Continuous casting tundish nozzle replacement process

A continuous casting tundish and tundish technology, applied in manufacturing tools, casting equipment, metal processing equipment, etc., can solve problems such as the impact of operation time on slab quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

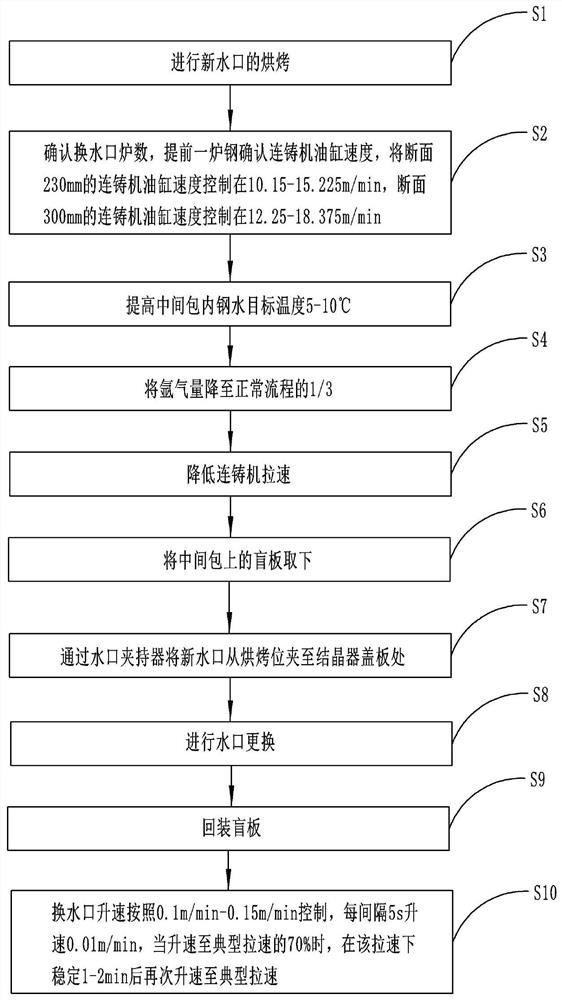

[0034] Such as figure 1 As shown, this embodiment provides a continuous casting tundish nozzle replacement process. During the operation steps, it is necessary to wear labor protection articles and put down the protective mask to effectively prevent facial burns. The specific operation of the continuous casting tundish nozzle replacement process is as follows:

[0035] S1. Baking the new nozzle, 40min≤baking time≤240min.

[0036] S2. Confirm the heat number of the water port, and confirm the speed of the oil cylinder. Confirm the cylinder speed one batch of steel in advance to control the crystallizer liquid level fluctuation during the replacement process. The continuous casting machine in this embodiment is a slab continuous casting machine, and includes a continuous casting machine with a section of 230 mm and a continuous casting machine with a section of 300 mm. The speed of the oil cylinder of the continuous casting machine with a section of 230mm is controlled at 10....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com