Process utilizing sheet billet continuous casting to manufacture low aluminum silicon calm carbon structural steel

A thin slab continuous casting, silicon-killed carbon technology, applied in the field of iron and steel smelting process, can solve the problems of increased manufacturing cost, excess product function, long production cycle, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further illustrated by the following examples.

[0013] In the embodiment, the process flow for producing low-aluminum-silicon killed carbon structural steel by thin slab short process is: blast furnace hot metal→converter smelting→LF refining→thin slab continuous casting.

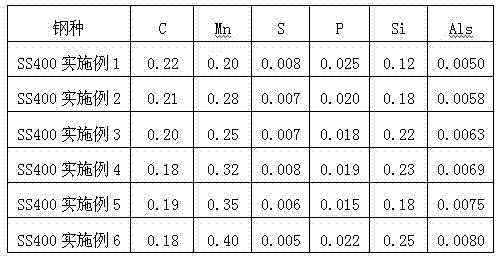

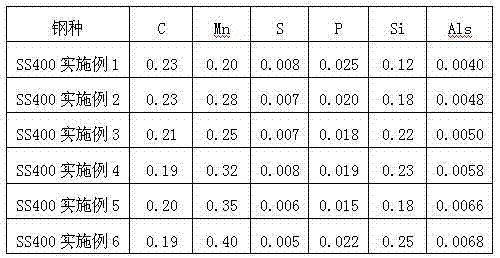

[0014] Example converter 150t, LF refining 150t, thin slab continuous casting: continuous casting slab width 1250-1500mm, thickness 65mm, production of low-aluminum silicon killed carbon structural steel, a total of six examples.

[0015] The specific operation steps and process parameter control of each process are as follows:

[0016] (1) Converter smelting process

[0017] a. The temperature of molten iron is 1350℃, S=0.030%, P=0.120%;

[0018] b. The main goal of the conversion process is to dephosphorize, and the slagging process is required to increase the furnace temperature steadily;

[0019] c. Final slag basicity R is 3.0-3.5, molten steel composition (mass percentage) C:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com