Junked tire particle drying machine

A technology for waste tire granules and dryers, which is applied in the direction of dryers, drying, non-progressive dryers, etc., and can solve the problems of inability to dry granules, no large-scale production equipment, and poor drying effects, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

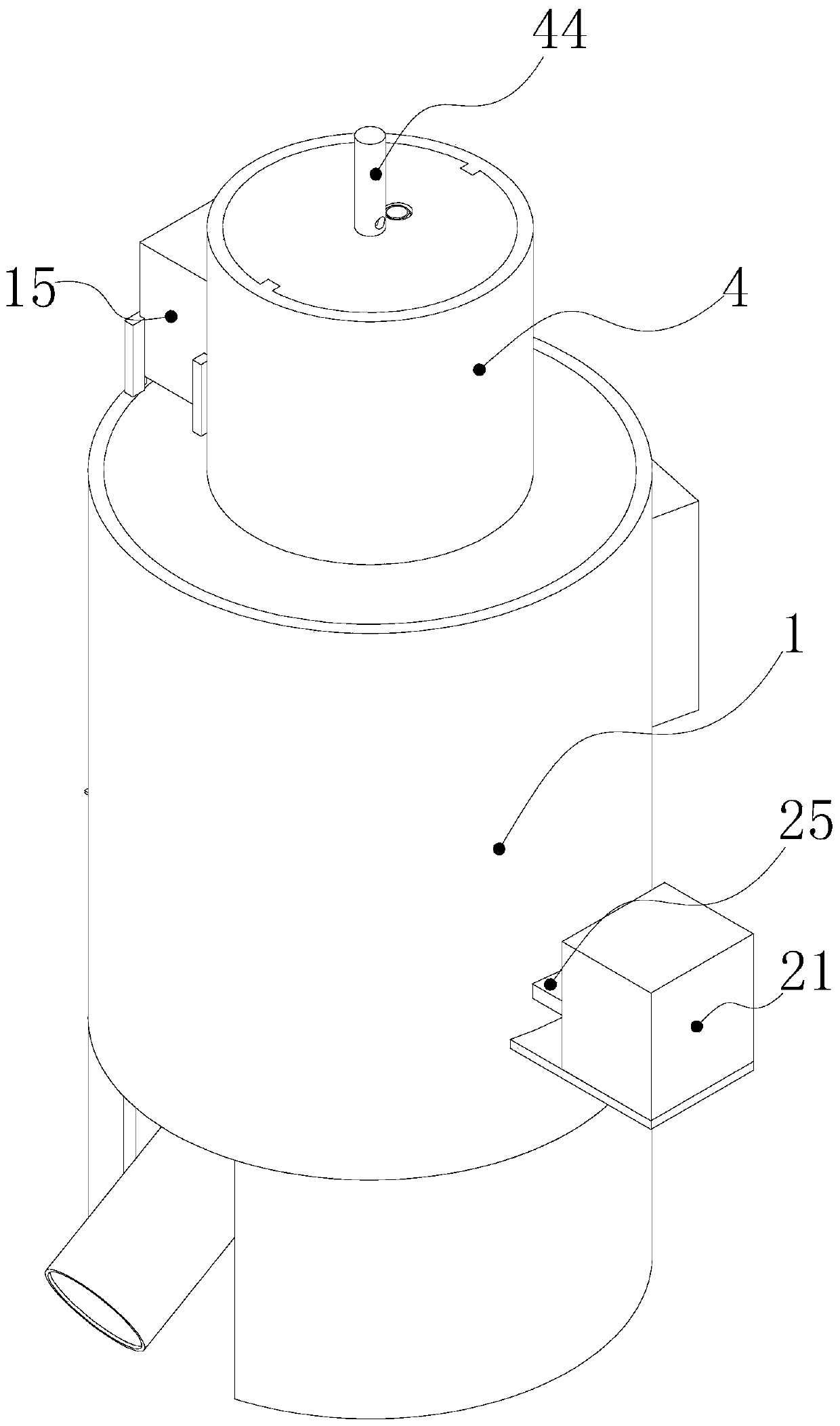

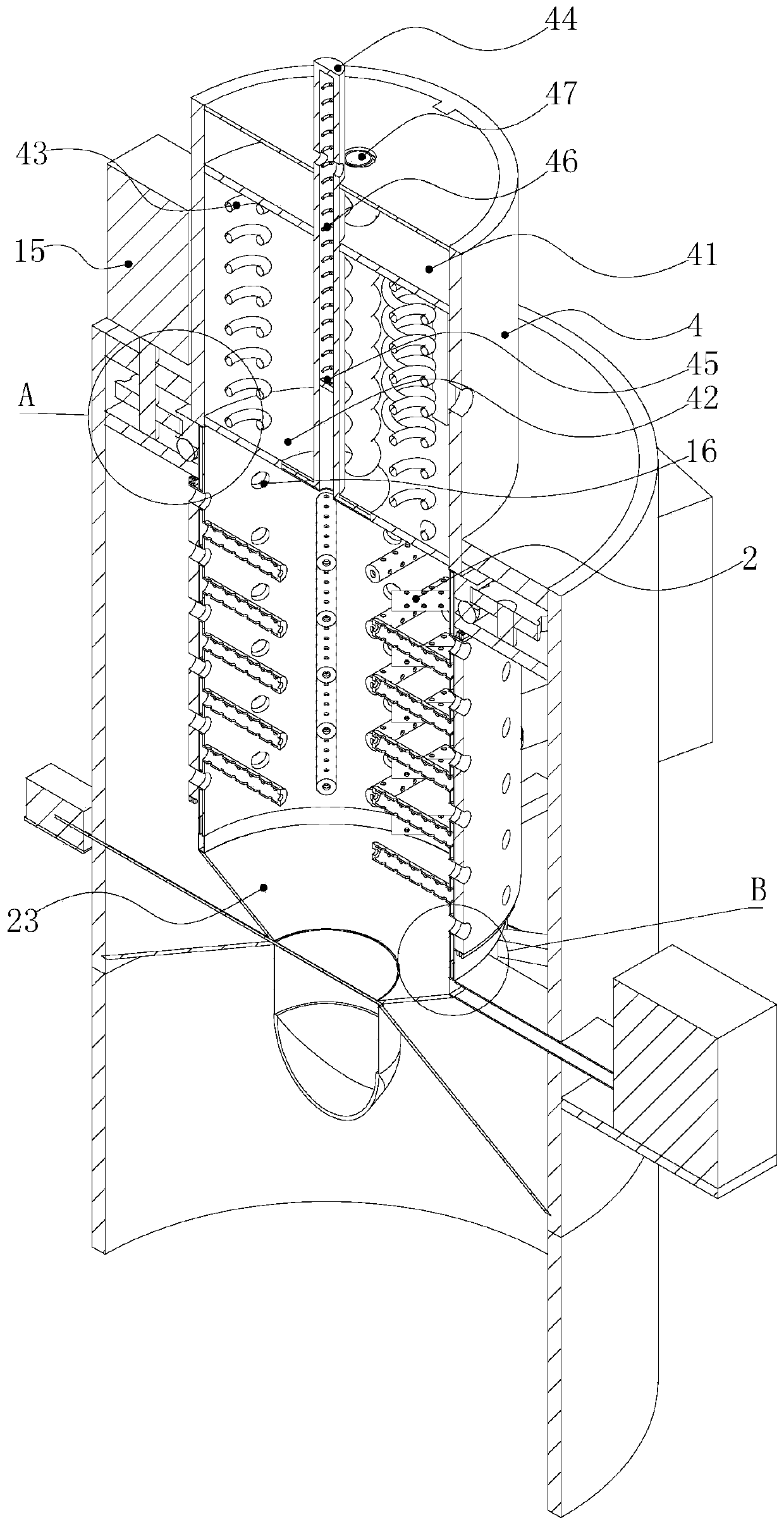

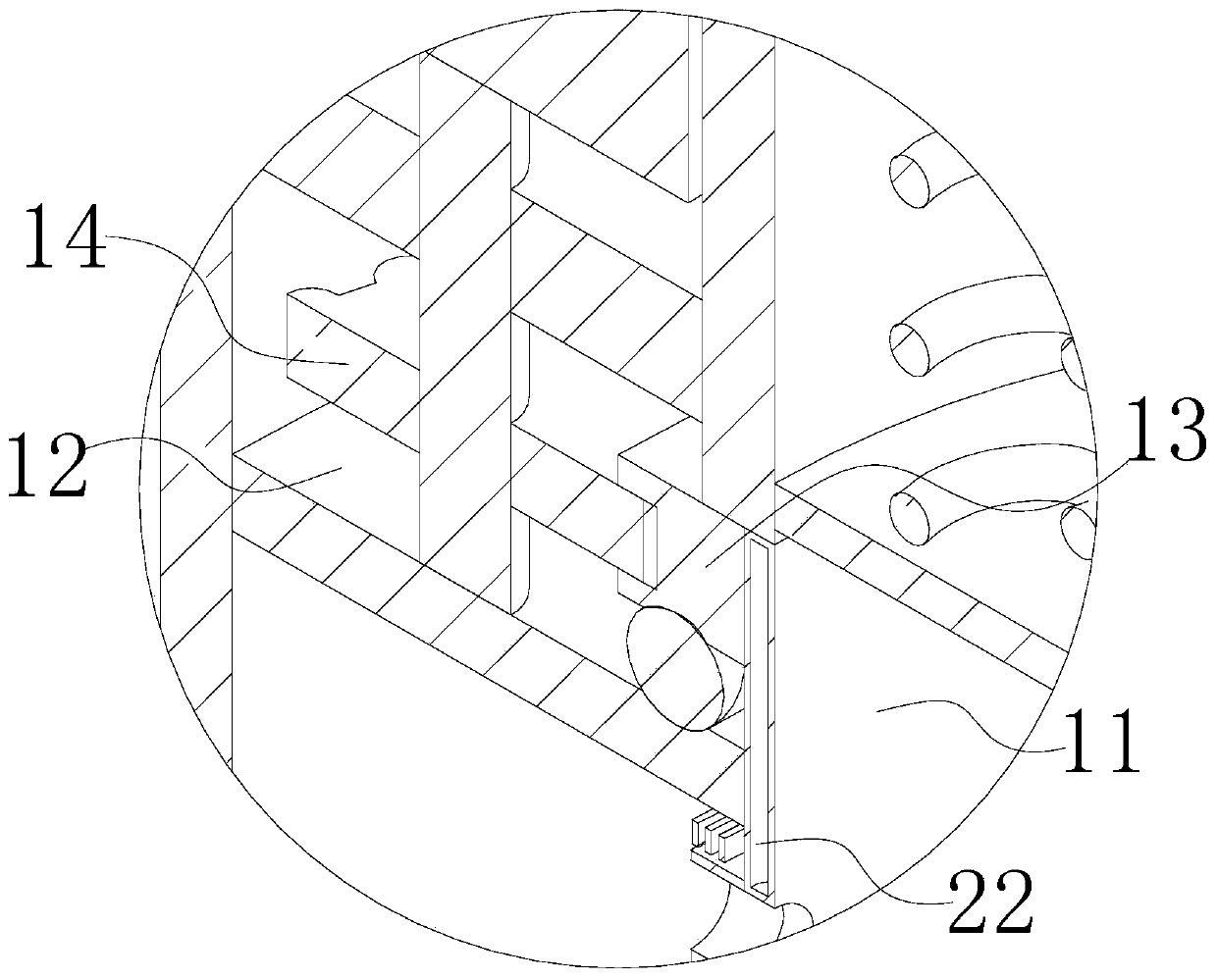

[0022] Such as Figure 1-8 As shown, a waste tire particle dryer includes a housing 1, a drying cylinder 11, a drying device, a dehydration device and a collection device. The dehydration device includes a first fixed plate 12, a driving tooth 13, a gear 14, The first driving member 15 and the second through hole 16, the first fixing plate 12 is fixed on the inner wall of the housing 1, and the center of the first fixing plate is provided with a round hole for the drying cylinder to pass through. Teeth 13 are conventional gears, which are fixed on the outer wall of the upper end of the drying drum. The gear 14 is a metal gear, connected to the first fixed plate through shaft rotation, and meshed with the driving teeth 13. The first driving member 15 A motor is selected, the output shaft of which is fixedly connected with the shaft of the gear, and the second through hole 16 is evenly opened on the wall of the drying cylinder, and the rotation of the gear can drive the drying c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap