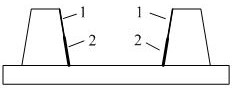

A pixel defining layer, its preparation method, and display device

A technology for defining a pixel definition layer and a display device, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., and can solve problems such as the difficulty of printing uniform films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

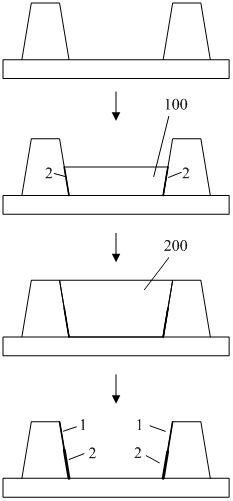

Method used

Image

Examples

Embodiment 1

[0049] Dissolve epoxy resin EPON826 in methyl isobutyl ketone solvent, put it in a three-necked flask, stir and heat to 70~80°C, according to the mass ratio of epoxy resin to sodium azide 1:1, add sodium azide Soluble in the mixture of water and methyl isobutyl ketone, and slowly add dropwise to the three-necked flask, the dropping time is 0.5~2h, continue to react for 1~3h after the dropwise addition, and then distill under reduced pressure to remove methyl isobutyl base ketone and water, and dissolve the solid in methyl isobutyl ketone, filter to remove sodium azide, obtain azide epoxy resin after vacuum distillation again;

[0050] Heat the azide epoxy resin to 70~80°C to melt, then mix the azide epoxy resin, polyoxypropylene diamine epoxy curing agent, and decylamine at a molar ratio of 4:1:2, and inject placed in a mold on the substrate, cured at 100-110 degrees Celsius for 1-2 hours, and then cured at 130-140 degrees Celsius for 1-2 hours, and after demoulding, an initia...

Embodiment 2

[0053] Dissolve epoxy resin E-51 in methyl isobutyl ketone solvent, put it in a three-necked flask, stir and heat to 60~70°C, according to the mass ratio of epoxy resin to sodium azide 1:1, add azide Dissolve sodium chloride in a mixture of water and methyl isobutyl ketone, and slowly add it dropwise to a three-necked flask for 0.5~2 hours. After the dropwise addition, continue to react for 1~3 hours, and then distill under reduced pressure to remove methyl isobutyl ketone and water, and the solid is dissolved in methyl isobutyl ketone, filtered to remove sodium azide, and then obtained azide epoxy resin after vacuum distillation again;

[0054] Heat the azide epoxy resin to 70~80°C to melt, then mix the azide epoxy resin, polyoxypropylene diamine epoxy curing agent, and decylamine in a molar ratio of 4:1:2, and then inject placed in a mold on the substrate, cured for 1 to 2 hours at 100 to 110 degrees Celsius, and then cured for 1 to 2 hours at 130 to 140 degrees Celsius, and...

Embodiment 3

[0057] Dissolve epoxy resin EPON826 in methyl isobutyl ketone solvent, put it in a three-necked flask, stir and heat to 70~80°C, according to the mass ratio of epoxy resin to sodium azide 1:1, add sodium azide Soluble in the mixture of water and methyl isobutyl ketone, and slowly add dropwise to the three-necked flask, the dropping time is 0.5~2h, continue to react for 1~3h after the dropwise addition, and then distill under reduced pressure to remove methyl isobutyl base ketone and water, and dissolve the solid in methyl isobutyl ketone, filter to remove sodium azide, obtain azide epoxy resin after vacuum distillation again;

[0058] Heat the azide epoxy resin to 70~80°C to melt, and then mix the azide epoxy resin, methyltetrahydrophthalic anhydride, 2-ethyl-4- Methylimidazole is mixed evenly and placed in an oven at 80 degrees Celsius to stand still. After the air bubbles are removed, it is then injected into a mold placed on the substrate, cured at 80~90 degrees Celsius for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com