Combined magnesium alloy casting-rolling machine front box liquid supply device

A combined casting and rolling machine technology, applied in the field of magnesium alloy casting and rolling, can solve the problems of large swing range of connecting rod, large liquid level fluctuation, and nozzle pressure fluctuation, so as to reduce the impact of liquid level and reduce oxide impurities , to achieve the effect of steady flow control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention. Based on the solutions in the present invention, all other solutions obtained by those of ordinary skill in the art without creative work are all Belong to the protection scope of the present invention.

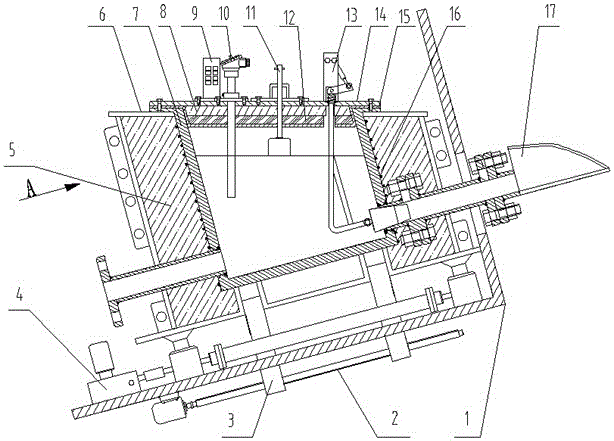

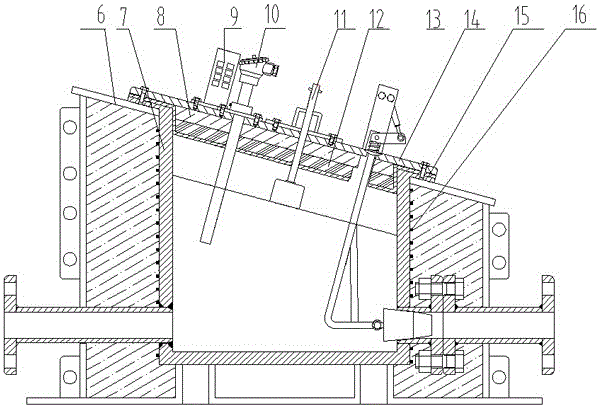

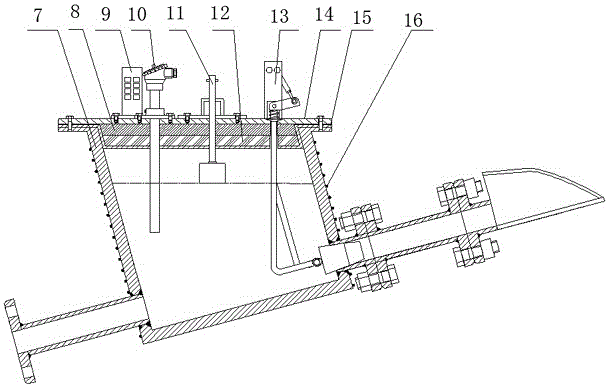

[0026] Such as Figure 1~3 As shown, a combined magnesium alloy casting and rolling machine front box with adjustment function in this embodiment mainly includes a vehicle frame 1, a screw nut mechanism 2, a drag slider 3, a screw jack 4, and a combined box body 5 and nozzle 17; the combined box body 5 includes a split shell 6, an inner tank 7, an insulating material 8, a protective gas input pipe 9, a temperature sensor 10, a liquid level detection device 11, a sealing material 12, a lead plug control flow device 13, cover plate 14, front case cover 15, and resistance band 16; wherein, the protective g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com