Novel driving method of motor vehicle and used torsion increase device

A driving method and technology for motor vehicles, which can be applied to control devices, vehicle components, transportation and packaging, etc., can solve the problems of large centrifugal force, energy consumption, and reduce efficiency, and achieve improved driving torque, increased efficiency, and reduced energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

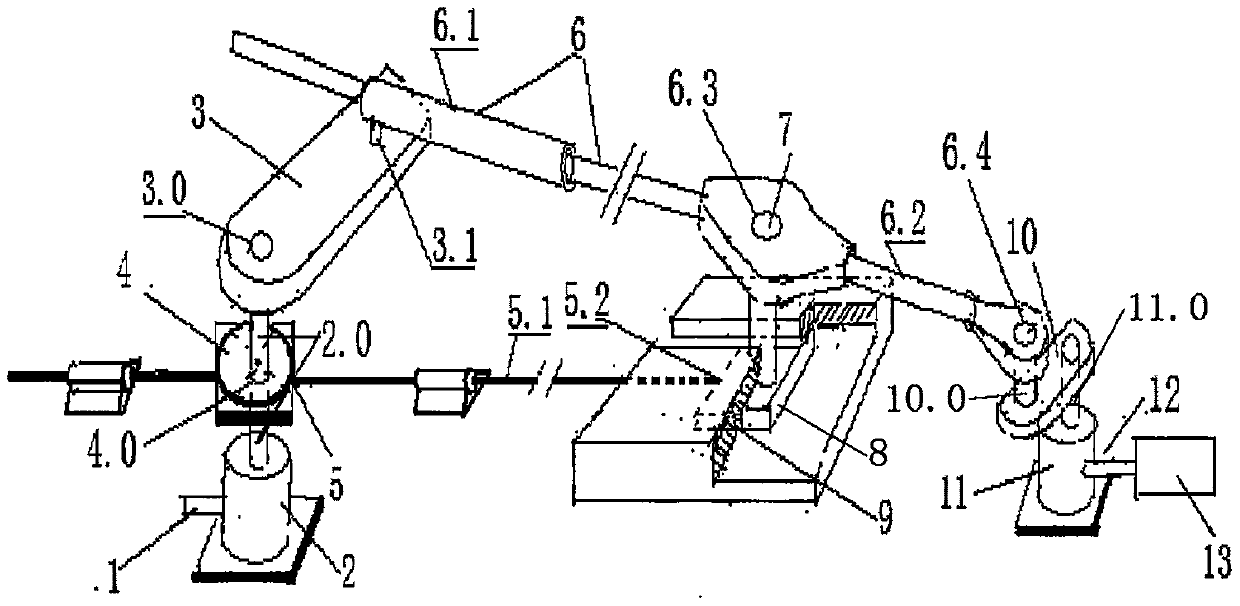

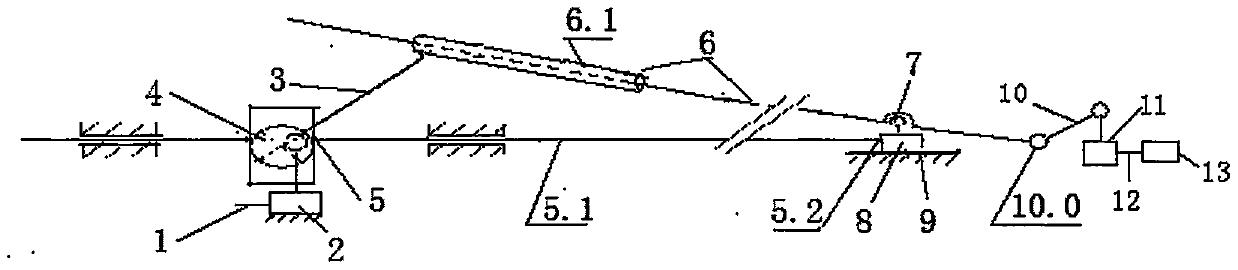

[0022] As shown in the figure, the new driving method of the motor vehicle can be carried out in sequence as follows:

[0023] (A) make the torque increasing device;

[0024] (B) the input shaft and the output shaft at both ends of the torque increasing device described in step (A) are respectively connected with the output shaft of the motor vehicle gearbox and the input shaft of the universal transmission device successively;

[0025] (C) The motor vehicle gearbox transmits the original power to the input shaft of the torque increasing device, and after swinging, it is transmitted to the input shaft of the universal transmission device through the output shaft, and finally drives the tire through the final reducer, differential and half shaft scroll.

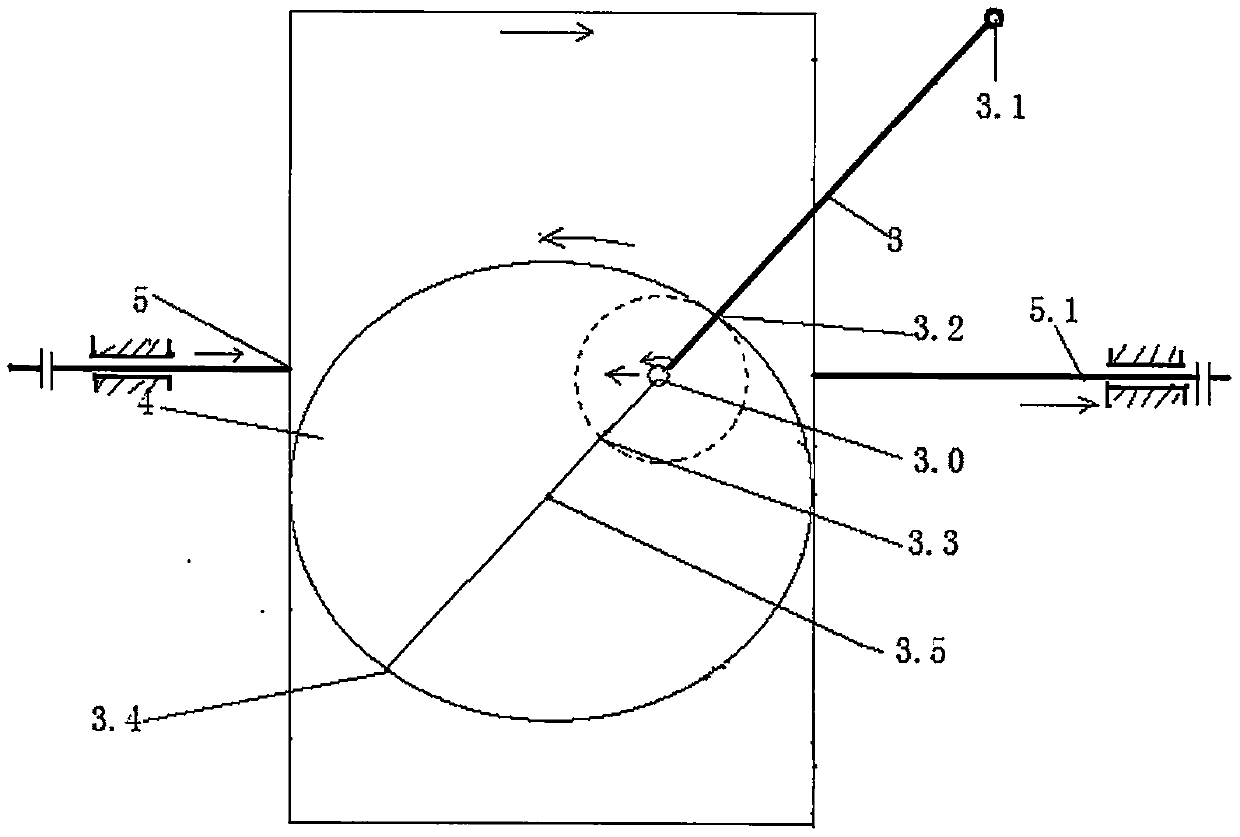

[0026] The torque increasing device adopted in the new driving method of the motor vehicle includes: input shaft 1, main transmission mechanism 2, driving crank 3, equal width cam mechanism, sleeve rocker lever 6, fulcrum 7, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap