Clothes washing equipment door body structure and clothes washing equipment

A technology for clothes washing and door body, which is applied in washing devices, other washing machines, textiles and paper making, etc. It can solve the problems of unfavorable detergent delivery department daily maintenance, detergent residue, increased production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

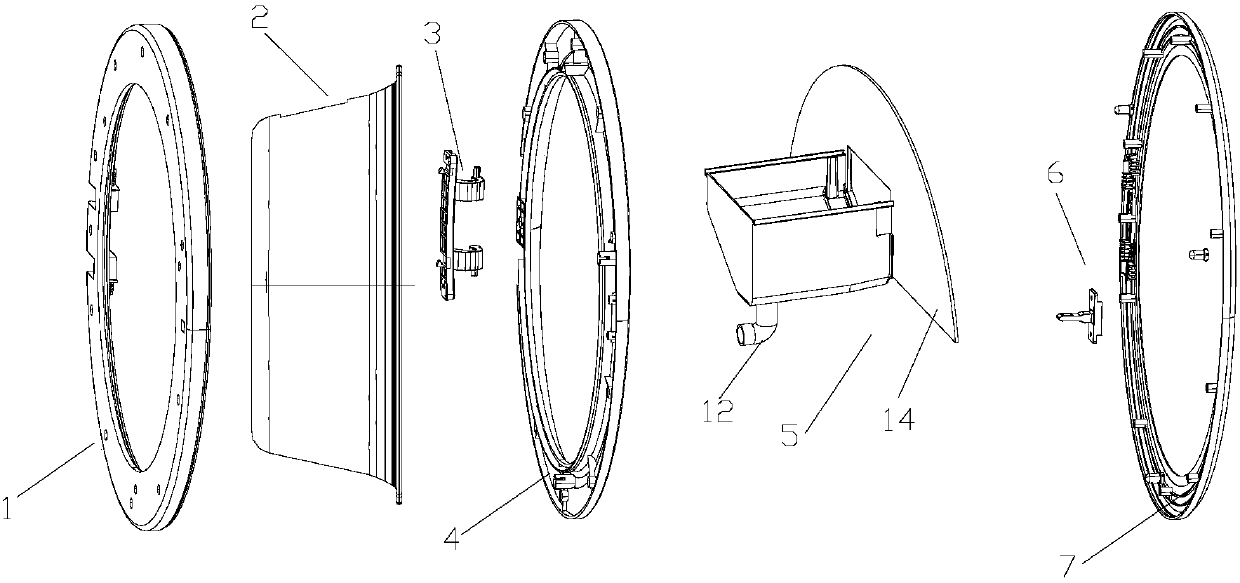

[0048] Such as Figure 1 to Figure 3 As shown, this embodiment introduces a door body structure of laundry washing equipment. A water box 5 is integrated on the door body of the laundry washing equipment. The water box 5 is embedded in the groove of the groove-shaped observation window 2, and the groove Shaped observation window 2 is vertically arranged and makes opening towards the horizontal direction, and water box 5 is located at a side of grooved observation window 2, only blocks part grooved observation window 2. The water box 5 and the groove-shaped observation window 2 can be arranged integrally, or can be installed in the groove-shaped observation window 2 in a detachable form such as a socket. The outside of the water box 5 is provided with a mounting plate 14, the mounting plate 14 extends outwards, and is semi-elliptical. The mounting plate 14 is clamped between the middle frame 4 and the outer frame 7, or is clamped between the inner frame 1 and the middle frame. ...

Embodiment 2

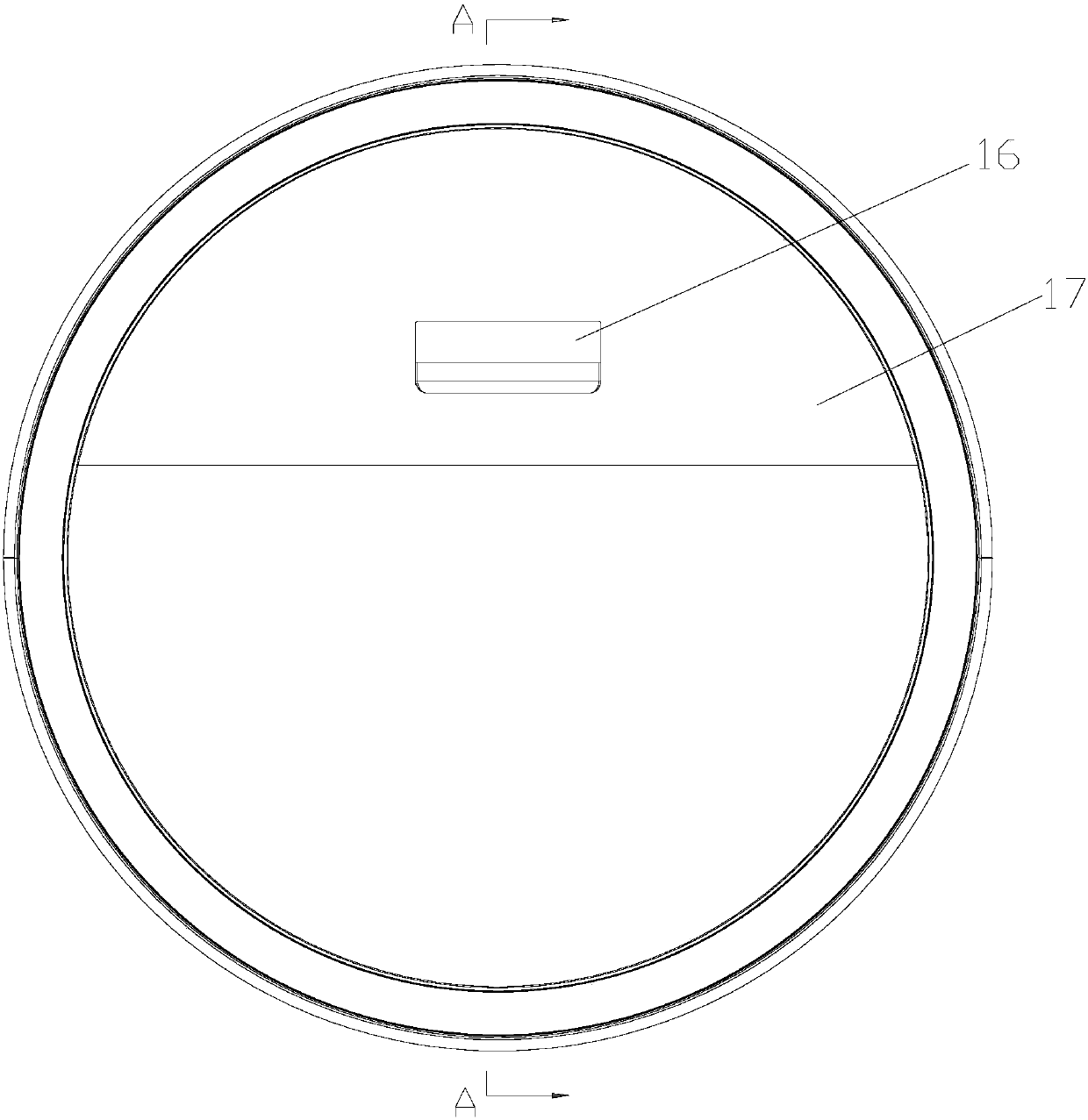

[0052] In this embodiment, a detergent dispensing part 9 is installed in the water box 5, and the water box 5 is provided with an opening near the door body. The detergent dispensing part 9 is pulled and moved horizontally from the opening of the water box 5. The delivery part 9 is set to a box-like structure, including a delivery chamber 18 and a lid 17. The top of the delivery chamber 18 is open, corresponding to the open top of the water box 5, and is used to inject detergent inward, and the washing water can pass through The top opening flows into the delivery chamber 18; the delivery chamber 18 is provided with a lid 17 on the side where the side of the door is drawn, and the lid 17 is used to pull the detergent injection part 9, and the lid 17 is vertically arranged. And protrude radially outwards, make the outer circumference of the box cover 17 protrude from the opening of the water box 5. After the detergent injection part 9 is pushed into the water box, the box cover...

Embodiment 3

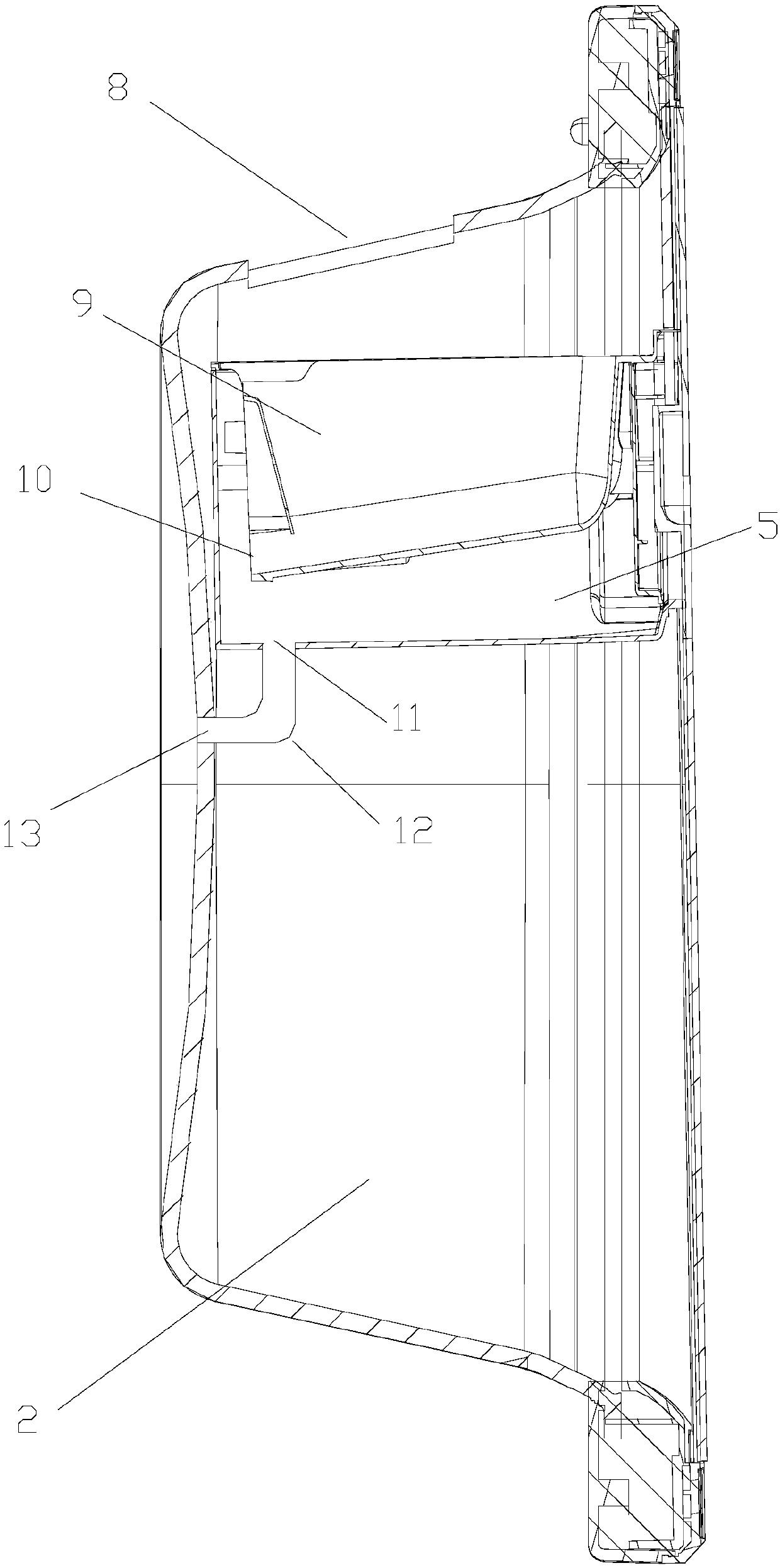

[0057] Such as Figure 3 to Figure 4 As shown, in this embodiment, the top of the groove-shaped observation window 2 is provided with a water inlet 8, and the water inlet 8 corresponds to the upper window pad nozzle 15, and communicates with the top opening of the detergent injection part 9 below. , the discharge port 10 provided at the bottom of the detergent dispensing part 9 communicates with the bottom of the water box 5, and the bottom of the water box 5 passes through the outlet pipeline 12 of the groove-shaped observation window 2 and the washing machine on the rear side of the groove-shaped observation window. The cylinder is connected.

[0058] In this embodiment, before the drum laundry washing equipment starts to work, the detergent injection part 9 is pulled out to the door side to inject detergent. After the injection is completed, the detergent injection part 9 is pushed into the water box 5 to make The box cover 17 of detergent dispensing part 9 is closely atta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com