Liquid gas circulation system

A liquid gas and circulating system technology, applied in pipeline systems, liquid degassing, auxiliary material liquid degassing, etc., can solve the problems of unstable liquid gas transmission, easy gasification of liquid gas, and difficult control of liquid level, etc. The effect of stable liquid level, reducing liquid level fluctuation and reducing discharge resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

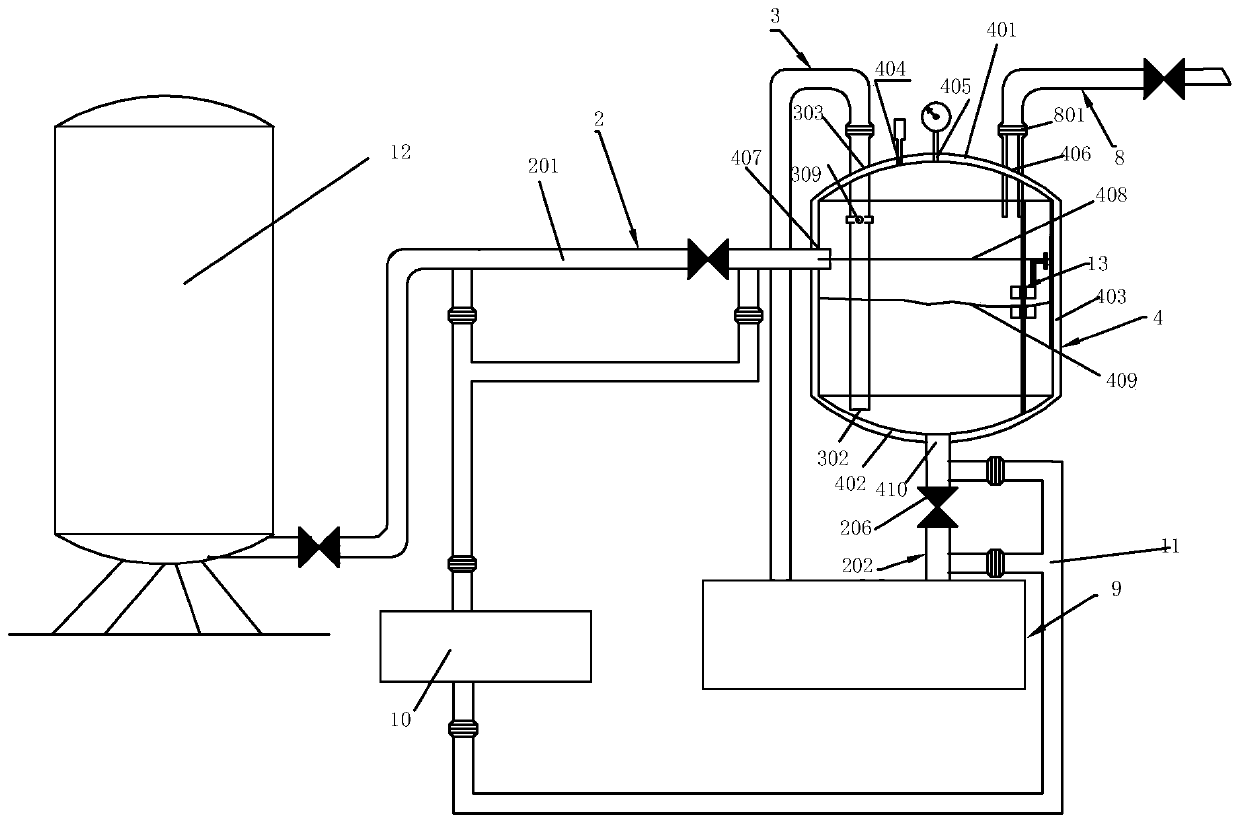

[0035] The system of the present invention will be further described below in conjunction with the accompanying drawings and examples.

[0036] like Figure 1-4 As shown, the liquid gas circulation system of the present invention will be described in detail below by taking the supply of liquid nitrogen for the MBE system as an example.

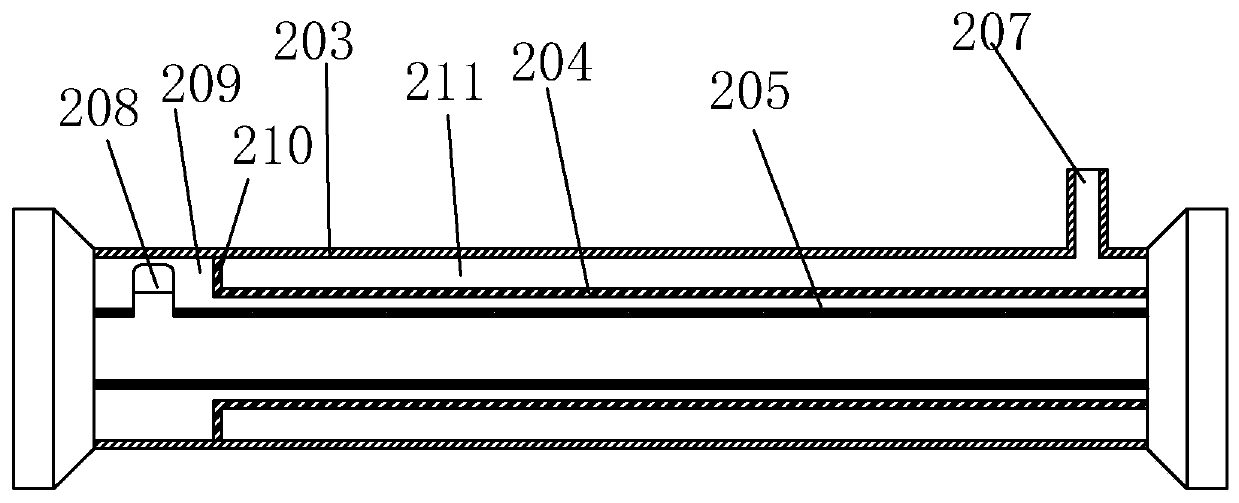

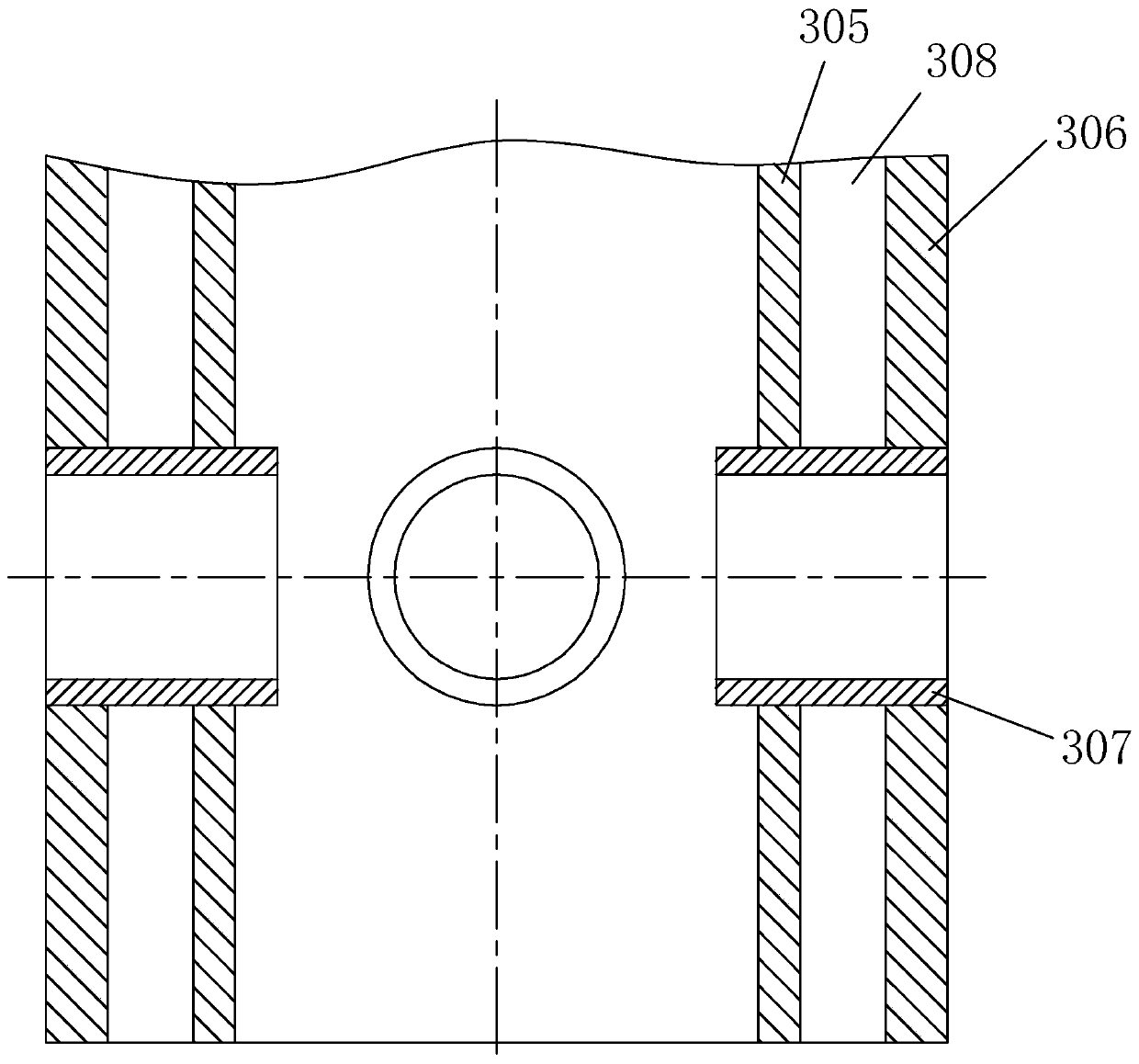

[0037] The liquid gas circulation system of the embodiment structure of the present invention includes a liquid nitrogen separator 4 , a vacuum infusion pipeline 2 , a liquid return pipe 3 , and an exhaust pipe 8 . The vacuum infusion pipeline includes a liquid inlet pipe 201 and a liquid outlet pipe 202 . The liquid nitrogen separator is provided with a liquid nitrogen inlet port 407 , a liquid nitrogen return port 303 , a nitrogen exhaust port 406 , a liquid outlet port 410 , a pressure gauge port 405 and a pressure protection port 404 . The vacuum stainless steel liquid inlet pipe 201 is connected to the liquid inlet 407 of the liquid nitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com