Large trough for blast furnace ore trough material and preparation method thereof

A material and ore trough technology, which is applied to the field of large troughs of blast furnace ore troughs and their preparation, can solve problems such as easy breaking and falling off, blocking production lines, affecting the production line, etc., and achieve the effect of avoiding cracking and falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

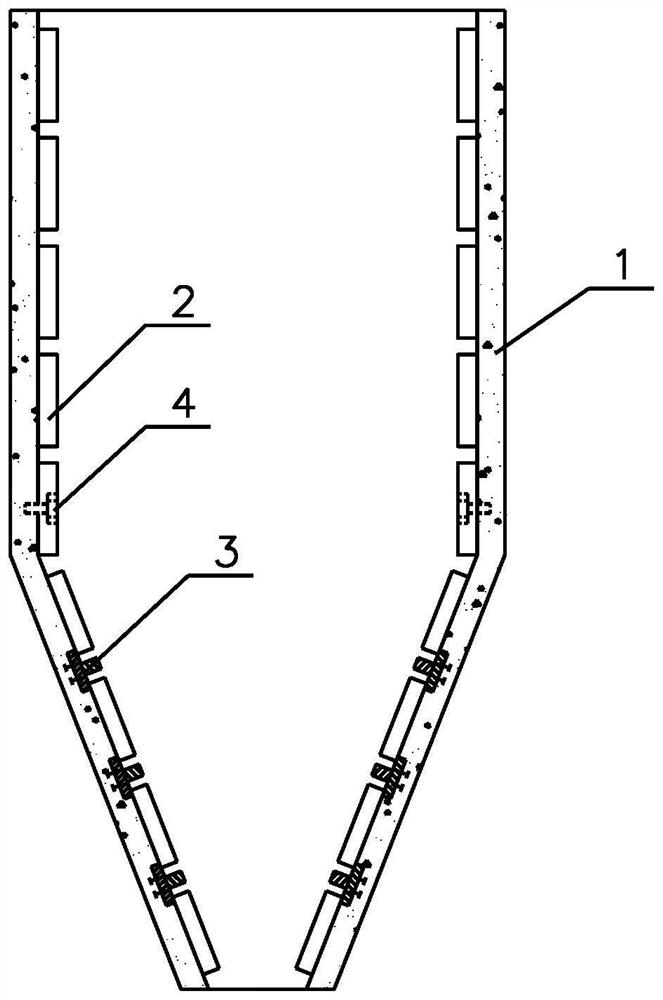

[0023] A method for preparing a large trough for blast furnace ore trough material, specifically comprising:

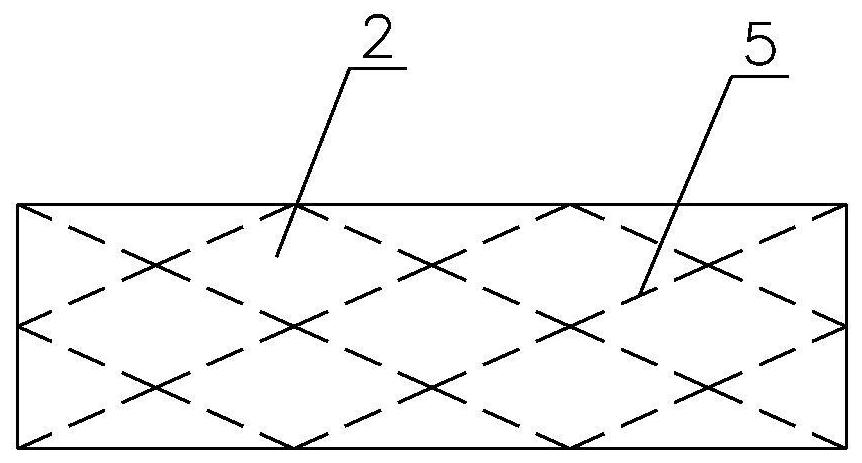

[0024] 1) Prepare the liner, and the inside of the liner is provided with a metal rhombic mesh skeleton;

[0025] 2) When the liner is bonded to the shell of the large material tank, spray a layer of sand particles with a particle size of 0.3mm-0.8mm on the surface of the adhesive to improve the adhesion;

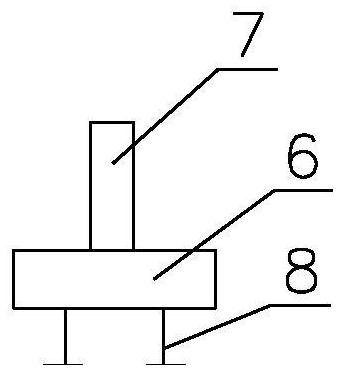

[0026] 3) Screw holes are reserved on the lining plate of the bottom material impact point on the vertical side wall of the material tank shell and the corresponding material tank shell. After the material tank shell and the liner are bonded, use expansion bolts reinforcement;

[0027] 4) A horizontal metal sliding plate is pre-embedded between the lining plates of the sliding part of the sloped side wall.

[0028] The lining plate is cast stone, and the index requirements of cast stone are: compressive strength ≥ 58860N / e㎡; bending strength ≥ 6377N / e㎡; impact to...

Embodiment

[0031] A method for preparing a large trough for blast furnace ore trough material, specifically comprising:

[0032] 1) The liner is prepared, and the inside of the liner is equipped with a metal rhombic mesh skeleton; the metal rhombic mesh skeleton is made of Φ5mm steel bars; the thickness of the liner is 45mm.

[0033] 2) When the liner is bonded to the shell of the large material tank, spray a layer of sand particles with a particle size of 0.3mm-0.8mm on the surface of the adhesive to improve the adhesion;

[0034] 3) Screw holes are reserved on the lining plate of the bottom material impact point on the vertical side wall of the material tank shell and the corresponding material tank shell. After the material tank shell and the liner are bonded, use expansion bolts reinforcement;

[0035] 4) A horizontal metal sliding plate is pre-embedded between the lining plates of the sliding part of the sloped side wall.

[0036] The lining plate is cast stone, and the index requ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com