A tightening method for a shaft system of a helium gas turbine and an axially loaded tightening tool

A technology of turbine shaft and axial loading, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of large plastic deformation and fracture of slender shafts, solve the problem of tightening, avoid shaft damage, and avoid strength damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the disclosed embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0039] The invention discloses a tightening method of a helium turbine shaft system, which can be used for tightening a helium turbine shaft system for a pre-cooled air turbine rocket engine, and is particularly suitable for tightening a small and compact helium turbine shaft system.

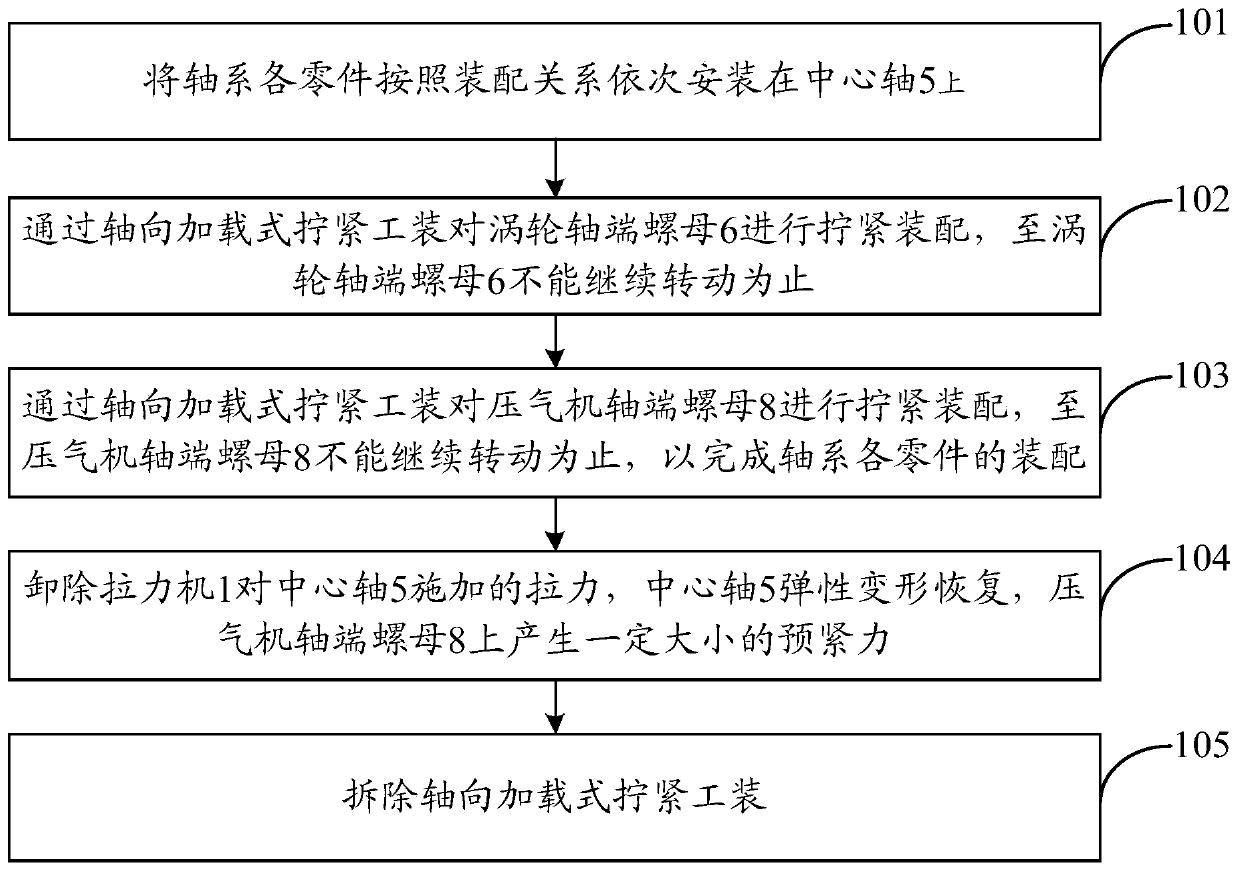

[0040] Such as Figure 1~4 In this embodiment, the tightening method of the helium turbine shaft system includes:

[0041] In step 101, the parts of the shaft system are sequentially installed on the central shaft 5 according to the assembly relationship.

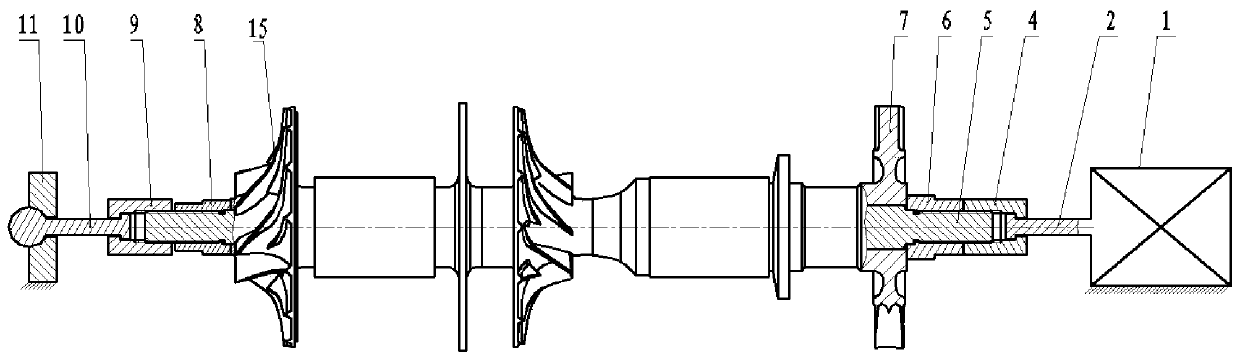

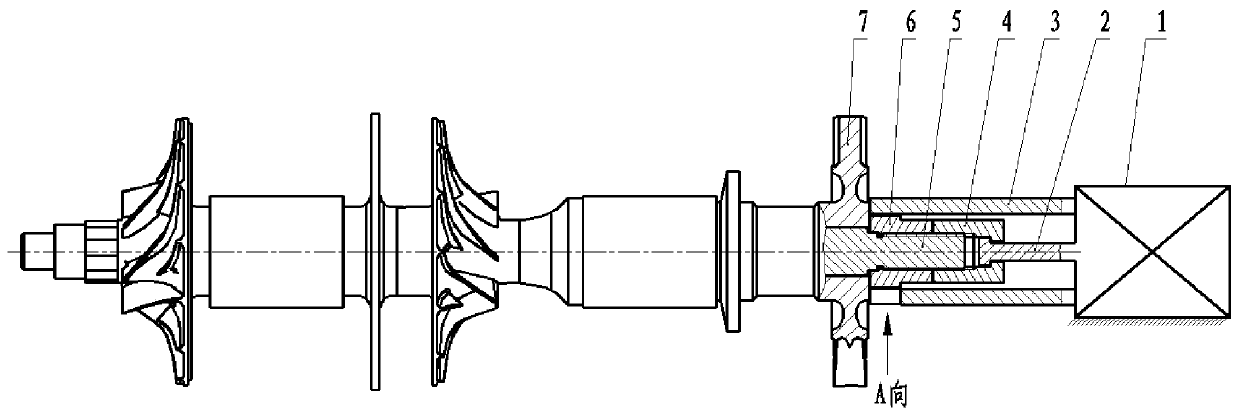

[0042] In this embodiment, as figure 2 , Each part of the shaft system may specifically include: a central shaft 5, a turbine shaft end nut 6, a turbine disk 7, a compressor wheel 15 and a compressor sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com