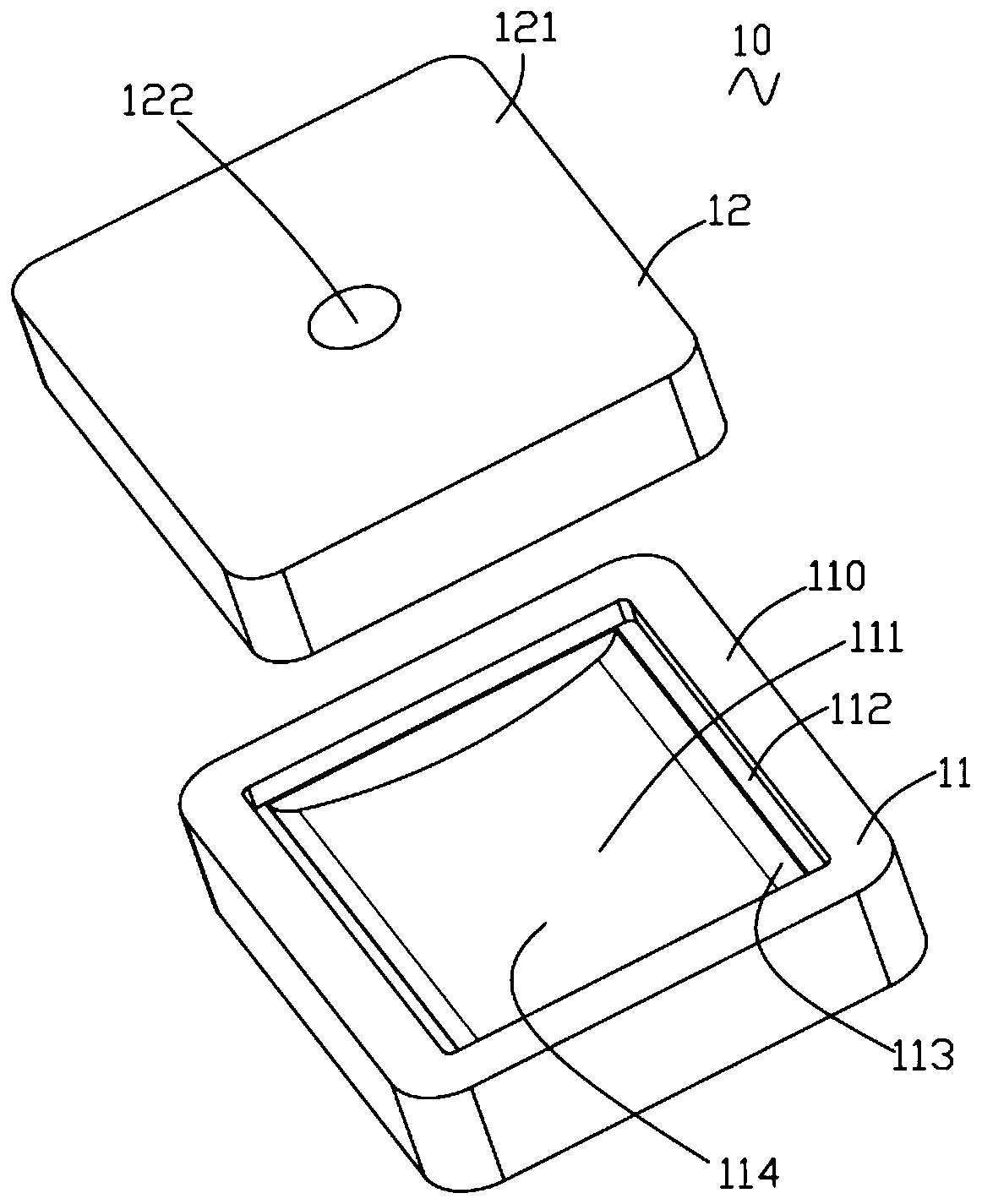

[0027] See figure 1 As shown, the molding die 10 for the glass-ceramic back cover of the present application includes a lower die 11 and an upper die 12 fitted above the lower die 11.

[0028] The lower mold 11 includes a lower mold plate 110 and a cavity 111 formed on the lower mold plate 110. At least two outer peripheries of the cavity 111 are provided with horizontal stepped portions 112. The cavity 111 includes a parallel or arc-shaped bottom cavity 114 and arc-shaped two ends 113 adjacent to the step portion 112. The arc-shaped two ends 113 have a greater arc than the bottom cavity 114. The horizontal position of the step portion 112 is lower than the upper surface of the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com