Automobile wheel casing part trimming die

A technology for trimming molds and parts, which is applied in the field of trimming molds for automobile wheel cover parts, which can solve the problems of operator safety hazards, easy damage of concealed punches, and inaccurate guidance, so as to improve product qualification rate, stabilize product quality, The effect of solving security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

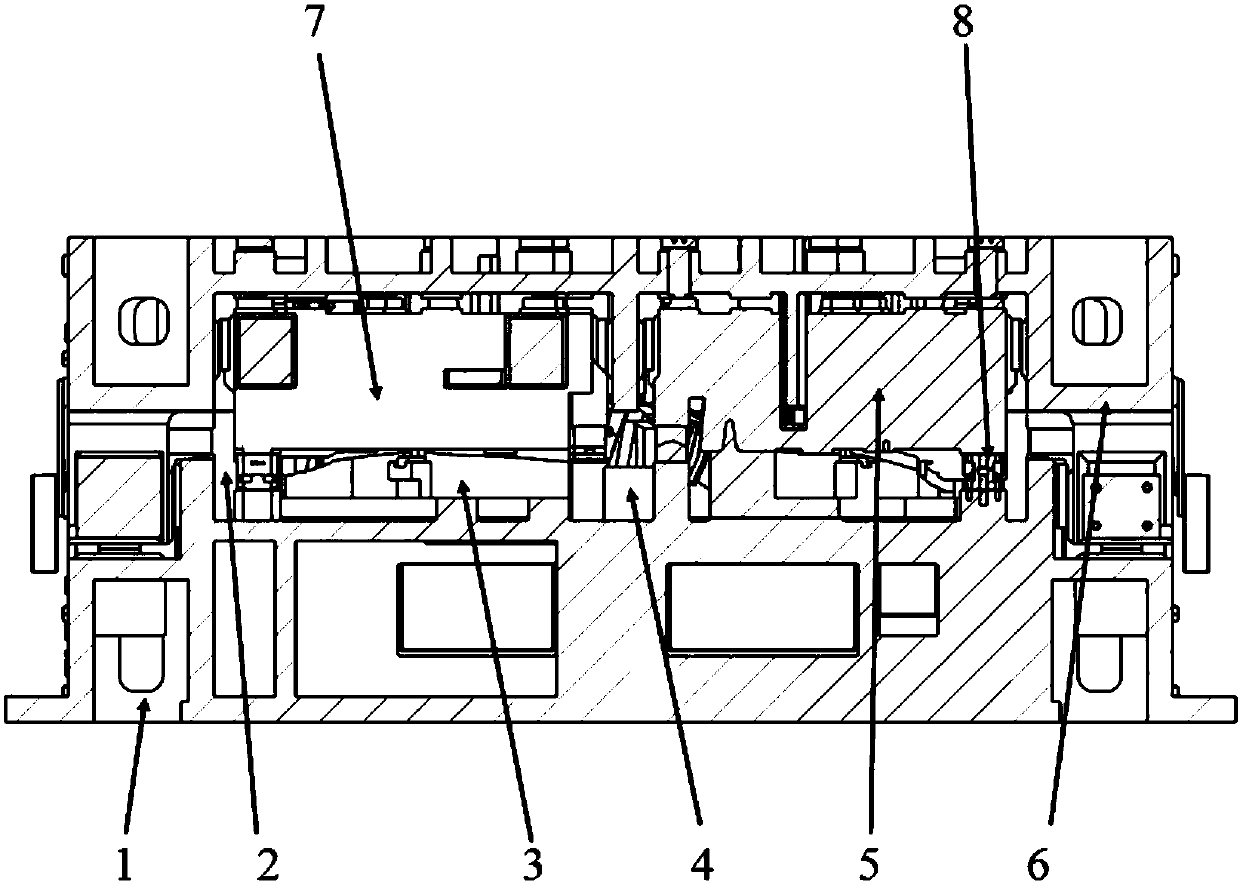

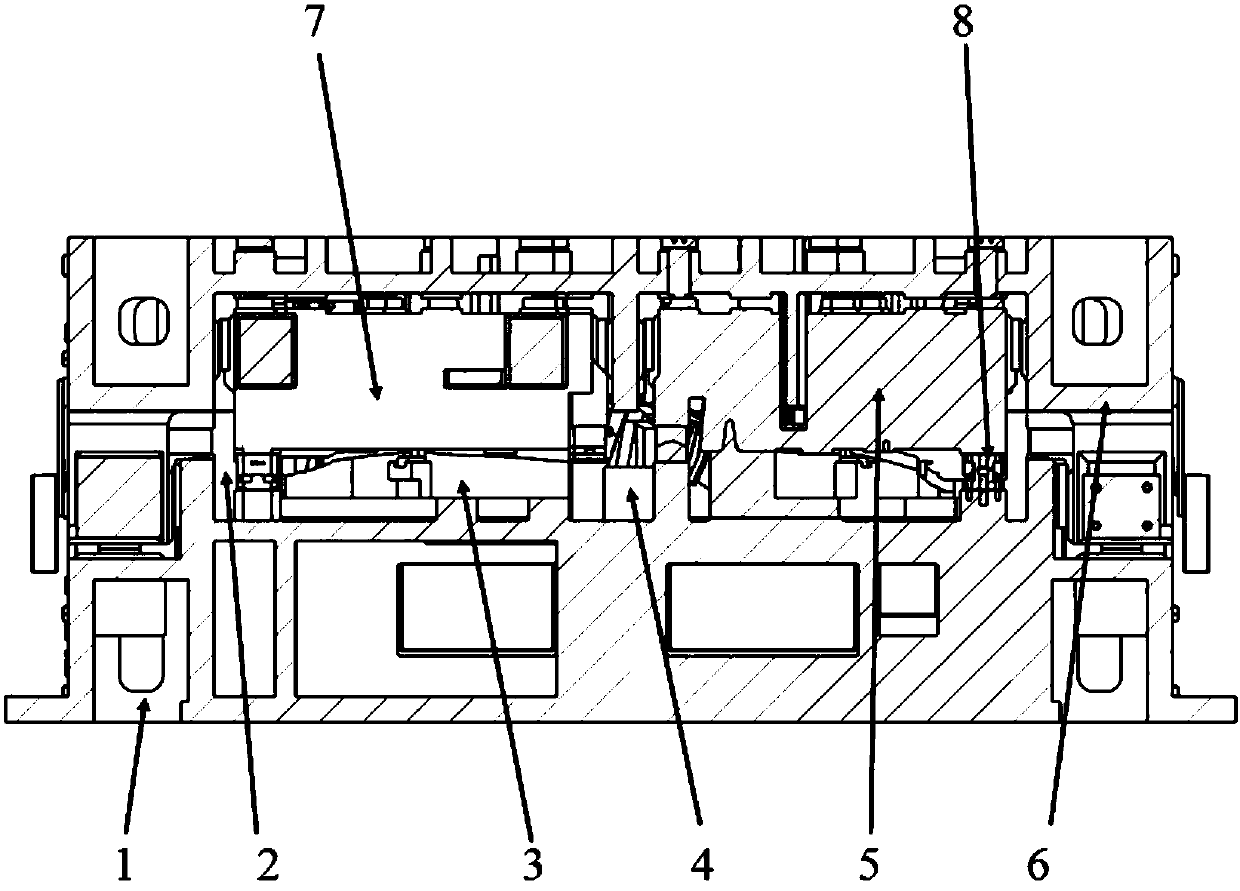

[0023] A kind of trimming mold of automobile wheel cover parts, its structure is as follows figure 1 As shown, it includes an upper mold and a lower mold. The upper mold includes an upper mold base 6, an upper mold presser 5, an upper mold insert 2 and an upper die trimming knife block 4, and an upper mold presser 5 is located below the upper die base 6. The upper die insert 2 and the upper die trimming cutter block 4 are located on the upper die base 6, and the upper die trimming cutter block 4 is arranged on the outer periphery of the workpiece to realize full-circle trimming. The lower mold includes a lower mold base 1, a lower mold core 3 and an ejector mechanism, the lower mold core 3 is positioned above the lower mold base 1, and the ejector mechanism is positioned on the lower mold base 1. In addition, it also includes a conical positioning block 8, which is sleeved on the guide plate provided on the lower mold base 1, and is a conical structure, the bottom of which is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com