Soil remediation machine and remediation method based on local agglomeration detection, fragmentation and replenishment

A soil remediation and liquid replenishment technology, which is applied in the field of soil remediation machines and remediation, can solve the problems of unsatisfactory process saving and energy saving, prolonging the length of processing process, and unsatisfactory crushing effect, etc., so as to avoid waste of remediation liquid, The effect of improving the service life and the degree of automation and shortening the length of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is further described in conjunction with the following examples.

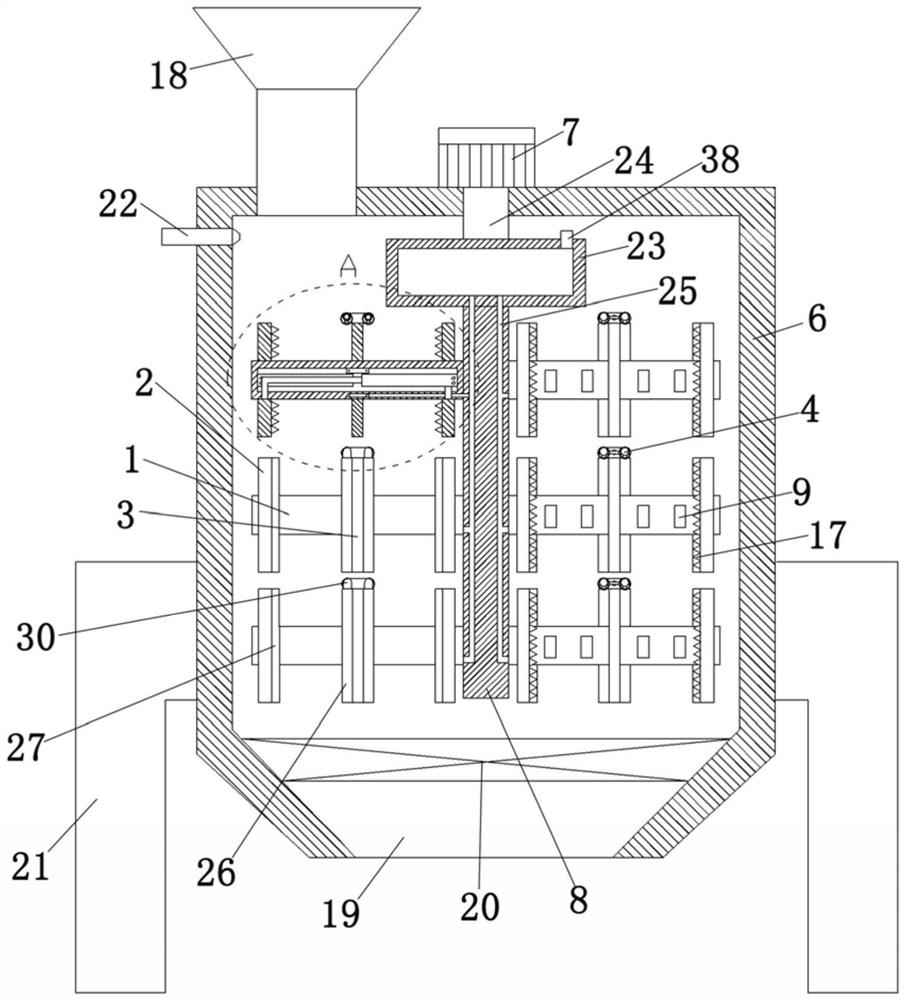

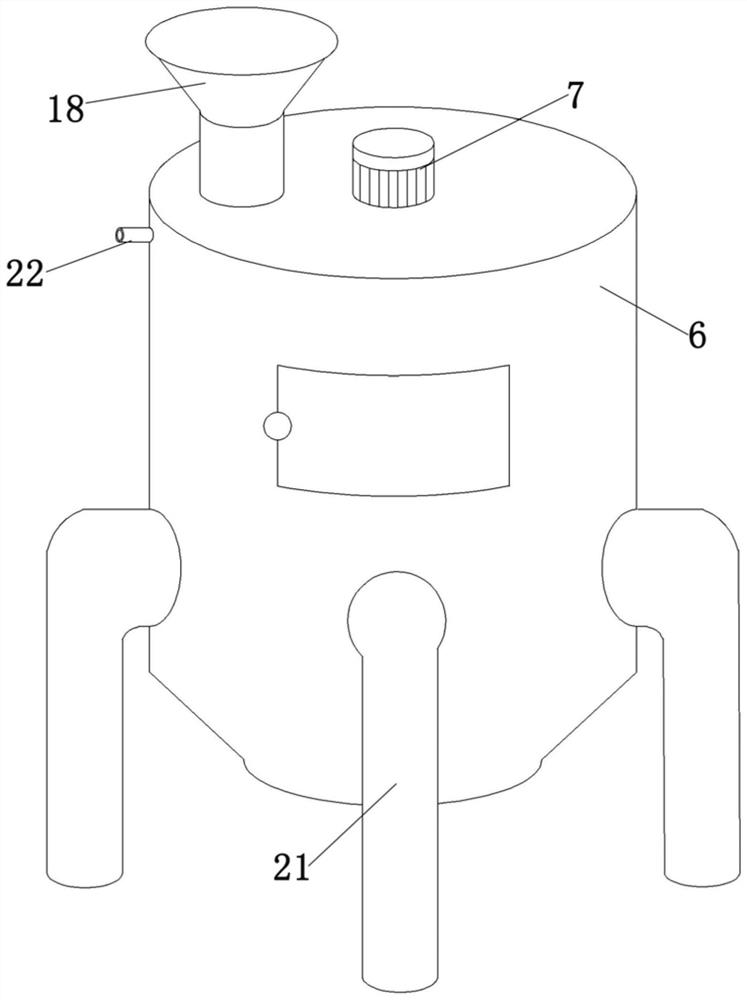

[0031] See eg Figure 1-10 The shown soil remediation machine based on localized agglomeration detection of broken and replenished fluids, including:

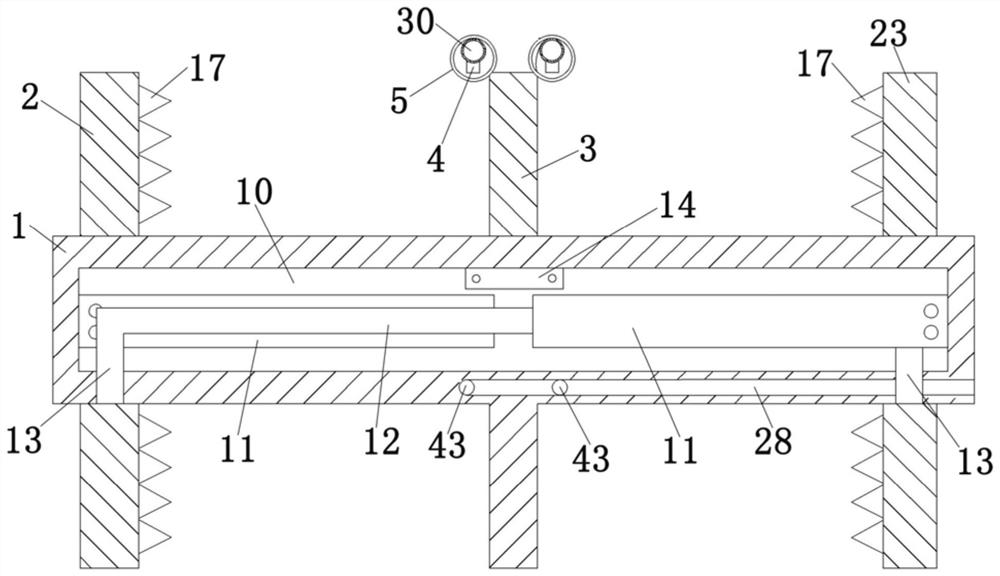

[0032] Stirring rod detection component: used to detect the soil agglomeration A that cannot be crushed by the stirring rod 1 when the stirring rod 1 hits the side wall of the soil during the rotation of the stirring rod 1 .

[0033] Partial pinching and crushing component: receiving the signal of the stirring rod detection component, it performs partial online pinching and crushing of the soil agglomerate A that cannot be crushed by the stirring rod 1.

[0034] Partial repair fluid replenishment component: integrated on the local pinch crushing component and linked with the local pinch crushing component, using the kinetic energy of the moving pinch plate 2 to provide a pressure head for the repair fluid, and pinching and crushing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com