Film coating device for light guide plates

A coating device and light guide plate technology, which is applied in packaging and other directions, can solve the problems of easy adhesion of dust, low processing efficiency, and affecting the coating effect, etc., and achieve the effect of increasing coating efficiency, avoiding manual cleaning, and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

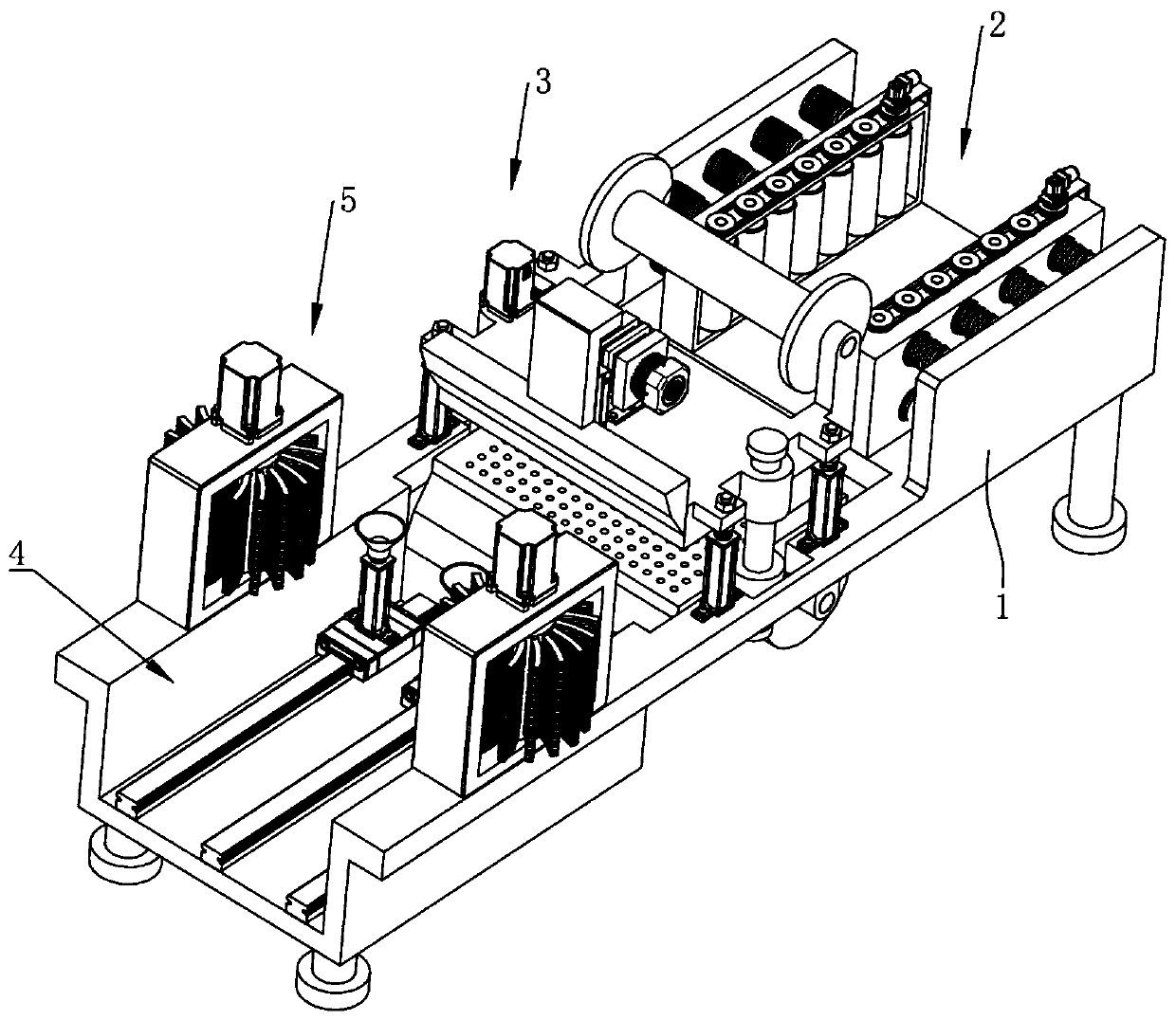

[0031] see Figure 1 to Figure 7 , the present invention provides a technical solution:

[0032] A film coating device for a light guide plate, comprising a frame 1, a front conveying mechanism 2, a film covering mechanism 3, a rear conveying mechanism 4, and a side cleaning mechanism 5, wherein:

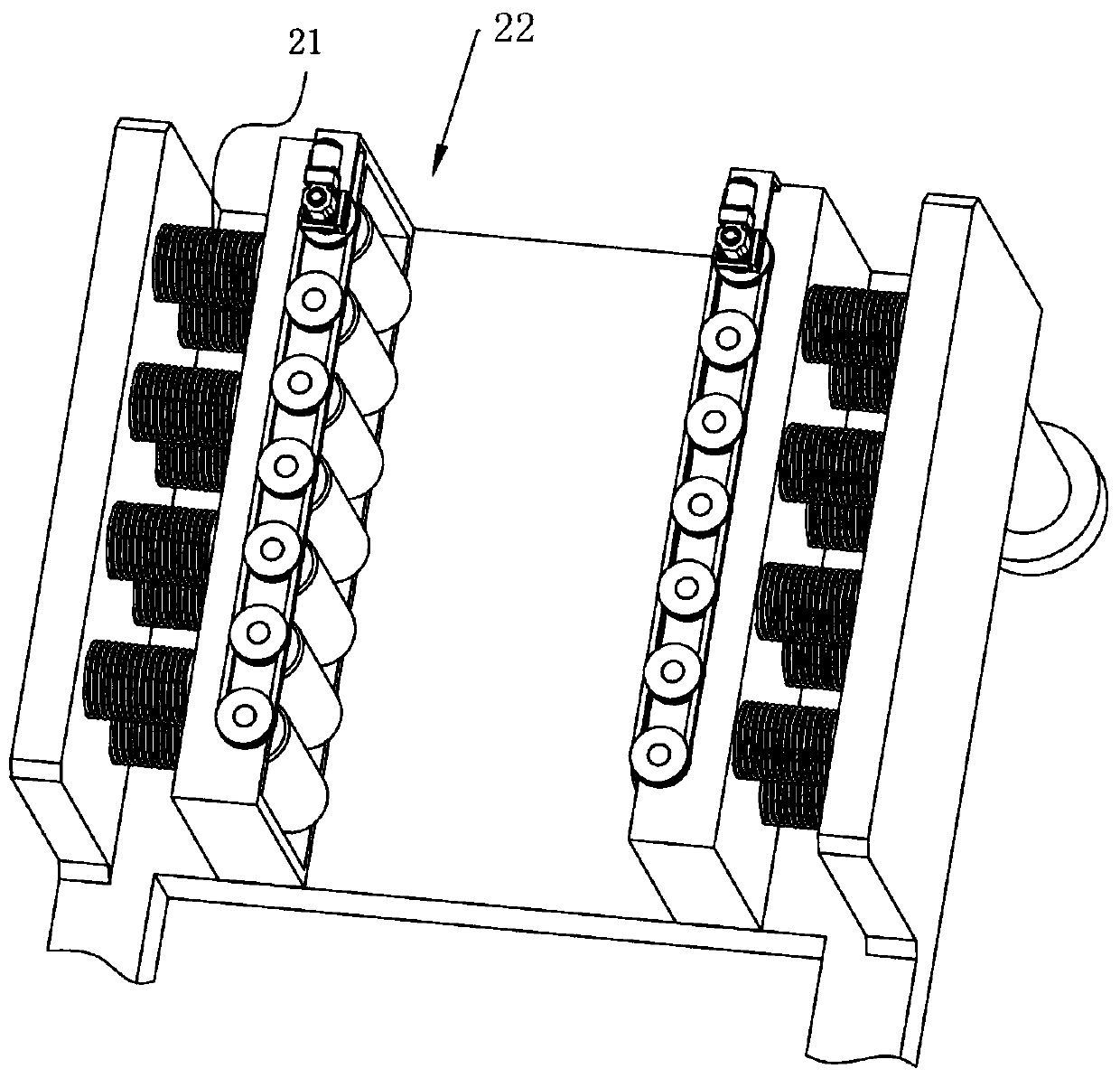

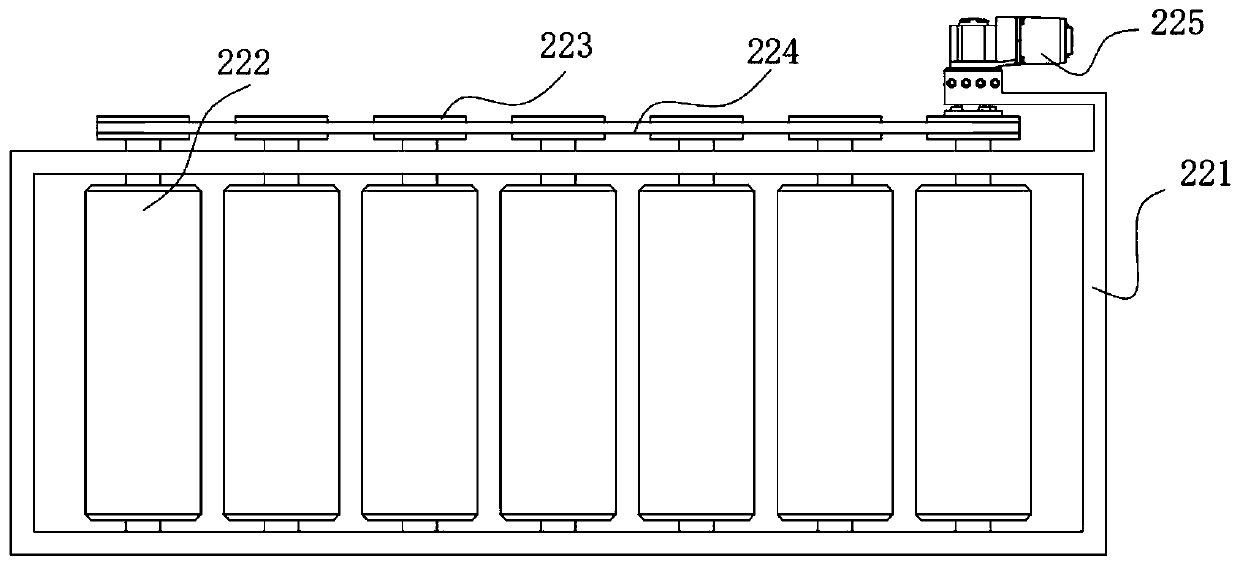

[0033] Front-end conveying mechanism 2 comprises spring 21 and driving mechanism 22, and two driving mechanisms 22 are installed on both sides of frame 1 through several springs 21 respectively, and driving mechanism 22 comprises support II 221, conveying roller 222, pulley 223, belt 224 and The motor III 225 and the bracket II 221 are movably installed on the side of the frame 1 through a number of springs 21, wherein the two ends of the spring 21 are fixedly connected with the bracket II 221 and the side of the frame 1 respectively, and then light baffles of different widths are placed on the bracket When supporting II221, the spring 21 can shrink, and then realize the fixed tran...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap