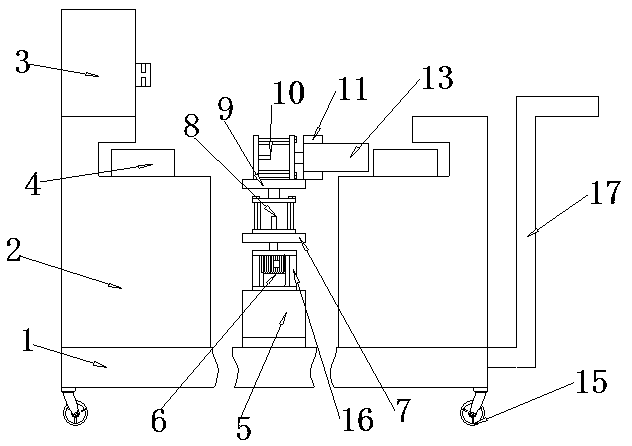

Wire cutting machine with automatic material box replacing function

A technology of automatic replacement and cutting machine, applied in the field of cutting machine, can solve the problems of trouble, waste of manpower, wire falling into the material box, etc., to achieve the effect of convenient use and convenient centralized placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

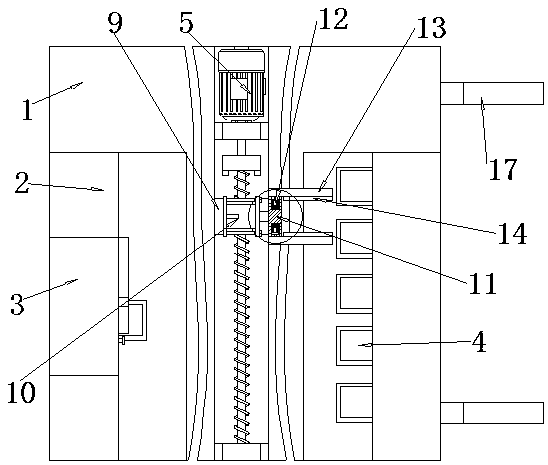

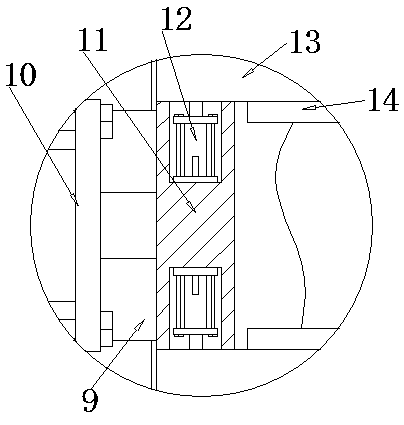

Method used

Image

Examples

Embodiment

[0021] Embodiment: when in use, turn on the power supply, make this device energize, the wire that needs to cut is placed on the cutting machine 3 and prepares according to routine operation, wherein one material box 4 is placed on the below of the cutting machine 3 discharging openings, The wire cutter 3 starts to work and cuts the wire. After cutting the fallen wire, it will fall into the material box 4. After the set time is reached, the second electric push rod 10 installed on the carrier plate 9 receives the signal from the motor driver. , drive the fixed plate 11 installed on its telescopic end to move horizontally, so that the splint 13 stops after being positioned at both sides of the material box 4, and the third electric push rod 12 installed in the fixed plate 11 drives after receiving the signal from the motor driver. The splint 13 installed on its telescopic end shrinks and tightens the material box 4. After the tightening is completed, the first electric push rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com