Component shipping method based on BIM technology

A component and technology technology, which is applied in the field of component shipment based on BIM technology, can solve the problems of difficult implementation of project progress control, time-consuming and labor-intensive loading and arrangement, and labor occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

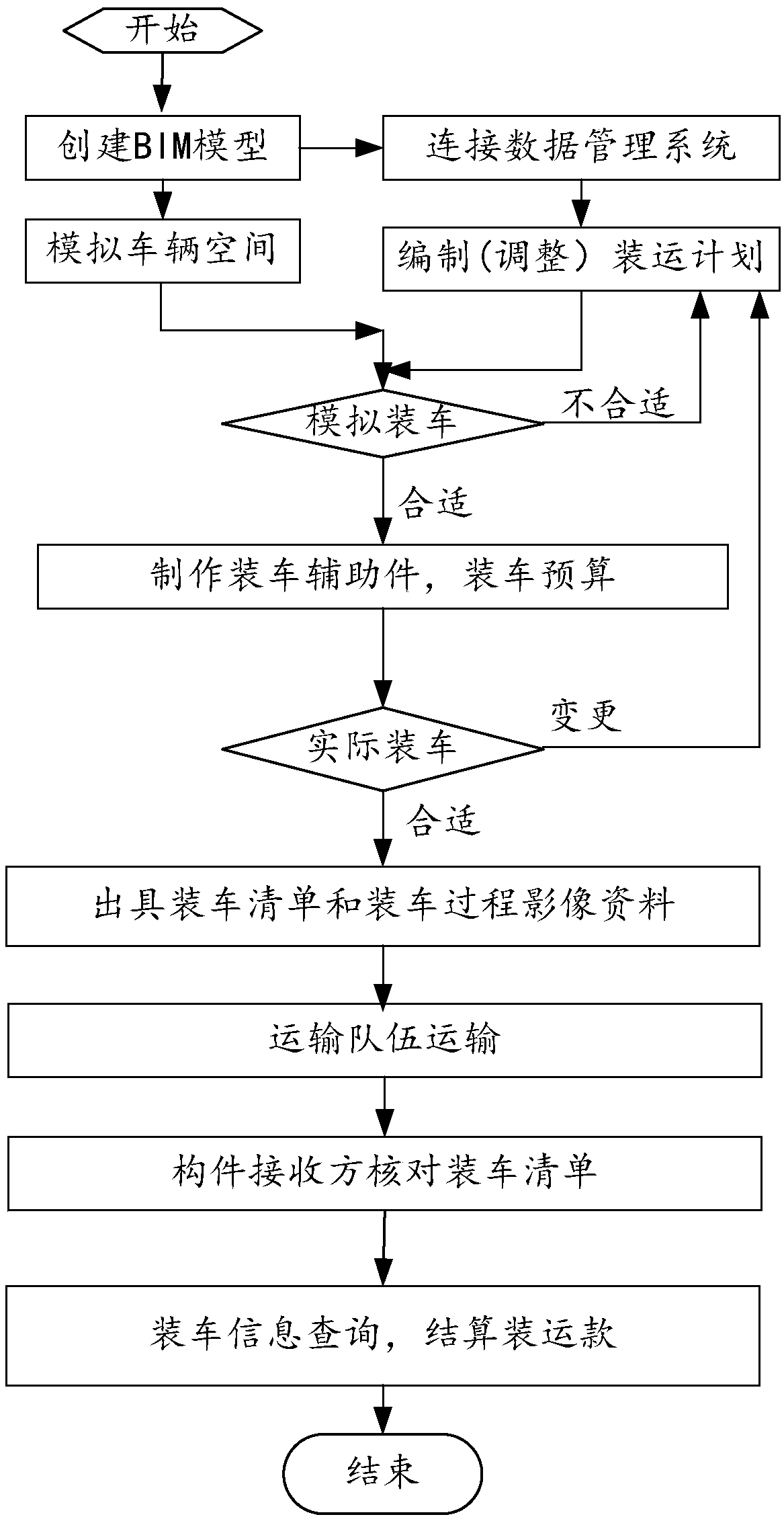

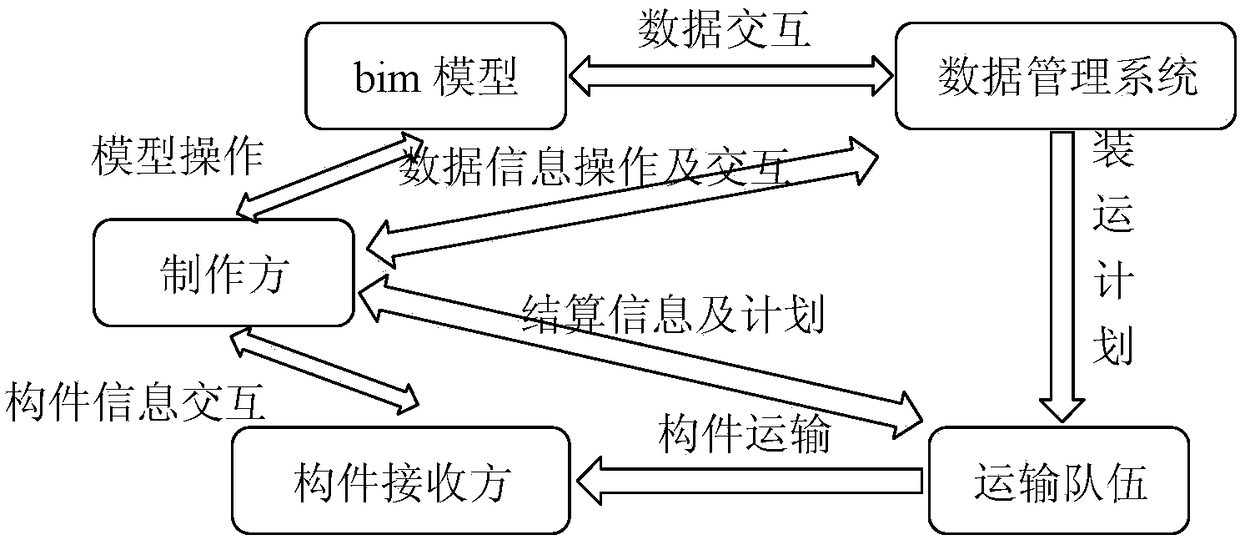

[0026] figure 1 It is a schematic flow chart of a component shipping method based on BIM technology in the present invention, figure 2 It is a schematic diagram of data communication of a component shipping method based on BIM technology in the present invention, as shown in the figure, a component shipping method based on BIM technology, the specific steps are as follows,

[0027] S1: The producer creates a BIM model based on the engineering blueprint and connects to the data management system, and the component receiver provides the preliminary component entry plan and change plan through the data management system. The BIM model contains component data including weight, volume, type and number, and is connected to the data management system through the data interface, so that the data management system can receive the data in the BIM model. The steel structure shipment plan needs to be prepared according to the steel structure production schedule and component entry plan....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com