Device and method for detecting cleanliness and flatness of flat plate

A technology for detecting flat panels and cleanliness, applied in the field of inspection, can solve the problems such as the inability to greatly improve the product yield, the inability to improve the front-end process, and the inability to accurately determine the type of contamination in the detection method, so as to improve the LED pulse current. , easy to re-check, improve the effect of brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

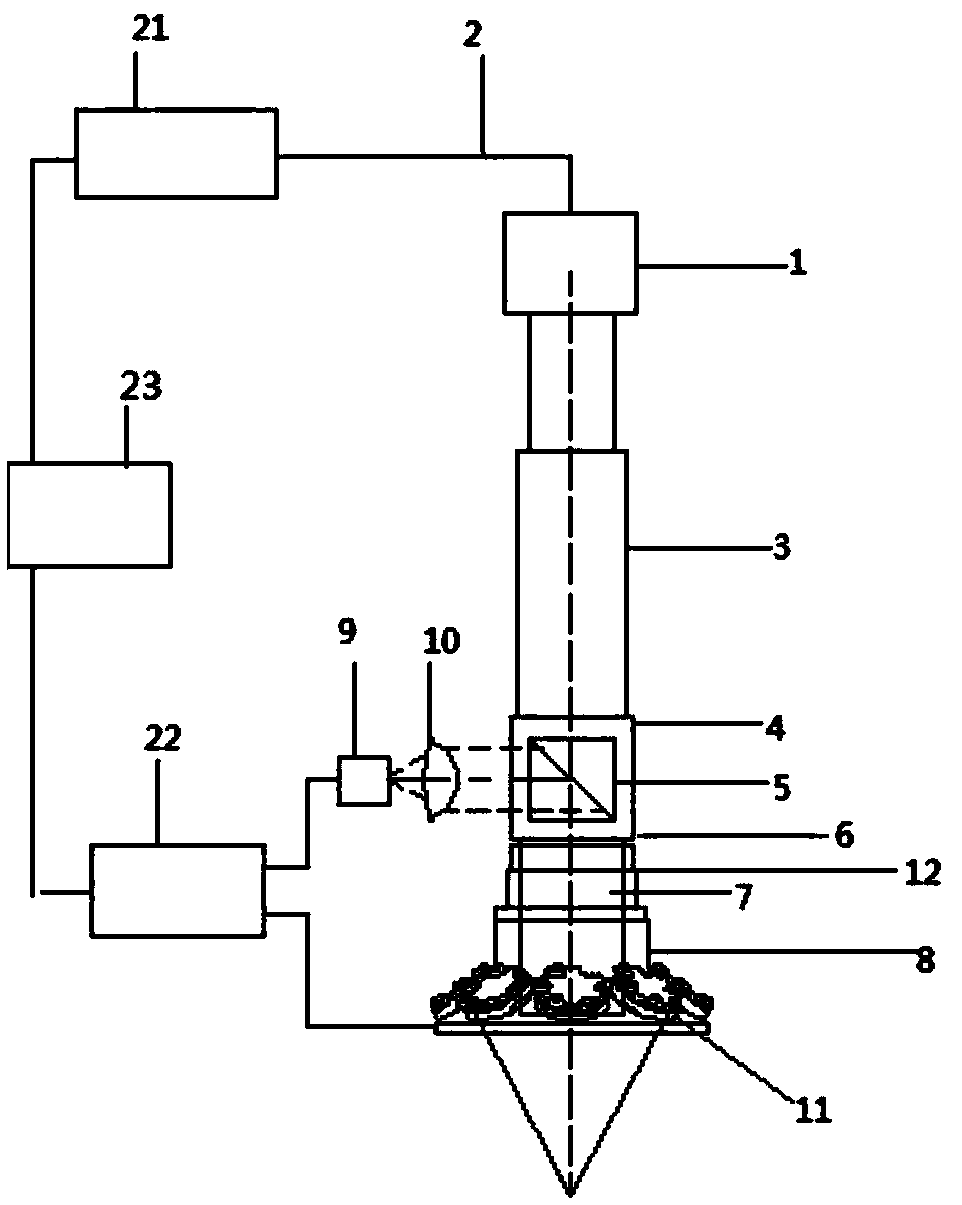

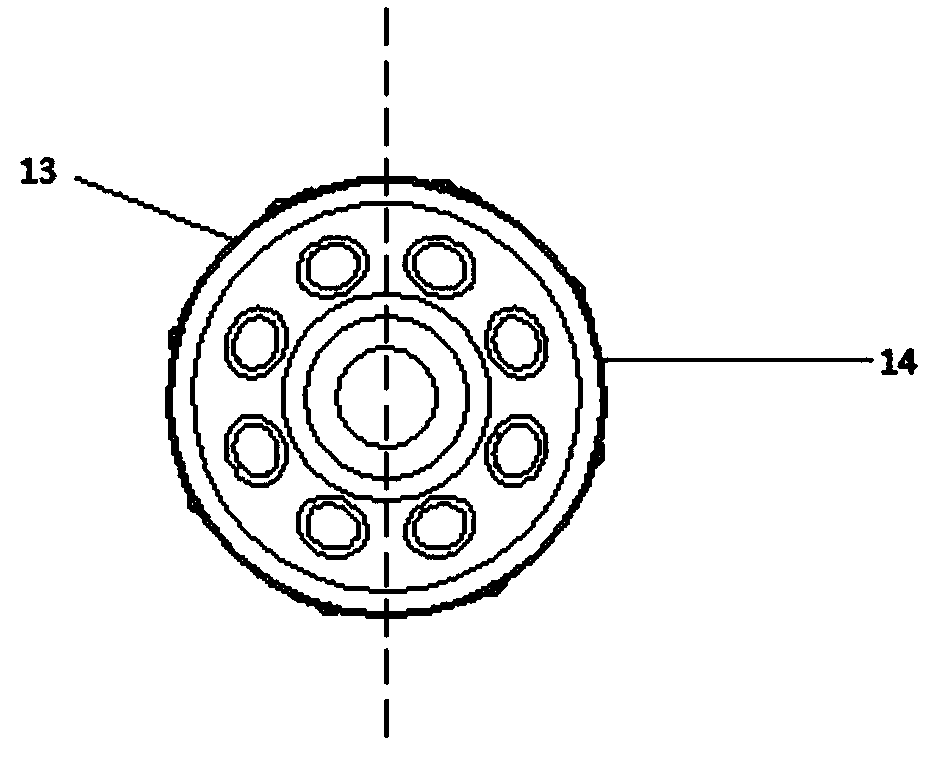

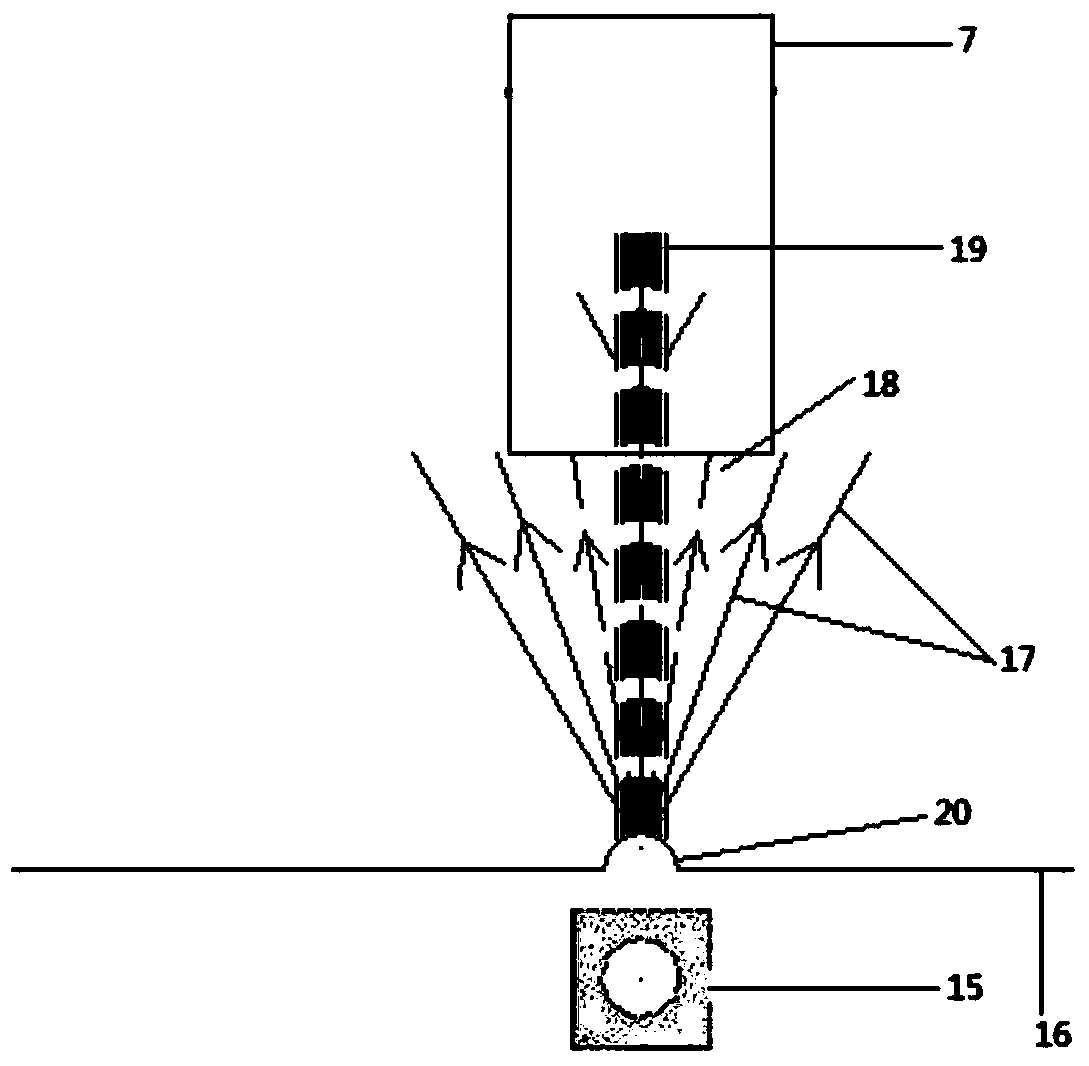

[0039] This embodiment provides a device for detecting the cleanliness and flatness of a flat panel, such as figure 1 As shown, it is a diagram of the imaging system of the present invention, including an image acquisition device, a relay lens 3, a dichroic prism 5, an objective lens 7, an objective lens housing 12, a power supply device, a dark field lighting device 8 and a light source control device, and the image acquisition device includes The camera 1 and the imaging system 2, the relay lens 3 and the A end 4 of the dichroic prism are connected together through a sleeve tube, the B end 6 of the dichroic prism is connected with the objective lens through the objective lens housing 12, and the dark field illumination The device 8 is connected with the objective lens housing 6 , and the light source control device includes a coaxial light source 9 , a control button and an illumination lens group 10 . When there are impurities or dirt defects on the smooth substrate 16 to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com