Continuous casting machine

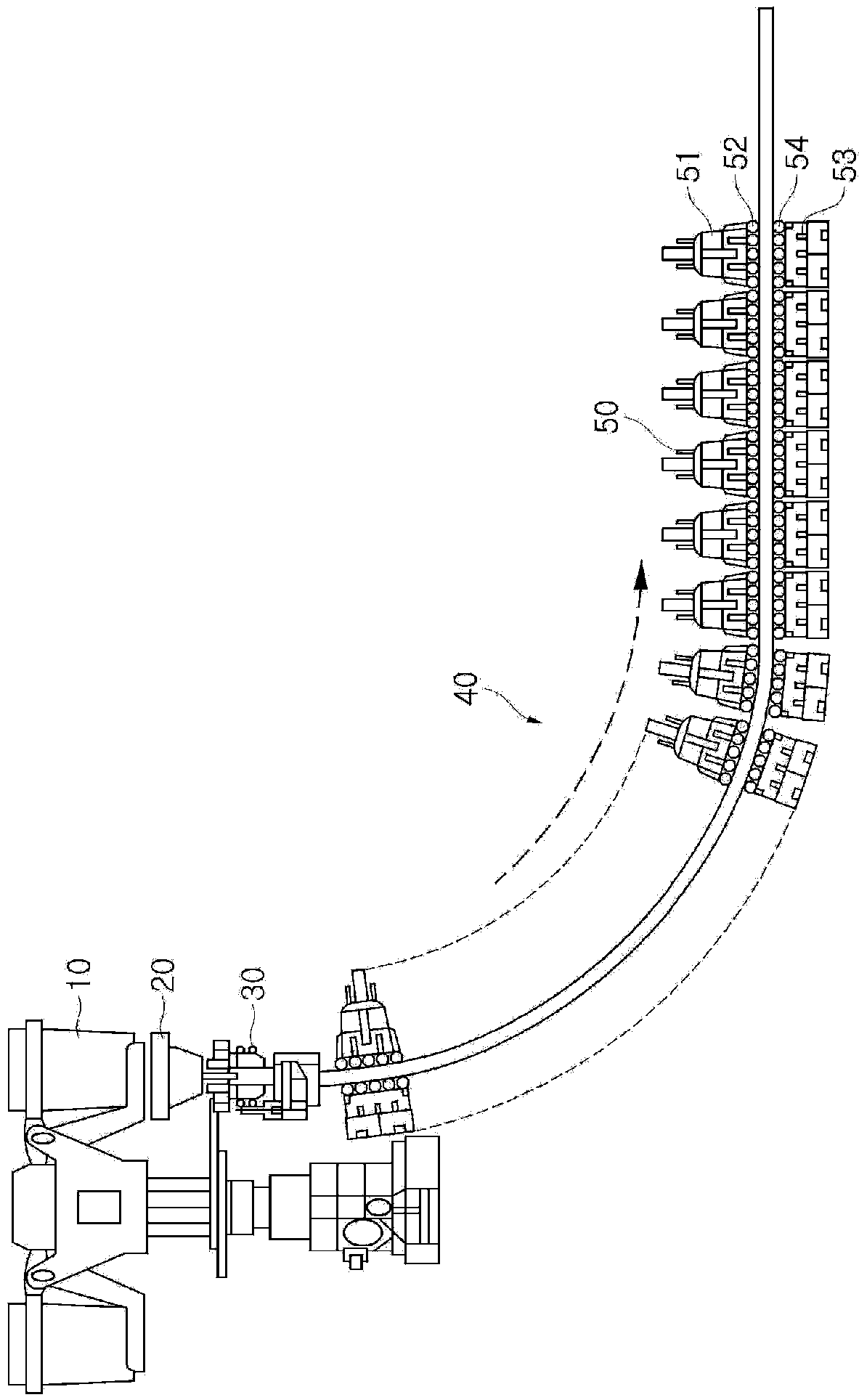

An equipment and continuous casting technology, applied in the field of continuous casting equipment, can solve the problems of mold liquid level fluctuation, the casting speed can no longer be increased, and the molten metal level changes, and the effect of reducing the liquid level fluctuation is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, specific embodiments of the present invention will be described in detail with reference to the accompanying drawings.

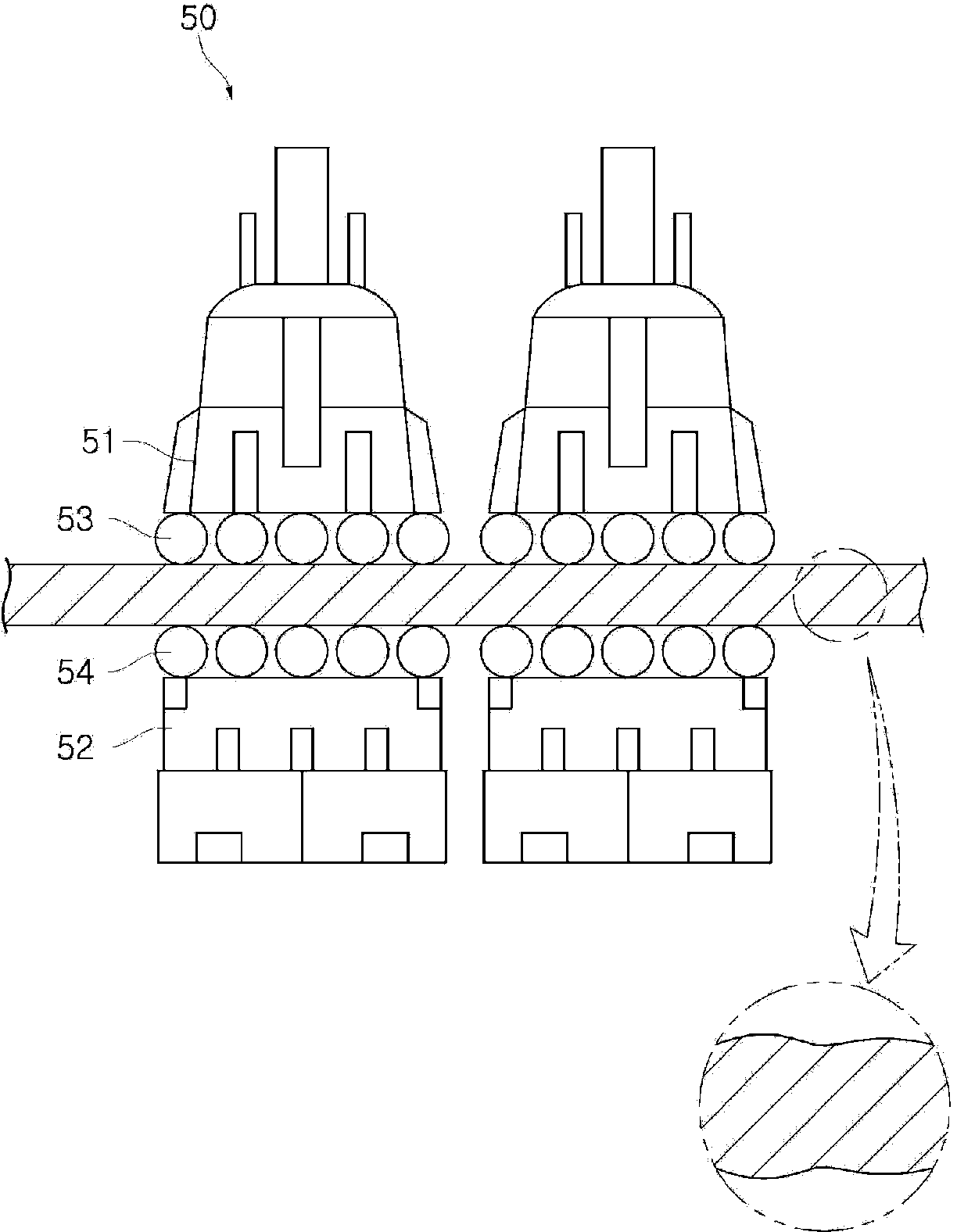

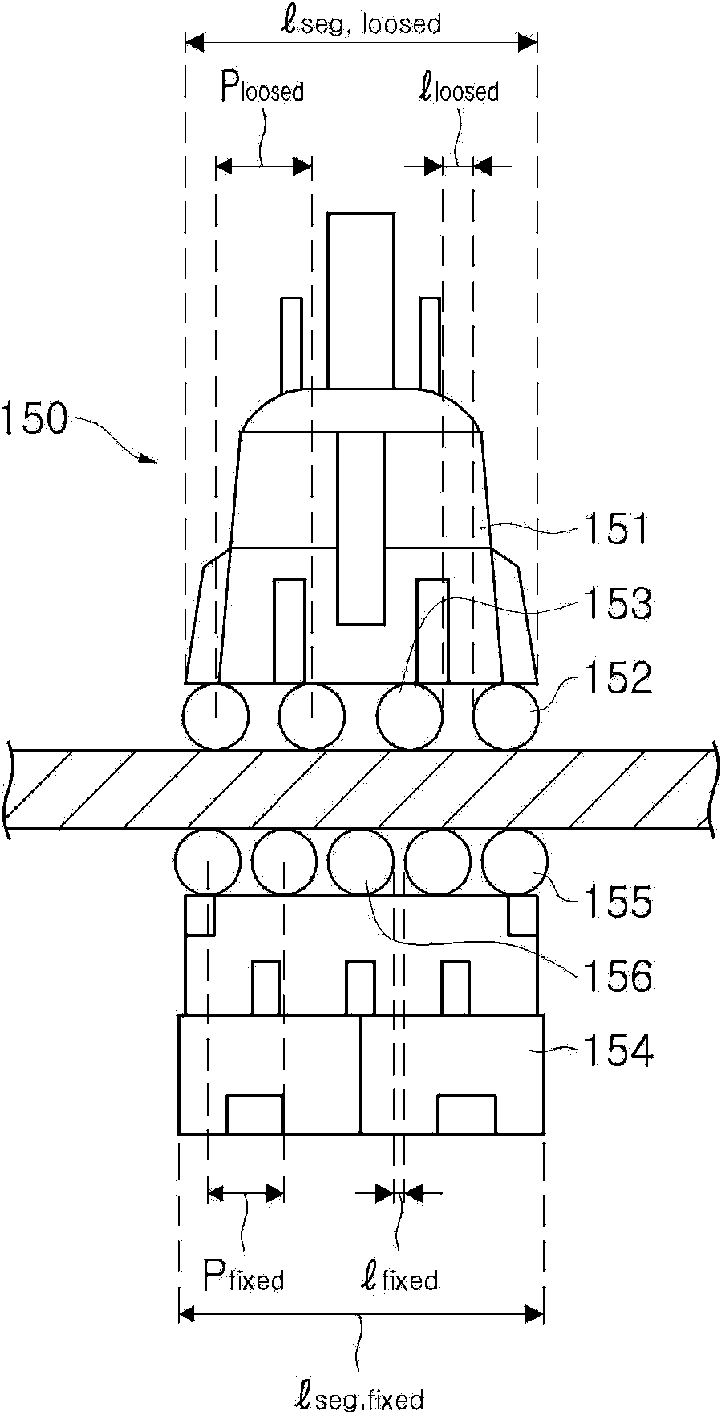

[0037] image 3 It is shown as a section of the invention, which is used in the horizontal part or the vertical part of the guide frame.

[0038] In the present invention, the section 150 includes: a loosed frame 151 as an inner frame, which is configured on the upper part and movable, and faces the radial center of the guide frame; and, a fixed frame (fixed frame) as an outer frame 154, which is configured at the bottom and fixed, and faces outward in the radial direction of the guide frame, wherein a plurality of rollers 152, 154 are arranged on the movable frame 151 and the fixed frame 154, and the plurality of rollers 152, 154 includes a pair of pinch rollers 153 , 156 .

[0039] In the movable frame 151 of the present invention, in the whole section length (l seg,loosed ) with multiple (N loosed ) the roller 152. Specifically, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com