Production plan change-oriented multi-objective constraint material substitution method

A production planning and multi-objective technology, applied in logistics, computing, data processing applications, etc., can solve problems such as no research records, infeasible scheduling plans, and few researches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

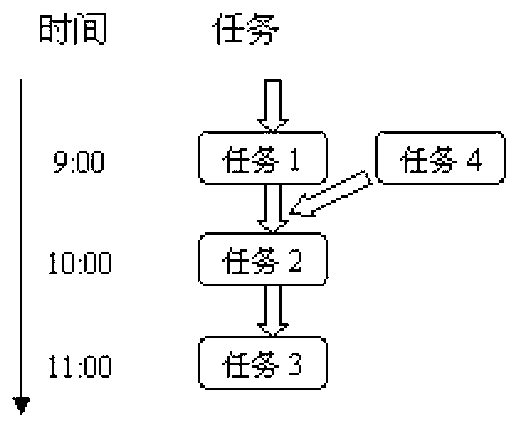

[0025] A multi-objective constrained material substitution method oriented to production plan changes, which includes the following steps:

[0026] Step 1: Establish a material substitution model;

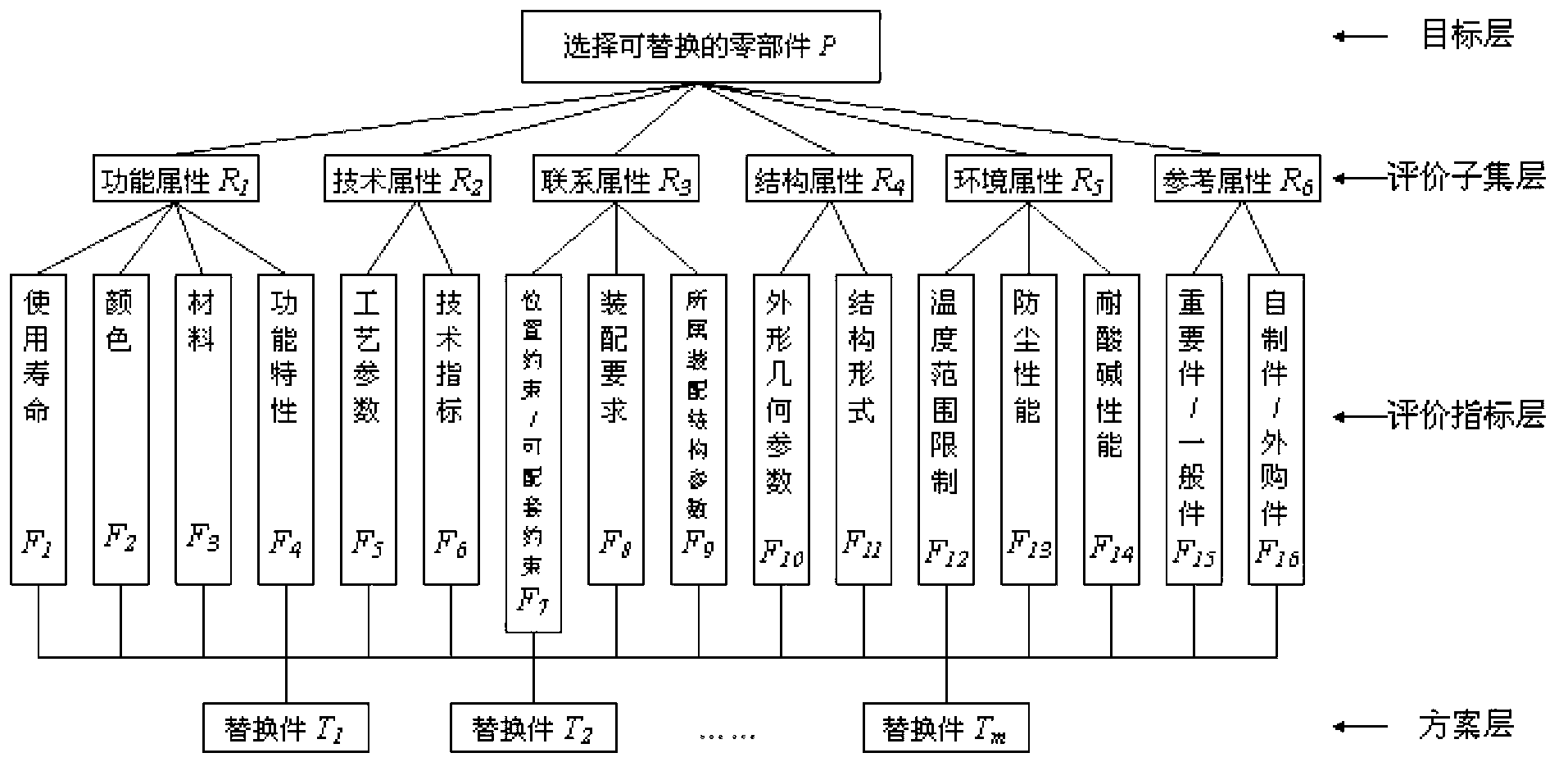

[0027] In the process of material replacement / displacement, different materials used in different planned tasks should be considered. In addition to the demand coordination among product BOM, process BOM, and planned BOM, different attributes of materials should also be considered Features to determine different material substitution rules and substitution models. The attribute features include design features, process features, and plan features. In general, the design features and process features are similar, but the plan features are different.

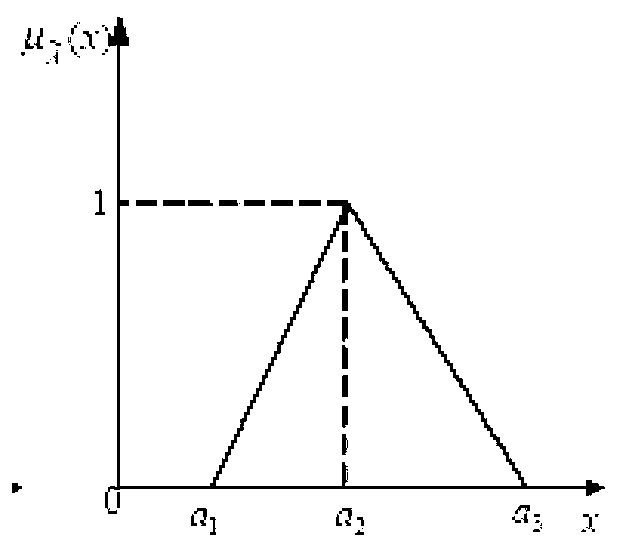

[0028] Dynamic material constraint rules (Dynamic Material Constrains): When establishing dynamic allocation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com