Bonding joint

A technology of glue joints and glue grooves, applied in the direction of pipes/pipe joints/fittings, non-detachable pipe connections, passing elements, etc., can solve the defects of glue layer, affect the connection strength of glue layer, and the connection strength of glue joints needs to be improved and other problems, to achieve the effect of consistent thickness and improved connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

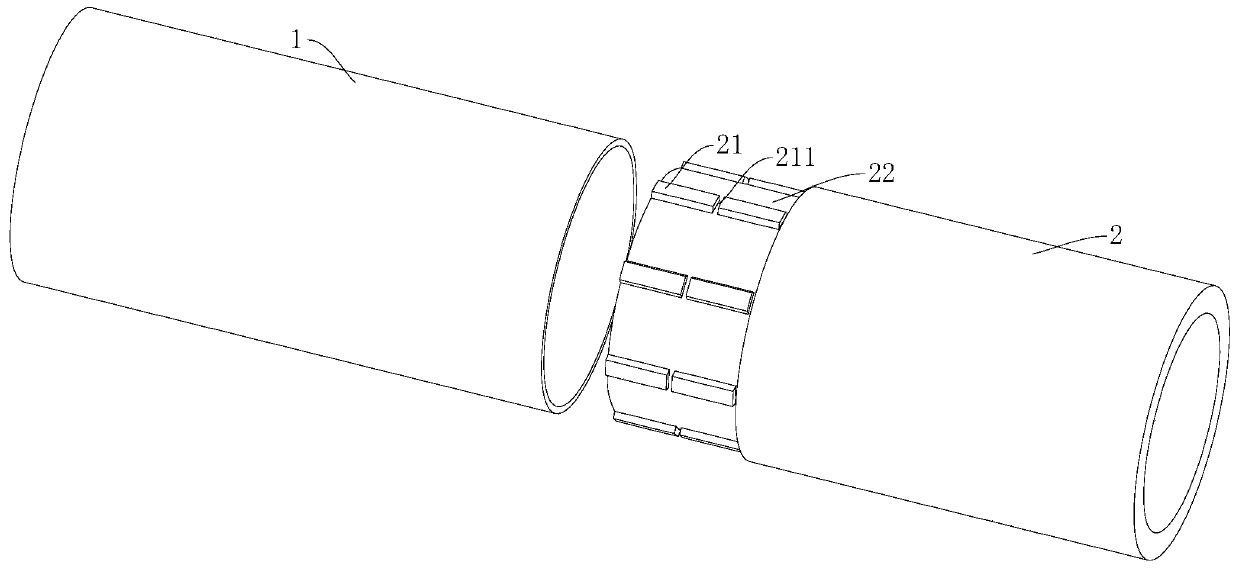

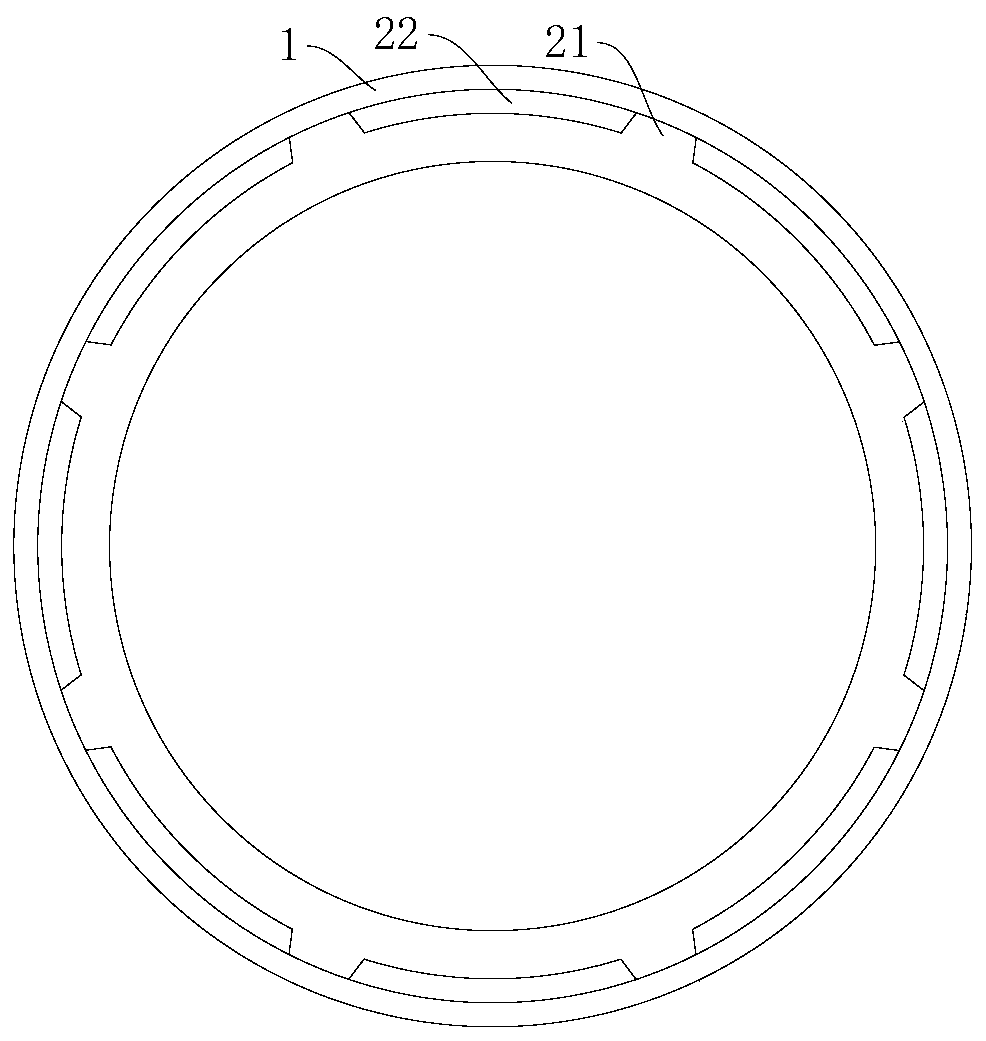

[0029] see Figure 1-Figure 3 , the adhesive joint of the present invention includes an inner pipe 2 and an outer pipe 1, the inner pipe 2 is sleeved on the outer pipe 1, and one of the inner pipe 2 and the outer pipe 1 is provided with several guide ribs 21, and the guide ribs 21 Adapted to abut against the other so that the axis of the inner tube 2 is collinear with the axis of the outer tube 1 . Adhesive grooves 22 are formed between adjacent guide ribs 21 , and the adhesive grooves 22 contain an adhesive, which is used to bond and fix the inner tube 2 and the outer tube 1 . A plurality of guide ribs 21 are provided on the inner tube 2 or the outer tube 1, so that when the outer tube 1 is socketed on the inner tube 2, the guide ribs 21 can be quickly positioned and guided, that is, quick installation is realized. And, because the guide rib 21 abuts against the outer wall surface of the inner tube 2, or the guide rib 21 abuts against the inner wall surface of the outer tube...

no. 2 example

[0035] Figure 4-Figure 5 Shows the glued joint of the second embodiment of the present invention, the second embodiment provides the glued joint including the first embodiment, which is different from the first embodiment in that the outer contour of the guide rib 21 is a ring structure, Several guide ribs 21 are arranged at intervals along the axis of the inner tube 2 or the outer tube 1 . It can be understood that after the guide ribs 21 abut against the inner wall of the inner tube 2 or the outer tube 1, each guide rib 21 can prevent the adhesive from migrating on a large scale, thereby preventing the adhesive from freeing from the glue groove 22 and entering the inner tube 2 or the outer tube 1. Inside of tube 1, and the blocking effect is better. In this embodiment, preferably, several guide ribs 21 are arranged at intervals along the axis of the inner tube 2 .

[0036] Preferably, the guide rib 21 is provided with a second water channel 212 , the second water channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com