Bottle preform water replenisher

A technology for replenishing water and bottle embryos is applied in the field of grouting ceramic bottle production equipment, which can solve the problems of poor water replenishment effect, high labor intensity of staff, irregular shapes, etc., and achieve the effect of simple structure, good water replenishment and cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below through specific examples.

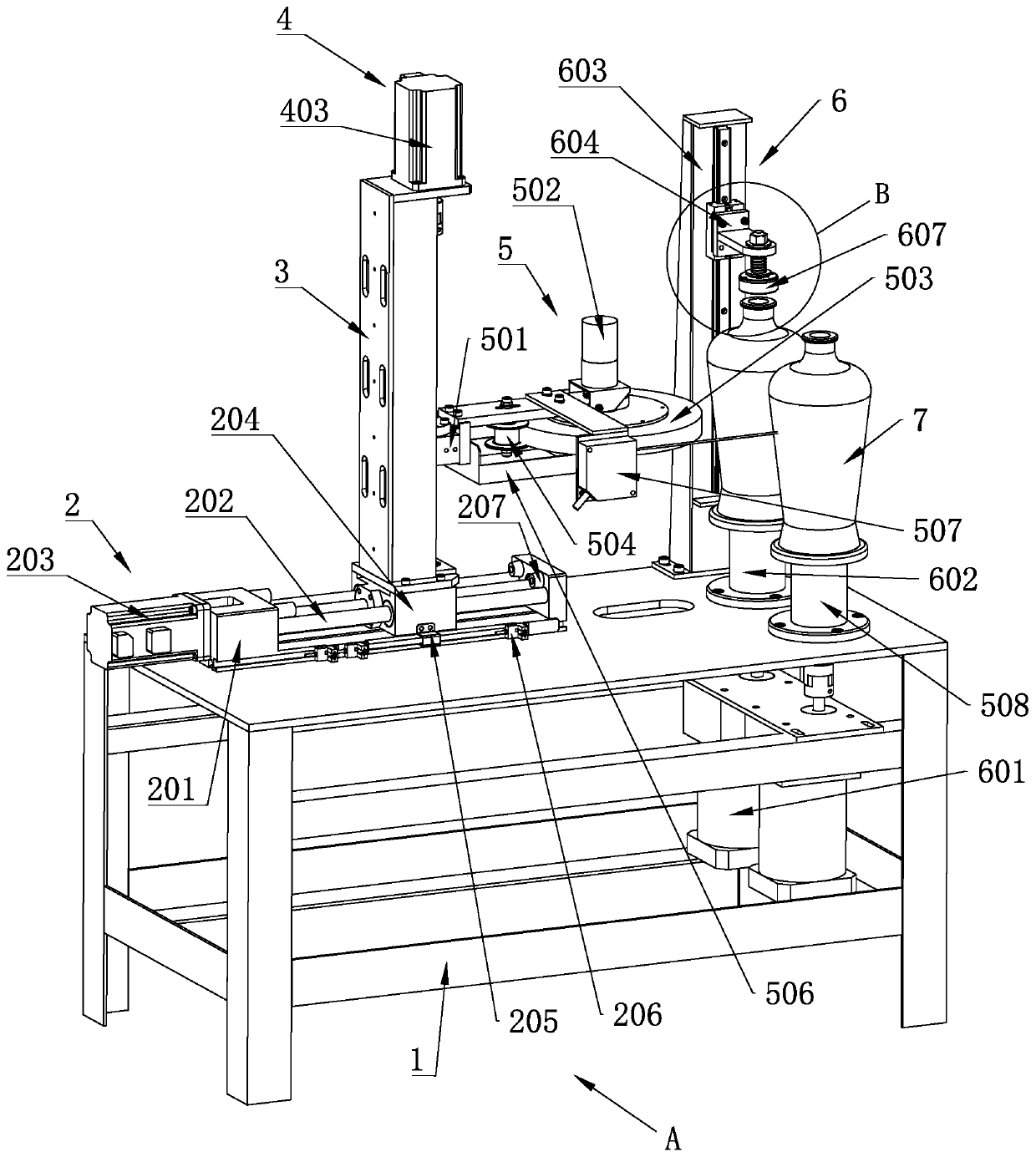

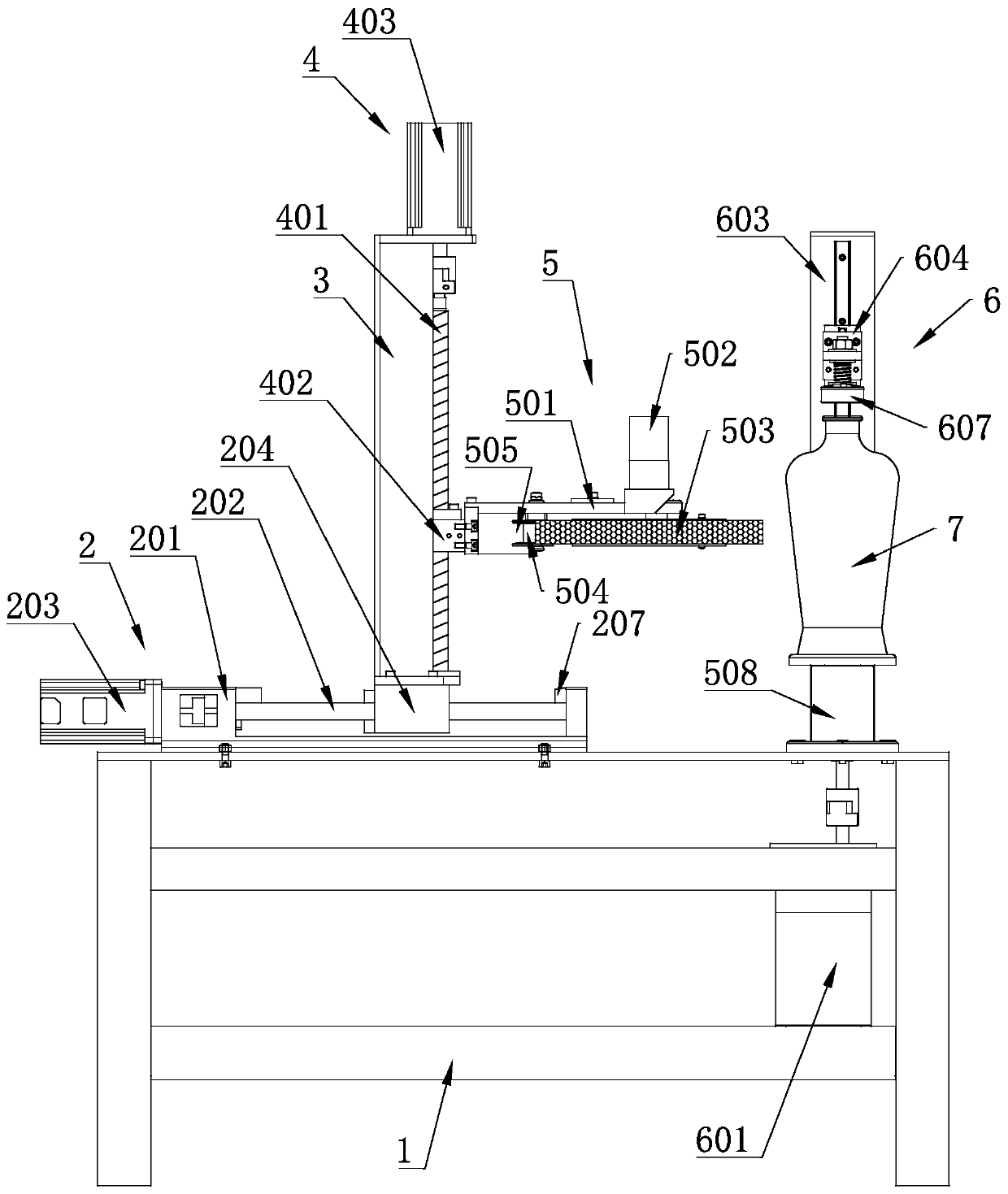

[0039]For ease of description, it is defined that: the length direction of the rack 1 is the X axis, and the height direction of the rack 1 is the Z axis. The preform mentioned in this embodiment can also be other ceramic products, for example, the preform of a ceramic can is also applicable.

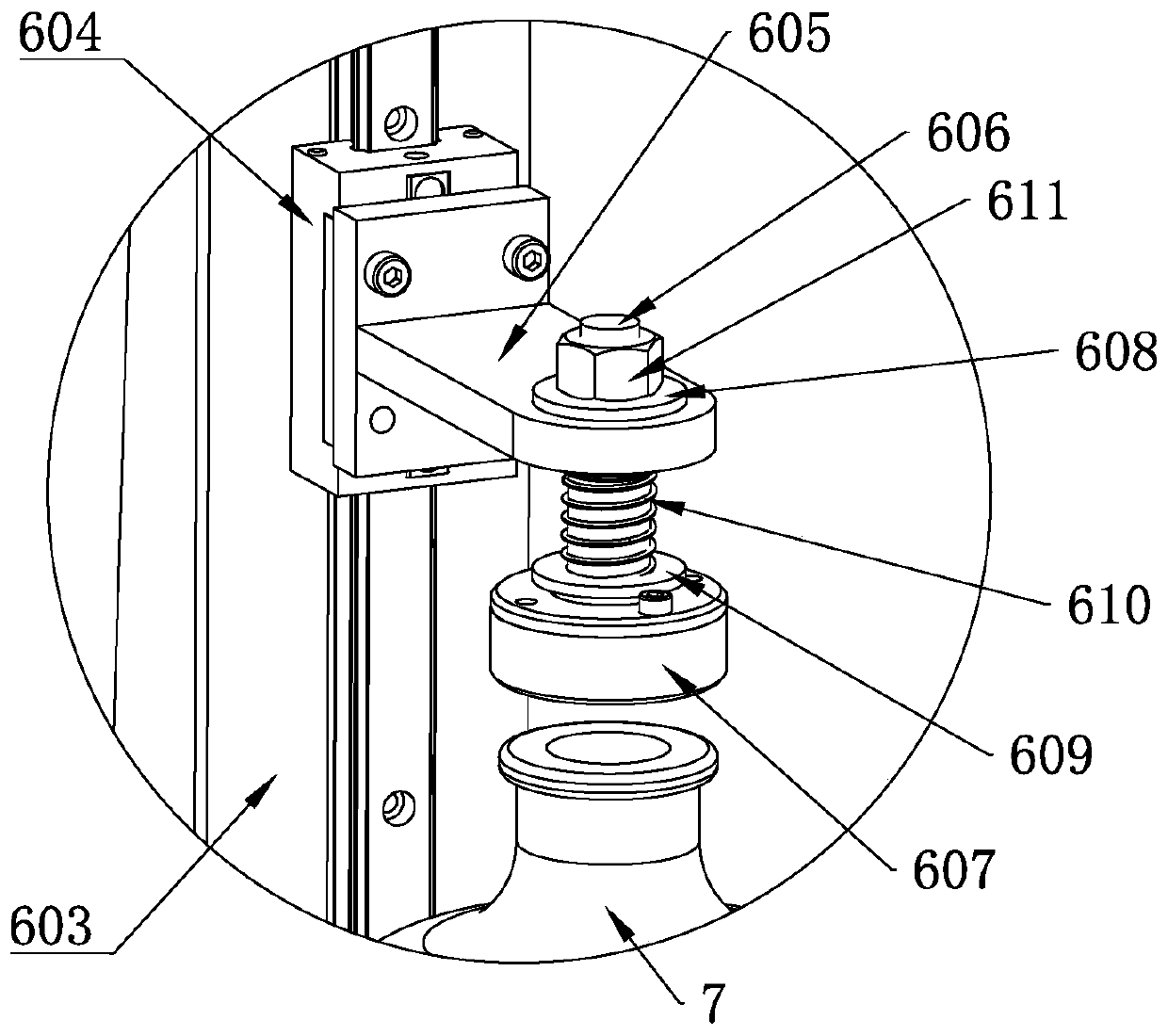

[0040] Such as figure 1 with figure 2 Commonly shown, a preform water replenishing machine includes a frame 1, a support frame 3 driven by a first power device 2 is slidably installed on the frame 1 along the X axis, and a first power device 2 is slidably installed on the support frame 3 along the Z axis. 2. A water replenishing mechanism 5 driven by a power unit 4;

[0041] The water supply mechanism 5 includes a sliding seat 501 arranged on the second power unit 4, on which a sponge wheel 503 driven by a third power unit 502 is rotatably installed, and the outer periphery of the spo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com