Patents

Literature

32 results about "Planned change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

One of the foundational definitions in the field of organizational development (aka OD) is planned change...

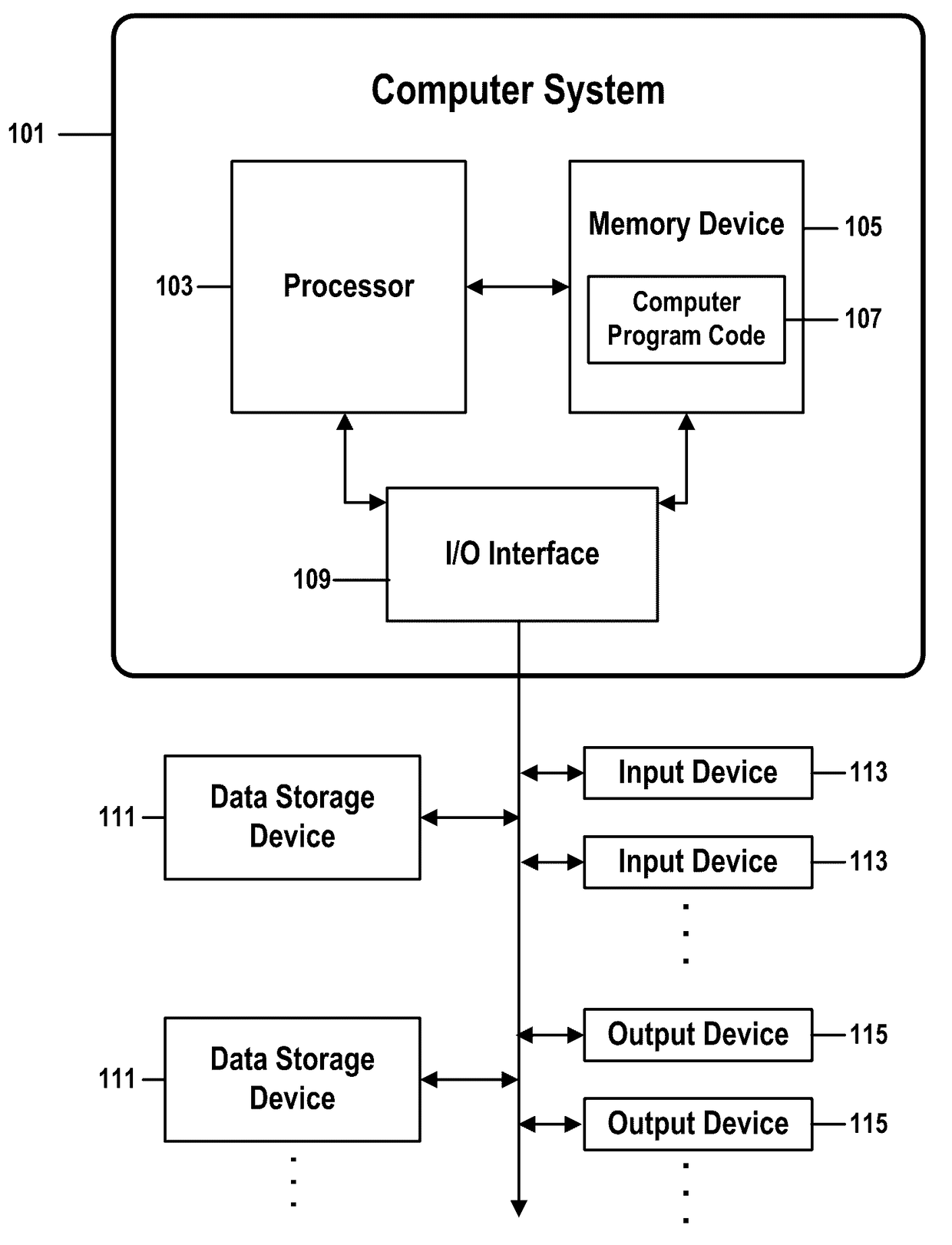

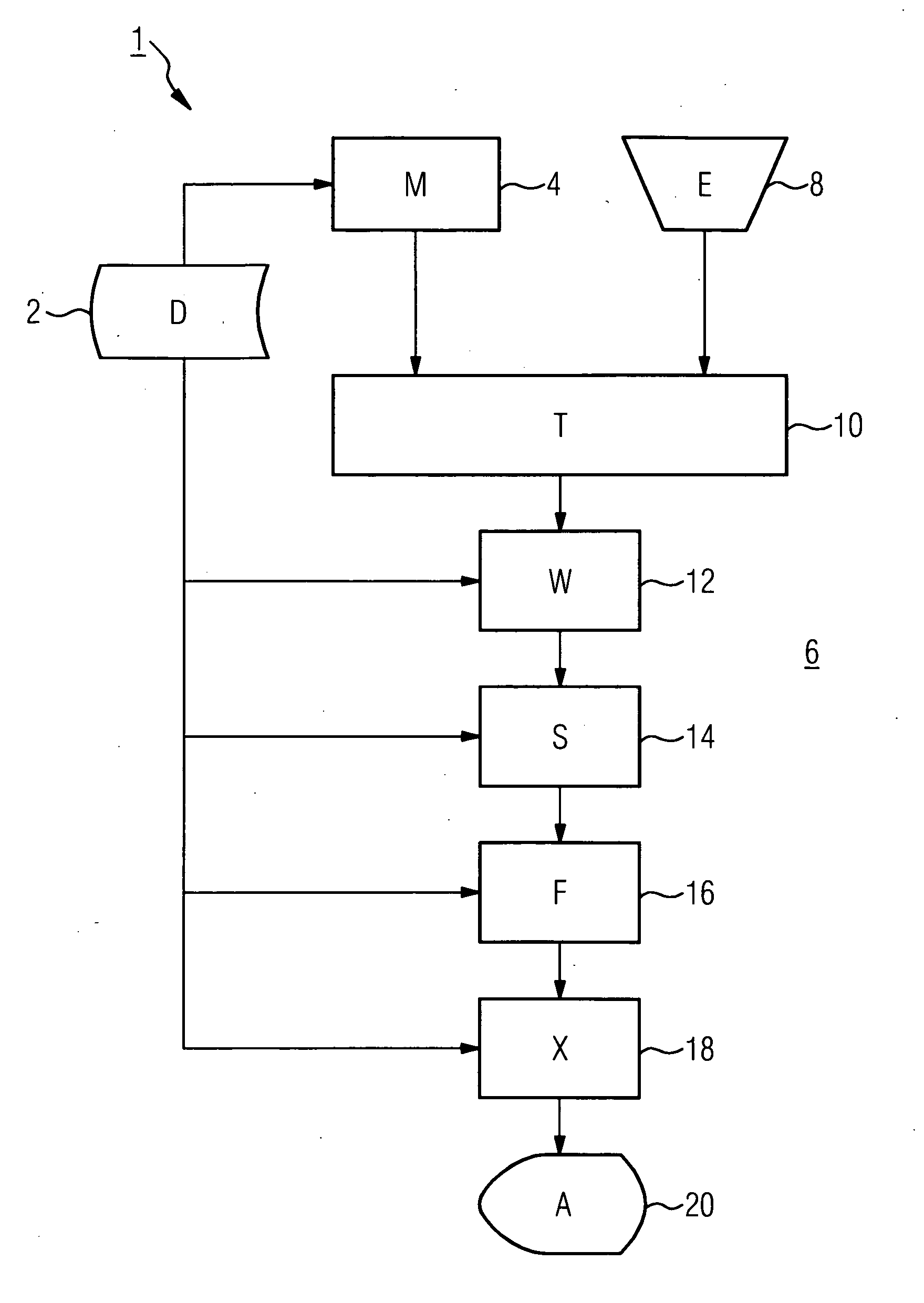

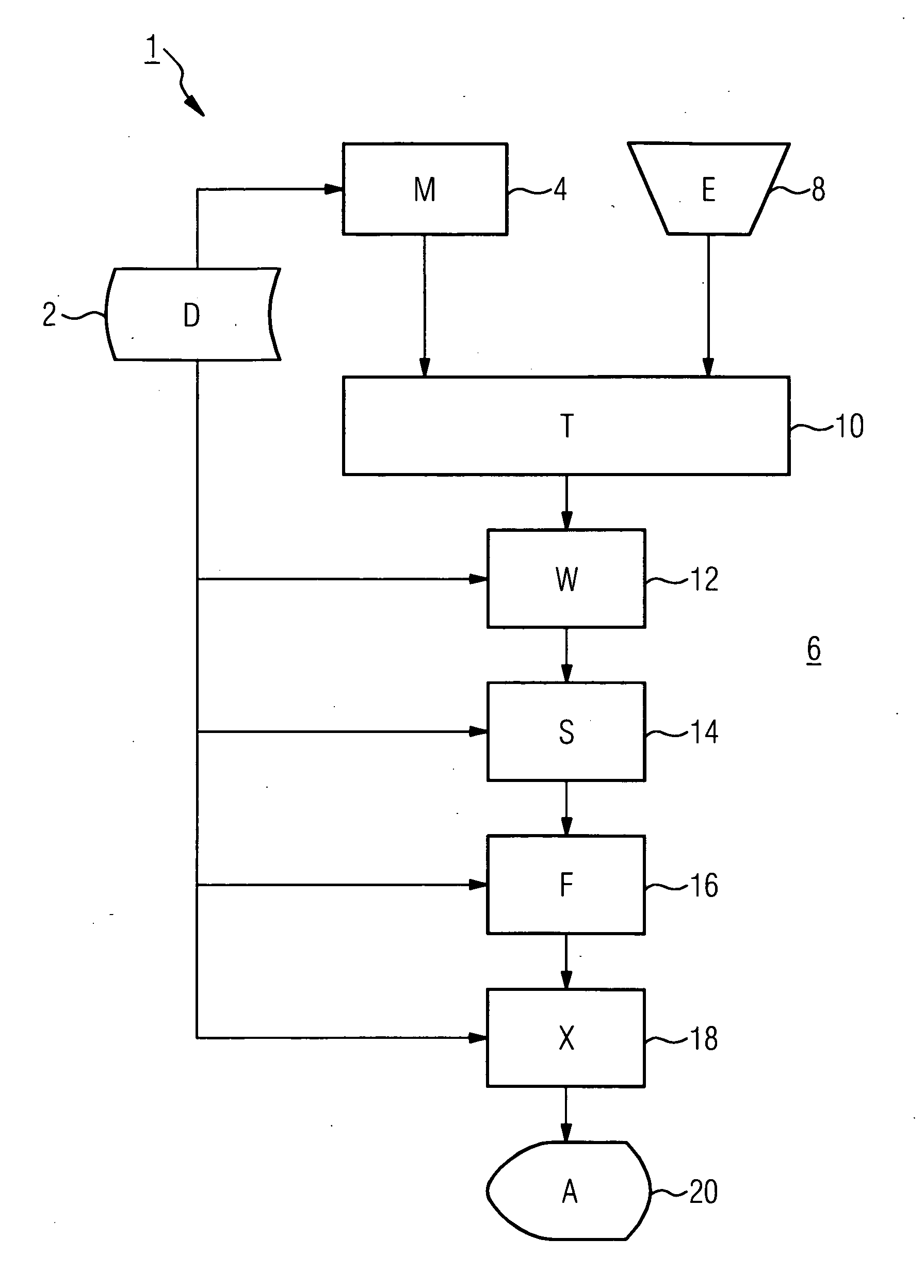

System and method for managing information technology models in an intelligent workload management system

ActiveUS20110126047A1Free computational resourceAgile and flexible managementFault responseDigital computer detailsPlanned changeService-oriented architecture

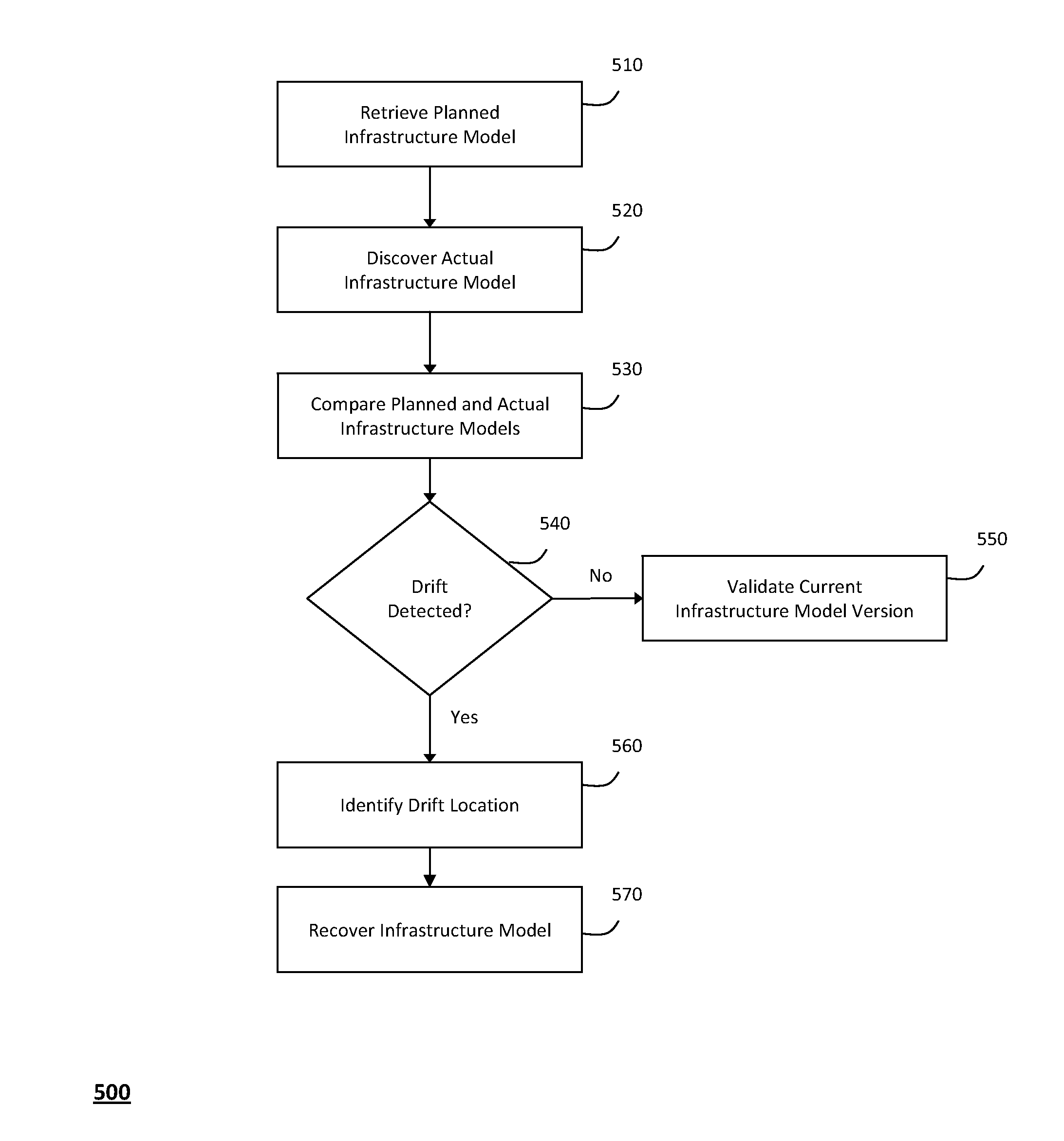

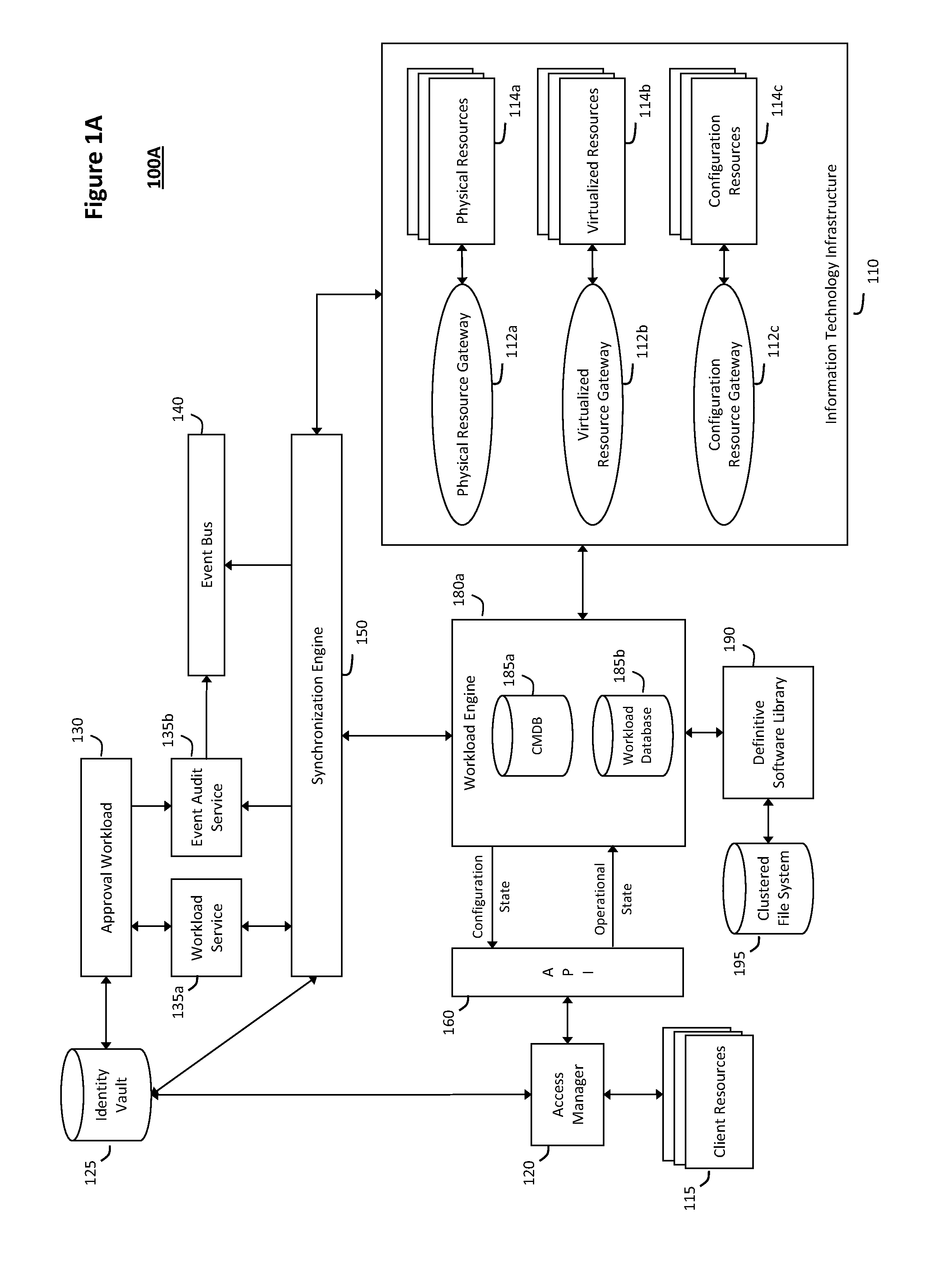

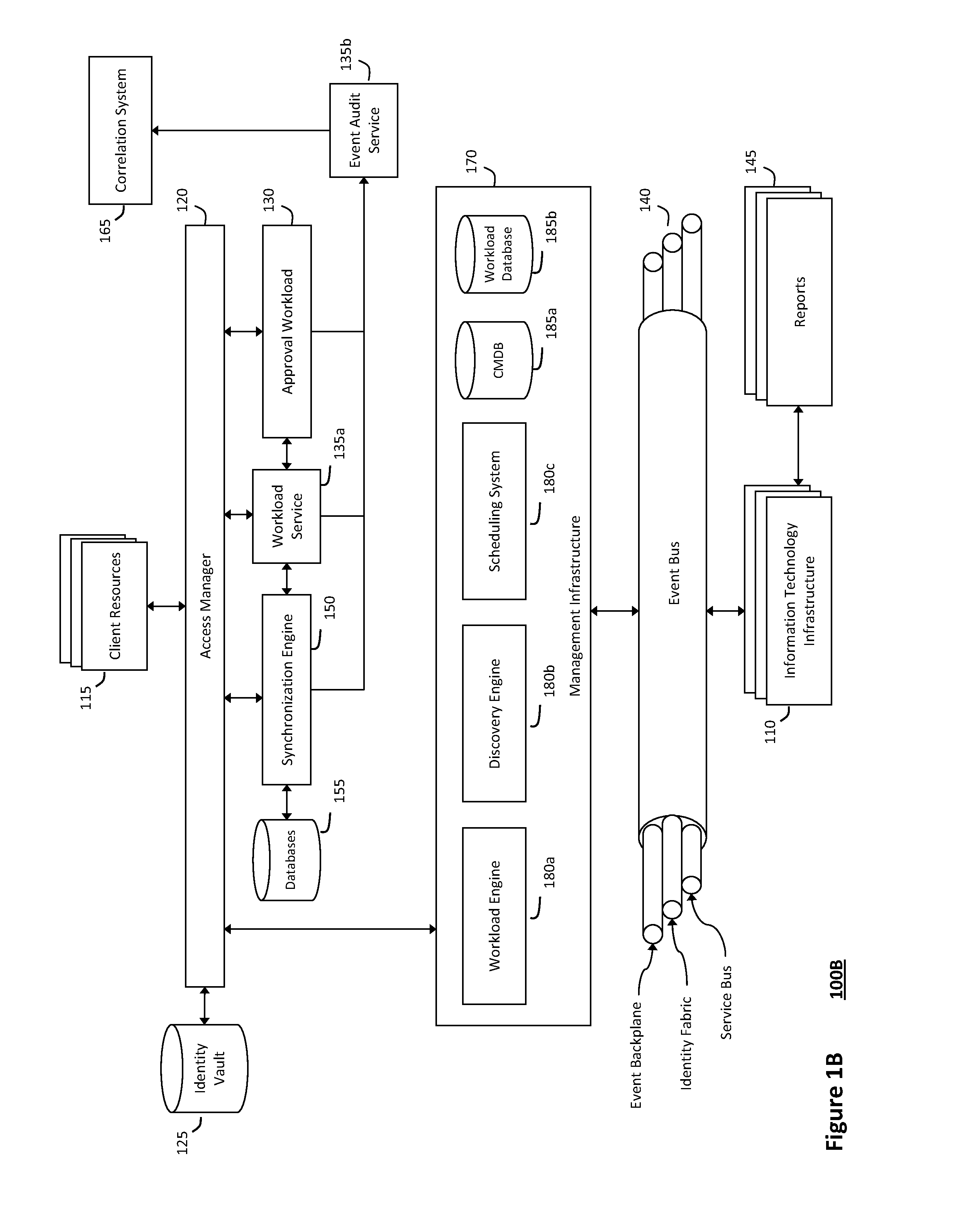

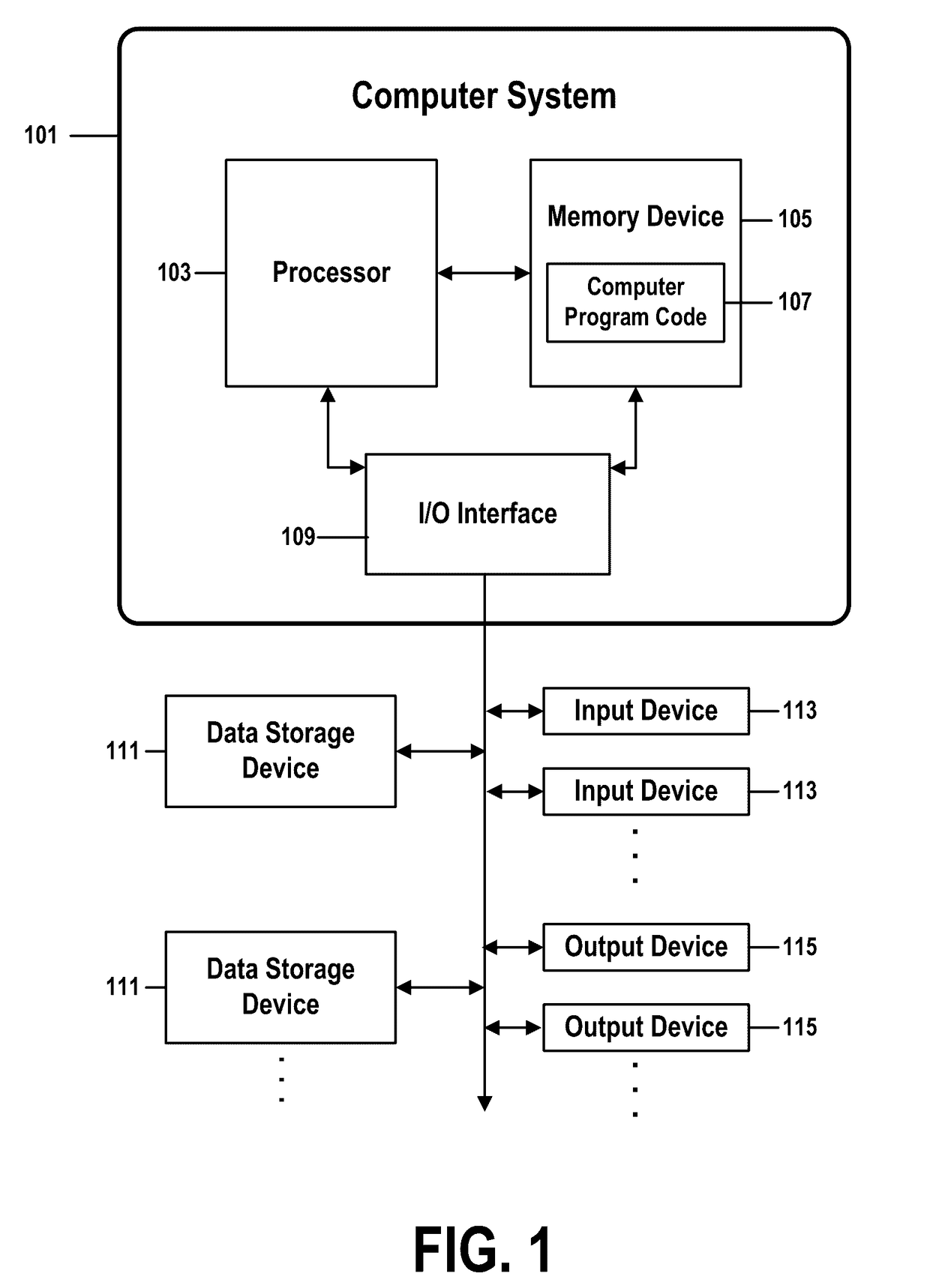

The system and method described herein for managing information technology models in an intelligent workload management system may include a computing environment having a model-driven, service-oriented architecture for creating collaborative threads to manage workloads. In particular, the management threads may converge information for managing planned changes and recovery processes for version-controlled snapshots of the information technology models. For example, a discovery engine may enrich models of an infrastructure with identity information obtained from an identity vault and the infrastructure itself, and a management infrastructure may then manage planned changes to the infrastructure model. In particular, the management infrastructure may construct implementation plans that coordinate interaction between managed entities to implement the planned changes, and may further detect drifts between operational states and planned states for the infrastructure models.

Owner:MICRO FOCUS SOFTWARE INC

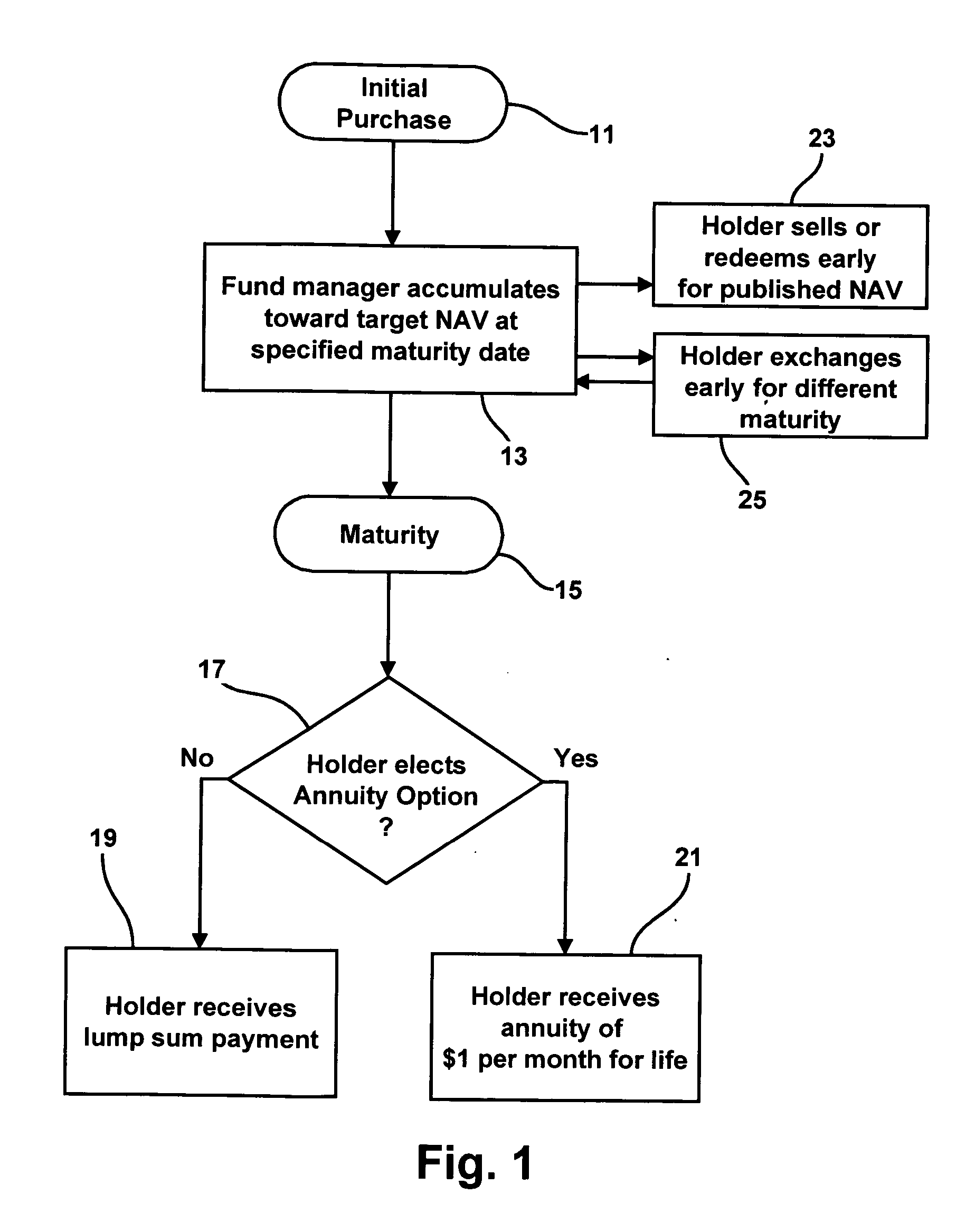

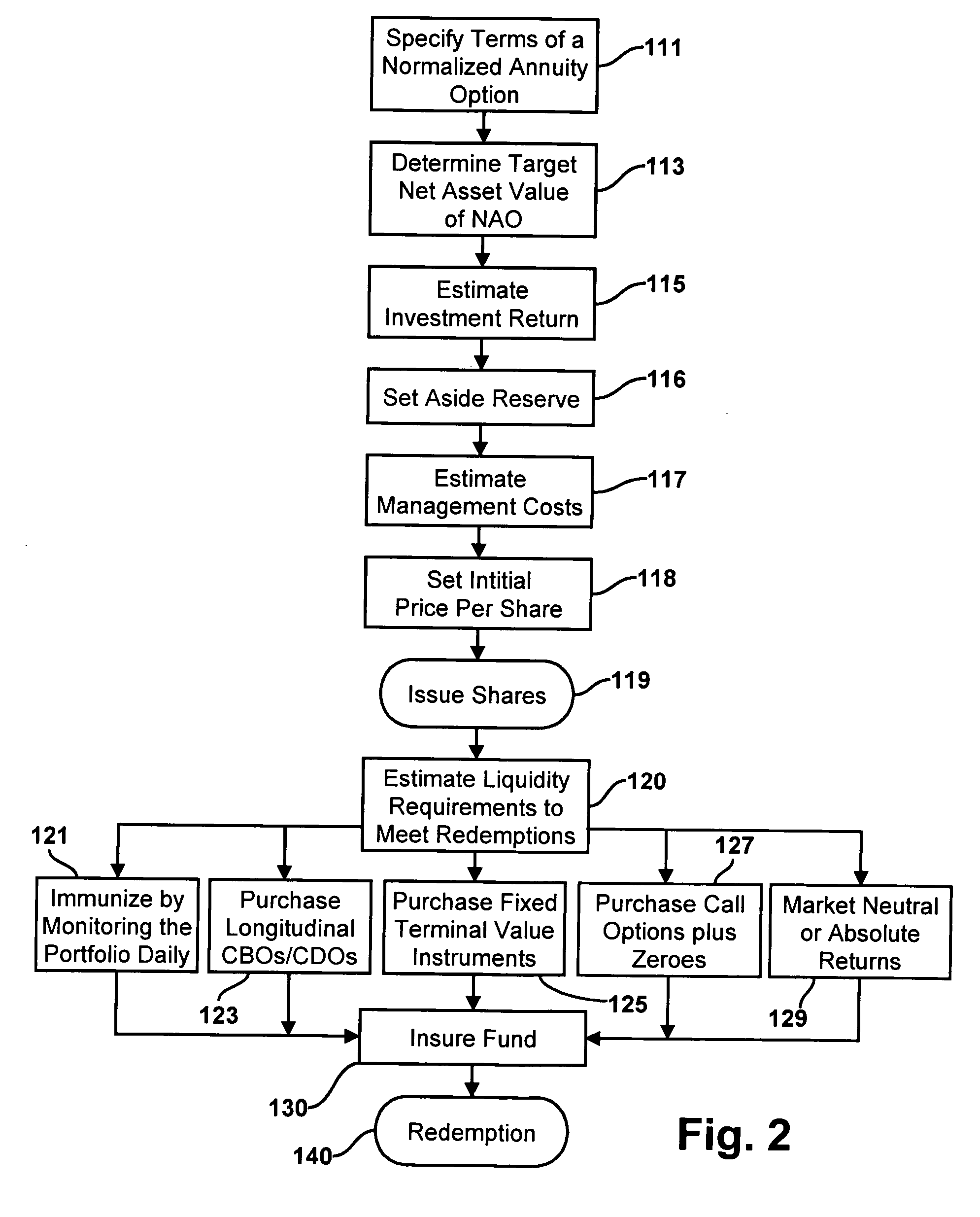

Methods for issuing, distributing, managing and redeeming investment instruments providing normalized annuity options

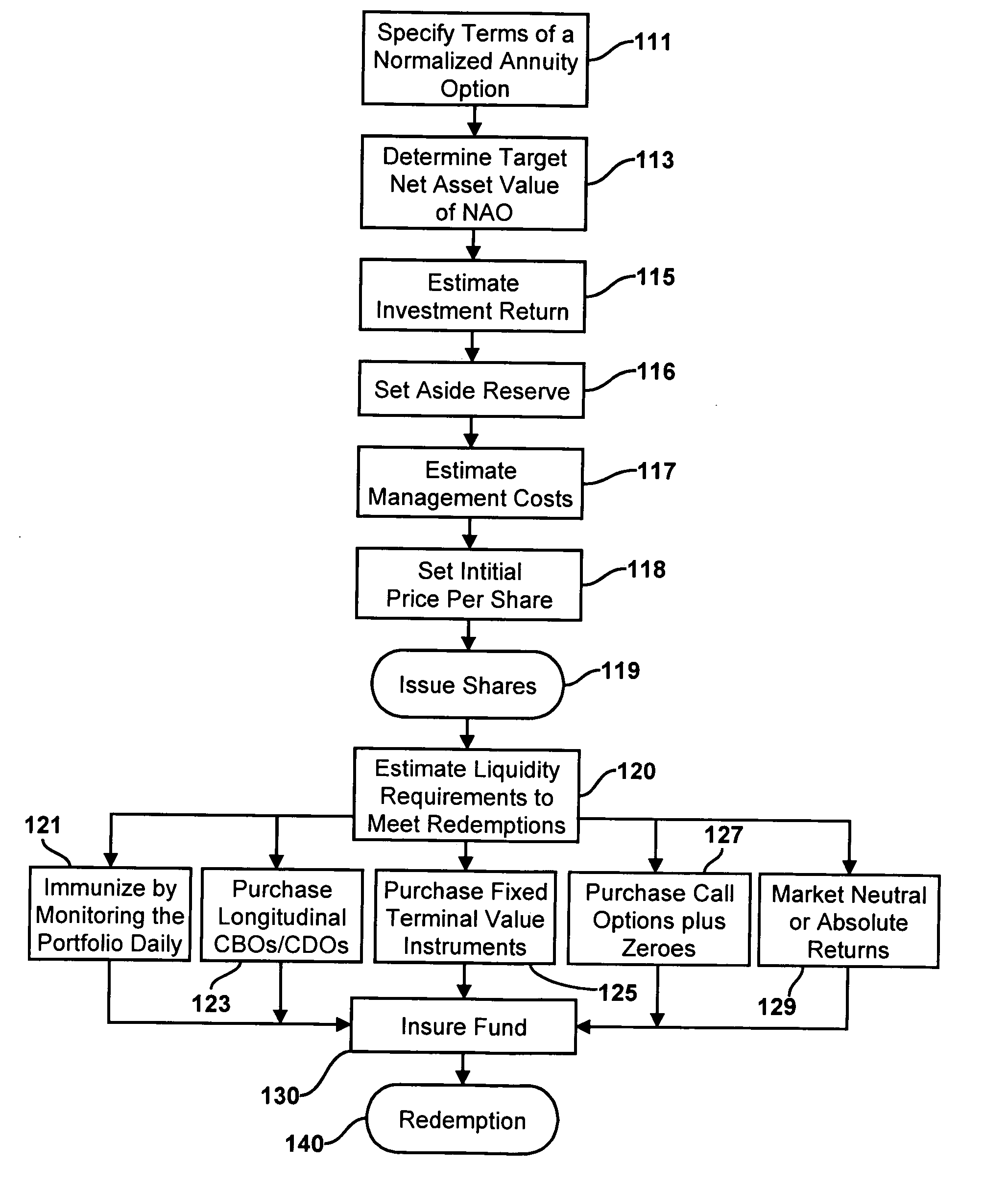

A method of issuing and managing investment instruments called “Pension Shares” which preferably take the form of securities that represents a claim against and is secured by an investment fund. A Pension Share entitles its holder to receive, at a specified maturity date, either a lump sum payment amount or, at the option of said holder, to receive a sequence of annuity payments. The Pension Share issuer creates and manages the investment fund such that its net asset value at the maturity date will be adequate to make the lump sum payment or provide the holder with the annuity. A preferred form of Pension Share provides an annuity option of one dollar per for the life of the holder, or his or her survivor, both of whom are at a predetermined age at the maturity date. A Pension Share may be redeemed on demand in advance of the maturity date so that it may be exchanged for a Pension Share having a different maturity date if the holder's plans change.

Owner:RETIREMENT ENG

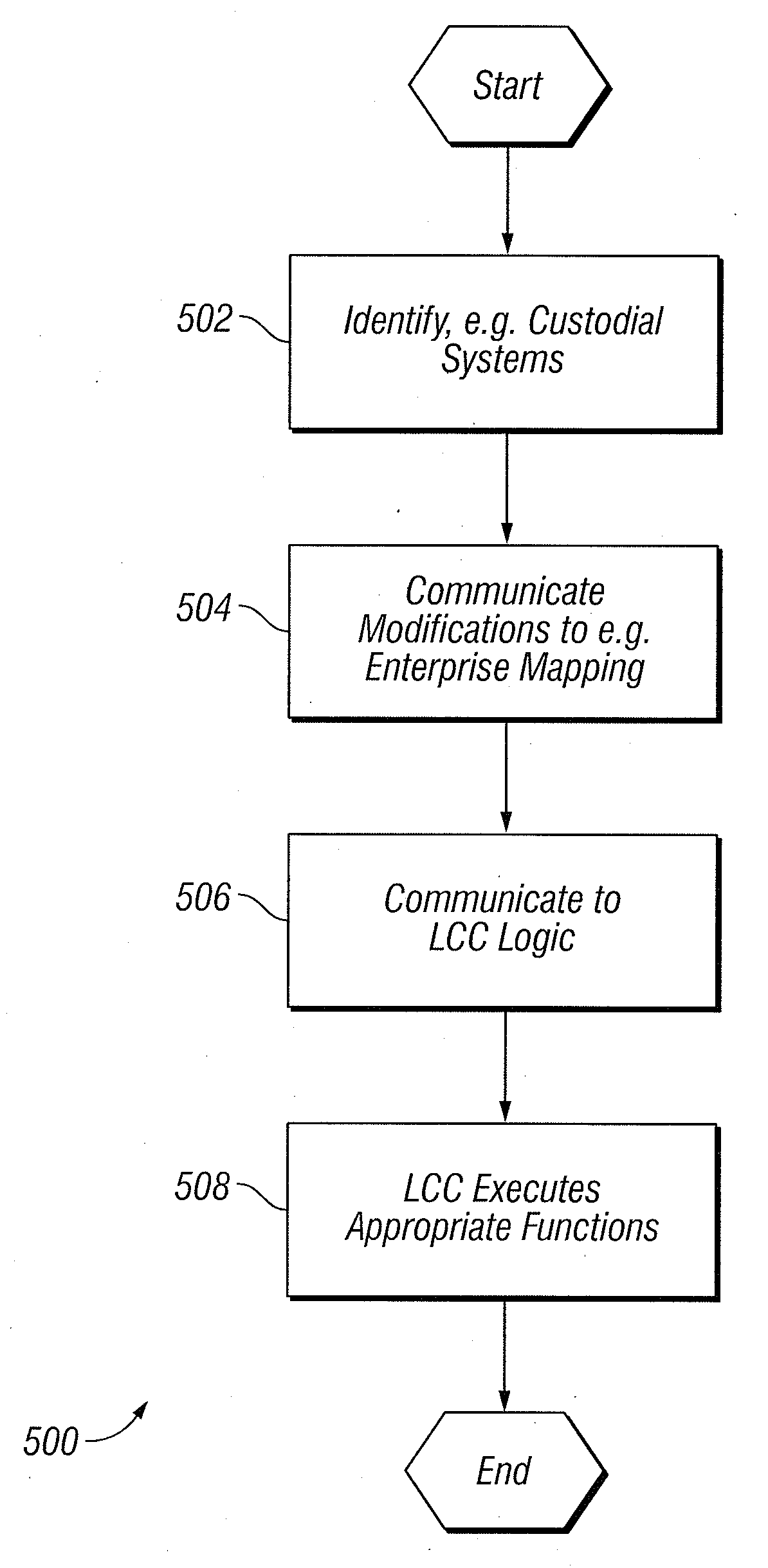

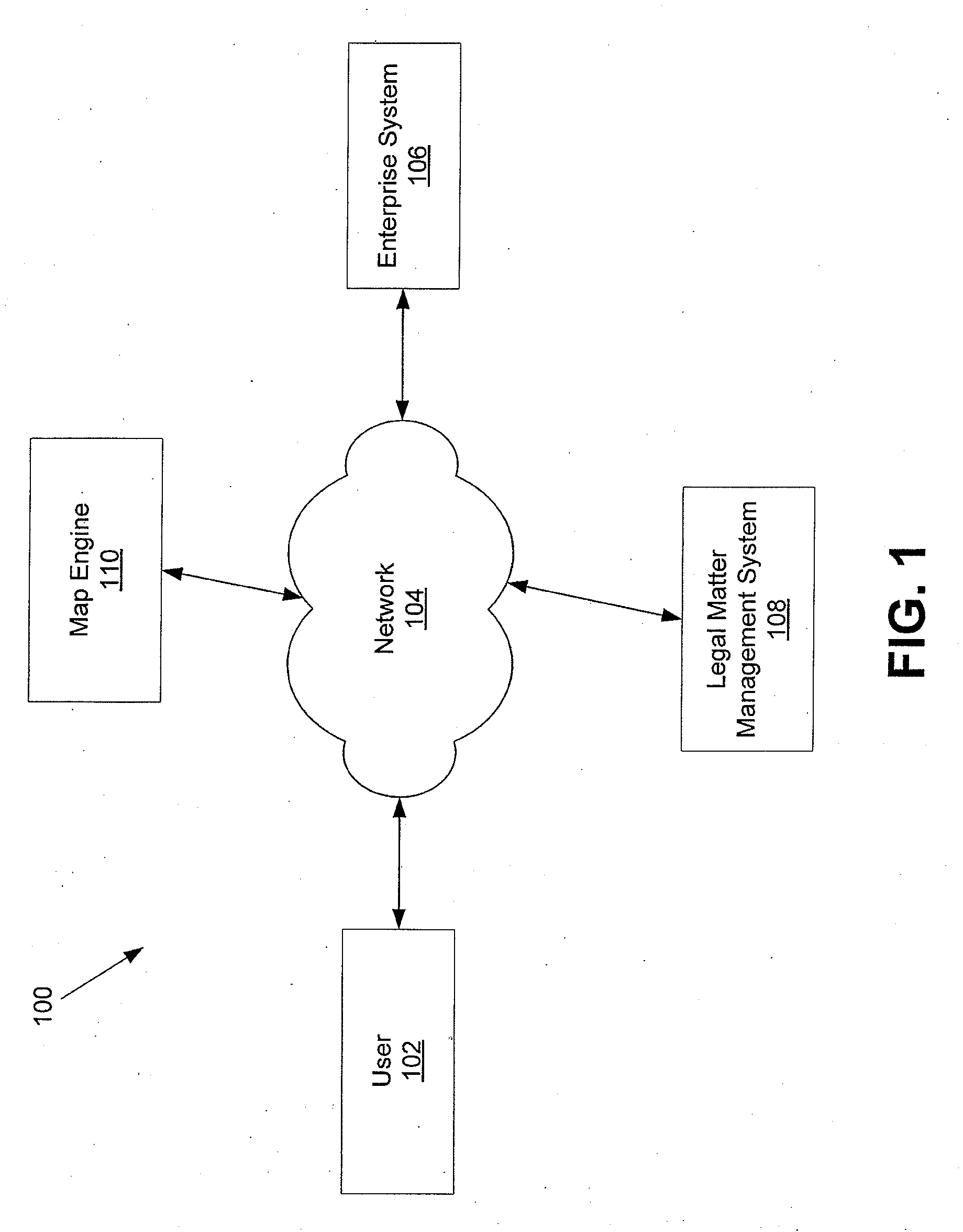

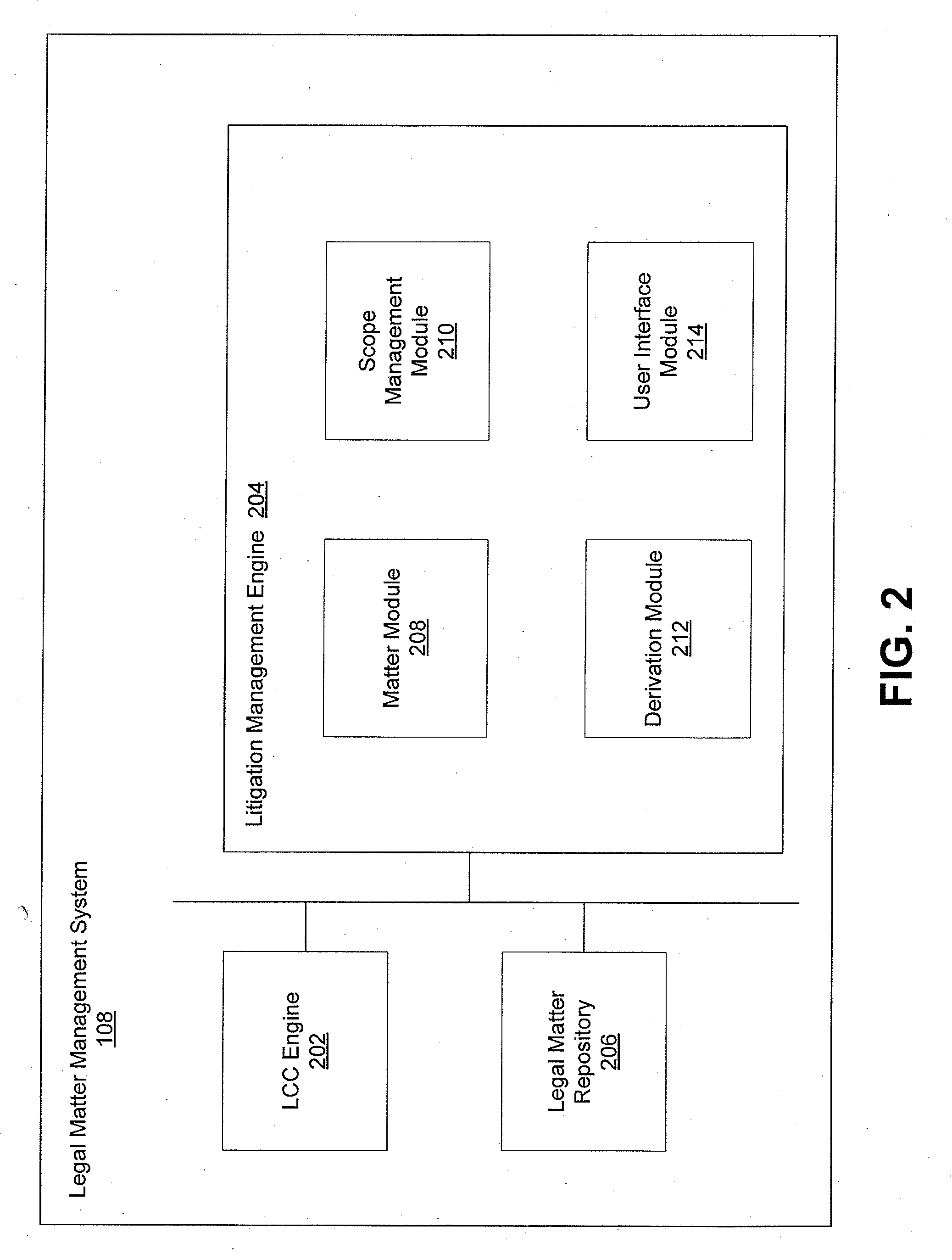

Proactively determining potential evidence issues for custodial systems in active litigation

InactiveUS20080294492A1Office automationSpecial data processing applicationsPlanned changeData science

The record of custodial systems' involvement in legal matters is coupled with a workflow that detects actual or planned changes affecting custodial systems themselves and / or their associations with other entities in the enterprise map, and that notifies the appropriate parties so the information is preserved.

Owner:IBM CORP

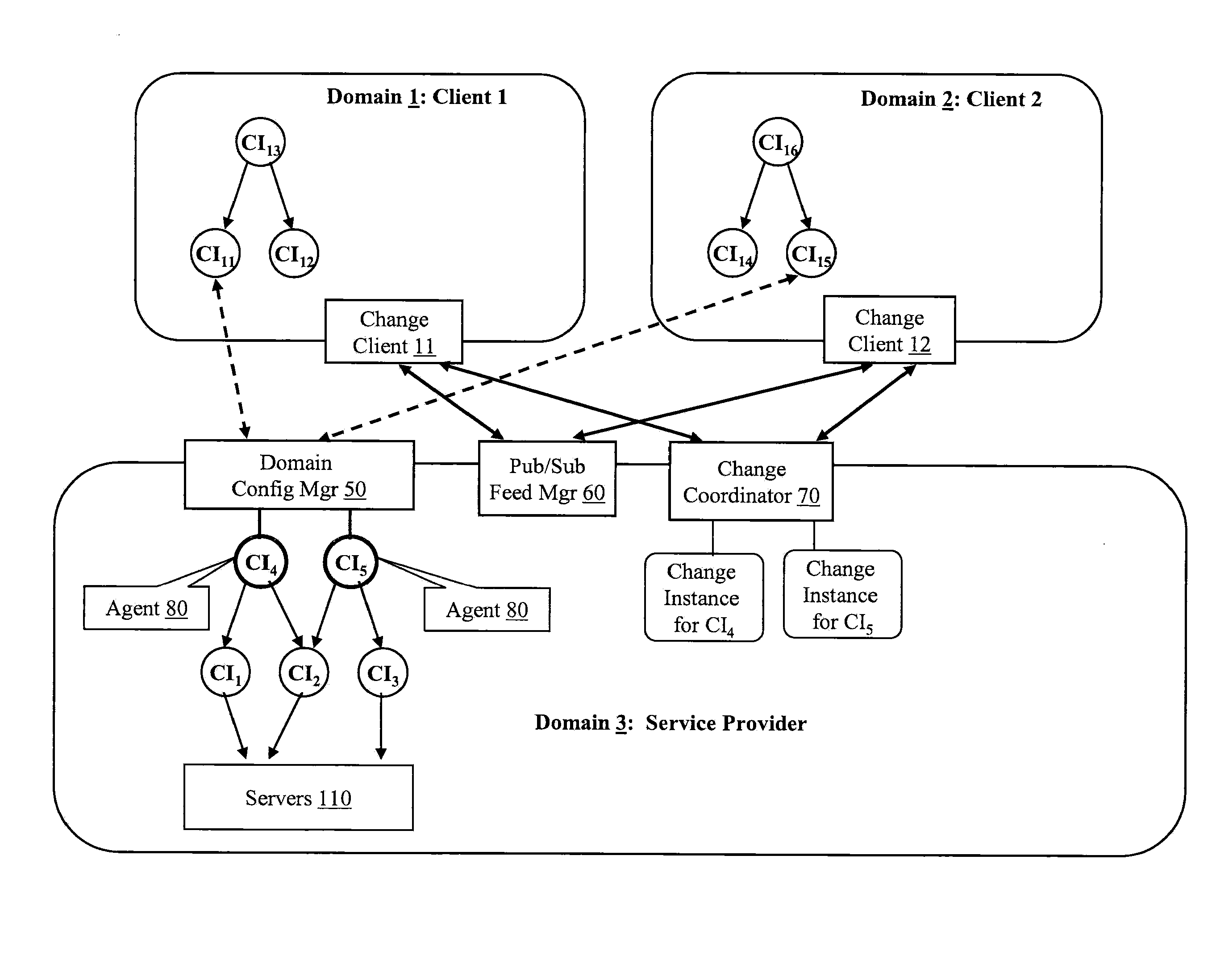

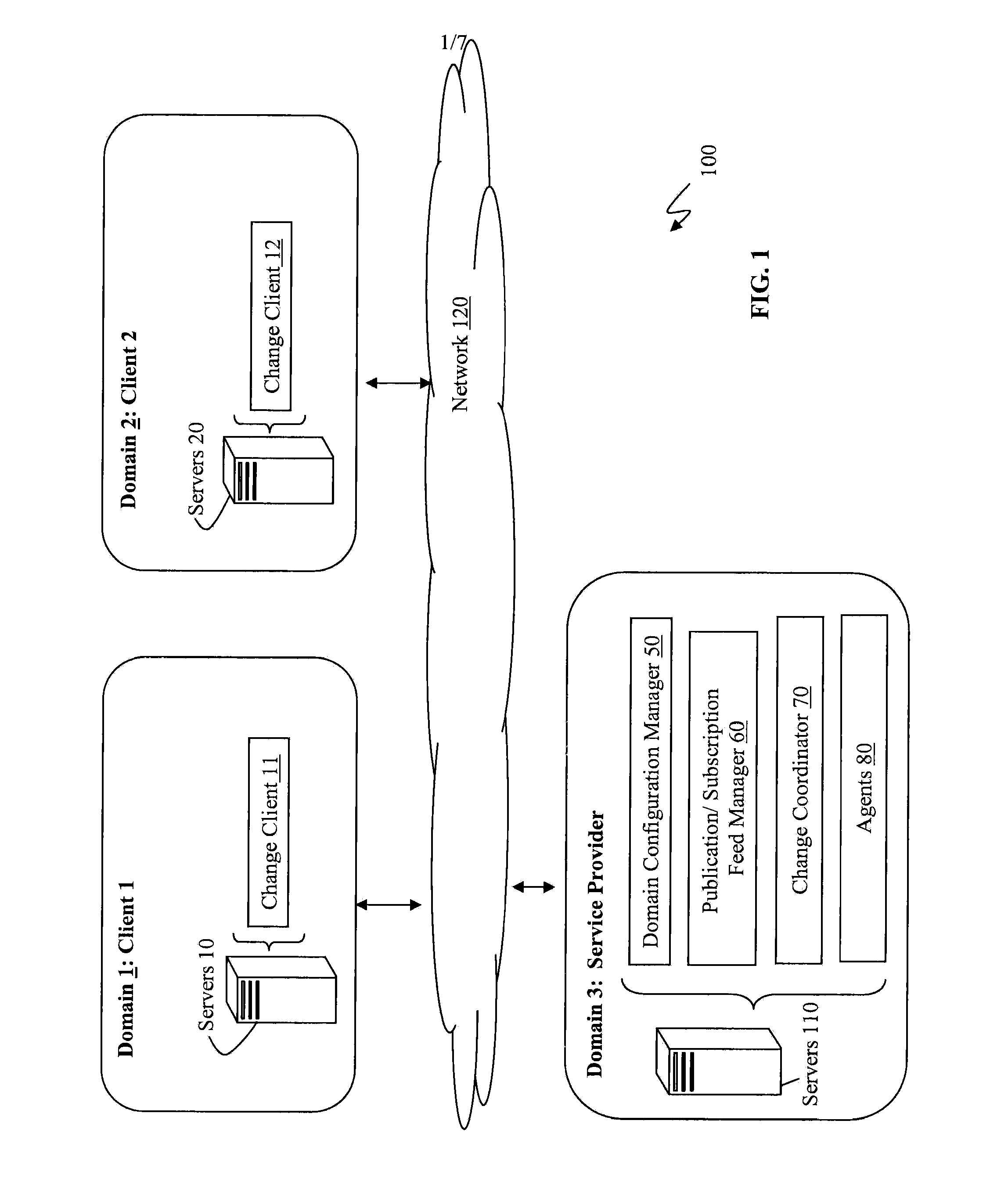

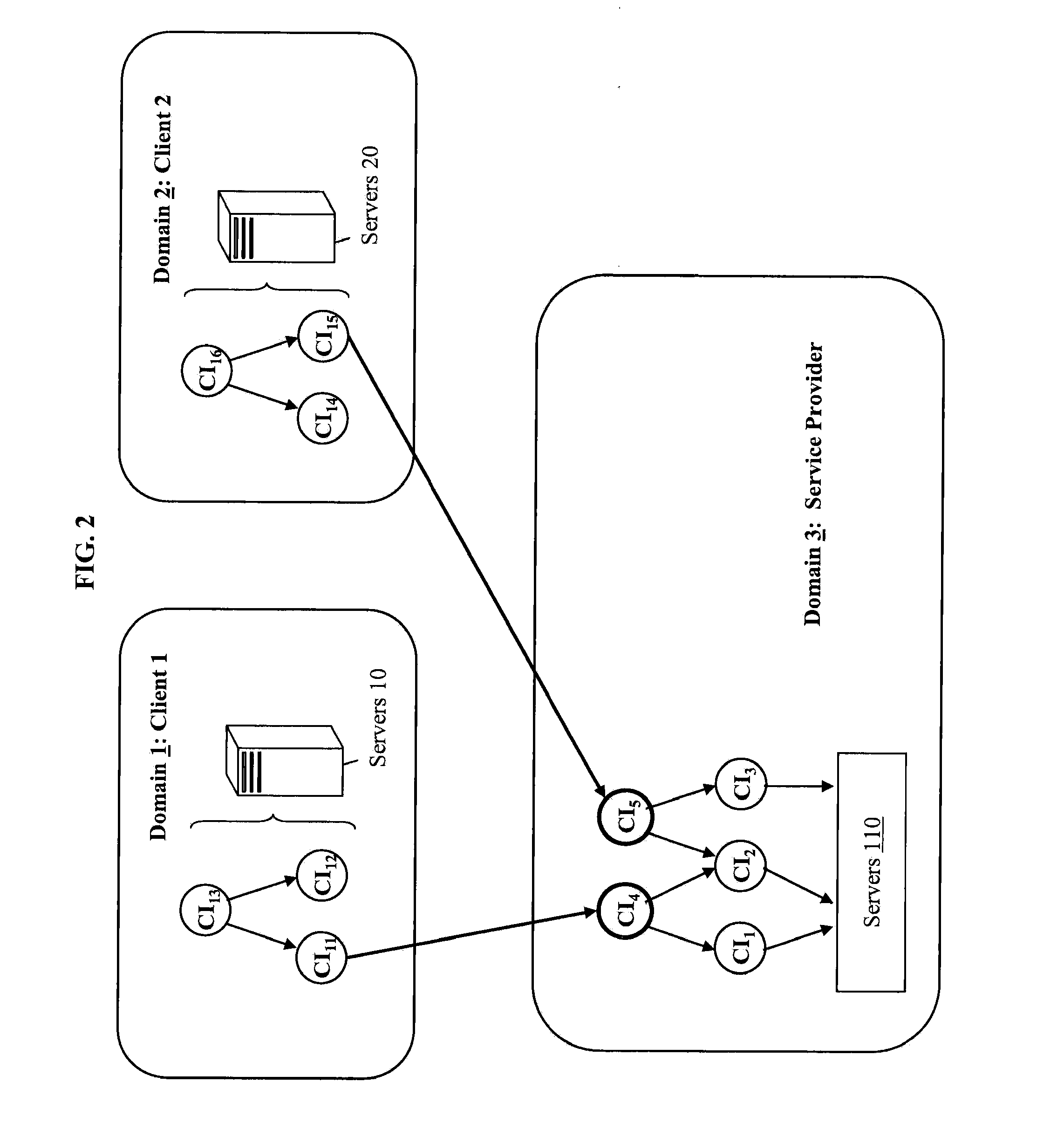

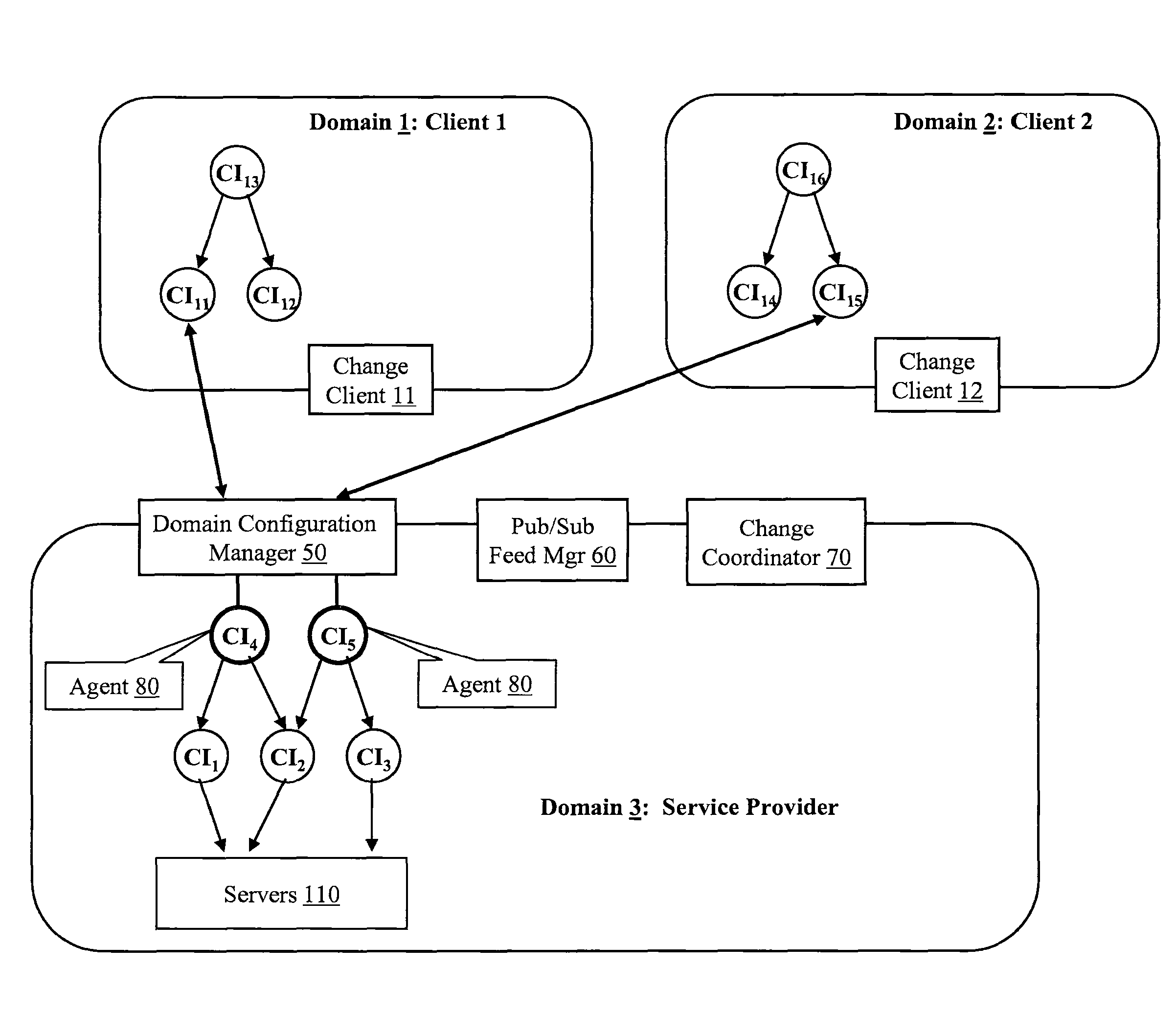

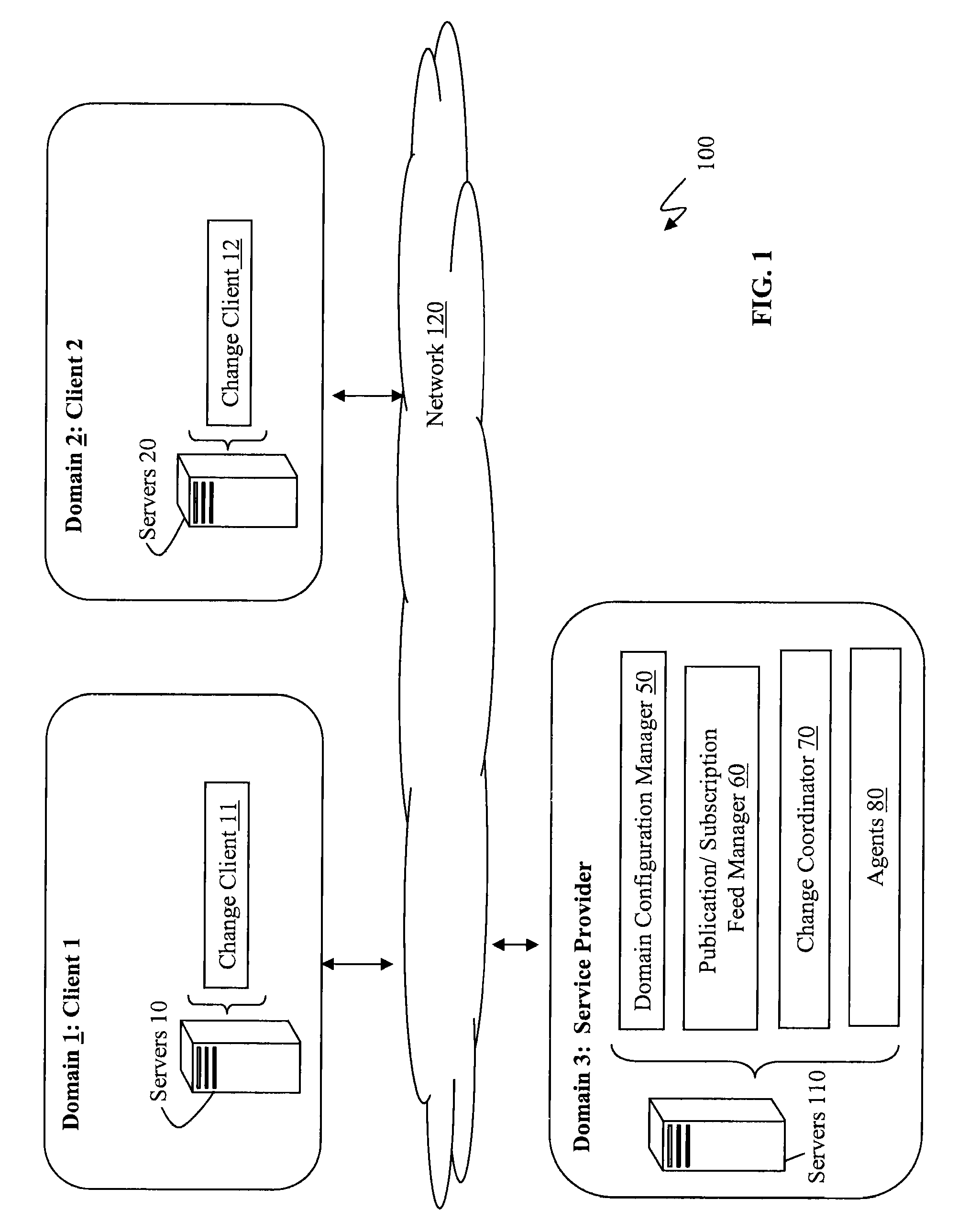

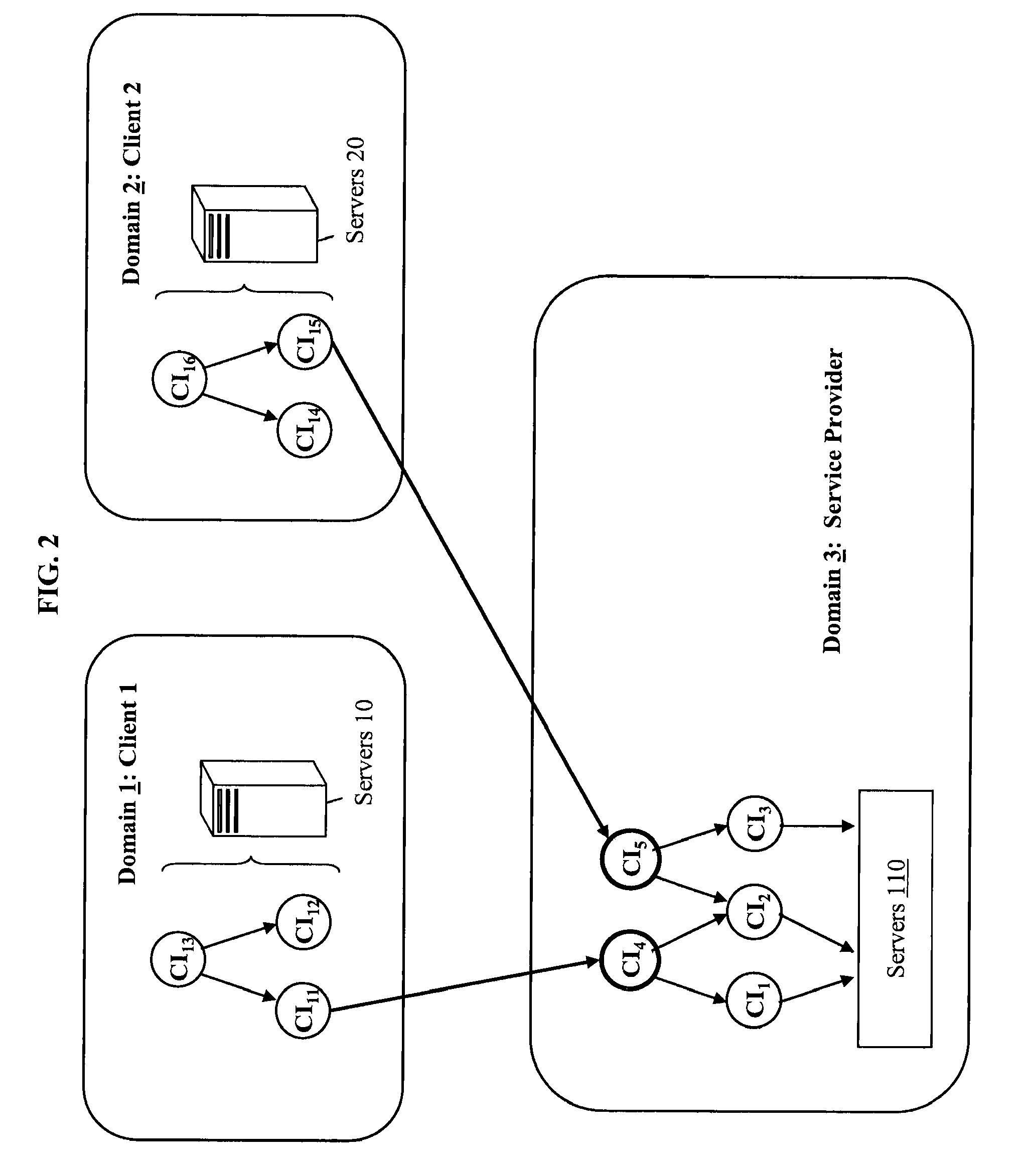

Change Management in Multi-Domain Environments

Method, server, and computer product are provided to implement change management across domains. Memory is included for storing a program. A processor is functionally coupled to the memory and is responsive to computer-executable instructions contained in the program. The processor is operative to announce planned changes for a configuration item to interested outside domains, and the configuration item is in an inside domain. Open subscription is provided to the interested outside domains such that the interested outside domains can subscribe to the subscription as participants. A change instance is created or the configuration item in the inside domain. Change progress of the change instance is reported for the configuration item to the participants of the interested outside domains. State progress notifications are distributed to the participants of the change. The change instance is executed to make planned changes to the configuration item.

Owner:IBM CORP

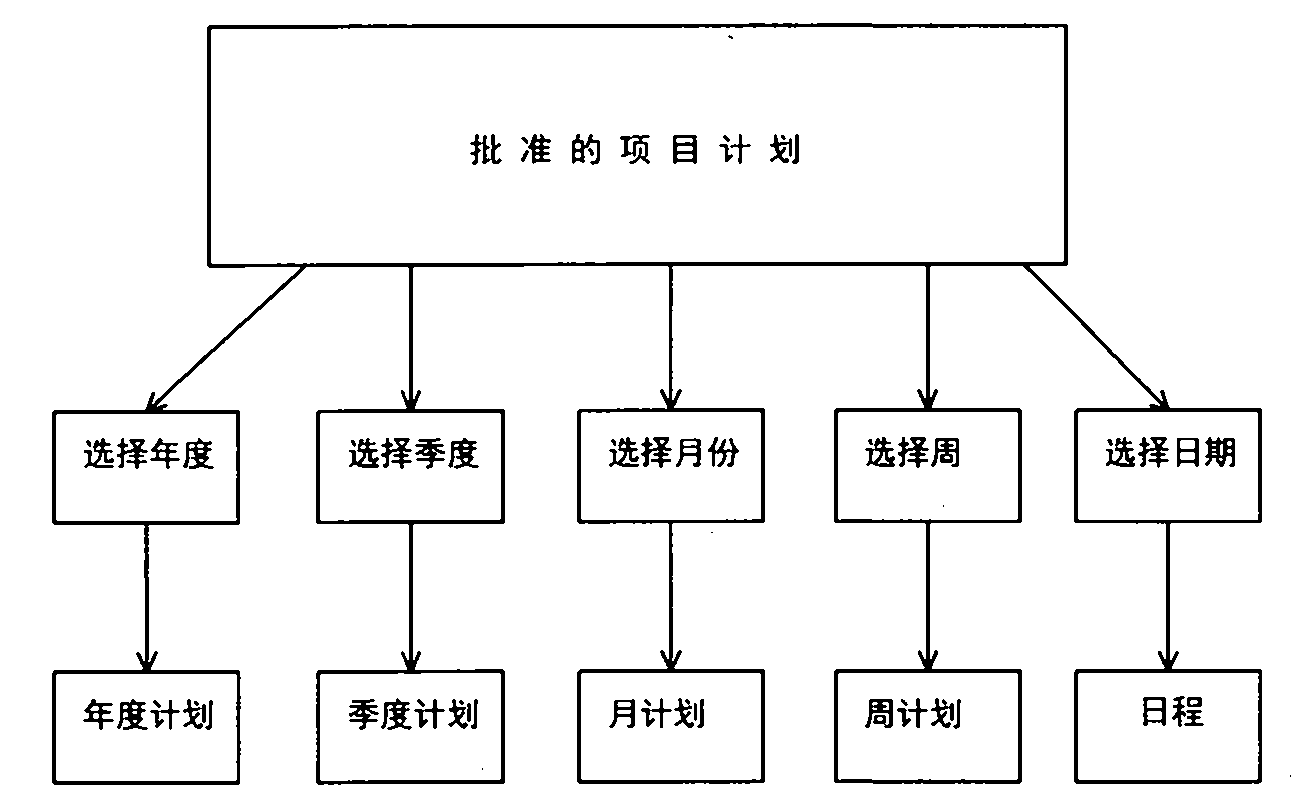

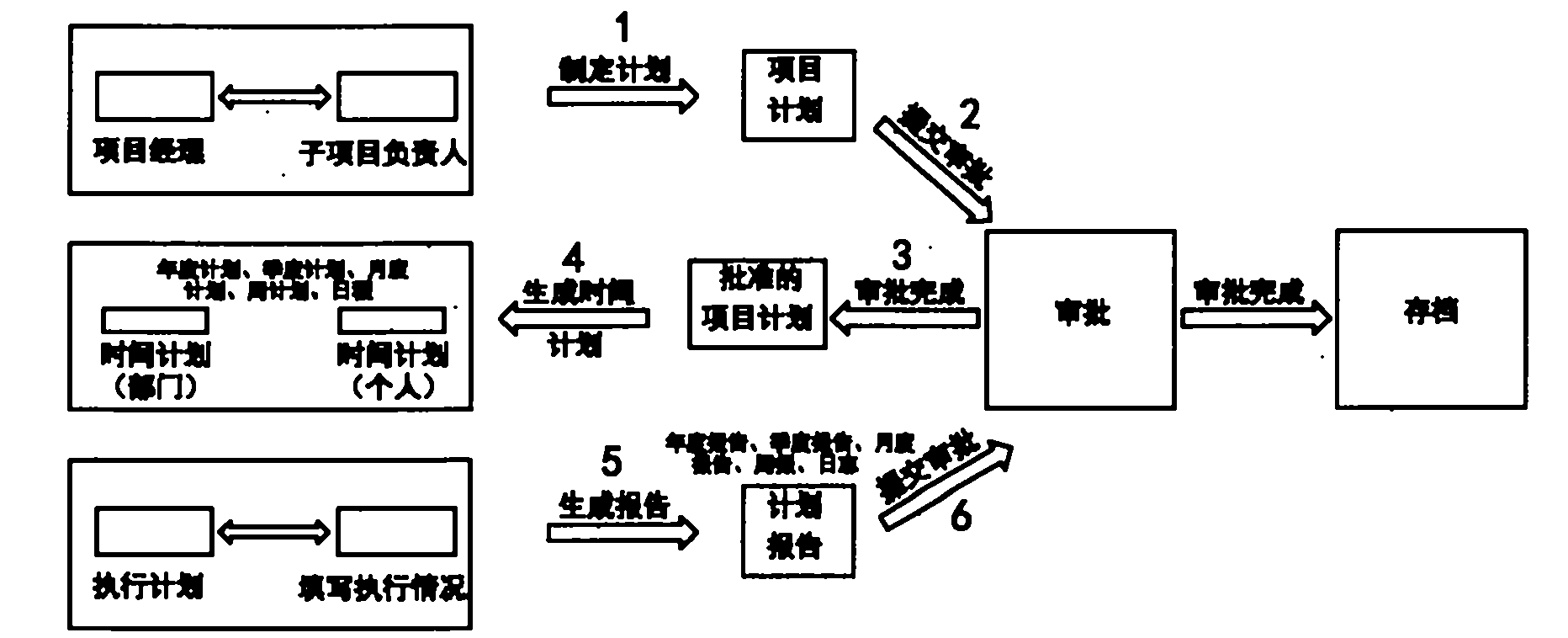

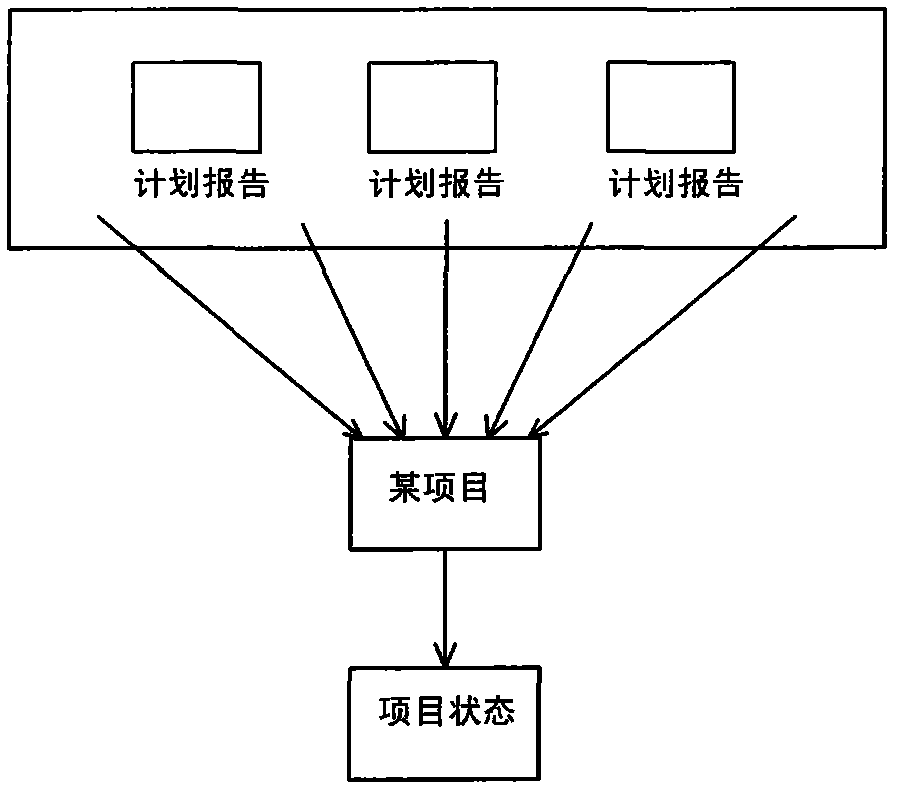

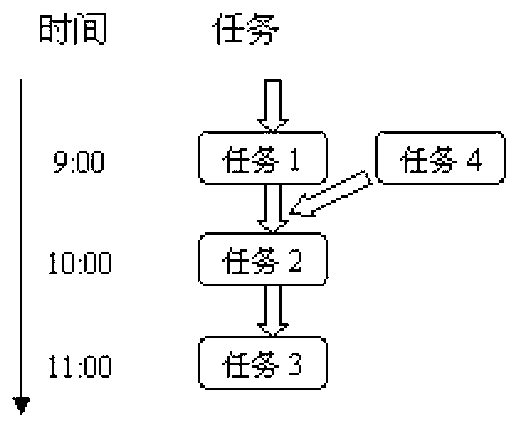

Cooperative office-based project type working plan management system

The invention discloses a cooperative office-based project type working plan management system, which belongs to the technical field of computer application. The system comprises a project view and a time plan view, wherein a user works in the project view and the time plan view; the project plan can be automatically converted into a time plan for guiding daily work; the change, approval, authority and the like of the plan are managed; after tracking is performed at the end of the time plan, tracking data is automatically reflected in the project plan; simultaneously, various plan summary reports, plan change reports and the like can be generated for management decision. Compared with the prior art, the system realizes automatic generation of the time plan according to data of the project plan; simultaneously, tracking data of the time plan is automatically synchronized into the project plan, the progress of a project is reflected and the user can exchange the plans or run the plans according to a flow in various processes, so that the project plan and the time plan are managed uniformly.

Owner:INSPUR COMMON SOFTWARE

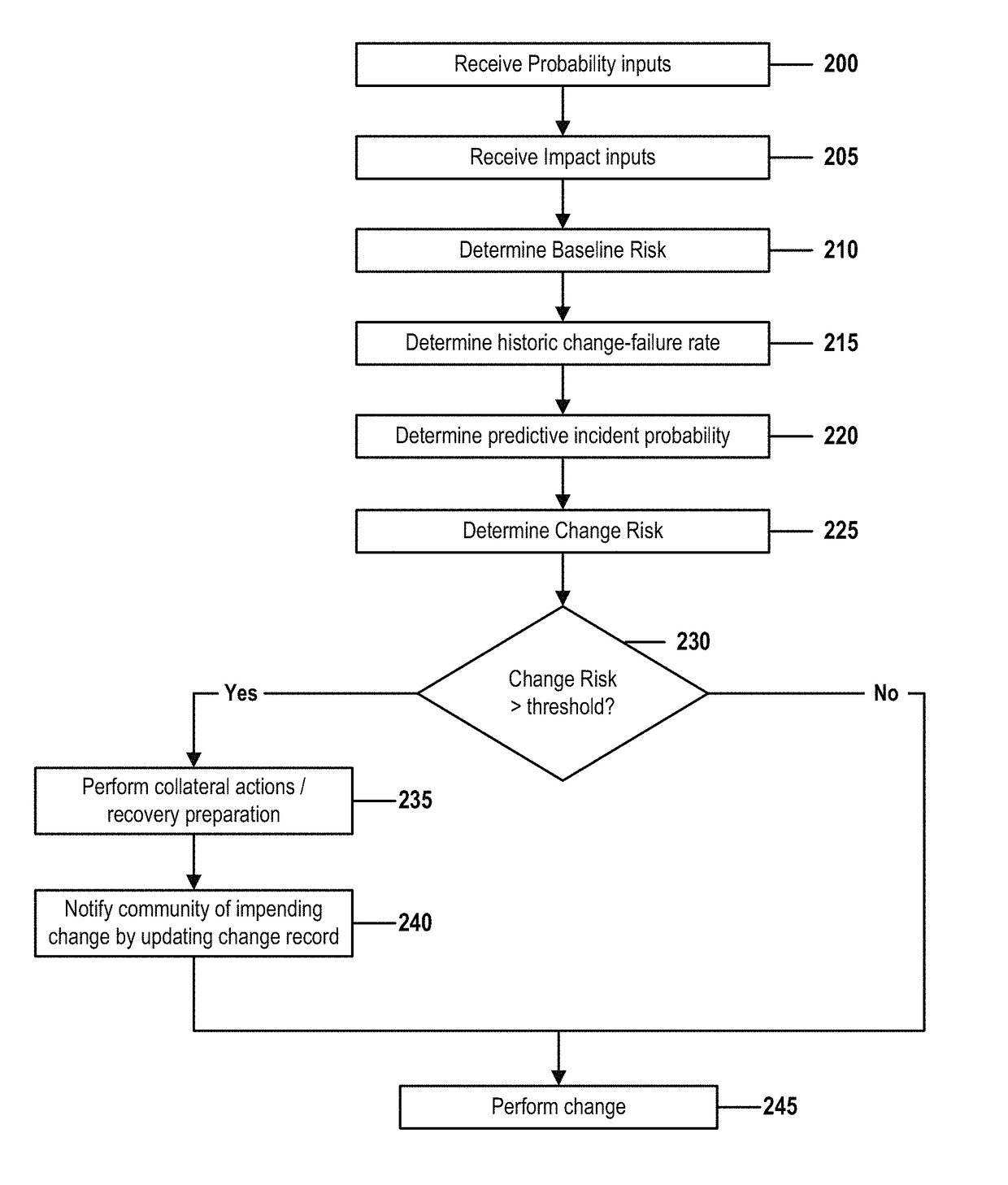

Estimating server-change risk by corroborating historic failure rates, predictive analytics, and user projections

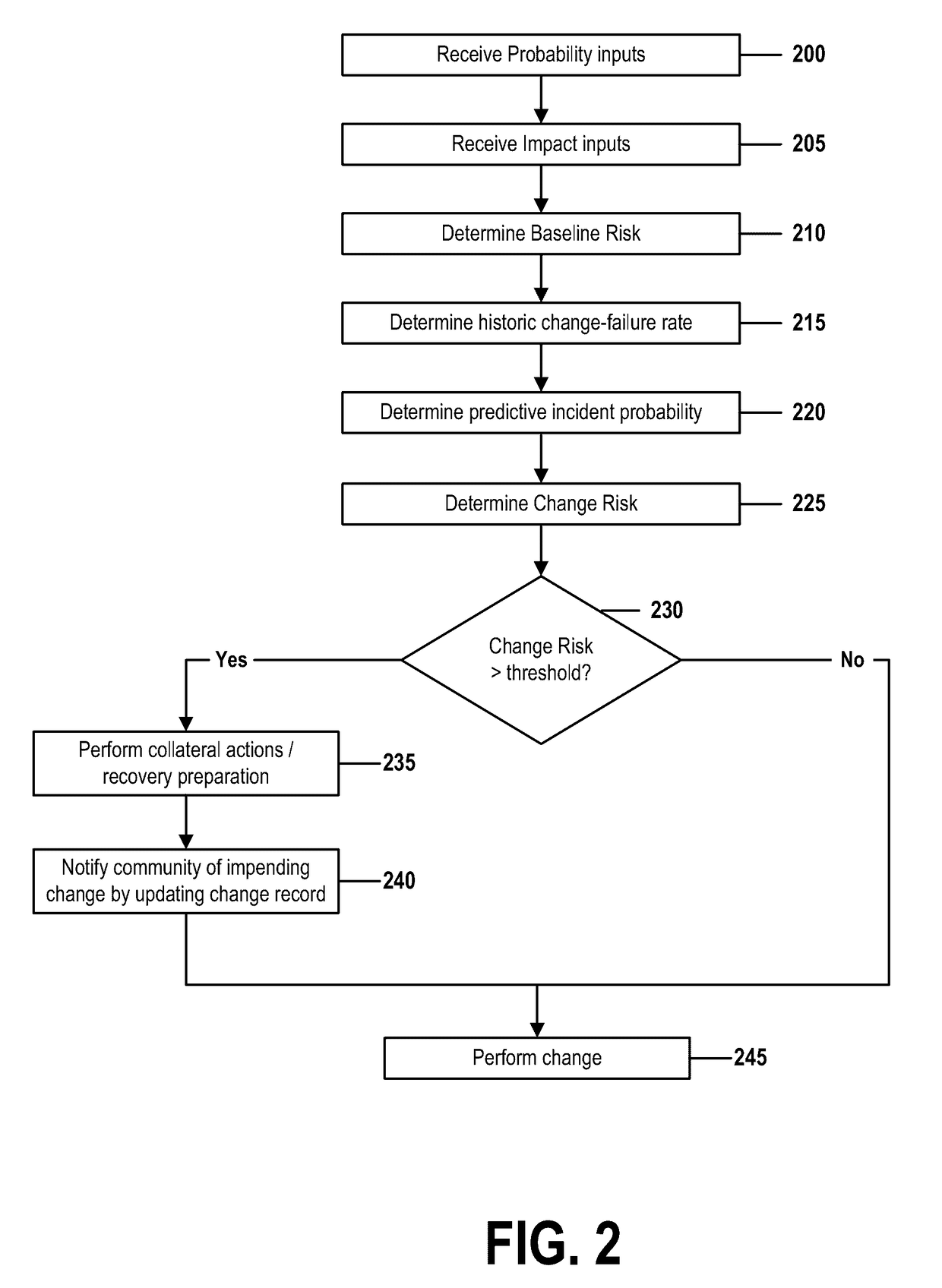

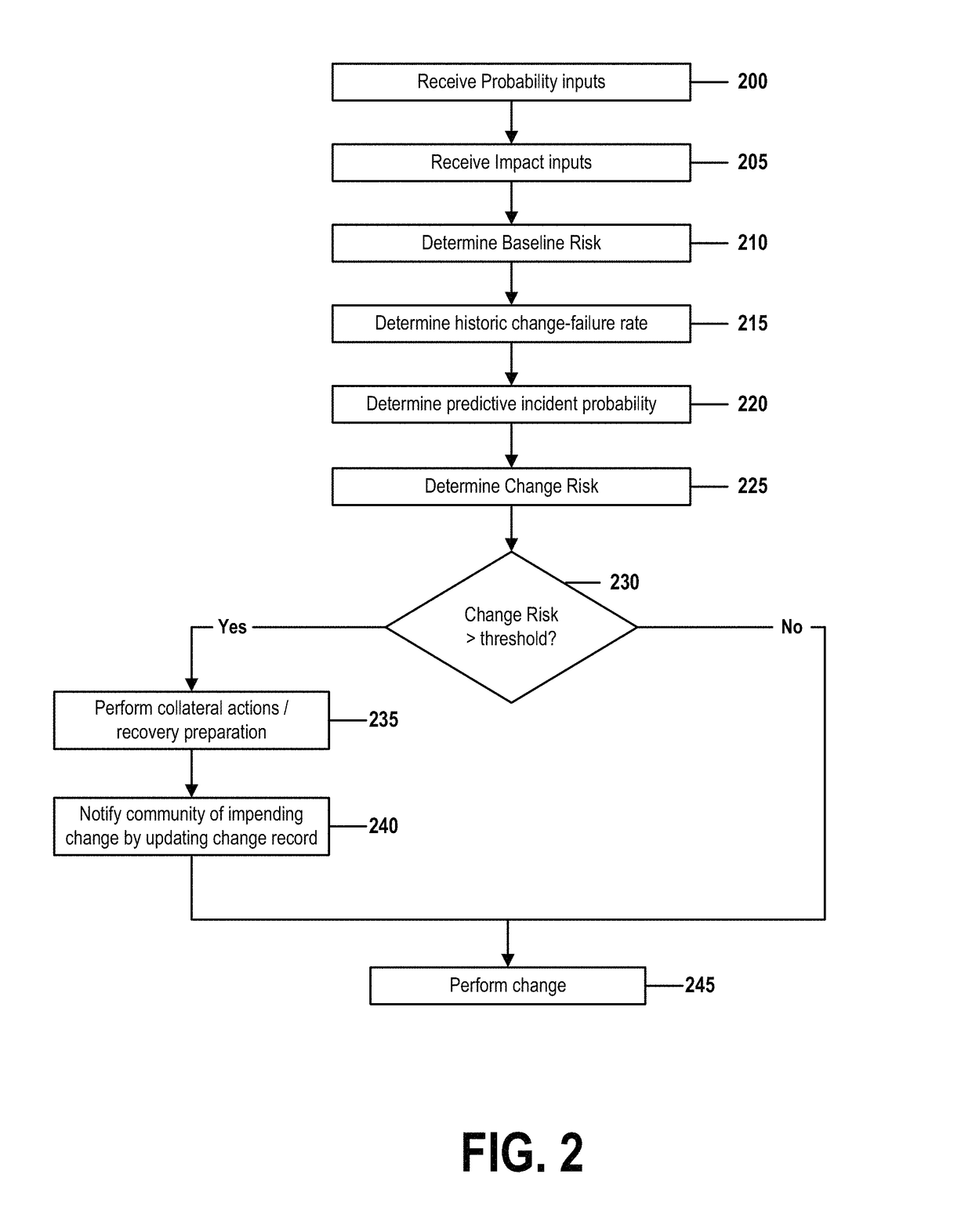

A method and associated systems for predicting a degree of risk associated with a planned change to a computer server or other electronic component. A computerized change-management system receives Probability and Impact inputs derived from user-derived input, from which it determines a Baseline risk of change failure. The system processes mined data to determine an historic change-failure rate as a function of a type of change, and computes a predictive incident probability based on a predictive analytics engine's forecast of whether a particular type of server will be problematic. The system then computes a final Change Risk by adjusting the Baseline risk as a function of the historic change-failure rate, the predictive incident-probability, and a Baseline-specific weighting factor. If the resulting Change Risk is judged to be elevated, the system initiates collateral actions and notifications intended to reduce the probability and impact of a change failure.

Owner:KYNDRYL INC

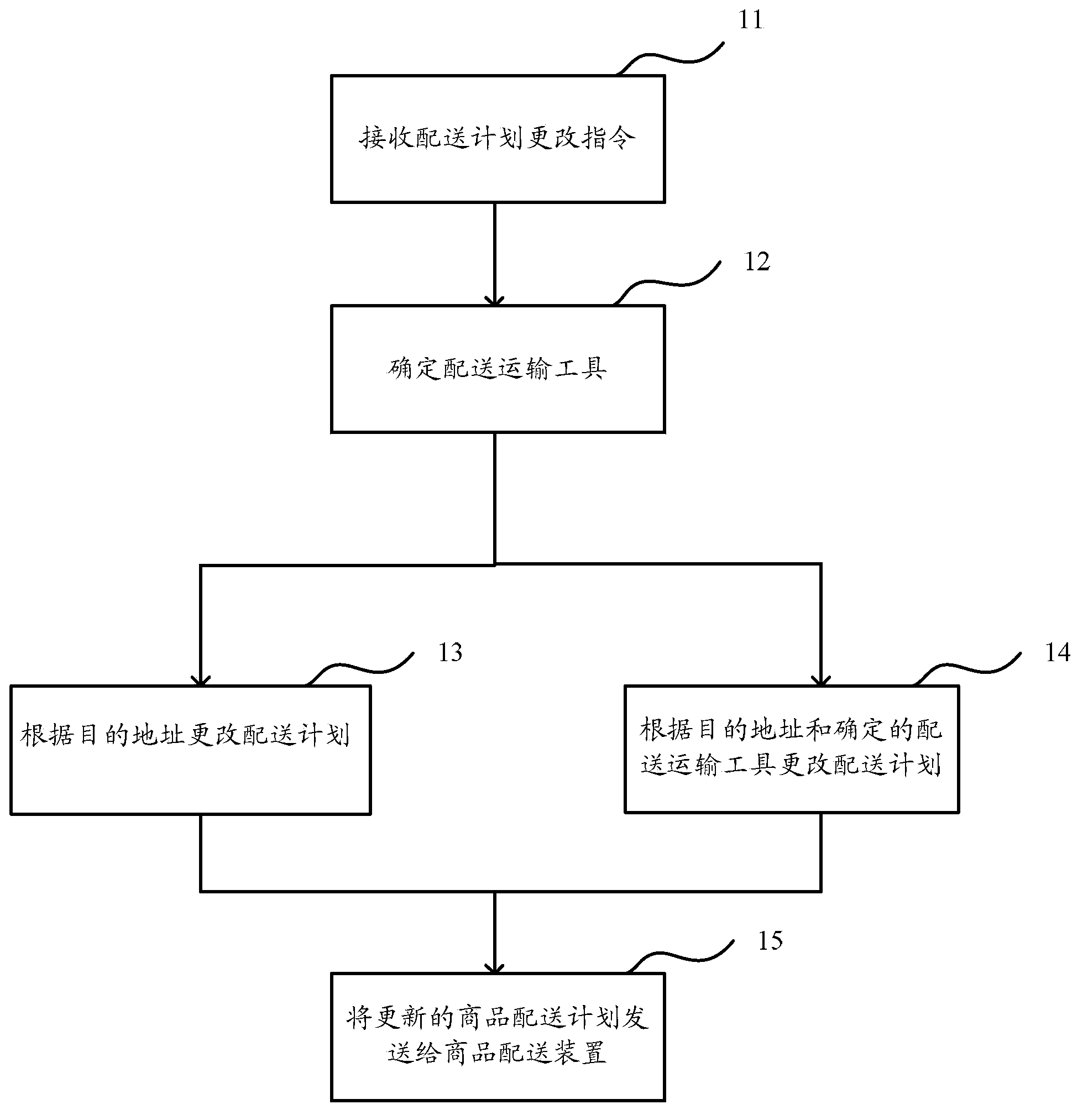

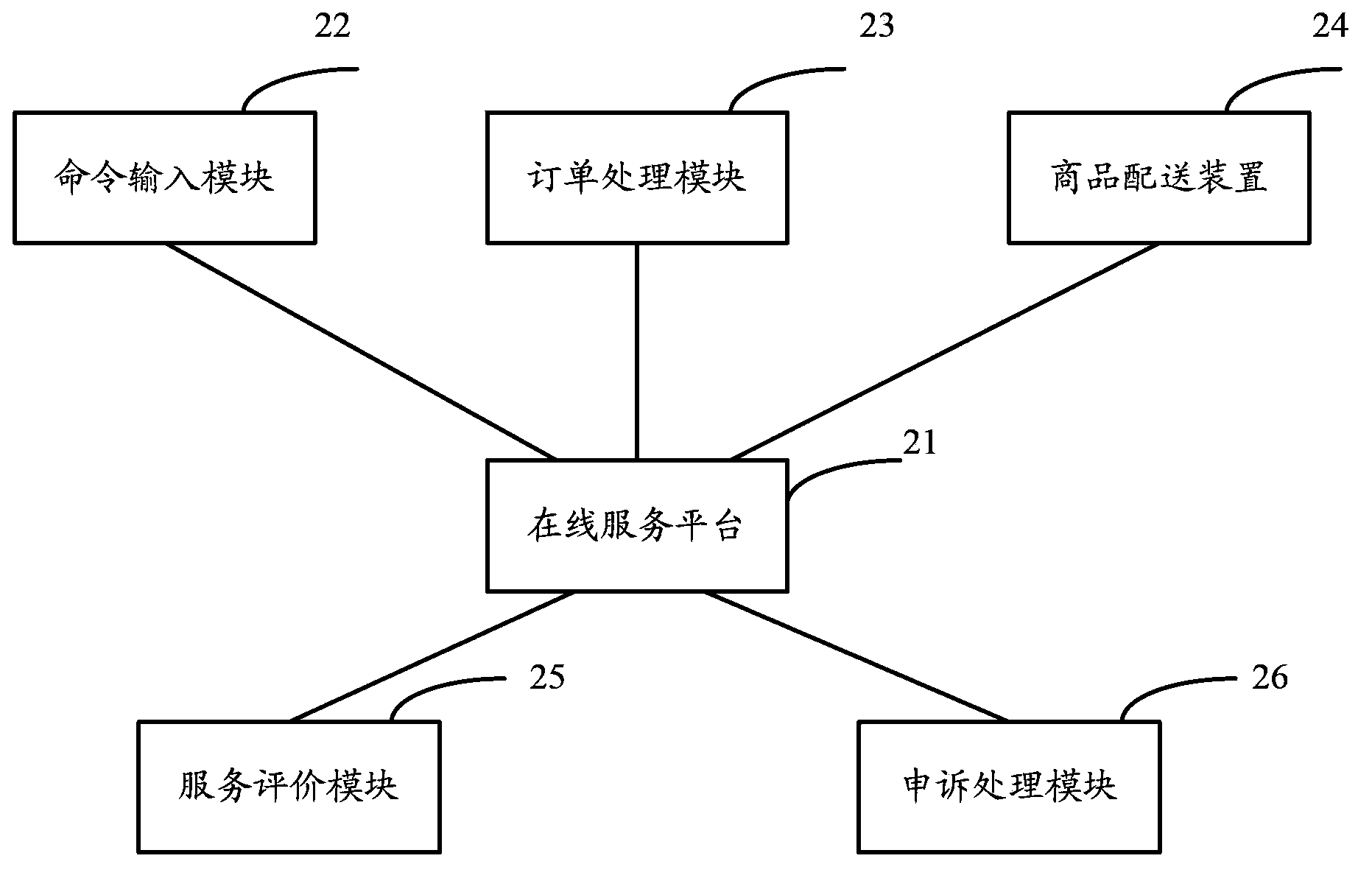

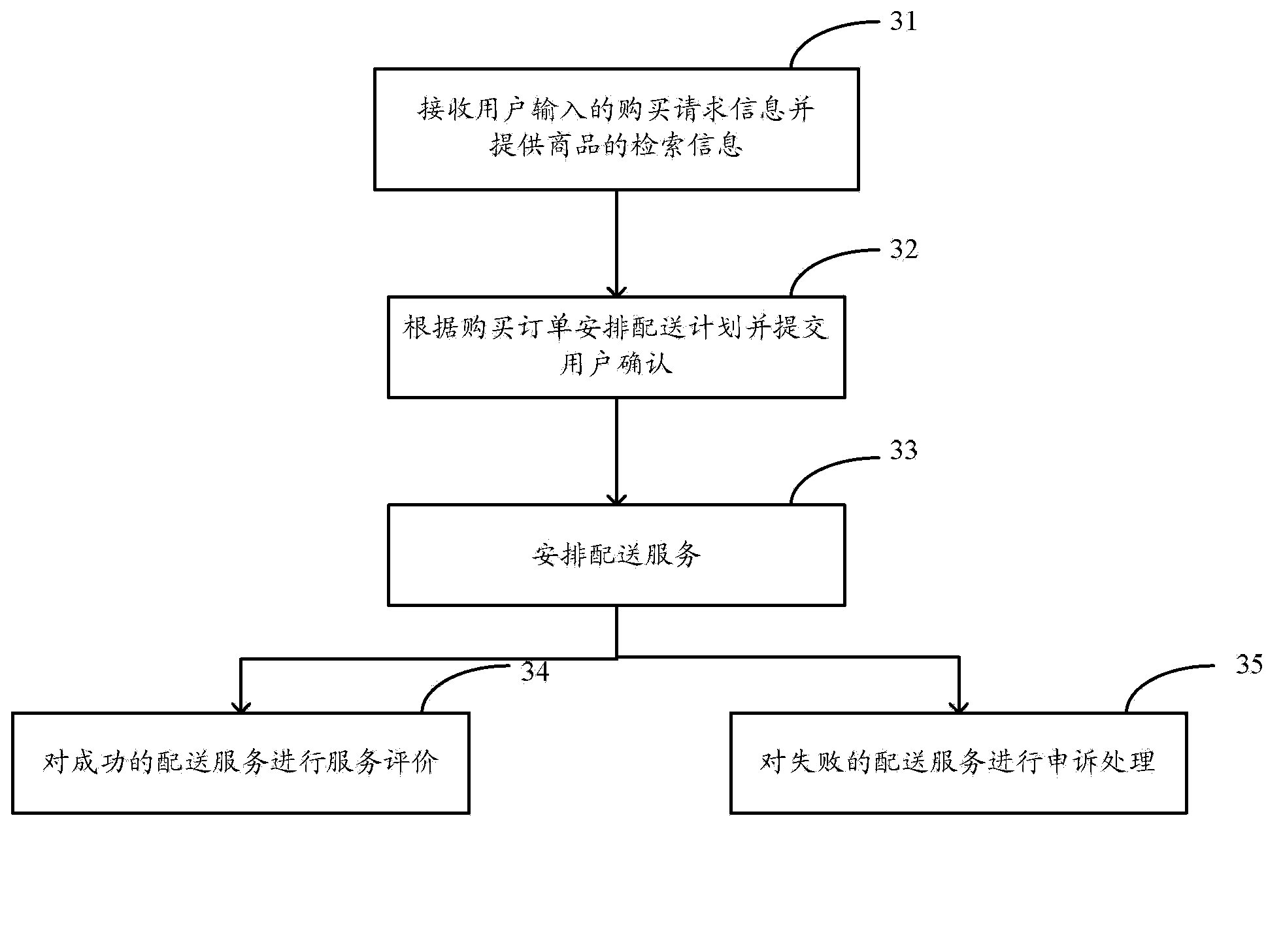

Real-time dispatching and delivery method and device

InactiveCN103679316ASave distribution resourcesReduce failure rateResourcesFailure ratePlanned change

Disclosed are a real-time dispatching and delivery method and device. When the real-time dispatching device receives a delivery plan change instruction which includes a commodity identification and a delivery destination address, a transportation facility which delivers a commodity represented by the commodity identification to the delivery destination address is determined according to a driving path of the transportation facility which delivers the commodity and the delivery destination address and a delivery plan of the commodity is updated according to the delivery destination address and the determined transportation facility. It thus can be seen that the real-time dispatching device is capable of changing the delivery plan in a real-time manner according to user demands so that a condition that after commodity delivery according to an original plan fails, the commodity needs to be delivered again according to the changed delivery plan is prevented and thus failure rate of the delivery is reduced on the basis that delivery resources are saved.

Owner:CHINA MOBILE COMM GRP CO LTD

Change management in multi-domain environments

InactiveUS7975031B2Error preventionFrequency-division multiplex detailsConfiguration itemPlanned change

Method, server, and computer product are provided to implement change management across domains. Memory is included for storing a program. A processor is functionally coupled to the memory and is responsive to computer-executable instructions contained in the program. The processor is operative to announce planned changes for a configuration item to interested outside domains, and the configuration item is in an inside domain. Open subscription is provided to the interested outside domains such that the interested outside domains can subscribe to the subscription as participants. A change instance is created or the configuration item in the inside domain. Change progress of the change instance is reported for the configuration item to the participants of the interested outside domains. State progress notifications are distributed to the participants of the change. The change instance is executed to make planned changes to the configuration item.

Owner:INT BUSINESS MASCH CORP

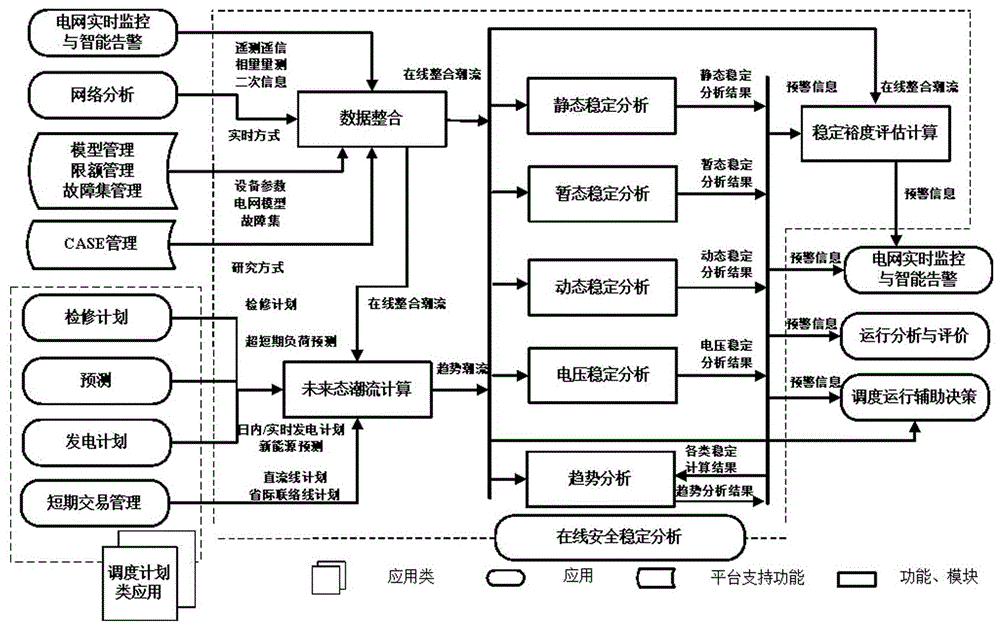

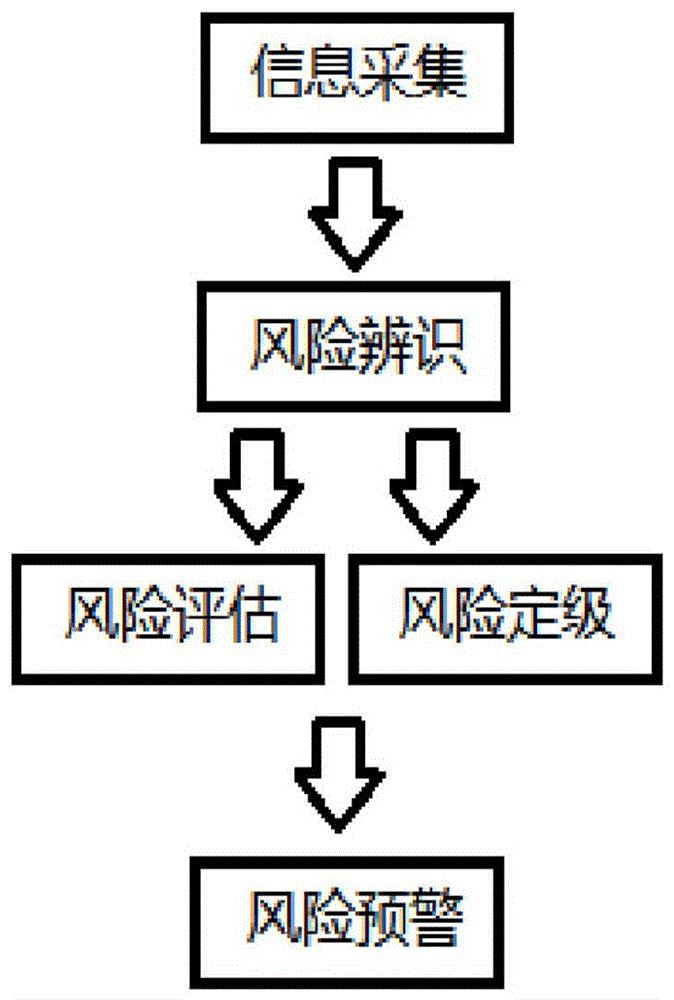

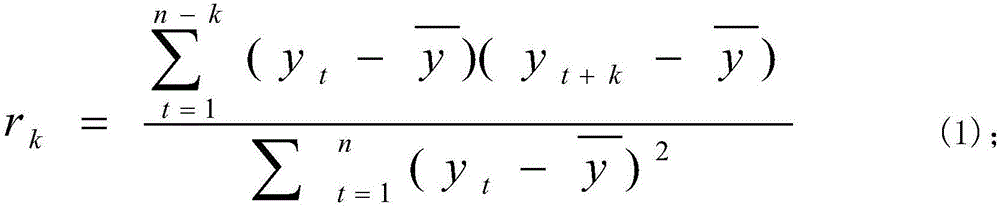

Power dispatching online trend early warning system based on ultra short term load prediction

The invention relates to the technical field of applying an online safety analysis result to load prediction, and particularly relates to a power dispatching online trend early warning system based on ultra short term load prediction. Particularly, through statistics, analysis and prediction on load data, a power grid future trend is calculated, and a power grid short term trend early warning and accident post-treatment plan is formed. The system of the invention comprises the following operation steps of short term load prediction based on electricity consumption large data analysis, trend tendency analysis through ultra short term load obtained based on an ARIMA algorithm, power grid risk assessment and warning, equipment maintenance schedule management, data access panoramic surveillance, treatment in the accident and power supply restoration after the accident. Linkage between the online trend early warning and dispatching plan change information can be realized, and a trend analysis early warning and assistant decision-making system with integration of a province and regions can be formed.

Owner:STATE GRID LIAONING ELECTRIC POWER RES INST +1

Estimating server-change risk by corroborating historic failure rates, predictive analytics, and user projections

A method and associated systems for predicting a degree of risk associated with a planned change to a computer server or other electronic component. A computerized change-management system receives Probability and Impact inputs derived from user-derived input, from which it determines a Baseline risk of change failure. The system processes mined data to determine an historic change-failure rate as a function of a type of change, and computes a predictive incident probability based on a predictive analytics engine's forecast of whether a particular type of server will be problematic. The system then computes a final Change Risk by adjusting the Baseline risk as a function of the historic change-failure rate, the predictive incident-probability, and a Baseline-specific weighting factor. If the resulting Change Risk is judged to be elevated, the system initiates collateral actions and notifications intended to reduce the probability and impact of a change failure.

Owner:KYNDRYL INC

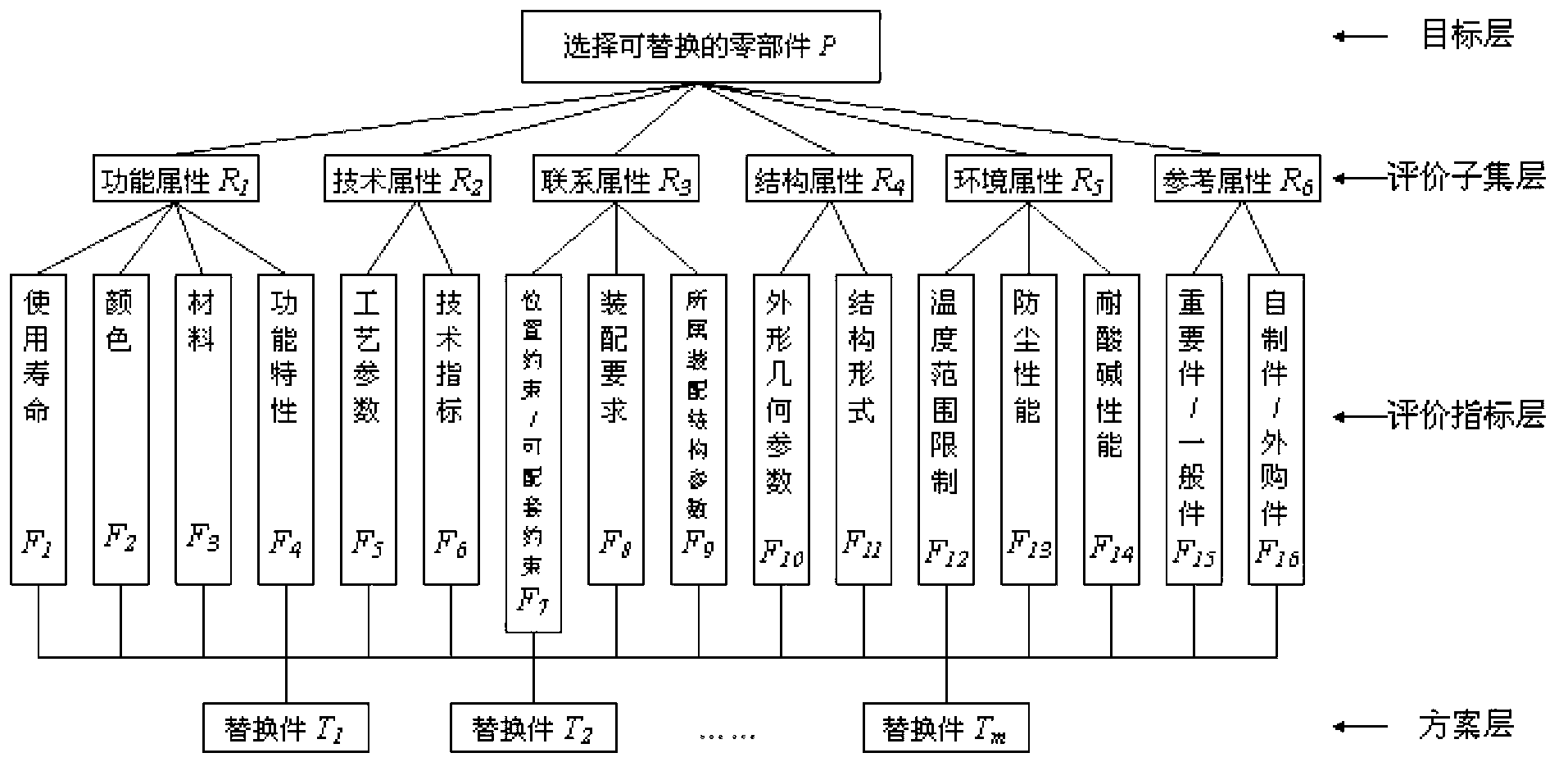

Production plan change-oriented multi-objective constraint material substitution method

The invention discloses a production plan change-oriented multi-objective constraint material substitution method, which comprises the following steps: 1, establishing a material substitution model; 2, establishing a material substitution algorithmic rule; and 3, performing an analysis and decision process of substitute material selection. According to the production plan change-oriented multi-objective constraint material substitution method disclosed by the invention, by aiming at material requirement coordination among a product bill of materials (BOM), a process BOM and a plan BOM, which is involved by the material substitution problem emerging in complex equipment due to a task change during an assembly production process, a multi-constraint and multi-objective-oriented material substitution model is established, and meanwhile, according to different attribute characteristics (a design characteristic, a process characteristic and a plan characteristic) of materials to be used as constrained parameters of material substitution, a substitute algorithm of the selection of different material substitutes so as to realize material section, matching and substitution among products, and therefore, the supply-demand relationship balance between substitute materials and product requirements under the assembly constraint environment of design, the process, the task change and resource capability and the like is guaranteed, on-hand inventory parts or parts expected to arriving in the future are reasonably distributed to meet the kitting requirements, and the goal that the total cost is minimized is achieved.

Owner:DALIAN OCEAN UNIV

Dialog system for warning and information systems

In order to make warning devices more efficient, it is known to design parameters to be variable and therewith to be adaptable depending upon the state or condition of a user of the warning information. Herein, for example, warning start points are changed or multi-stage warnings are engineered depending upon urgency. The disadvantage of such an adaptive system can however reside therein, that the mechanistic detection of the condition of the operator using various sensor systems and the subsequent output to the operator or the operator assistant system is not always acceptable, which can irritate the vehicle operator or occupants. In order to increase the acceptance by the user of the warning information it is proposed that in the lead-up to a planned change in the mode and manner of the output of the warning information, communication is initiated with at least one of the users. In the framework of this communication a user can indicate his acceptance or declining with respect to the planned change.

Owner:BAYERISCHE MOTOREN WERKE AG

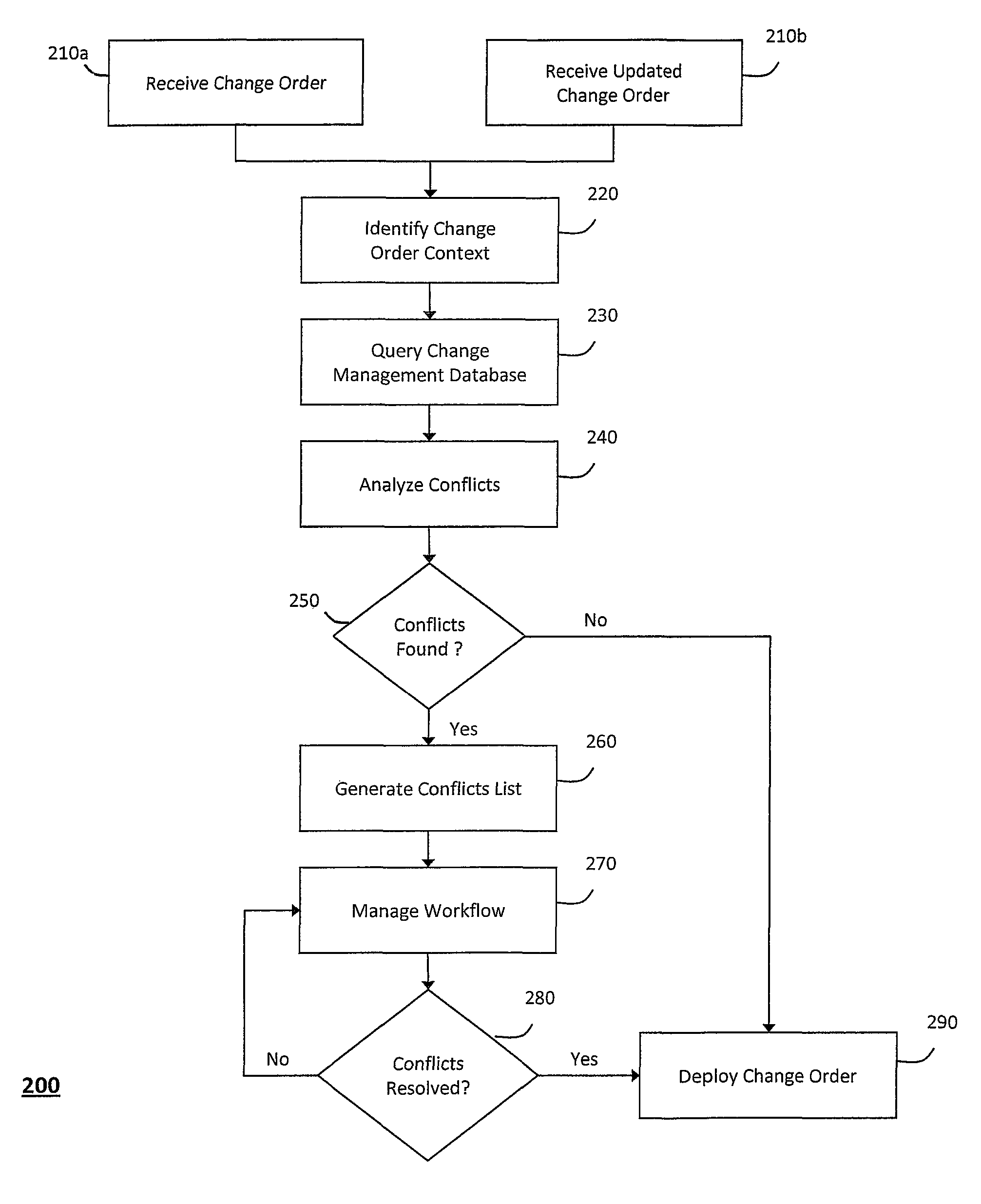

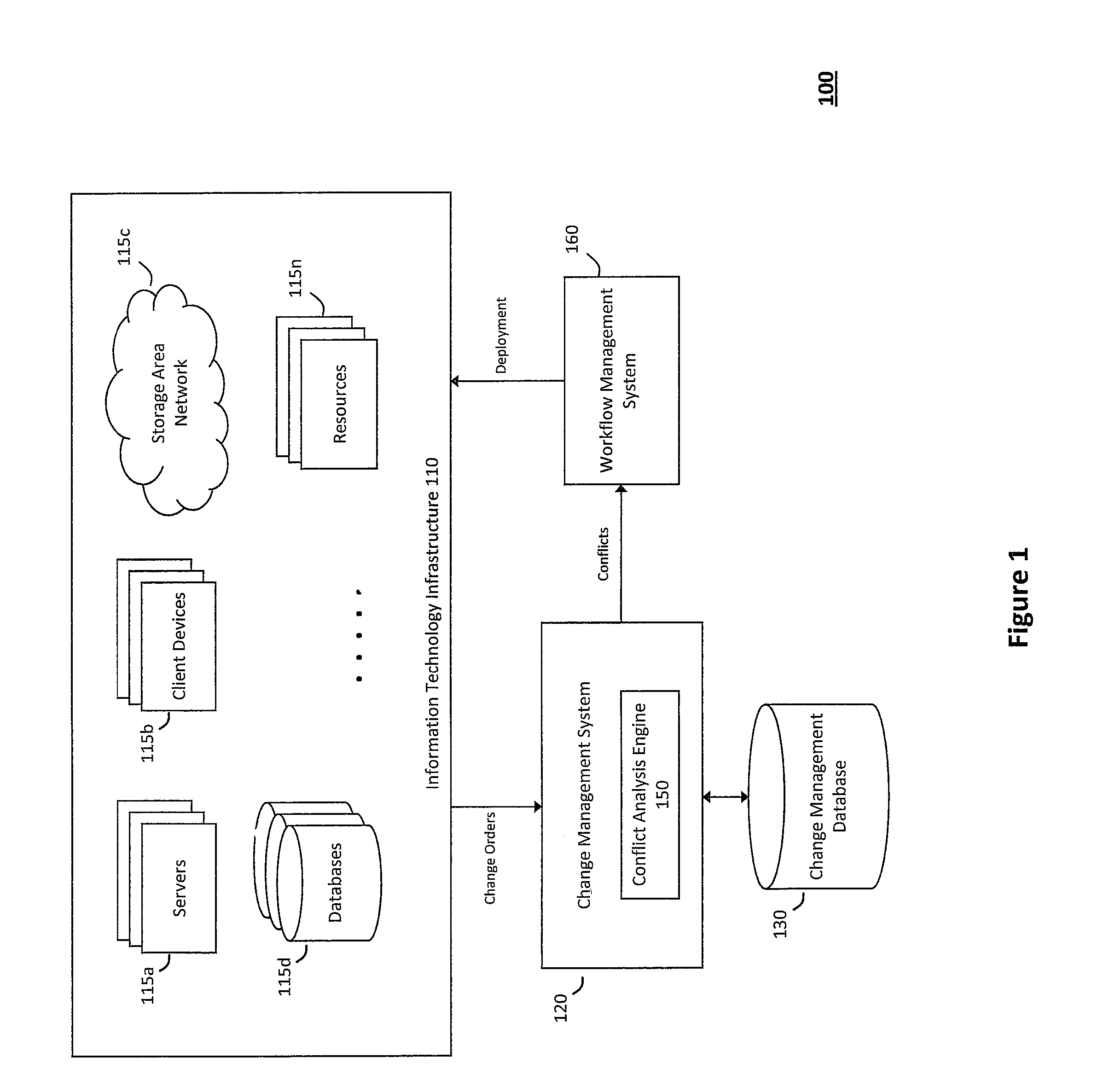

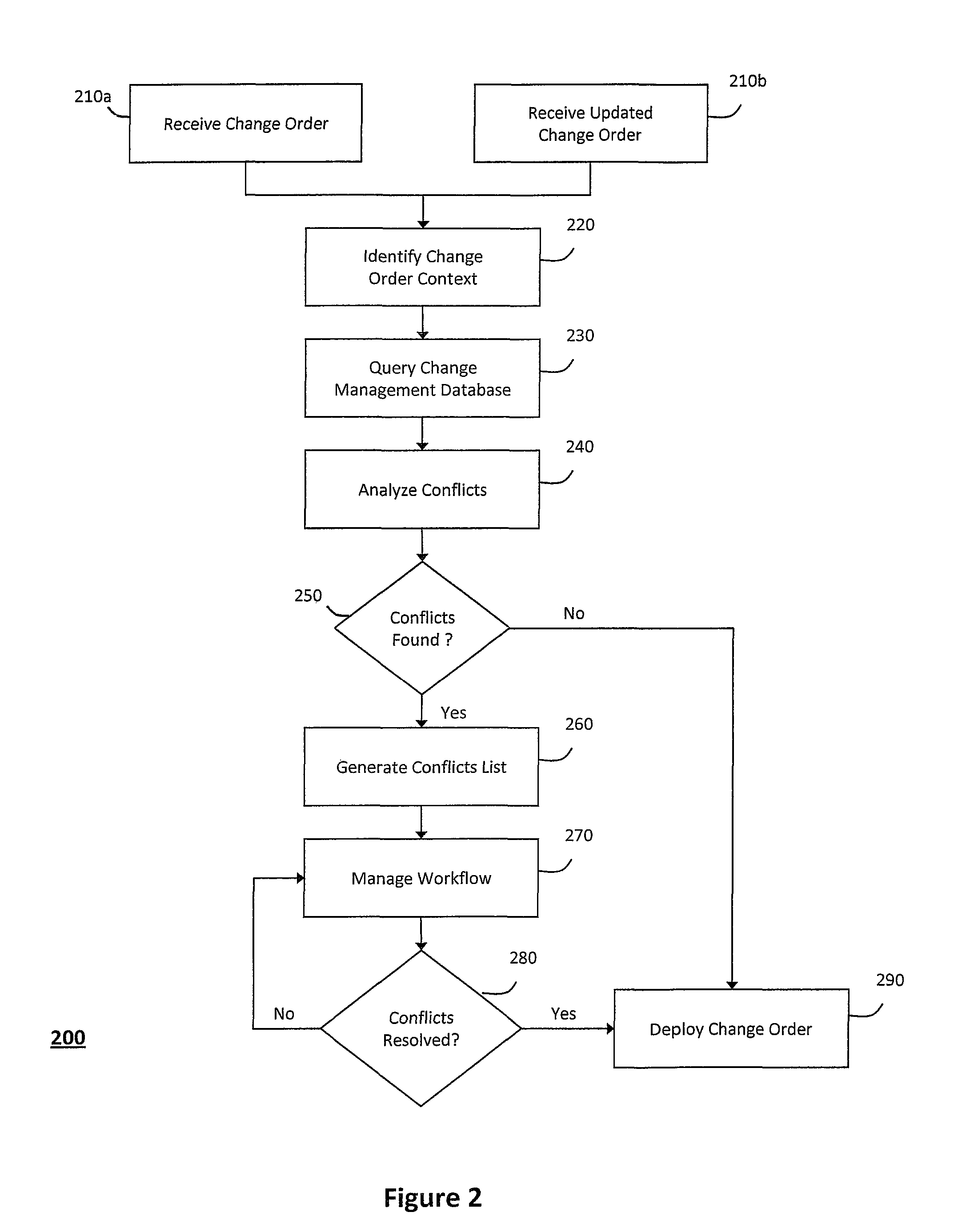

System and method for automatically detecting, reporting, and tracking conflicts in a change management system

Owner:CA TECH INC

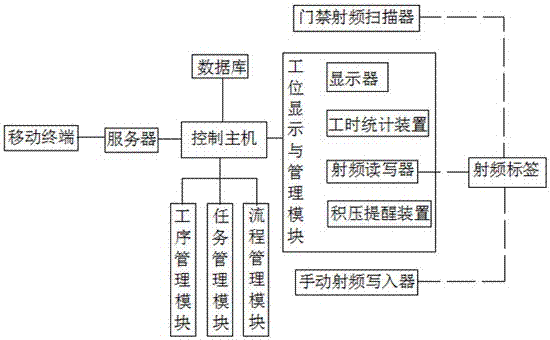

Discrete type work shop production process management system

InactiveCN106934528AGuaranteed real-timeEnsure coordinationCo-operative working arrangementsResourcesProduct typePlanned change

The invention relates to a discrete type work shop production process management system comprising a control host, a server, a database, a task management module, a process management module, a flow management module, station display and management modules, a radio frequency tag, a hand-operated radio-frequency writing-in device and a mobile terminal. The server, the database, the task management module, the process management module, the flow management module, and the station display and management module are connected with the control host. The station display and management modules arranged at all stations consist of display device and station management units; and the station management units include work hour statistic devices, overstock prompting devices, and radio frequency readers. The task management module is used for receiving a task and making a plan; the process management module is used for decomposing a production task and sending the decomposed tasks to the corresponding display devices; and the flow management module is used for adjusting a production plan or a station setting situation. On the basis of characteristics of various product types, small batches, and frequent plan changing of the discrete type workshop, the invention provides the discrete type work shop production process management system, so that the real-time performance, coordination, and product quality of enterprise production scheduling can be guaranteed.

Owner:浙江红旗机械有限公司

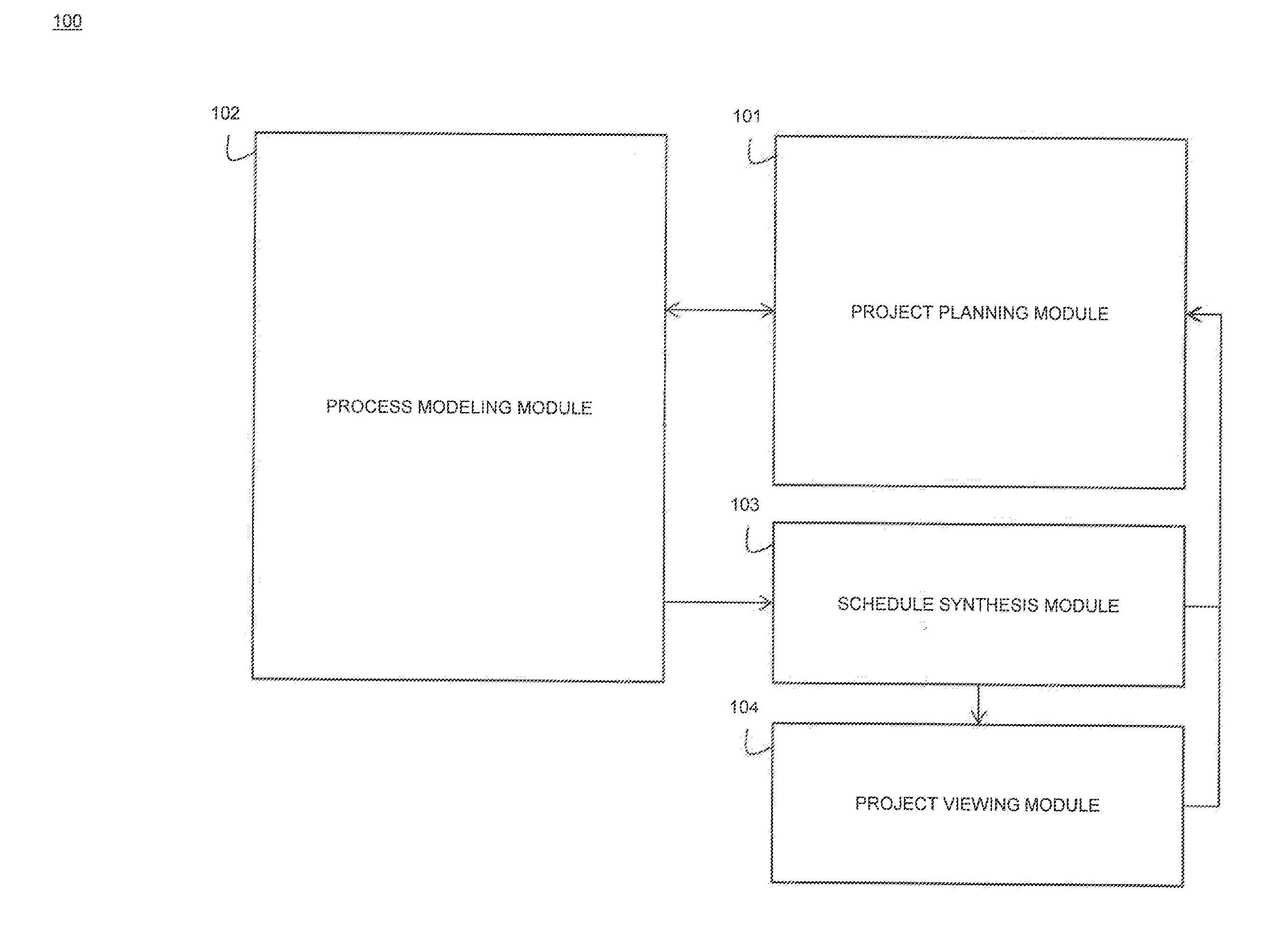

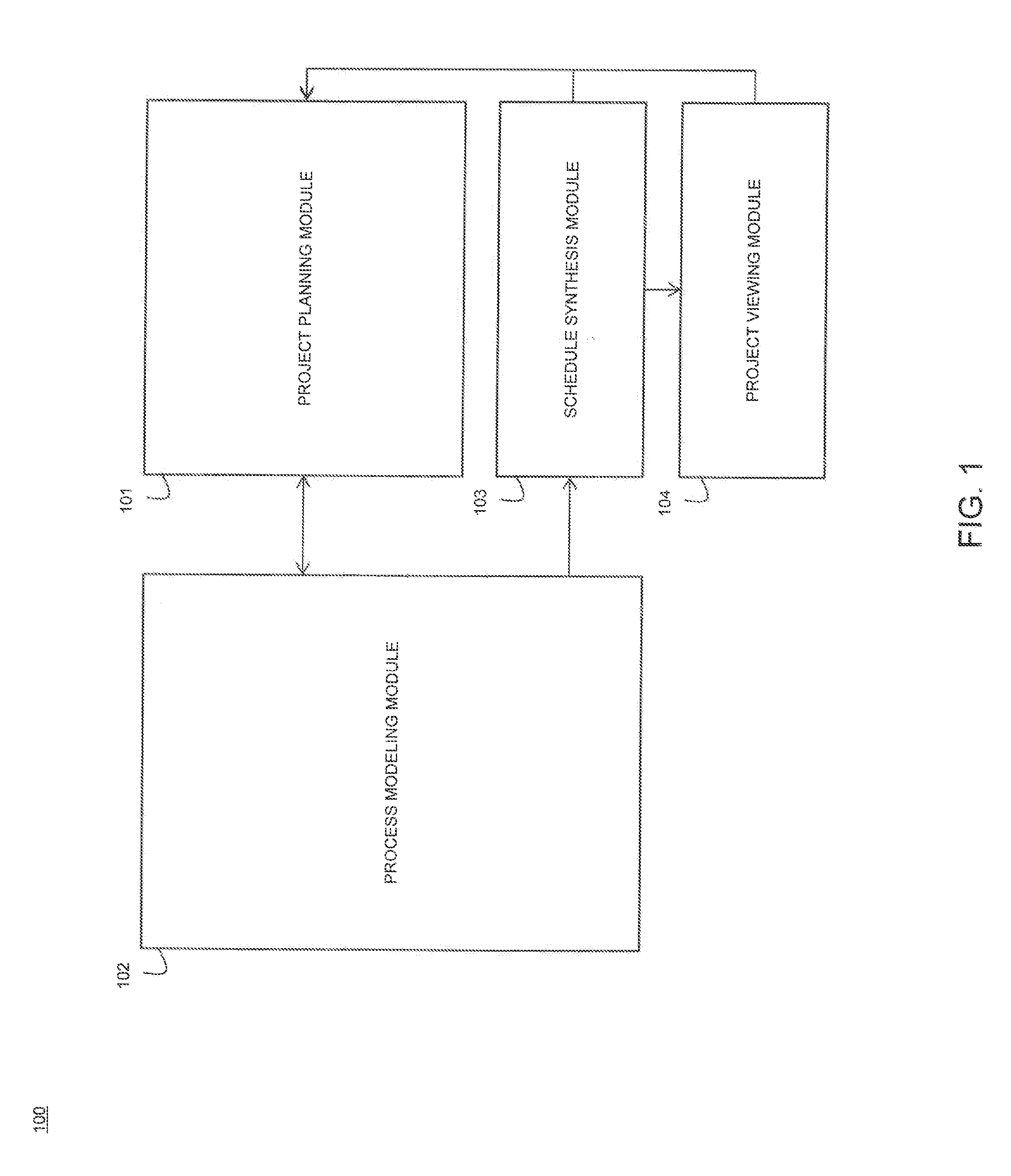

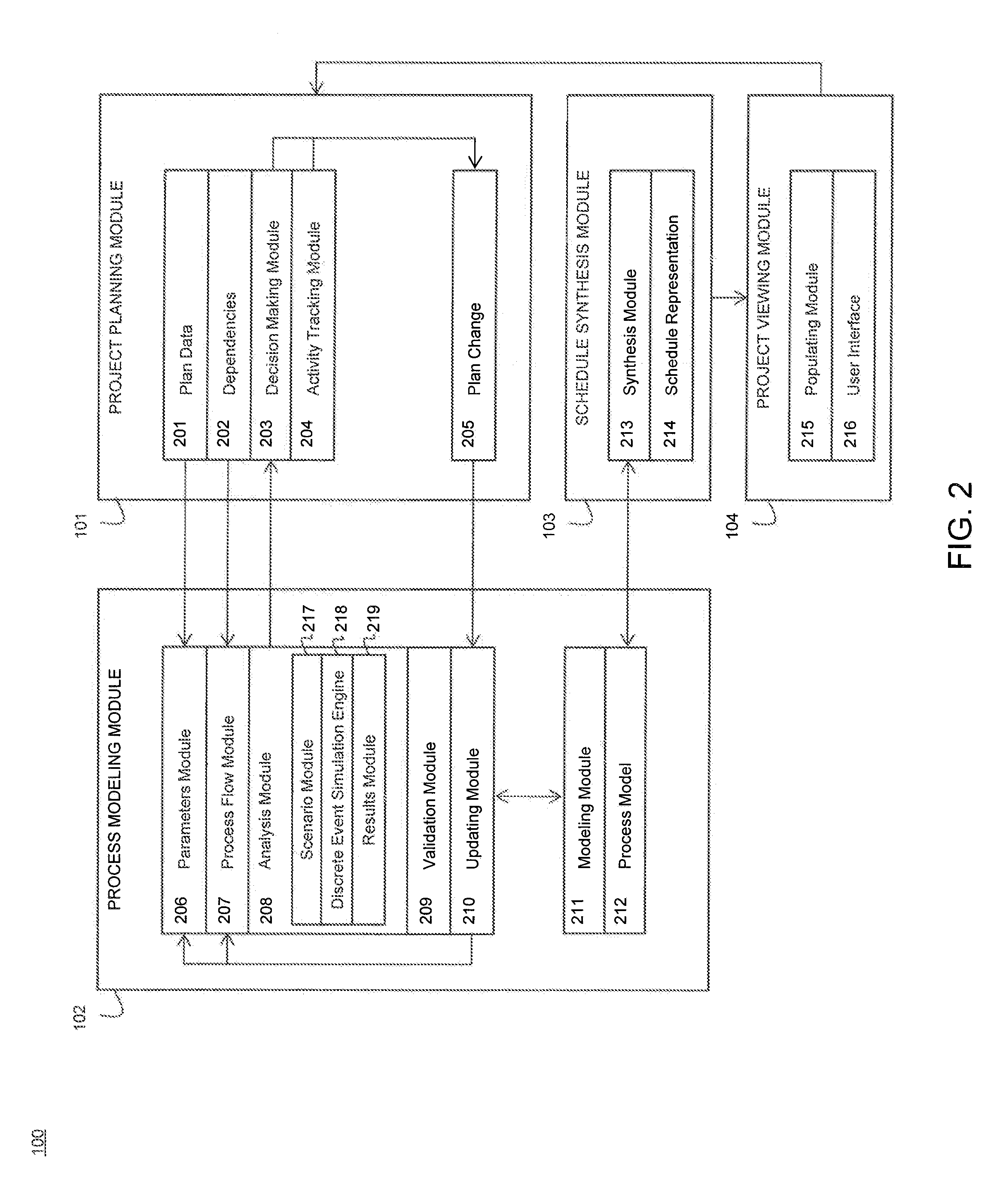

Synthesis of a schedule representation from a process model

Synthesizing a schedule representation from a process model includes: defining a process model for a project plan by capturing model parameters and process flow; performing quantitative analysis on the process model, such as, for example, stochastic and queuing analysis; and synthesizing a schedule representation from the process model. In an exemplary embodiment, a discrete event simulation engine is used to synthesize a schedule representation from a process model. In an exemplary embodiment, the synthesized schedule is exported to a project viewer capable of interacting with one or more users. The system and method may include receiving one or more plan change and / or decision inputs, modifying the process model based on such inputs, performing quantitative analysis on the modified process model, and synchronizing the modified process model and the schedule representation.

Owner:MITRE SPORTS INT LTD

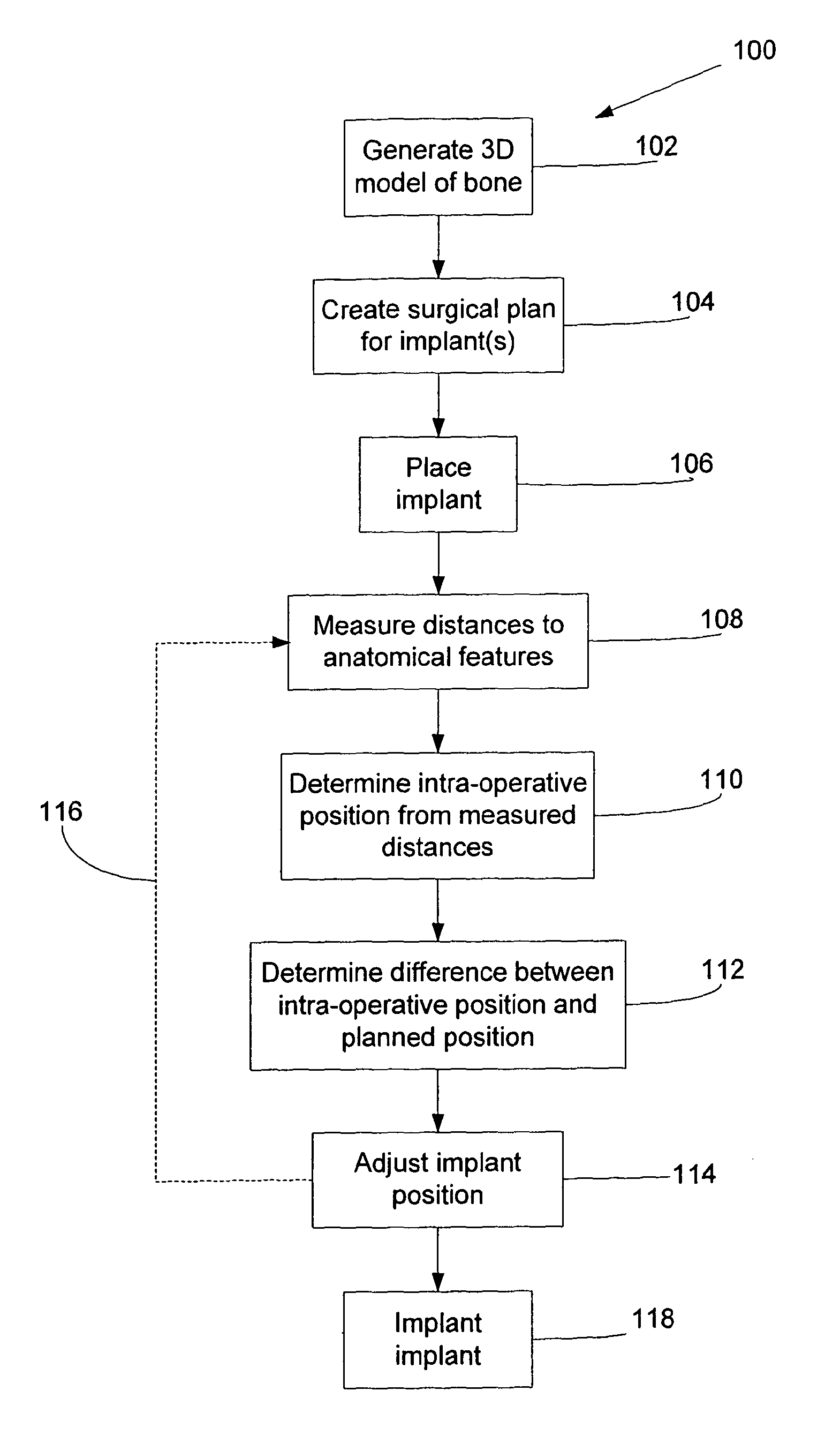

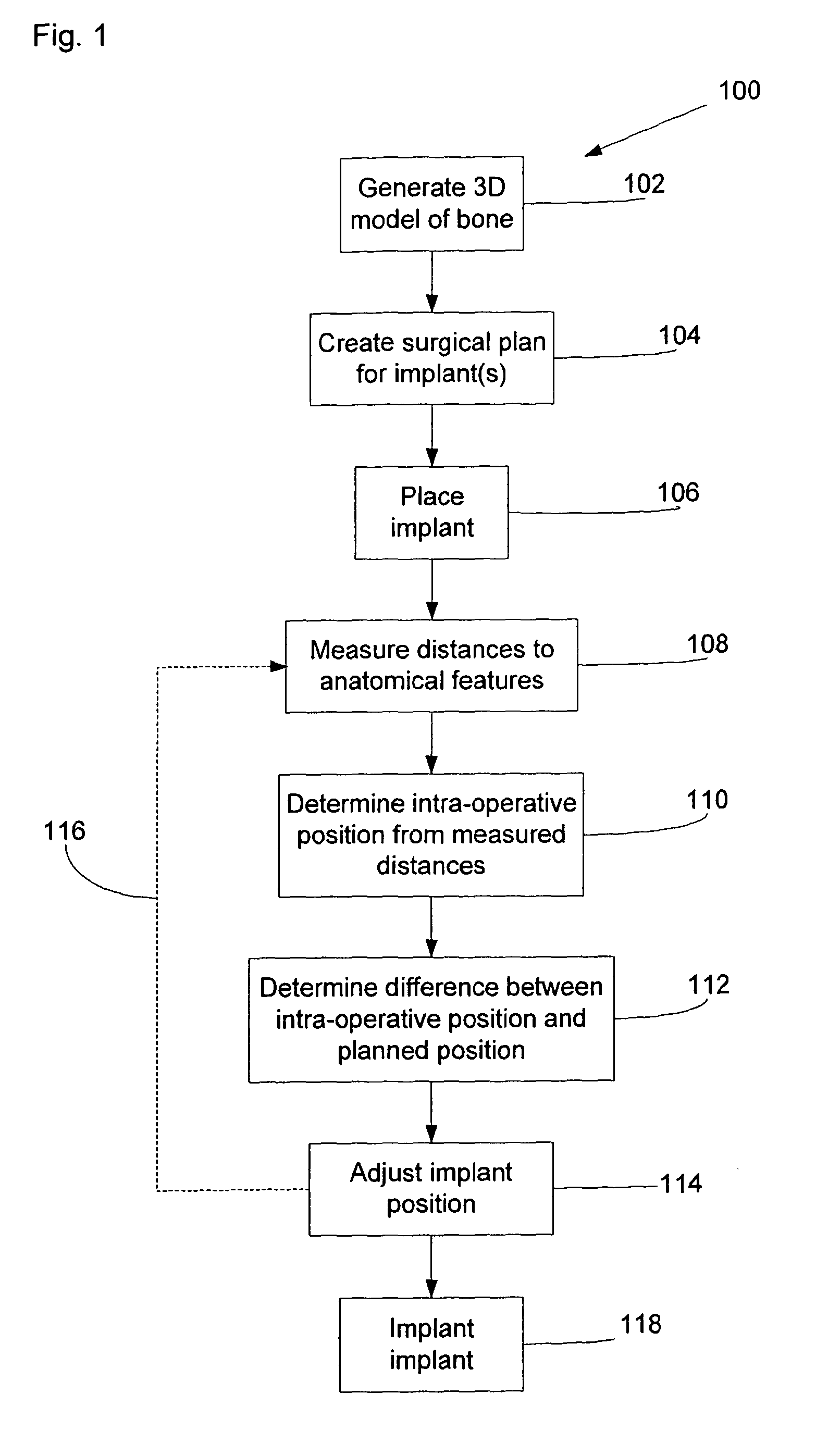

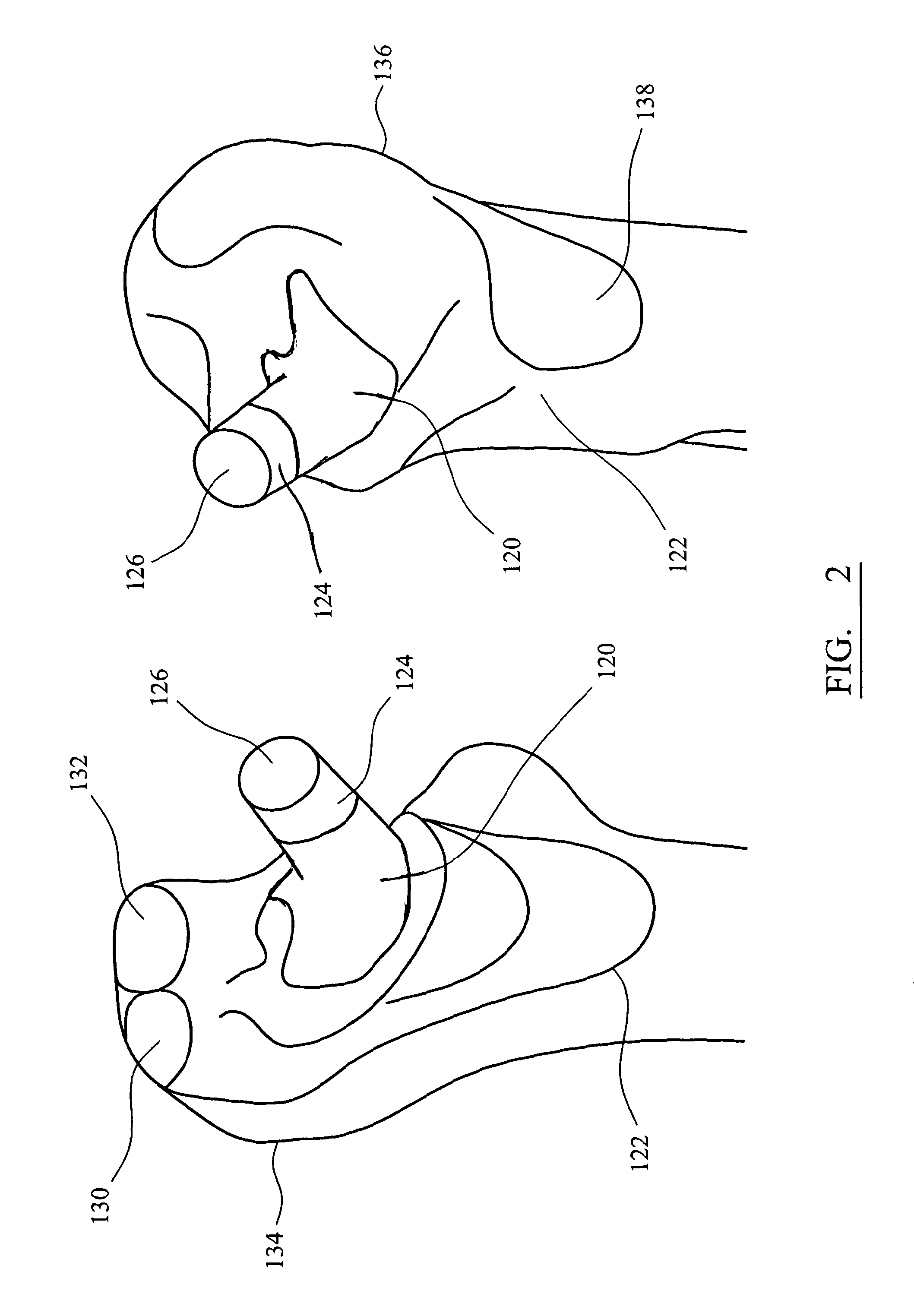

Intra-operative surgical plan changing

ActiveUS9042621B2Reduce the differenceMechanical/radiation/invasive therapiesAnalogue computers for chemical processesPlanned changePlastic surgery

A system and computer implemented method for use in determining the deviation of an intra-operative position of an orthopaedic implant from a planned position is described. The position of the orthopedic implant in the bone is defined by a plurality of implant position parameters. The distance of a plurality of anatomical features in a three dimensional model of the surface of the bone relative to a model of the implant at a first position is calculated. The first position corresponds to a first set of values for the implant position parameters. The distance of the plurality of anatomical features to a model of the implant at a second position in the bone is calculated. The second position corresponds to a second set of values for the implant position parameters, and the second position is different to the first position.

Owner:DUPUY INT LTD +1

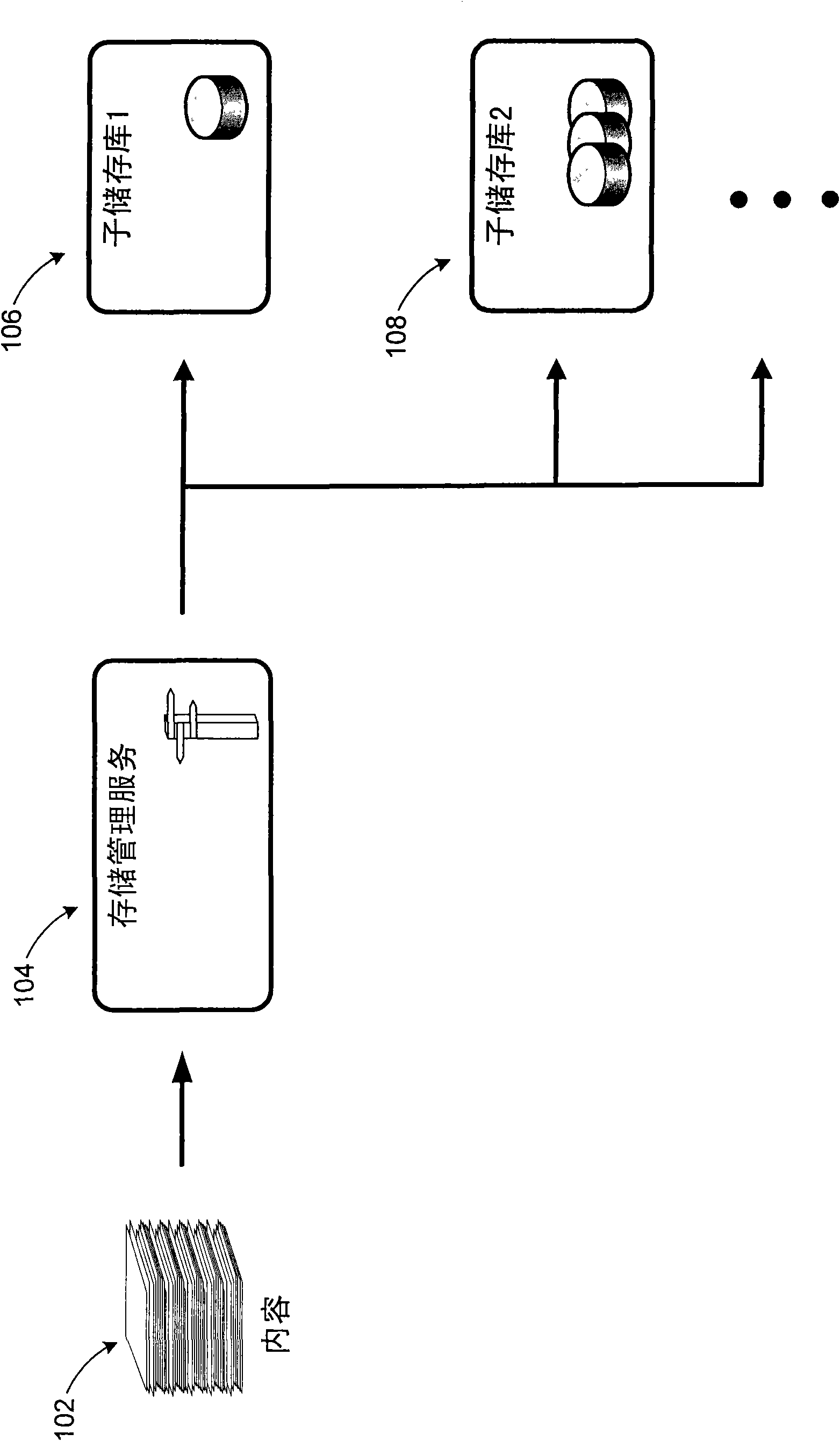

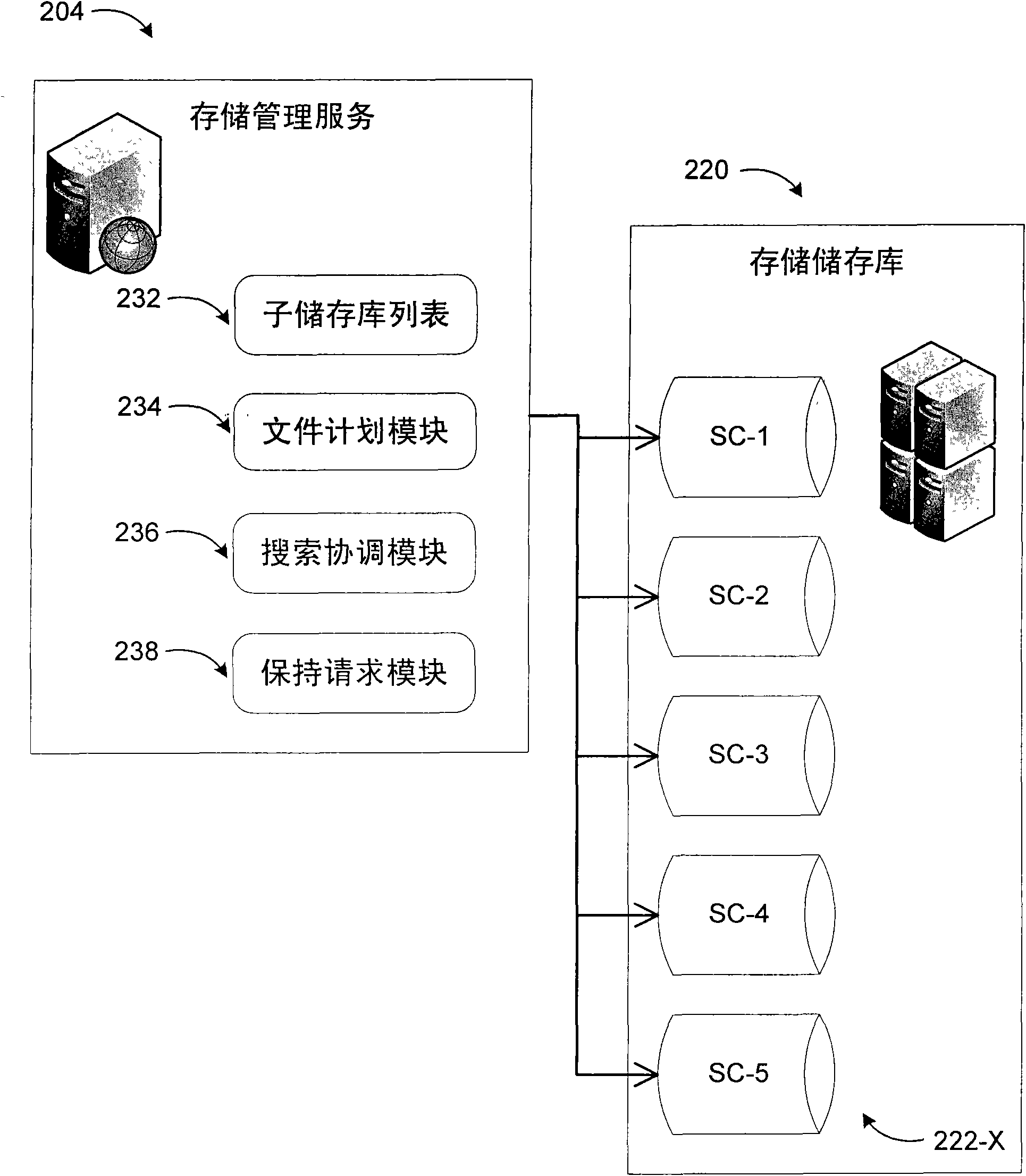

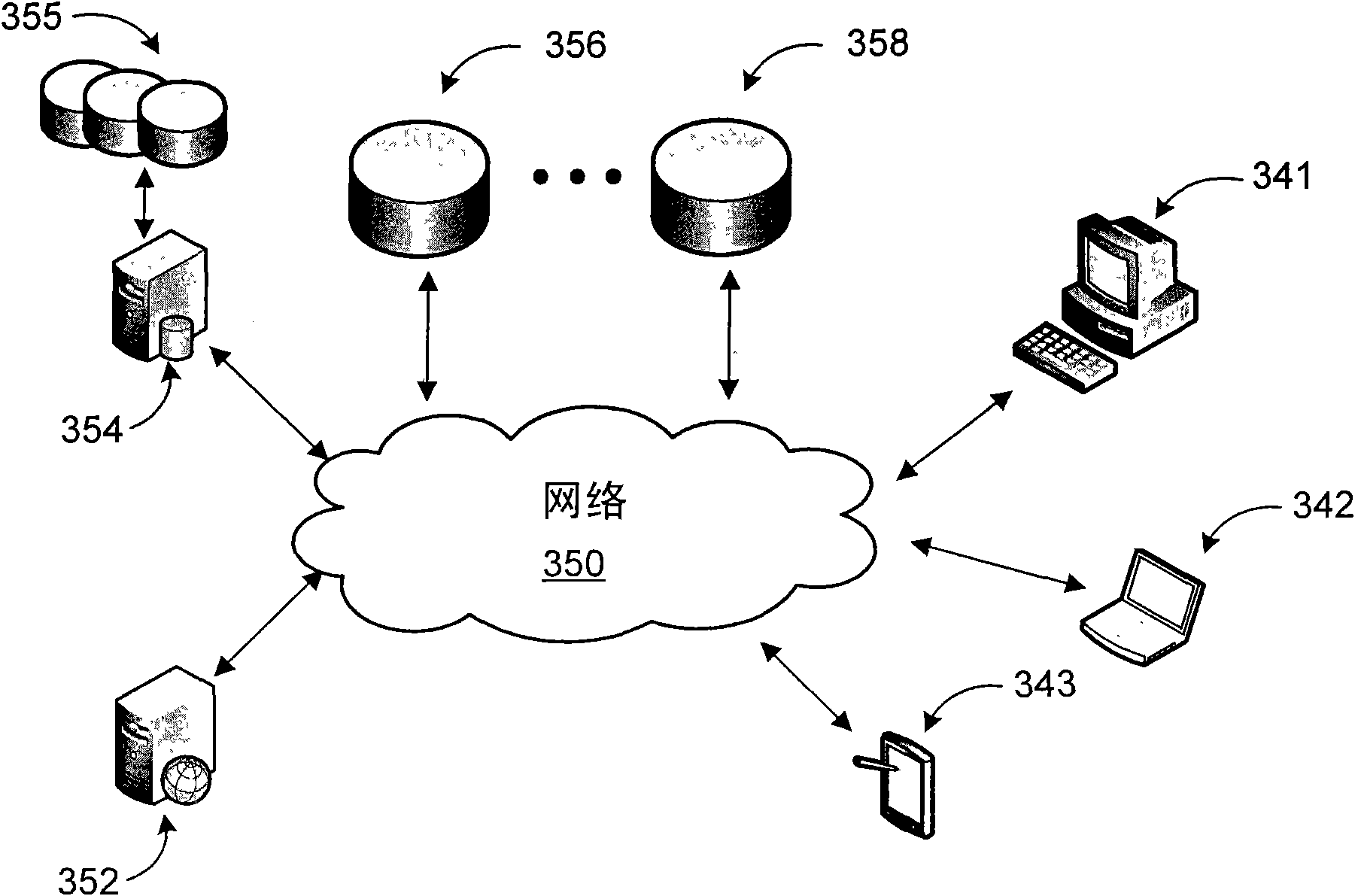

Increasing file storage scale using federated repositories

InactiveCN101689135AInput/output to record carriersMemory adressing/allocation/relocationPlanned changeProgram planning

A storage management system using federated repositories directs content to child repositories in a hierarchical structure. A service for managing the storage maintains a list of active and historic repositories and routing of the content for storage is performed based on a file plan that includes the structure of the child repositories, policies for storage, and the like. Repositories reaching their capacity are retired to historic status, where they are available for search purposes, but not for further storage. File plan is updated as new repositories are added or old ones retired. File plan changes and other information such as content types, search terms, workflow, etc. is made available to child repositories when they query the service.

Owner:MICROSOFT CORP

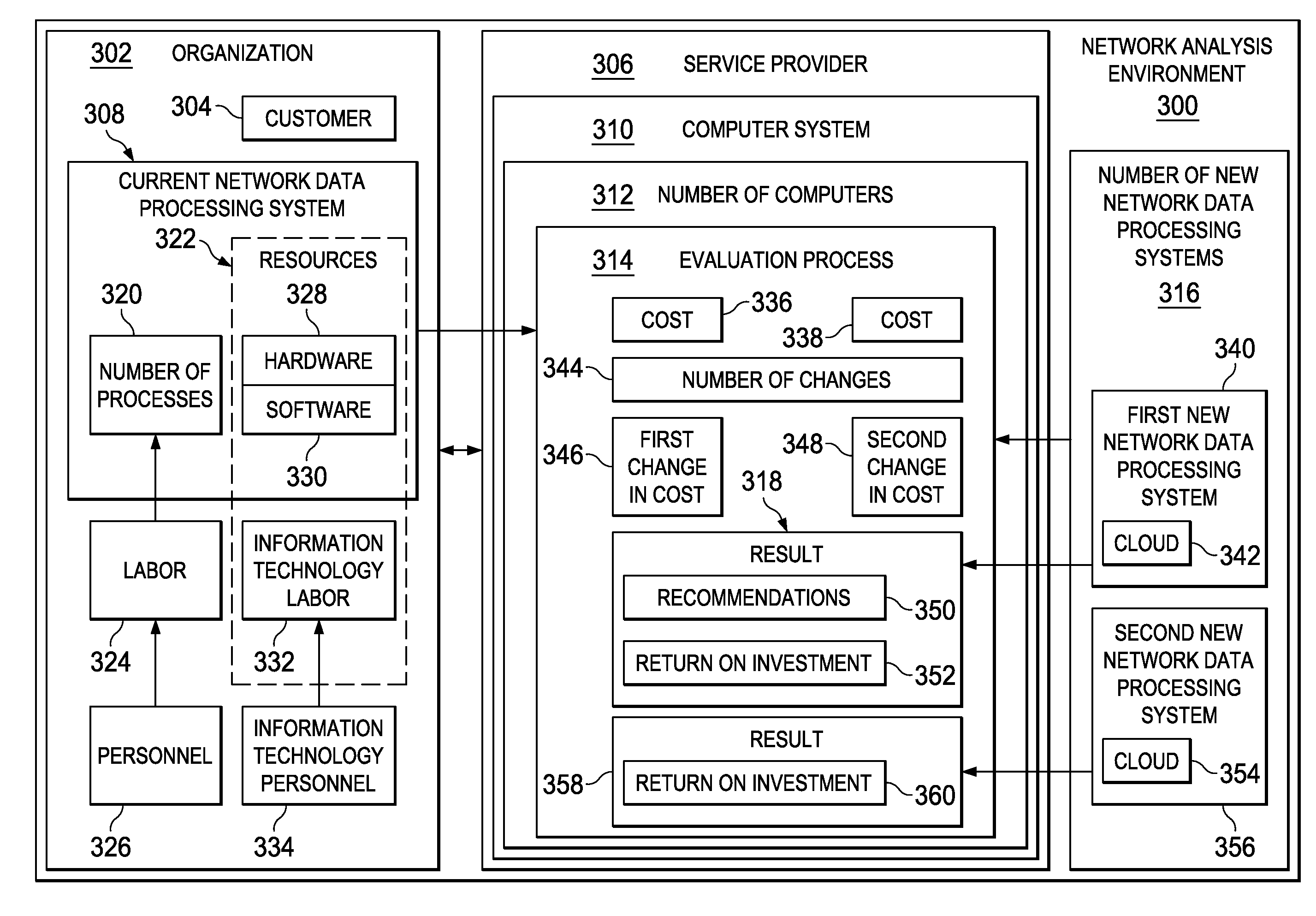

Cost benefit based analysis system for network environments

A method, apparatus, and computer program product for planning changes to network data processing systems. A number of processes performed in a current network data processing system and labor used to perform the number processes are identified. Resources in the current network data processing system used by the number of processes are identified. A first cost for labor used to perform the number of processes using the current network data processing system is calculated. A second cost for the resources in the current network data processing system is calculated. A first change in the first cost for labor in a new network data processing system based on a number of changes to the number of processes when the number of processes is performed in the new network data processing system is identified. A second change in the second cost for the resources in the new network data processing system is identified.

Owner:IBM CORP

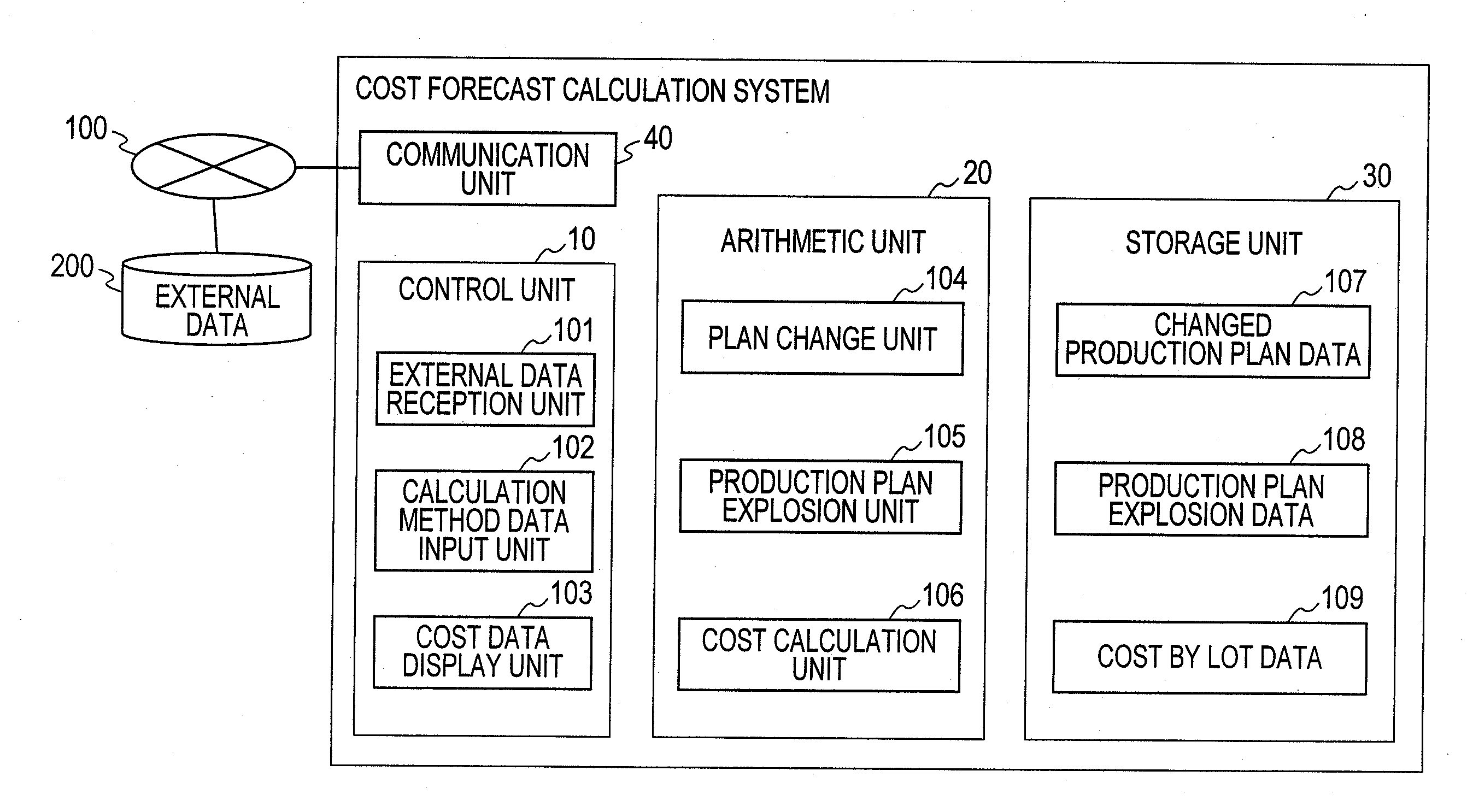

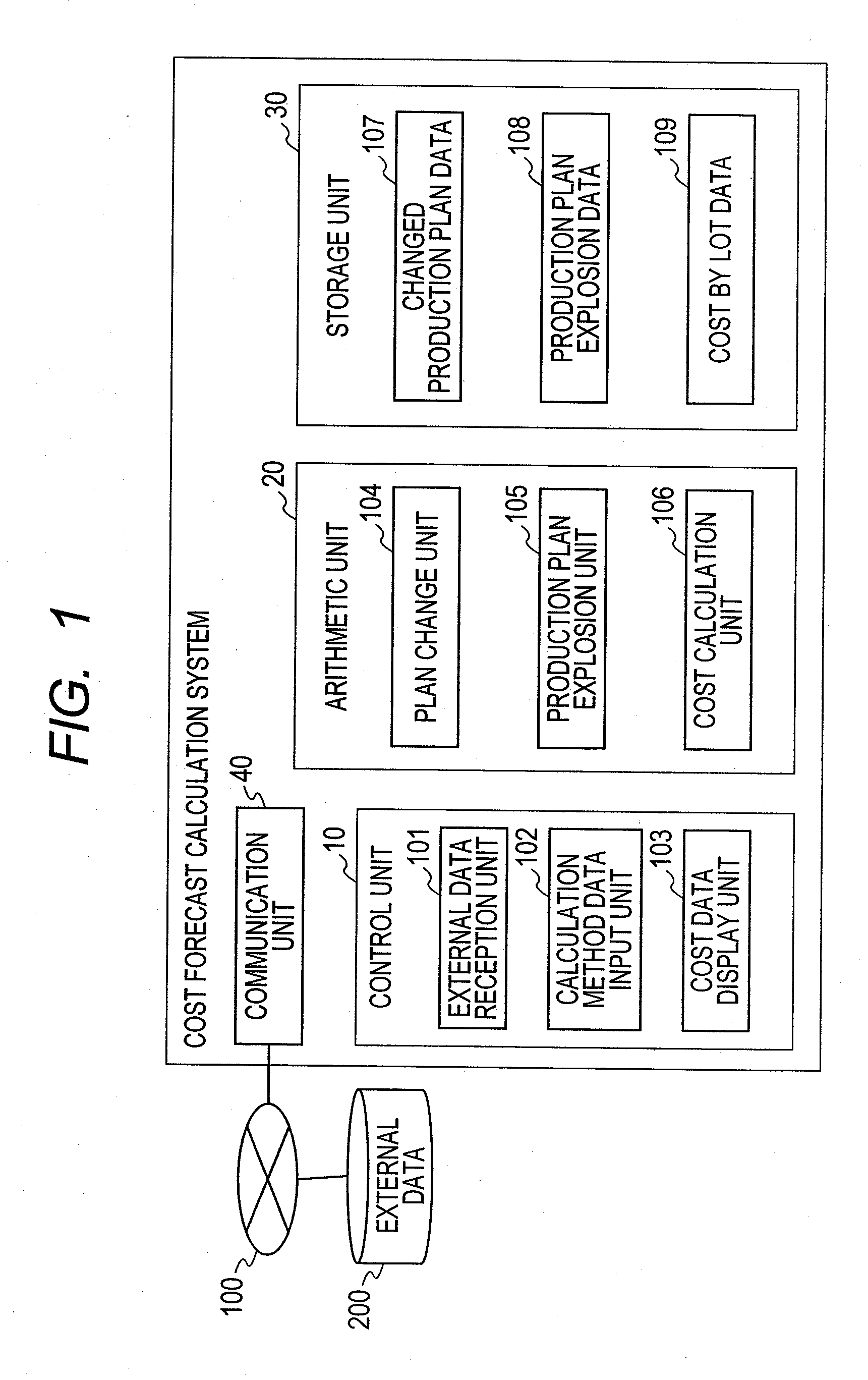

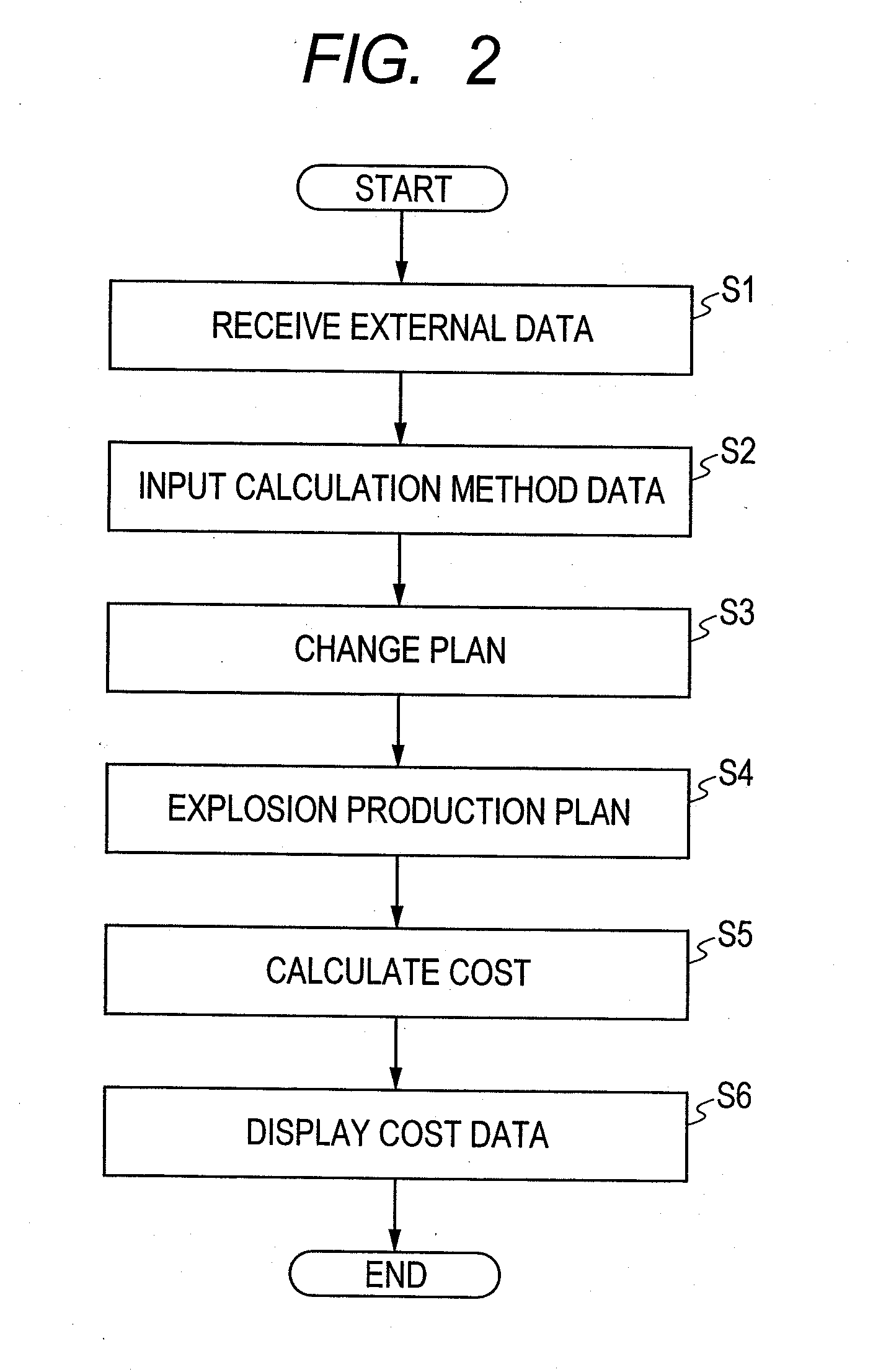

Information processing apparatus, cost forecast calculation method, and cost forecast calculation program

An information processing apparatus, a cost forecast calculation method, and a cost forecast calculation program are provided that enable the calculation of cost forecast without cost performance data such as initial inventory and warehousing schedule. The information processing apparatus includes: a reception unit for obtaining production plan data indicating the production plan of a product including date data; a plan change unit that changes the initial inventory data to the production plan data based on the product identification data and the plan identification data; and a cost calculation unit that calculate the cost.

Owner:HITACHI LTD

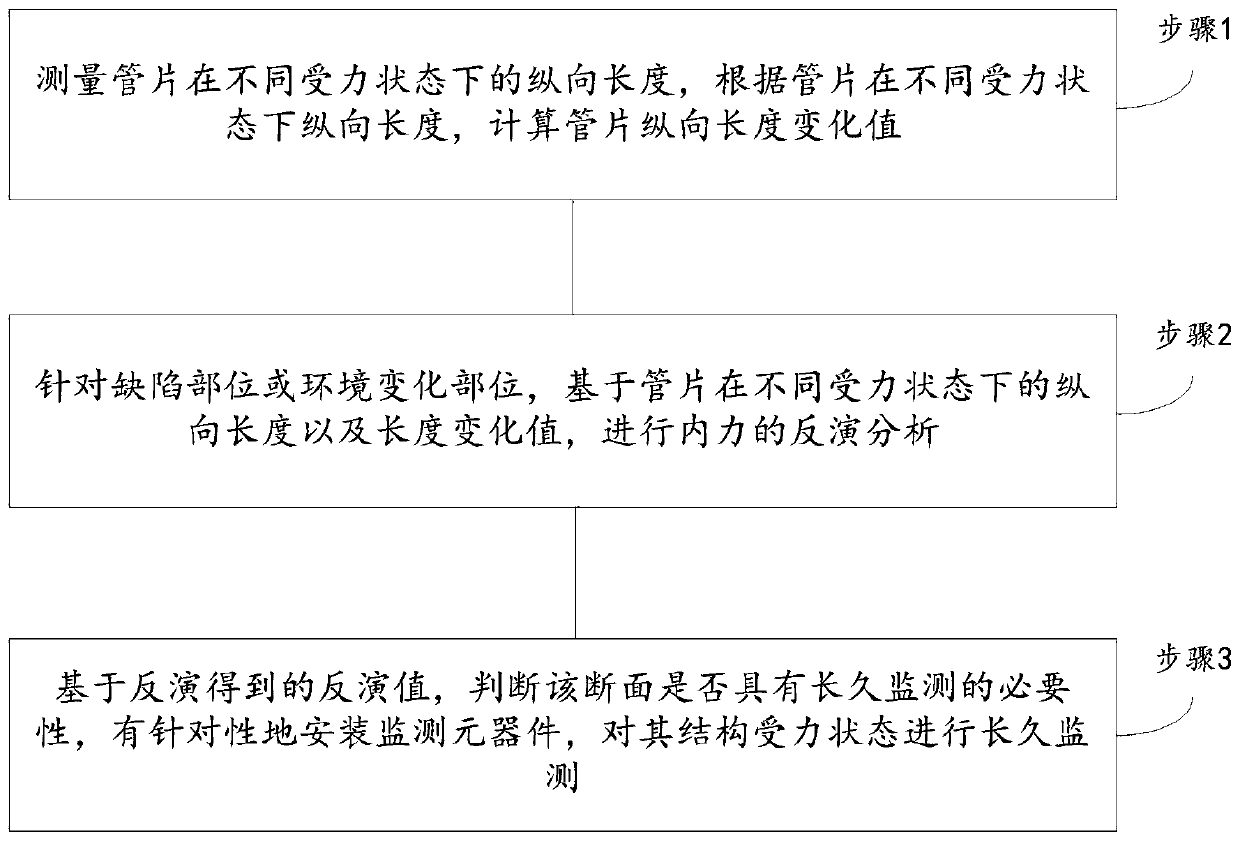

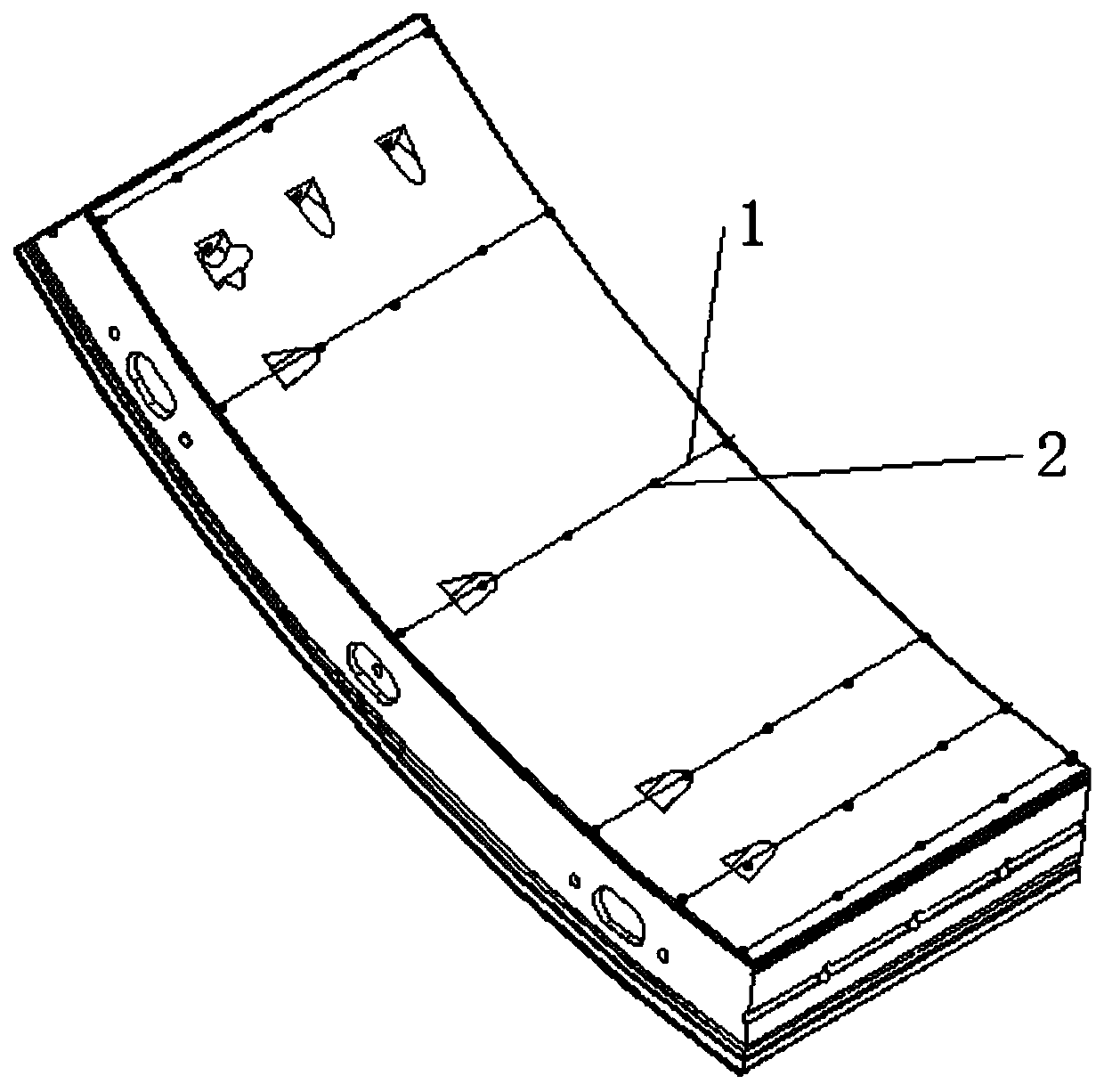

Shield tunnel longitudinal internal force non-pre-buried type monitoring method

ActiveCN110230516AAccurate monitoringImprove survival rateMining devicesUnderground chambersPlanned changeEngineering

The invention discloses a shield tunnel longitudinal internal force non-pre-buried type monitoring method. The shield tunnel longitudinal internal force non-pre-buried type monitoring method comprisesthe steps that aiming at a defective part or an environmental-change part, longitudinal lengths of a segment under different stress states are measured, and change values of the longitudinal lengthsof the segment are calculated; inverse analysis of internal force is carried out based on the longitudinal lengths of the segment and the length change values; and based on the inverse analysis results, whether a fracture surface has the necessity of long-time monitoring or not is judged, and monitoring components and parts are installed in a targeted mode so as to perform long-time monitoring onthe structural stress states of the fracture surface. According to the shield tunnel longitudinal internal force non-pre-buried type monitoring method, in terms of structural long-term health, the fracture surface which is really the most dangerous and needs to be monitored for a long time most is a defective position caused by various causes in construction in most cases, due to the fact that construction factors have randomness, defective positions are difficult to predict, environmental-change factors are further difficult to predict either due to plan changes or various special causes, andthe components and parts are difficult to pre-bury. According to the shield tunnel longitudinal internal force non-pre-buried type monitoring method, the components and parts are pre-buried in the later period, so that parts which are the most dangerous and need to be monitored most are monitored accurately.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

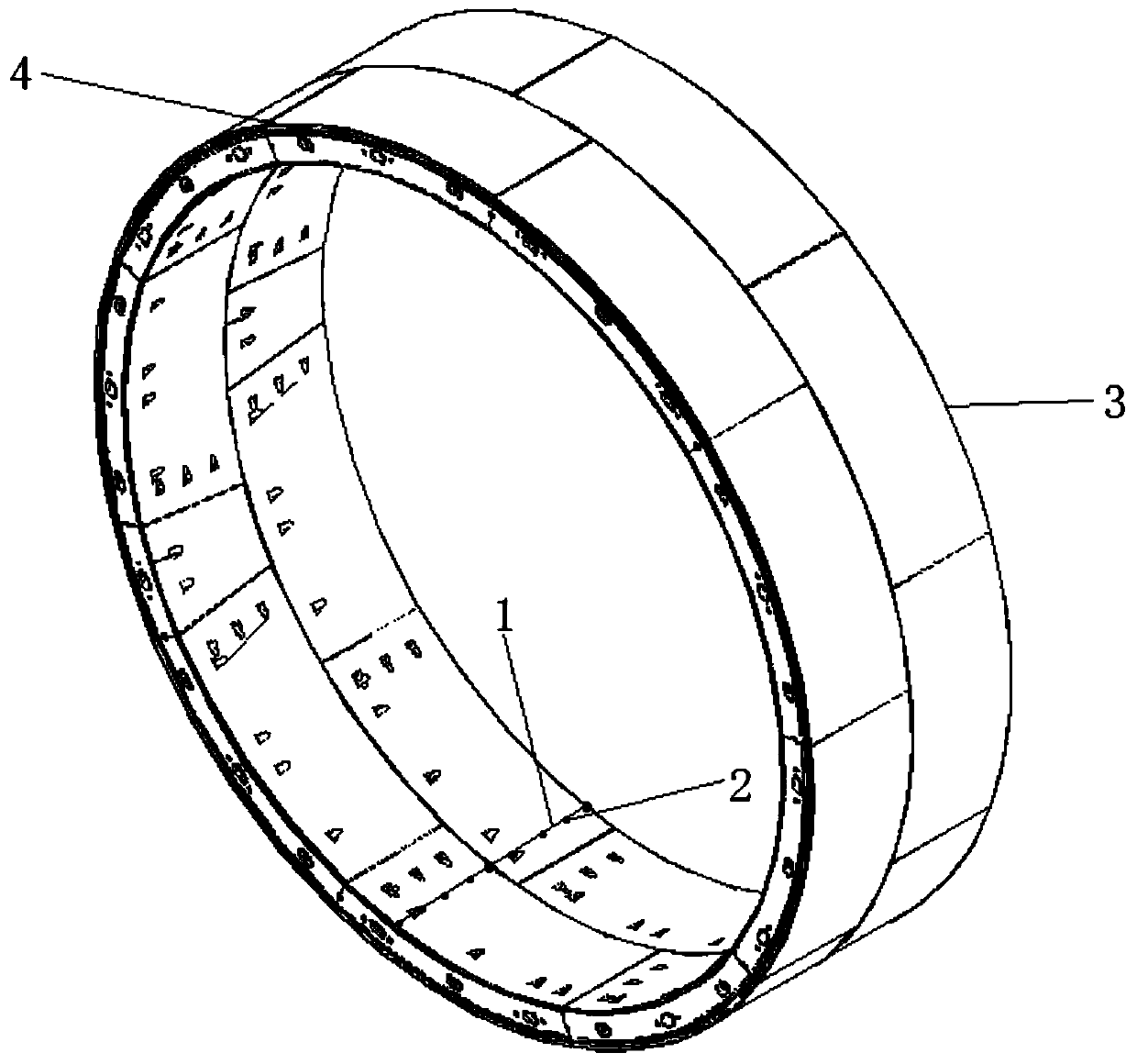

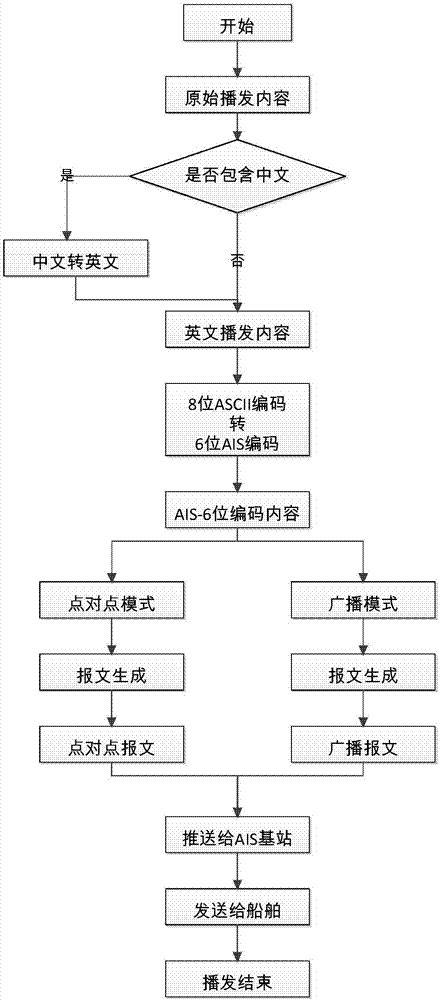

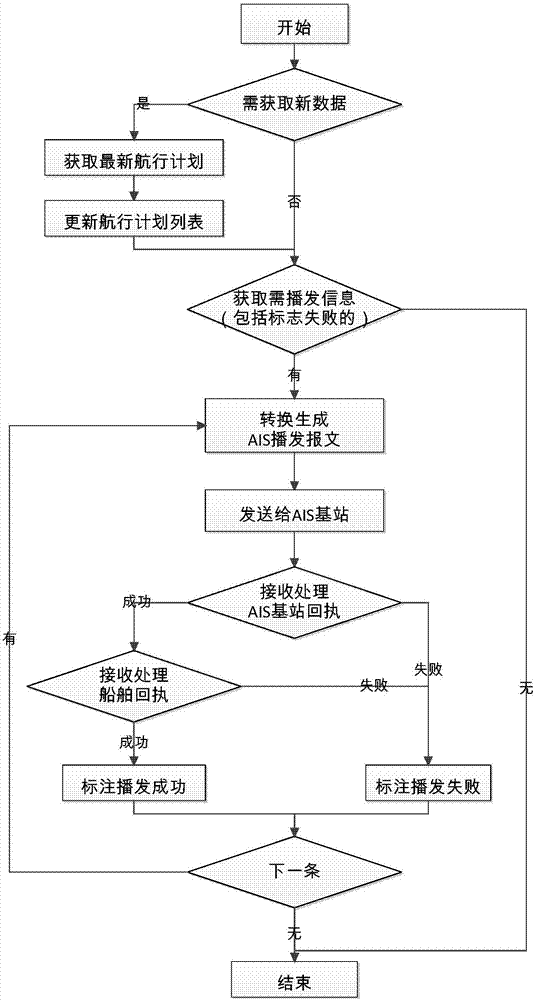

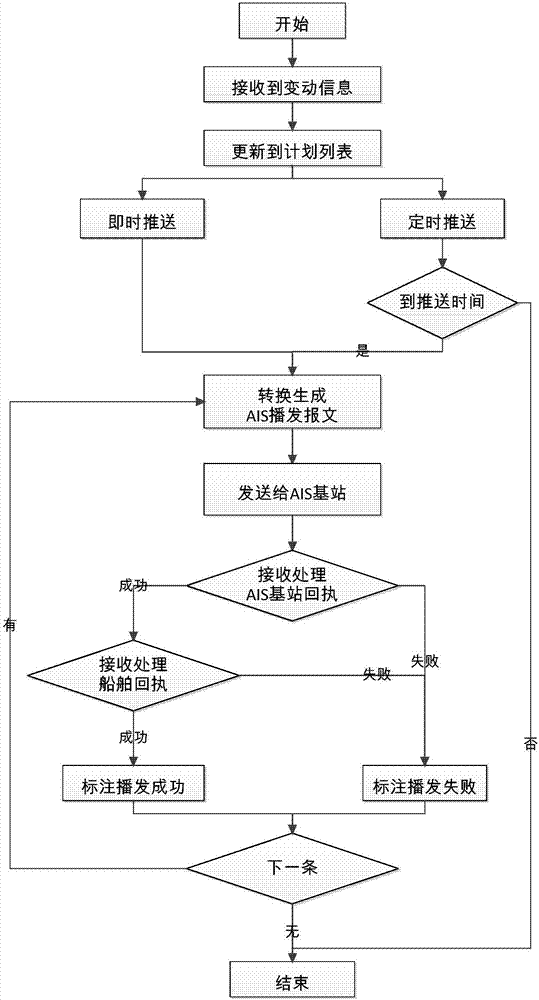

VTS information intelligent pushing system based on ship automatic identification system

InactiveCN107483633AQuick confirmationEasy to confirmBroadcast service distributionMessaging/mailboxes/announcementsPlanned changeNavigation safety

The invention discloses a VTS information intelligent pushing system based on a ship automatic identification system. The pushing system is composed of an AIS message generating and broadcasting module, a ship sailing plan timed pushing module, a ship sailing plan change pushing module, a sailing security related information pushing module and an intelligent reply information pushing module; when the pushing system is started, the system procedure is to start the threads of the sailing plan timed pushing module, the sailing plan change pushing module, a sailing security related information pushing module and the intelligent reply information pushing module; when the information needing to push is produced, the AIS message generating and broadcasting thread finishes the conversion to the AIS broadcasting message from the original information, and the AIS broadcasting message is sent to an AIS base station, the AIS base station finally sends the message to the target ship through a VHF way. The pushing system disclosed by the invention can guarantee the fast, convenient and accurate confirmation of the ship sailing dynamic information and the sailing security related information between a VTS center and the ship, and the occupancy on a VHF communication channel by this type of information communication is reduced at the same time.

Owner:中华人民共和国天津海事局

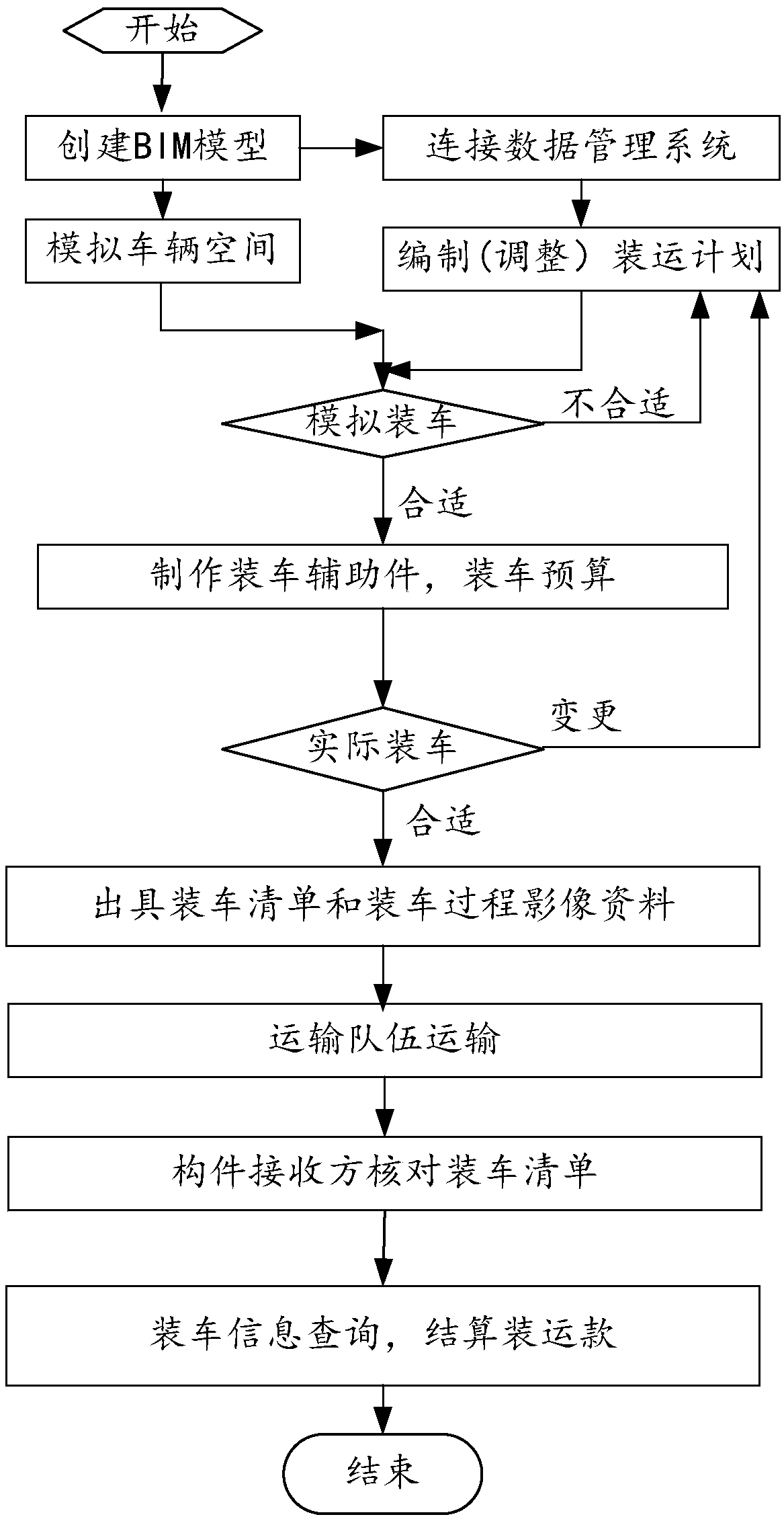

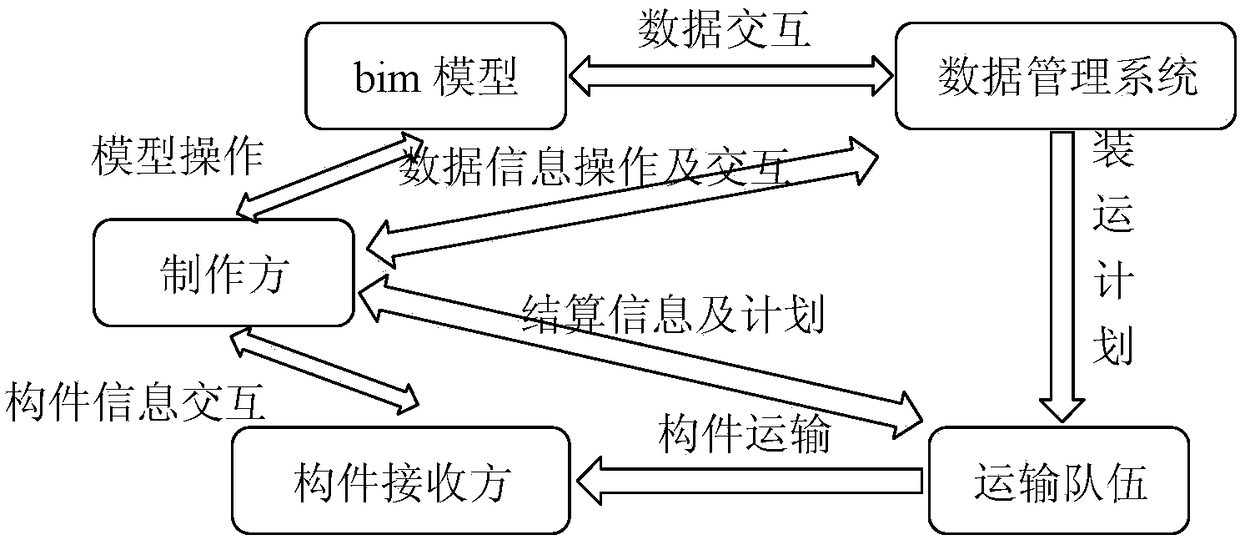

Component shipping method based on BIM technology

ActiveCN109388879AImprove space utilizationModify in timeDesign optimisation/simulationSpecial data processing applicationsPlanned changeEngineering

The invention discloses a component shipping method based on the BIM technology, which comprises the following steps: creating a BIM model, and allowing a component receiver to provide a preliminary component approach plan and a change plan; simulating loading in BIM model; according to the simulation loading, allowing the manufacturer to make the loading auxiliary parts and the loading budget; performing actual loading, if there is any change in actual loading, adjusting the shipment plan, and uploading the special loading arrangement to the loading special case database; after the completionof loading, issuing and transporting the loading list and loading process image data by the transportation team; checking the loading list and sending the result to the manufacturer; performing loading information inquiry, settlement of shipment. The invention adopts a component loading method based on the BIM technology of the structure, simulates loading ahead of time, can predict the componentlayout problem in advance to modify the loading plan, improve the space utilization rate, the component receiving party feeds back the admission information and provides the plan change in time, modifies the loading plan in time, and the cost settlement is clear and convenient.

Owner:HEBEI CONSTR GRP CO LTD

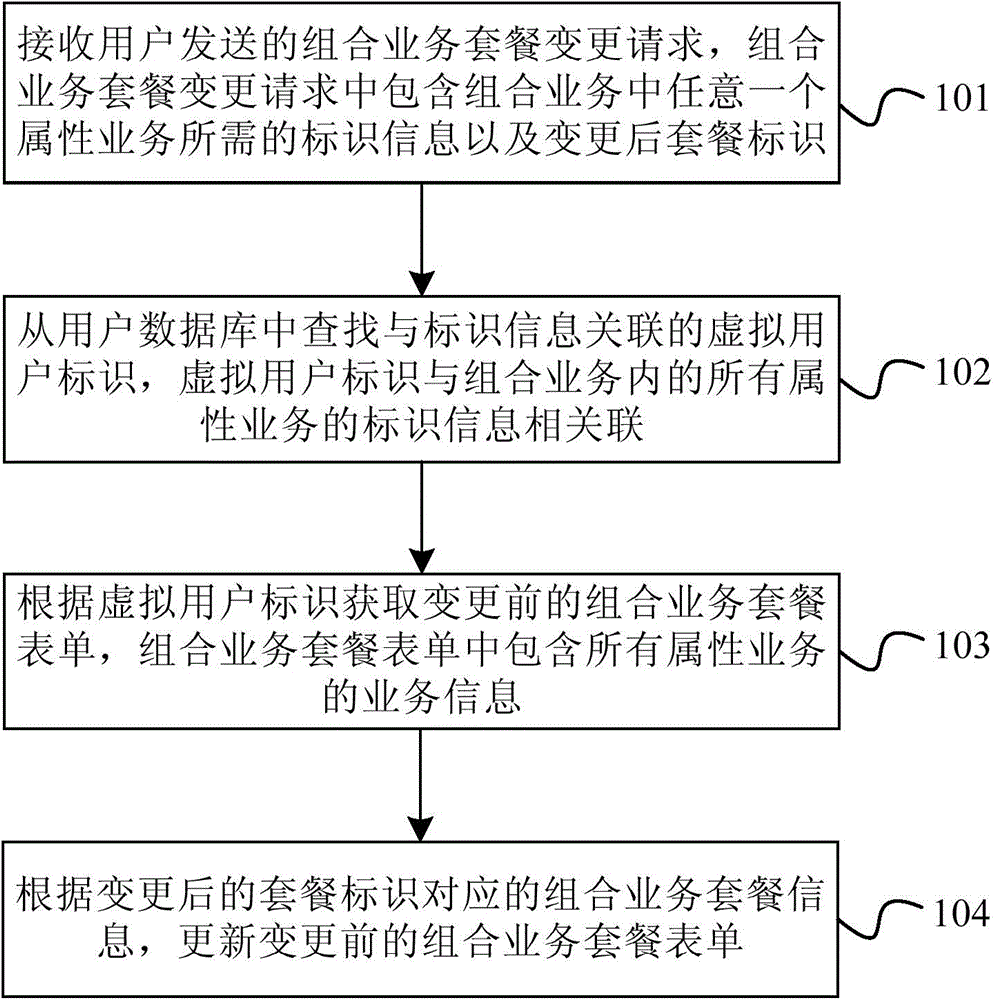

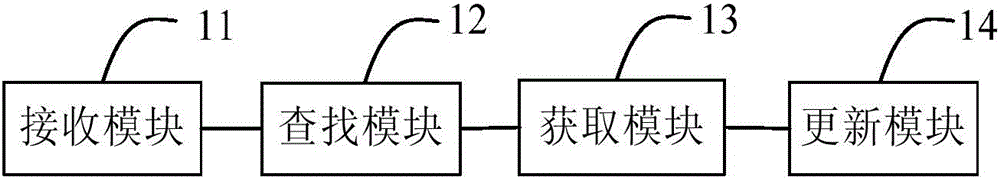

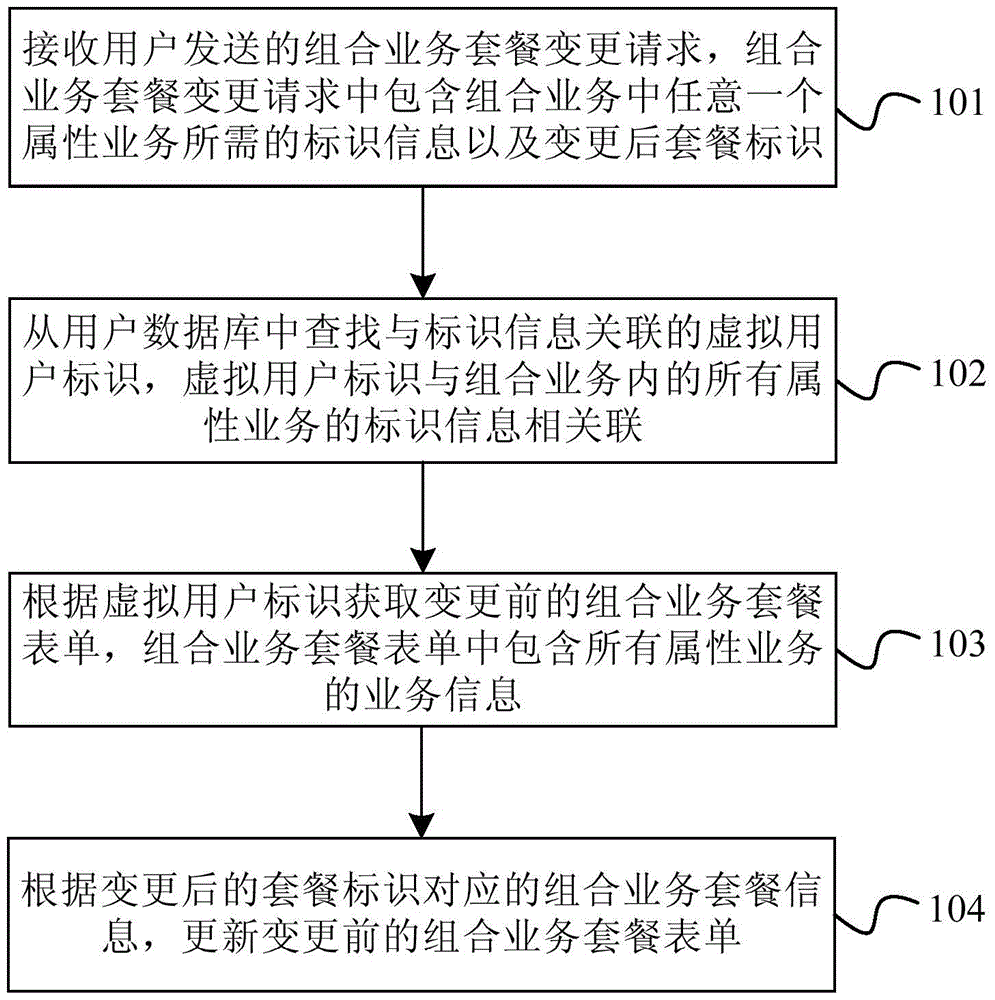

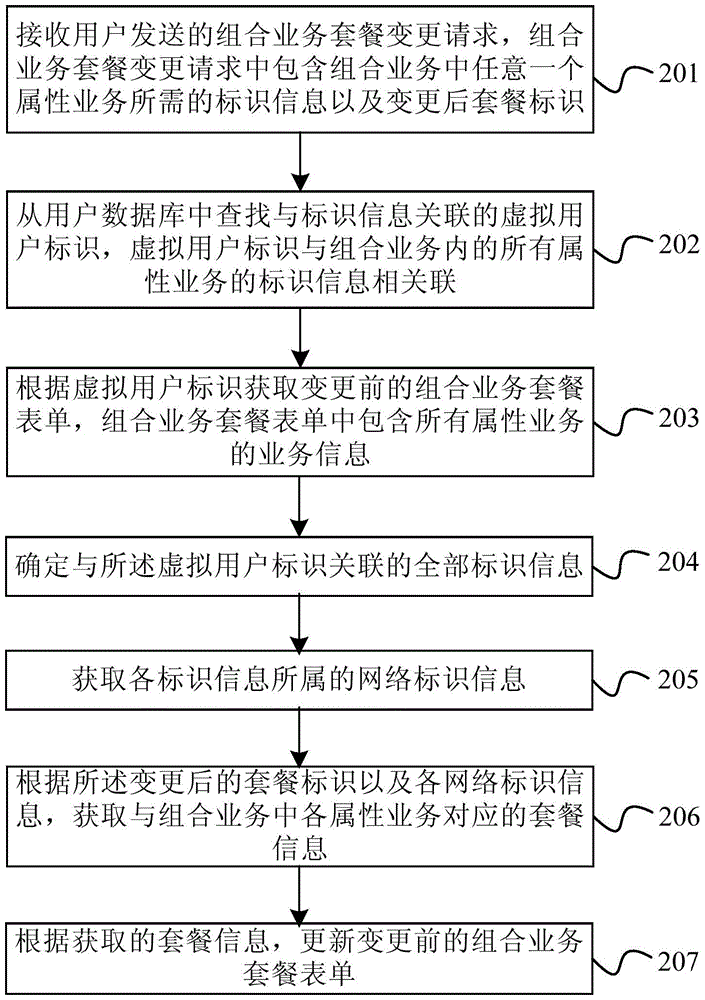

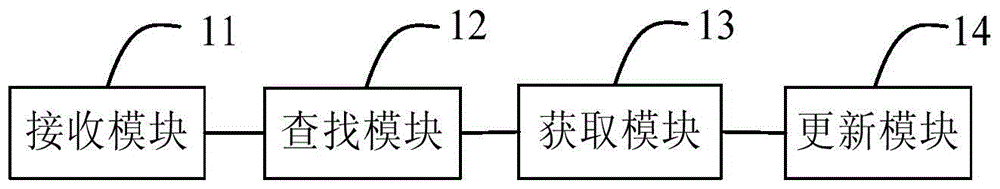

Composite service information processing method and device

ActiveCN104410757ASimplify the change handling processImprove processing efficiencySpecial service for subscribersComposite servicesInformation processing

The invention relates to a composite service information processing method and device. The method comprises the following steps: receiving a composite service plan change request sent by a user, wherein the composite service plan change request comprises identification information needed by any attribute service in a composite service, and a changed plan identifier; searching for a virtual user identifier correlated with the identification information from a user database, wherein the virtual user identifier is correlated with identification information of all attribute services in the composite service; acquiring an unchanged composite service plan form according to the virtual user identifier, wherein the composite service plan form comprises service information of all the attribute services; and updating the unchanged composite service plan form according to composite service plan information corresponding to the changed plan identifier. Therefore, parallel processing of a plurality of attribute services in the composite service is realized; the change processing process of a composite service plan is simplified greatly; and the composite service processing efficiency is increased.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

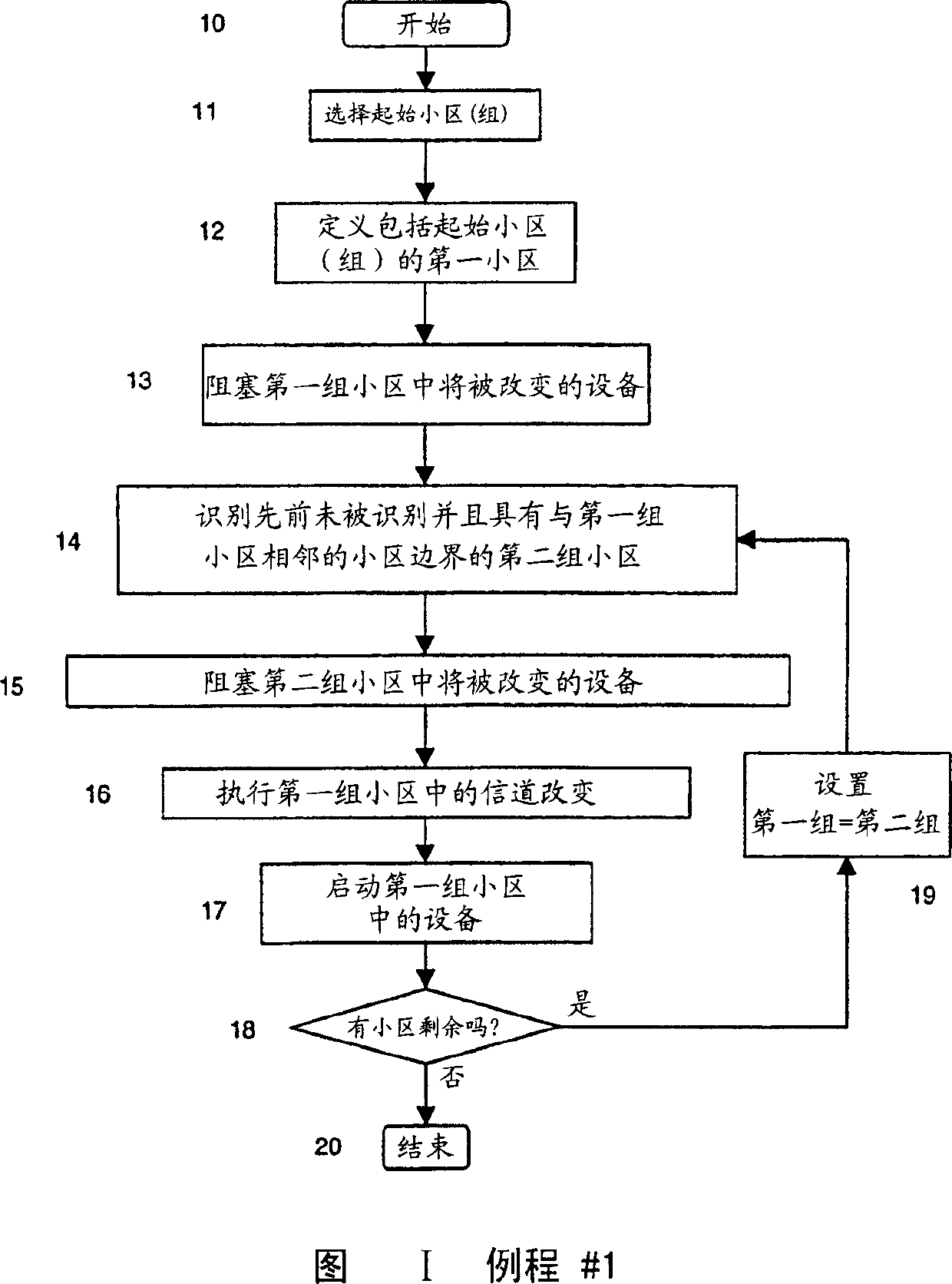

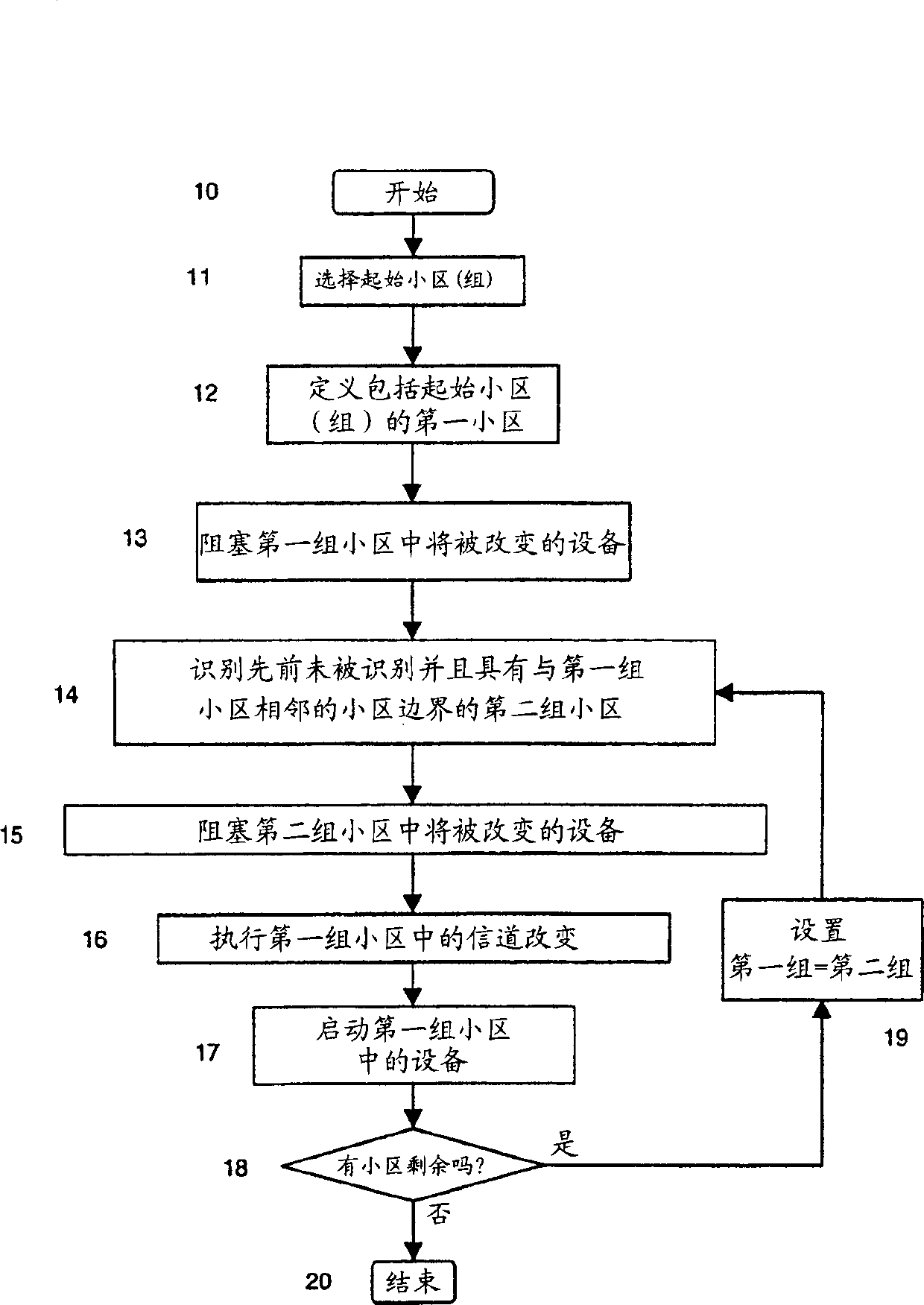

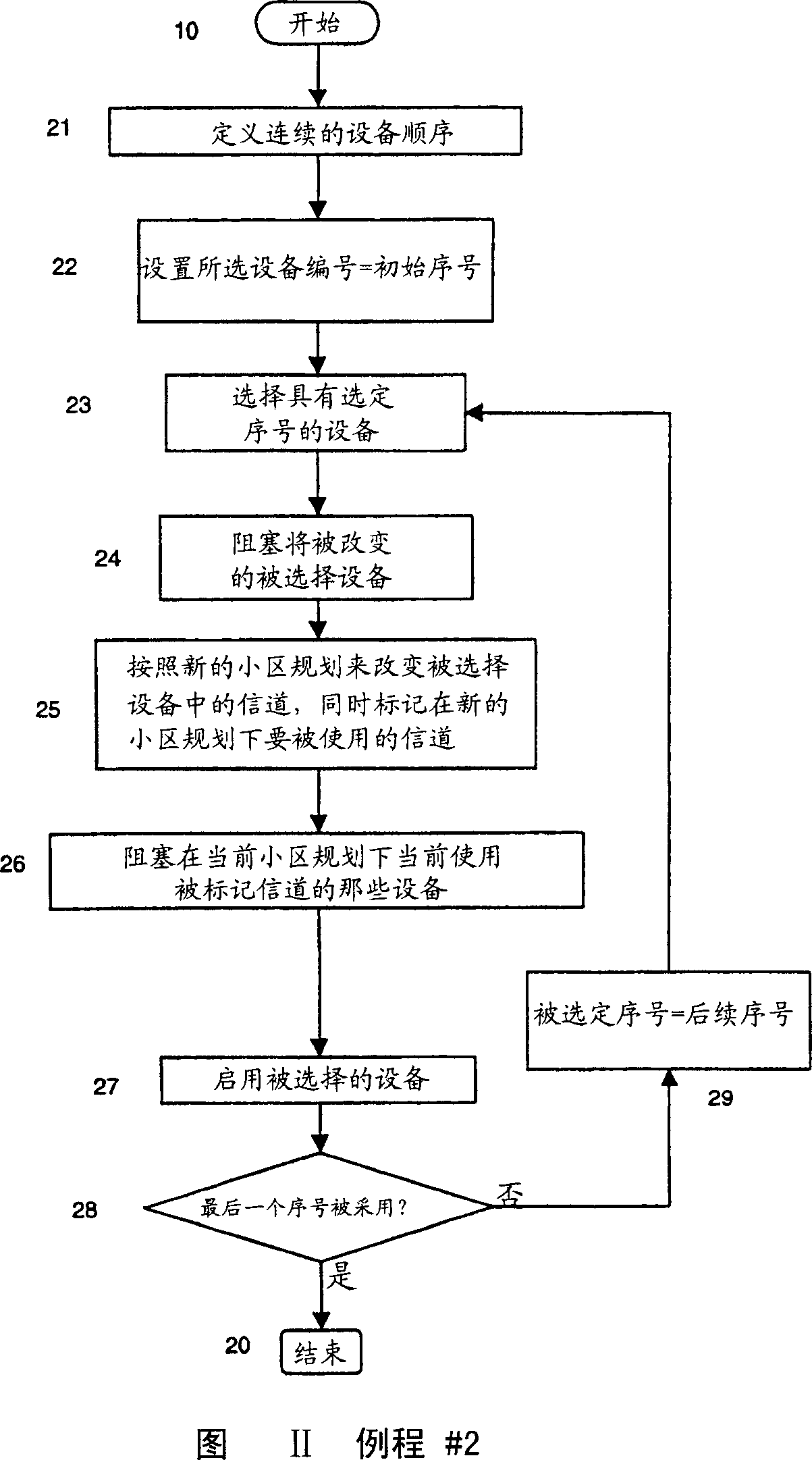

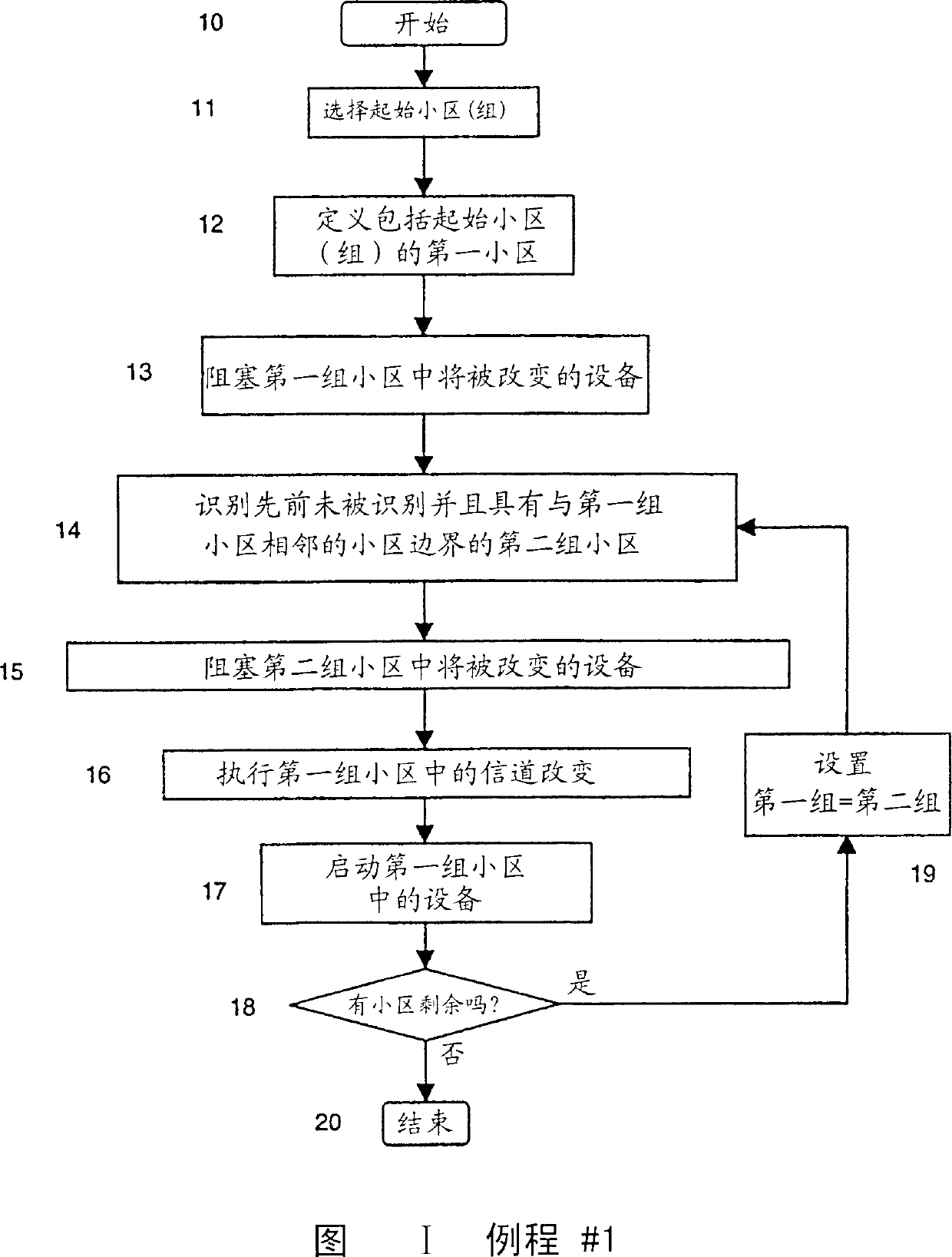

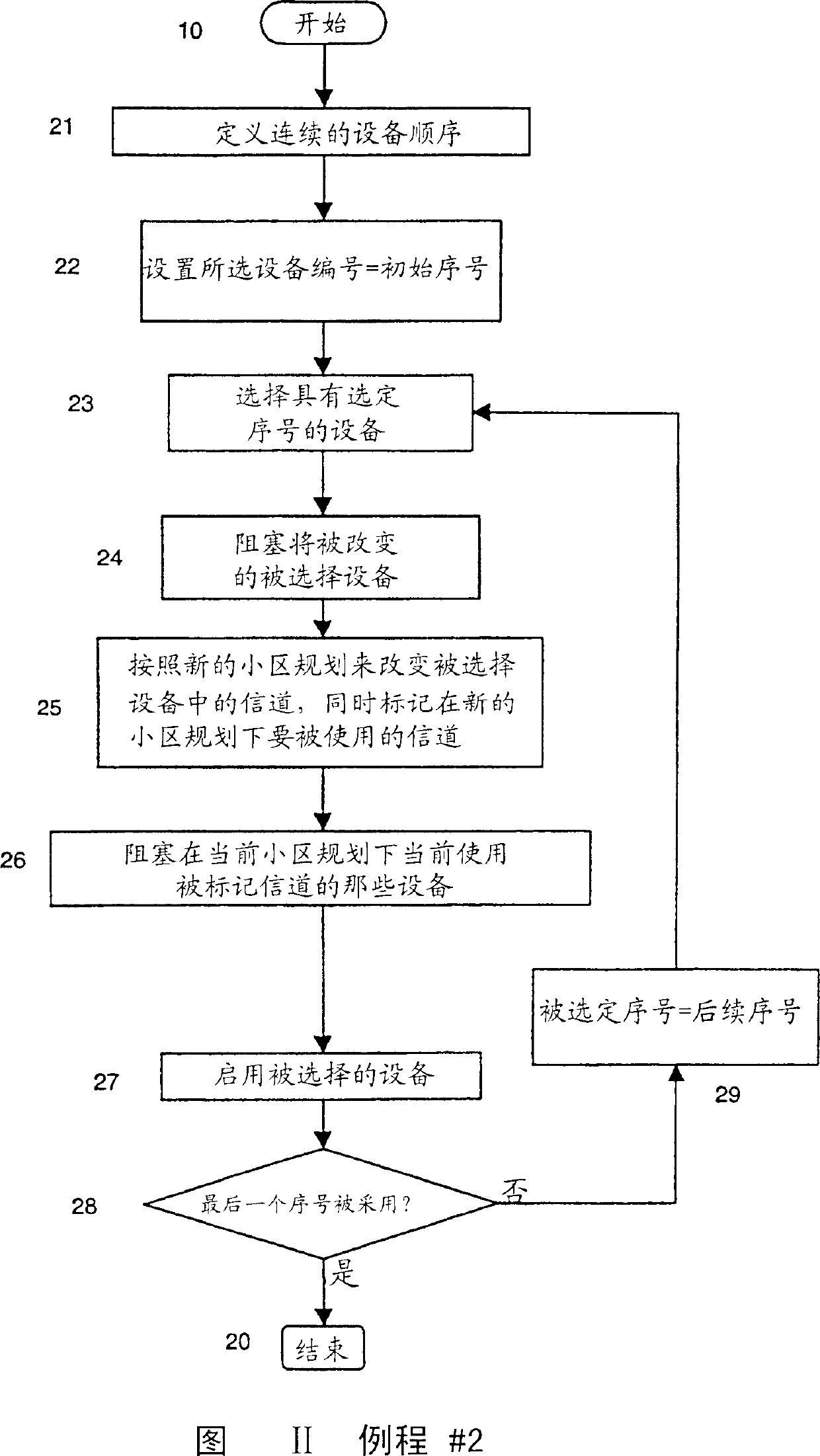

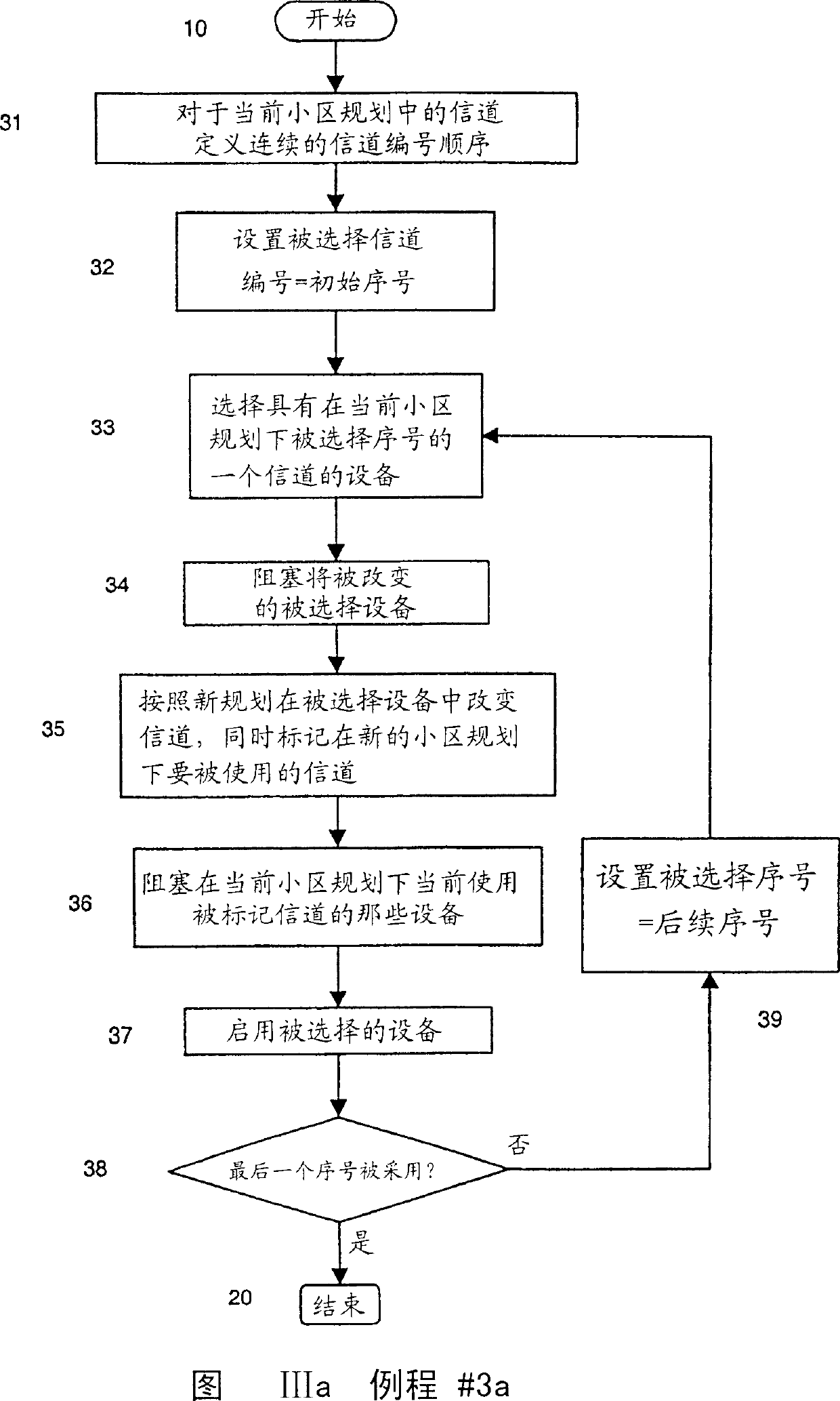

Automatic implementation of channel plan change in cellular network

InactiveCN1372775ARadio/inductive link selection arrangementsWireless communicationCurrent channelPlanned change

The invention relates to a method for automatically changing a channel from a current plan to a new predetermined plan in a cellular network, the cellular network comprising a plurality of cells, each cell corresponding to at least one device to which a device can be allocated Channels are used to transmit signals to and from mobile end stations in the cell. The method includes: determining how the equipment will be changed by a sequence number related to the cell location, the equipment number, the current channel number or the new channel number. The present invention provides efficient implementation of a given channel change causing minimal interference.

Owner:OPTIS CELLULAR TECH LLC

Method for operating an industrial scale installation and guidance system for same

ActiveUS20100023175A1Avoid unnecessary stoppage timeGuaranteed economical operationLevel controlRegistering/indicating working of machinesGuidance systemPower station

A method and a guidance system for operating an industrial scale installation, especially a power plant installation, are provided. For this method and guidance system a number of installation operating parameters characterizing the operating state of the installation and several component operating parameters of selected components of the installation are monitored and stored in a memory device. A characteristic fatigue value characterizing the current fatigue state of each component is determined, as required, using the stored installation operating parameters and / or the stored associated component operating parameters. The purpose of this method and guidance system is to develop an operation of the installation which protects resources. To this end, an associated fatigue prognosis value is determined from the characteristic fatigue value characterizing the current fatigue state for each selected component using guiding parameters characterizing a planned change of state.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

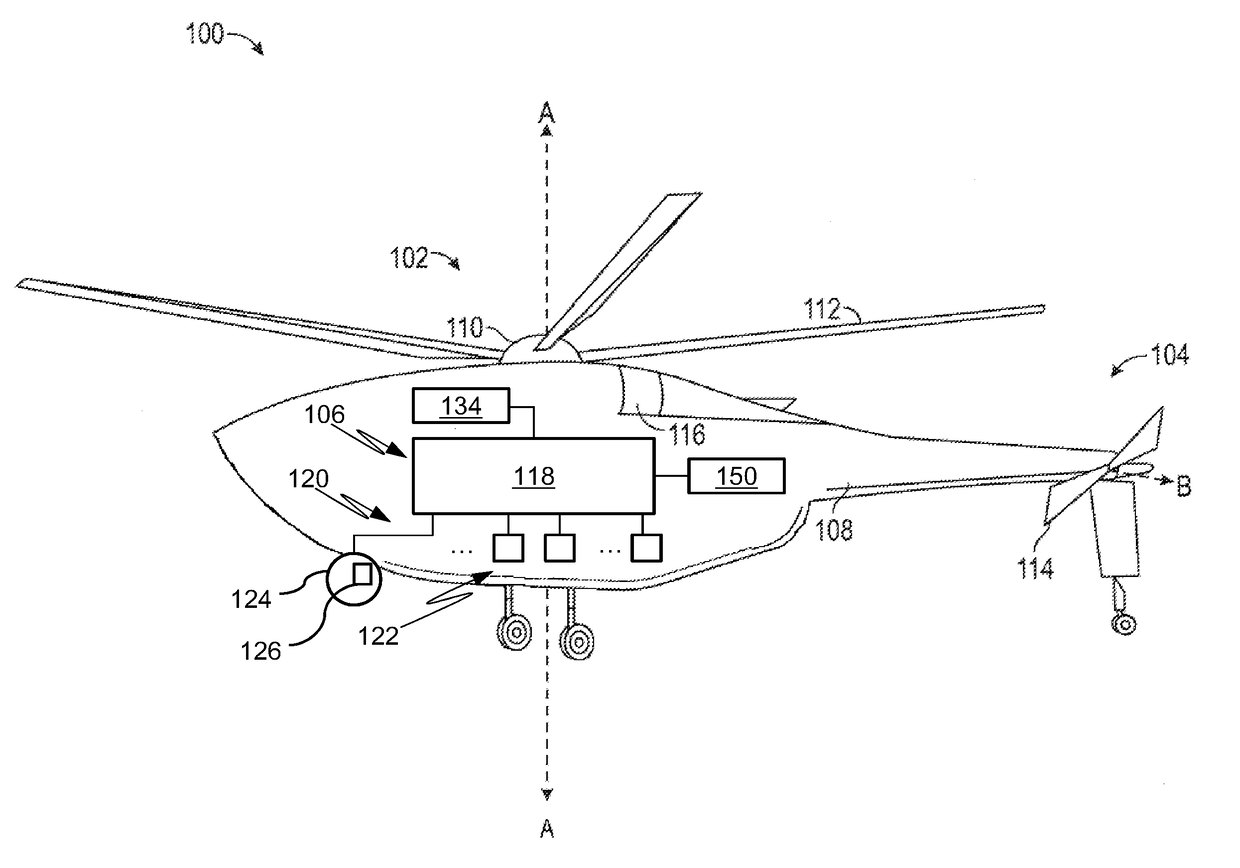

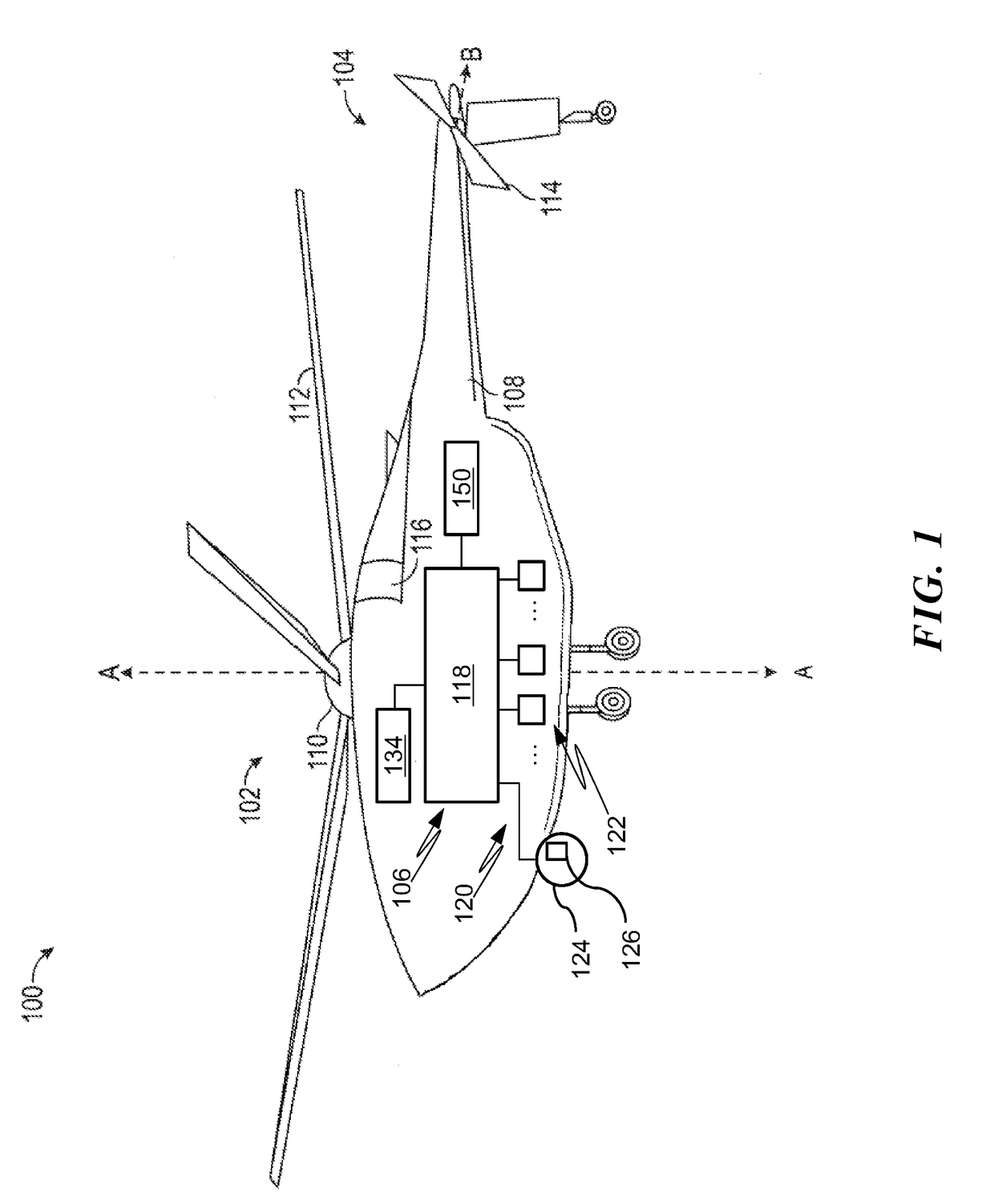

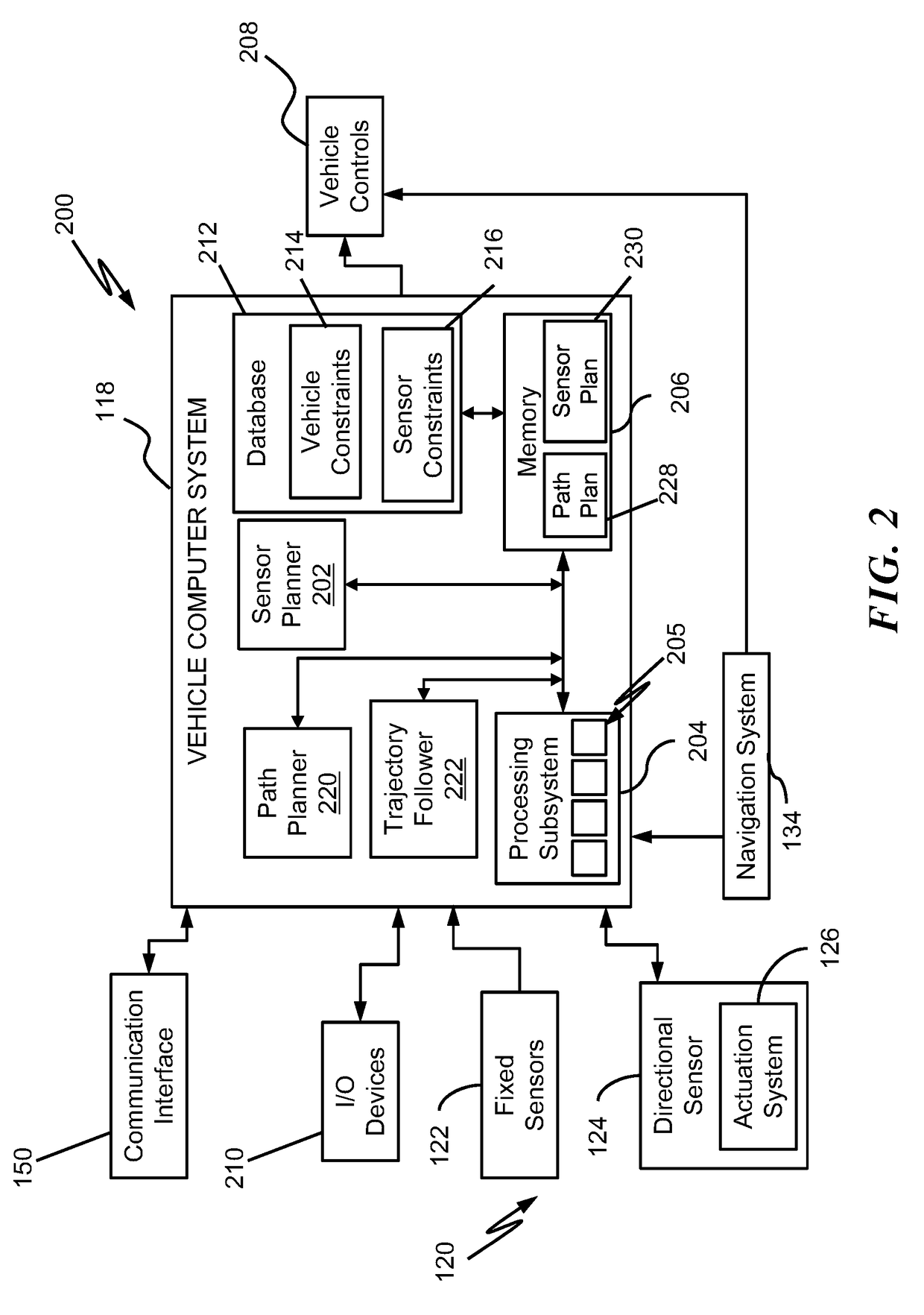

Trajectory-based sensor planning

ActiveUS20170242445A1Electromagnetic wave reradiationPosition/course control in three dimensionsPlanned changeSimulation

According to an aspect of the invention, a method of trajectory-based sensor planning for a vehicle includes receiving an indication of a planned change in a trajectory of the vehicle. A processing subsystem determines a current field of view of a directional sensor and a planned adjustment in the current field of view of the directional sensor relative to the vehicle to align with the planned change in the trajectory of the vehicle. The planned adjustment in the current field of view of the directional sensor is initiated prior to changing the trajectory of the vehicle.

Owner:SIKORSKY AIRCRAFT CORP

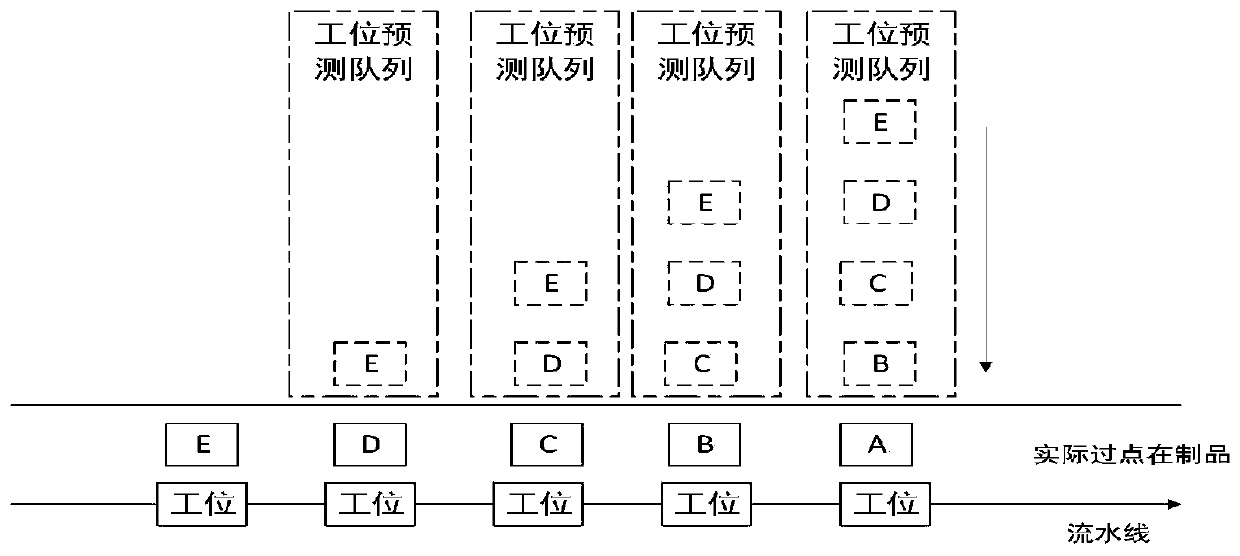

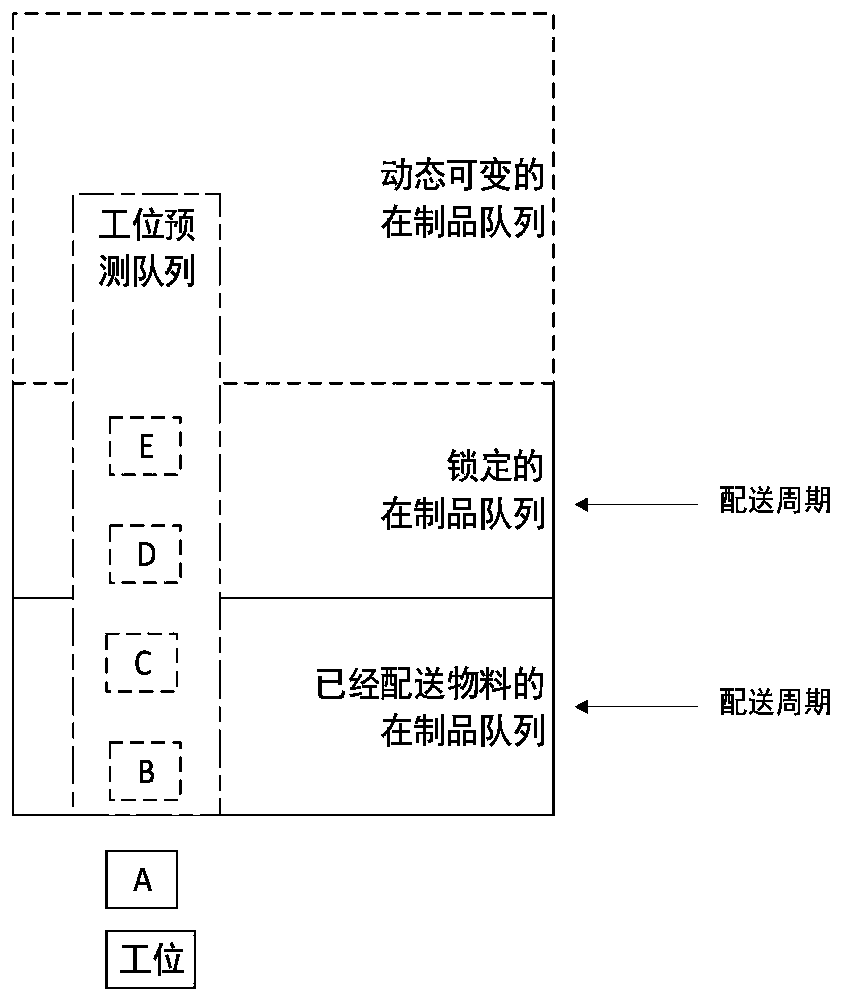

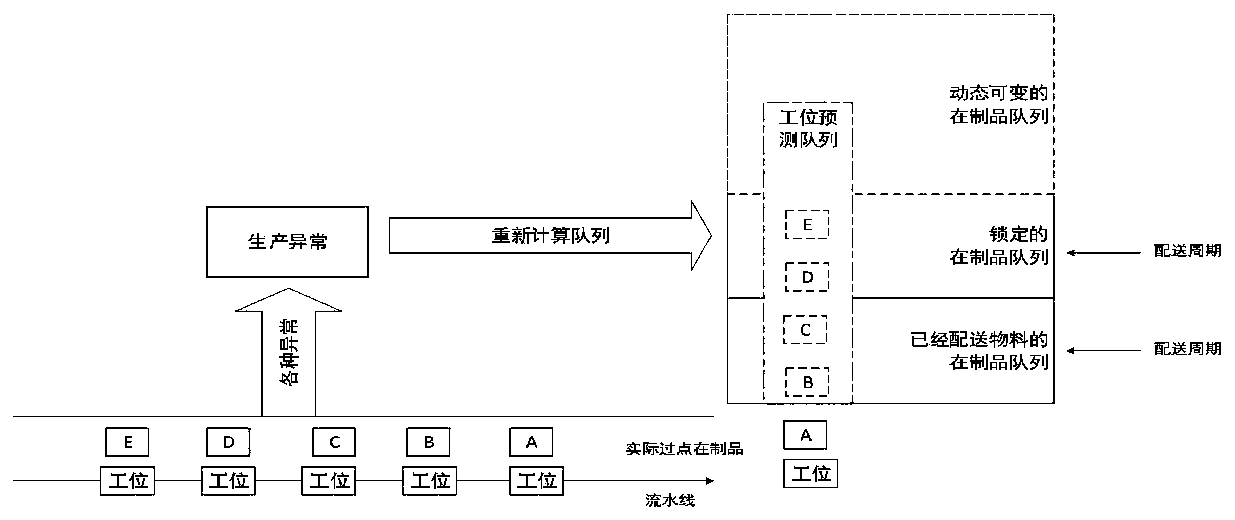

A method for predicting sequential delivery in a product queue based on dynamic adjustment prediction

ActiveCN109948972AChallengingEnsure matching production needsForecastingLogisticsPlanned changeMaterial distribution

Owner:CHINA NORTH IND NEW TECH PROMOTION INST +1

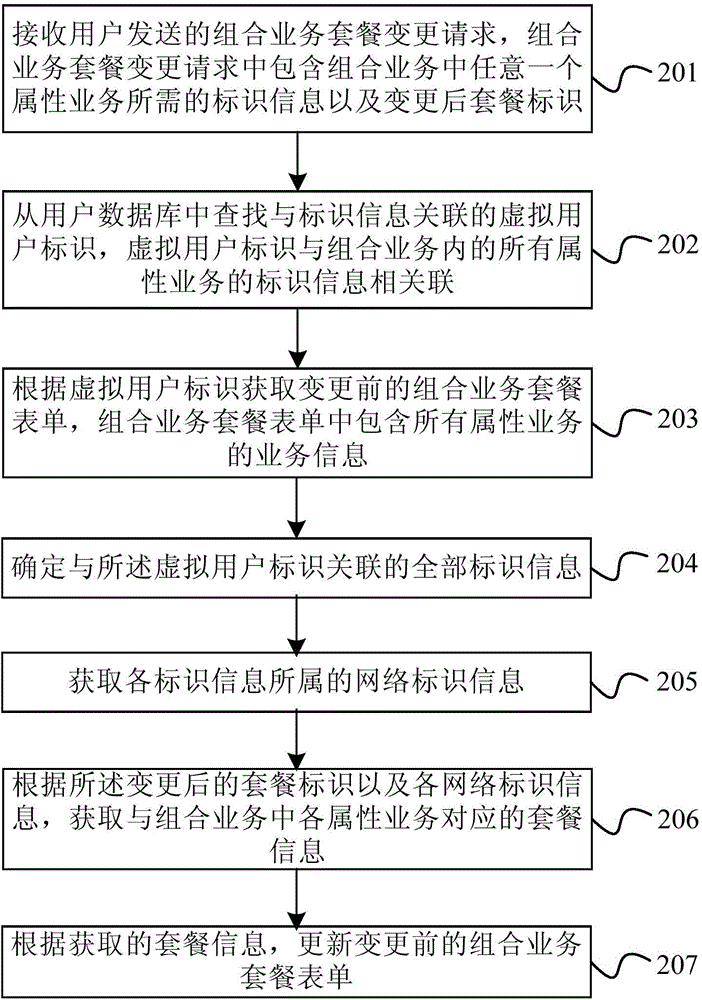

Combined service information processing method and device

ActiveCN104410757BSimplify the change handling processImprove processing efficiencySpecial service for subscribersInformation processingComposite services

The invention relates to a composite service information processing method and device. The method comprises the following steps: receiving a composite service plan change request sent by a user, wherein the composite service plan change request comprises identification information needed by any attribute service in a composite service, and a changed plan identifier; searching for a virtual user identifier correlated with the identification information from a user database, wherein the virtual user identifier is correlated with identification information of all attribute services in the composite service; acquiring an unchanged composite service plan form according to the virtual user identifier, wherein the composite service plan form comprises service information of all the attribute services; and updating the unchanged composite service plan form according to composite service plan information corresponding to the changed plan identifier. Therefore, parallel processing of a plurality of attribute services in the composite service is realized; the change processing process of a composite service plan is simplified greatly; and the composite service processing efficiency is increased.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

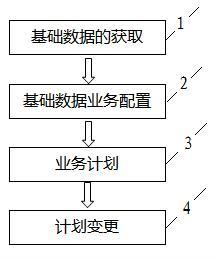

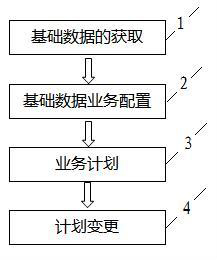

Comprehensive arrival-departure linkage business method

The invention discloses a comprehensive arrival-departure linkage business method, which comprises the following steps: 1, obtaining basic data, obtaining external ticketing system data through an interface program, and forming train timetable data required by an integrated platform after comparison of data; 2, configuring basic data business, and configuring business relations such as station tracks, check starting and closing time, broadcasting, orientation, waiting rooms, entrances, exits and gate machines for each train number in the train timetable data; 3, planning business, enabling the timetable data and configured basic data business of each train to be generated into execution time of each business in every day, operating corresponding business according to time sequence, and achieving consistency of execution of platform business; and 4, changing plans, and changing linkage corresponding business plans synchronously according to relevance of configuration. The comprehensive arrival-departure linkage business method can exchange and share information of various service systems of stations, and ensures consistent, accurate and efficient service for passengers.

Owner:苏州博远容天信息科技股份有限公司

Automatic implementation of channel plan change in cellular network

InactiveCN1218604CRadio/inductive link selection arrangementsWireless communicationPlanned changeMobile end

The invention concerns methods for automatically implementing channel changes from a current plan to a new predetermined plan in a cellular network comprising a plurality of cells, each cell corresponding to at least one equipment, to which a channel may be allocated for communicating signals to and from mobile end stations in the cell. The methods involve that the sequence for how the equipment should be changed is determined by an order number, relating to cell location, equipment number, present channel number or new channel number. The invention leads to an efficient implementation of given channel changes causing a minimum of disturbances.

Owner:OPTIS CELLULAR TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com