A kind of crystalline form and preparation method of btk kinase inhibitor

A crystallization and organic solvent technology, applied in the field of crystallization and preparation of BTK kinase inhibitors, can solve the problems of poor stability of amorphous and I crystal forms, and achieve repeatable and controllable production process, stable production process, The effect of good crystal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

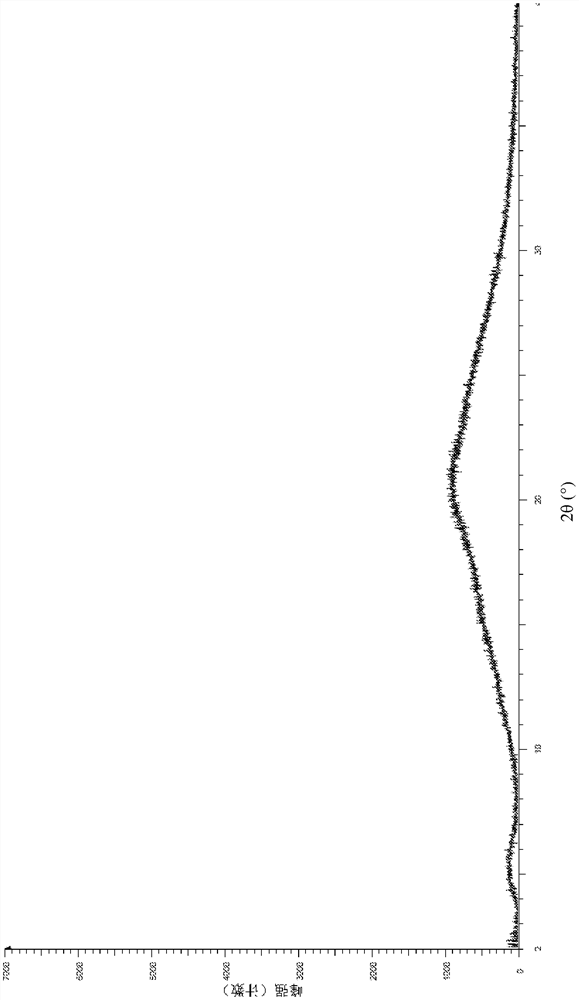

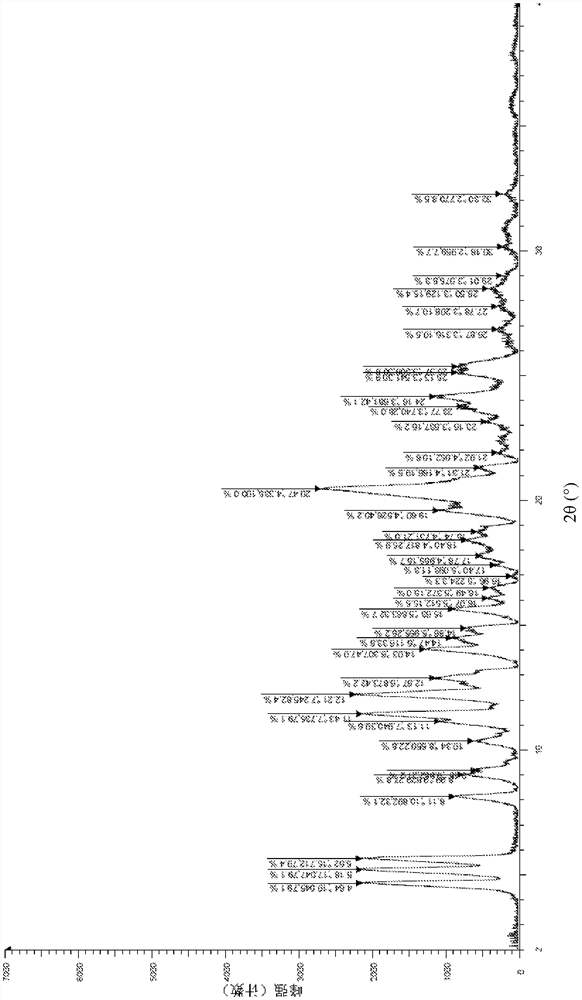

[0039] The compound (i) shown in Formula (I) (prepared in WO 2016 / 007185) was added to 100 mL of a single mouth bottle, and 50 ml of acetonitrile was added, and heated to all dissolved, cooling crystallization, stirring overnight. The next day, filtration, dried solid 4.03 g, and the yield was 80.6%. X-ray diffraction of this crystalline sample image 3Among them, in about 4.64 (19.04), 5.18 (17.05), 5.62 (15.71), 10.84 (8.5), 11.13 (7.94), 11.43 (7.74), 12.21 (7.24), 12.87 (6.87), 14.03 (6.31), 14.47 (6.12), 14.8 (5.37), 17.78 (4.53), 17.78 (4.98), 18.4 (4.82), 19.60 (4.53), 20.47 (4.34), 21.31 (4.17), 24.16 (3.68), 25.13 (3.54), 26.87 (3.32) and 28.50 (3.13) are characterized at a feature. DSC spectrum Figure 4 There is a molten heat absorbing peak near 165 ° C, which is defined as the II crystal form.

Embodiment 2

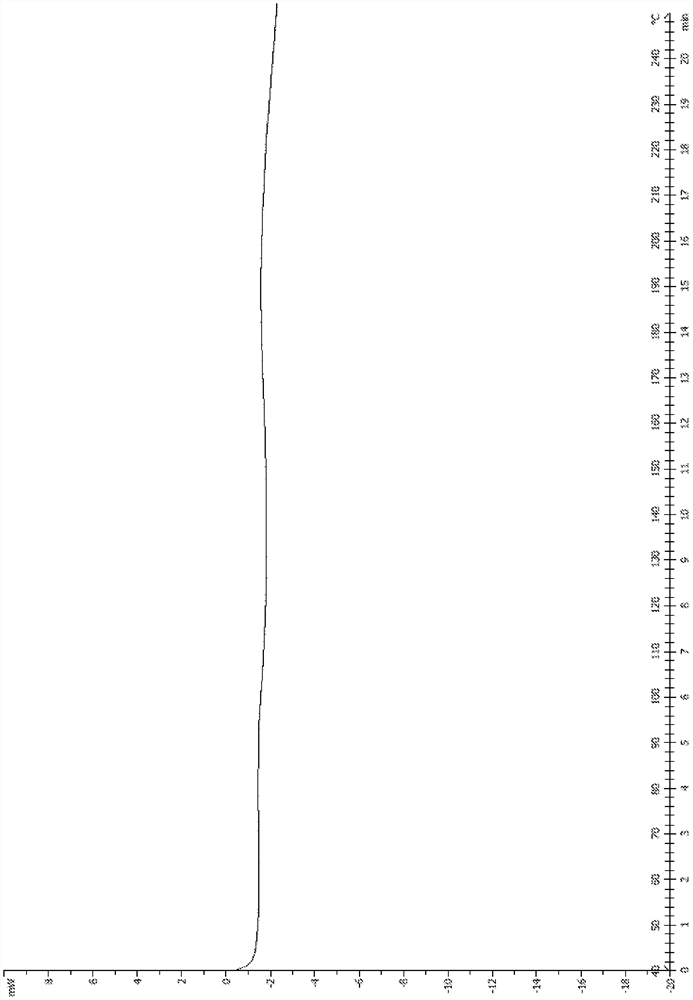

[0041] The compounds (I) were taken from the compound of formula (I) (prepared according to the method disclosed in WO 2016 / 007185) in a 25 ml single-mouth bottle, and 2 mL of ethanol was added, heated, dissolved, cooling crystallization, stirring overnight. The next day, filtration was filtered, and the solid was dried 241 mg, and the yield was 80.3%. X-ray diffraction of this crystalline sample Figure 5 It is from about 4.29 (20.56), 6.58 (13.42), 7.58 (11.66), 10.7 (8.7.68 (7.57), 12.49 (7.08), 13.74 (6.44), 14.12 (6.26), 15.86 (5.58) and 19.98 (4.44) have a characteristic peak. DSC spectrum Image 6 There is a molten heat absorbing peak near 141 ° C, which is defined as the I crystalline form.

Embodiment 3

[0043] The compound (prepared according to Example 2) was taken from 200 mg of the formula (I), and 2 ml of acetonitrile was added, stirred overnight. The next day, filtration was filtered, and the solid was dried 172 mg, and the yield was 86.0%. The X-ray diffraction and DSC map of the crystalline sample were determined to be a crystalline form.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com