A method for predicting sequential delivery in a product queue based on dynamic adjustment prediction

A dynamic adjustment and queuing technology, applied in the field of manufacturing and assembly, which can solve problems such as changing plans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

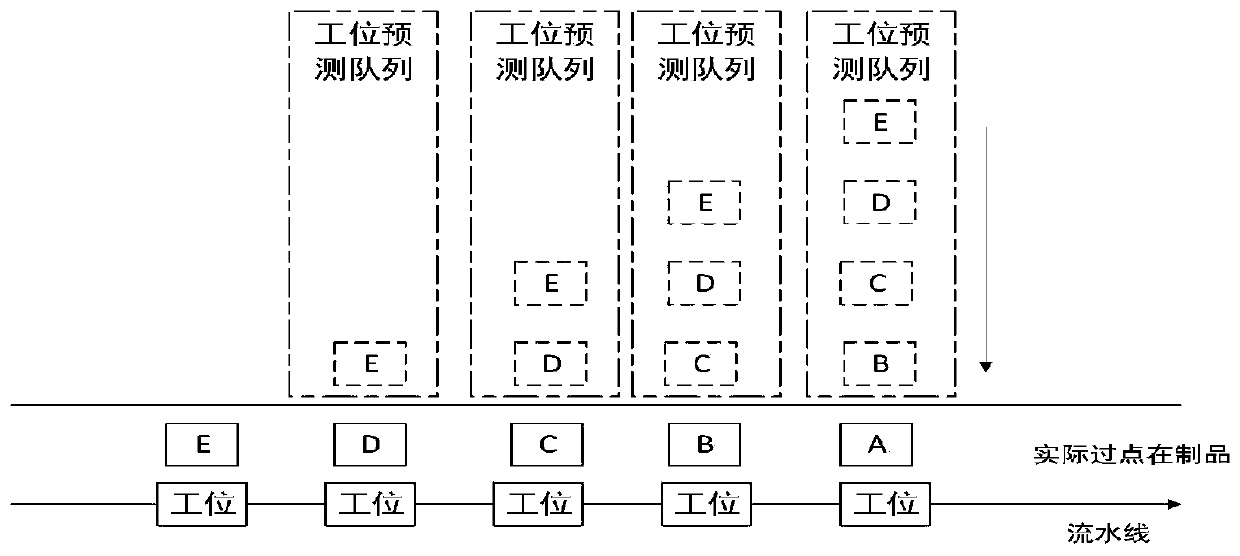

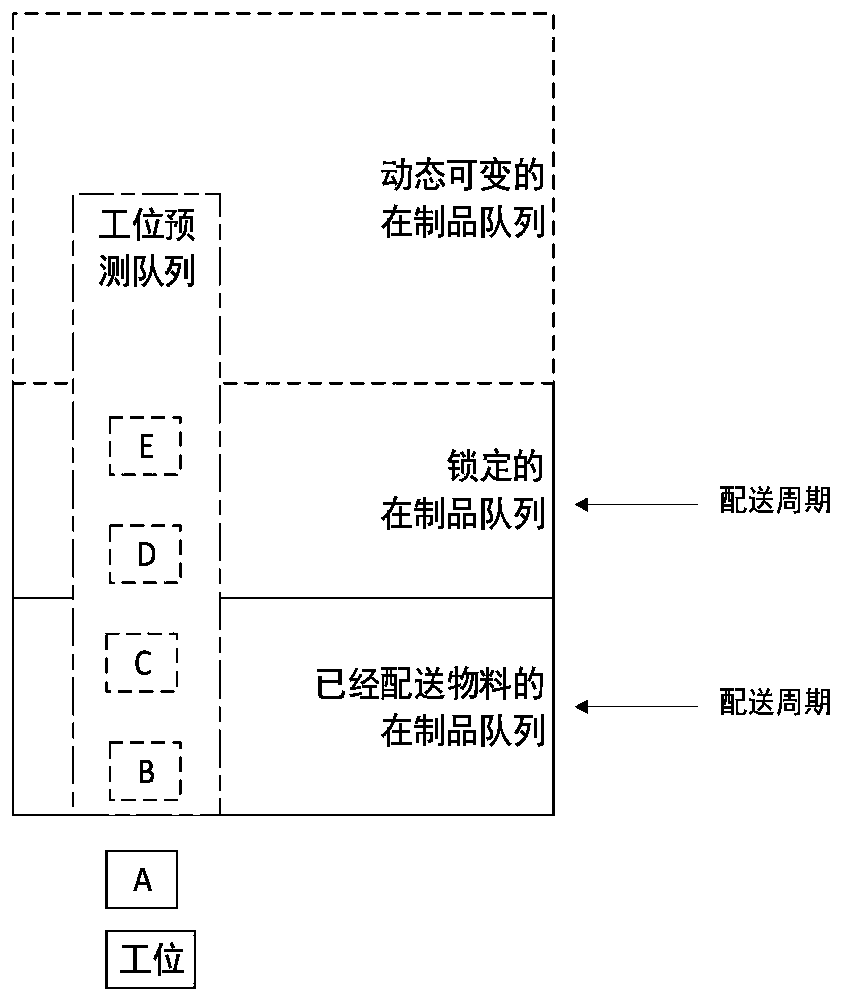

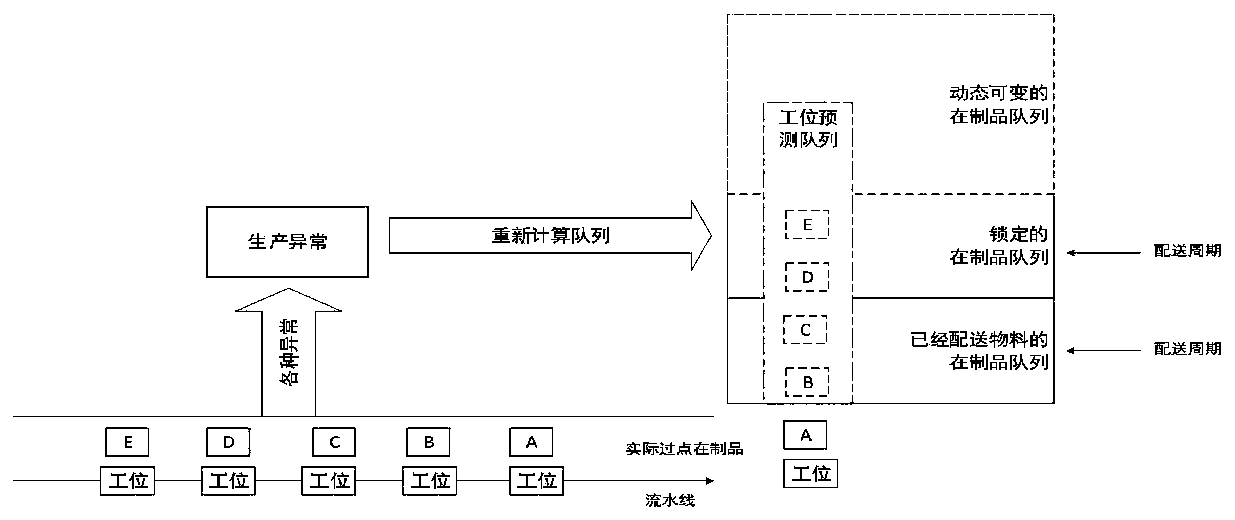

[0044] The method of sequential parts distribution based on the forecasted WIP queue based on dynamic adjustment, the implementation process is as follows:

[0045] 1. Factory model and basic data

[0046] 1) Define the assembly line and station

[0047] Line1, station: S1, S2, S3, S4, S5;

[0048] On-line station S1,

[0049] The sequence of stations: S1->S2->S3->S4->S5.

[0050] 2) Maintain the product

[0051] Define products A, B, C, D

[0052] 3) Maintain BOM

[0053] Material distribution method: JIT (Just-In-Time): sets of kits, JIS (Just-In-Sequence): sequential delivery

[0054]

[0055]

[0056]

[0057]

[0058] 4) Maintain production beat

[0059] product

the beat

A

10 minutes

B

20 minutes

C

25 minutes

D

15 minutes

[0060] Due to the mixed-line production, at any moment, there may be any combination of products A, B, C, and D on the assembly line. In order to simplify the calculation, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com