Rotor iron core magnet assembling device

A technology of rotor core and assembly device, applied in the direction of manufacturing stator/rotor body, etc., can solve problems such as injury to operators, difficult to remove magnets, complicated magnet assembly process, etc., and achieve the effect of reducing removal problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

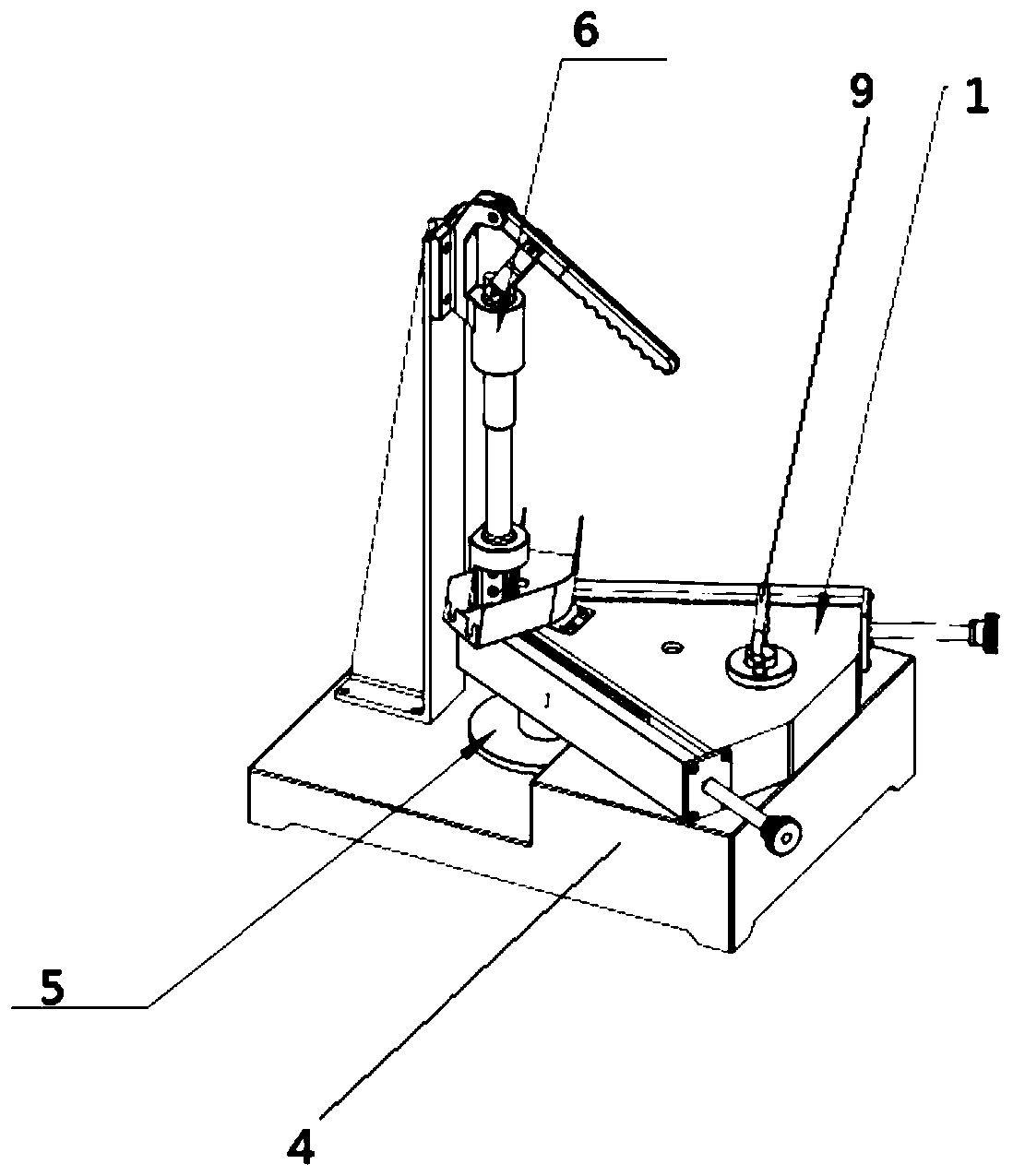

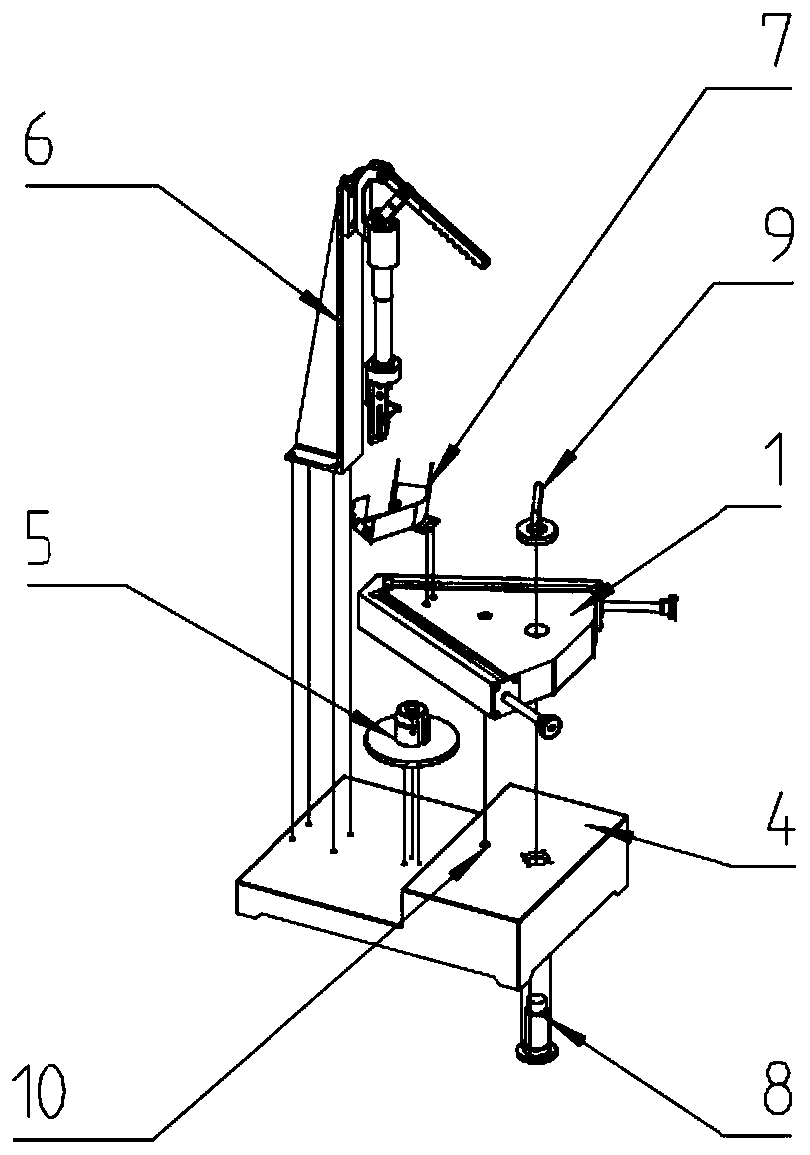

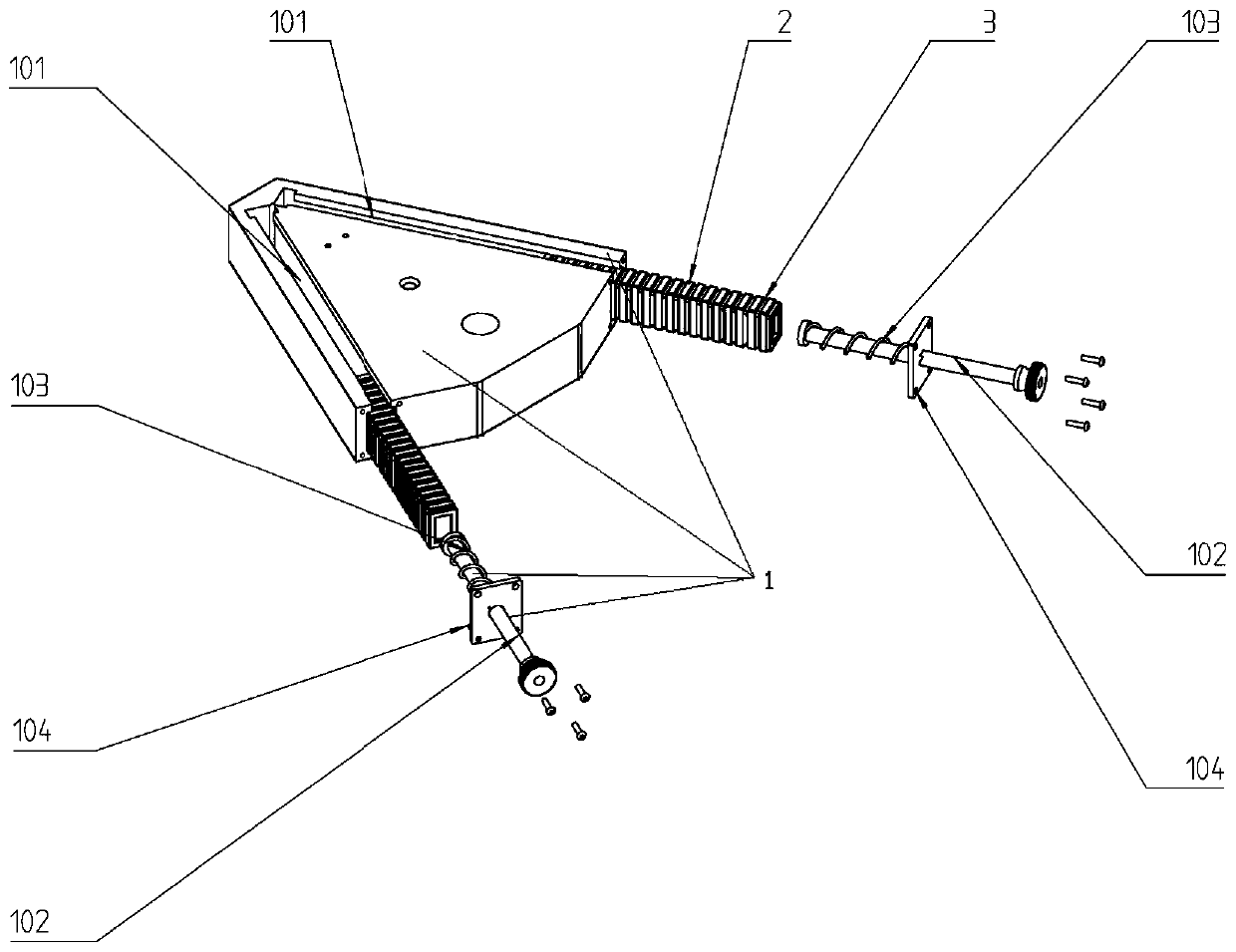

[0030] refer to Figure 1 to Figure 13 , the present invention provides a rotor core magnet assembly device, which includes a stepped base 4, a pressing magnet assembly 6 and an indexing plate assembly 5 that are detachably arranged on the lower steps of the stepped base 4 in turn, Disassemble a magnet bin mechanism 1 that is arranged on a step on the stepped base 4, and a magnetic isolation pad purge tray 7 that is arranged directly above the magnet bin mechanism 1; the magnet bin mechanism 1 includes two horizontal magnet placement channels 101 And two magnet push rod assemblies, two magnet placement passages 101 intersect at the head of the magnet bin mechanism to set a magnet outlet through up and down, each magnet placement passage 101 corresponds to a magnet push rod assembly, for placing a number of rotor core magnets arranged at interva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com