Low-retracting secondary stretch-draw anchorage supporting nut screwing device

A supporting nut and tensioning technology, applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of weakening the concrete structure size of bridges, difficult construction operations, and narrow space, and achieves improved construction efficiency, reduced operation difficulty, and reduced The effect of cutting the section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

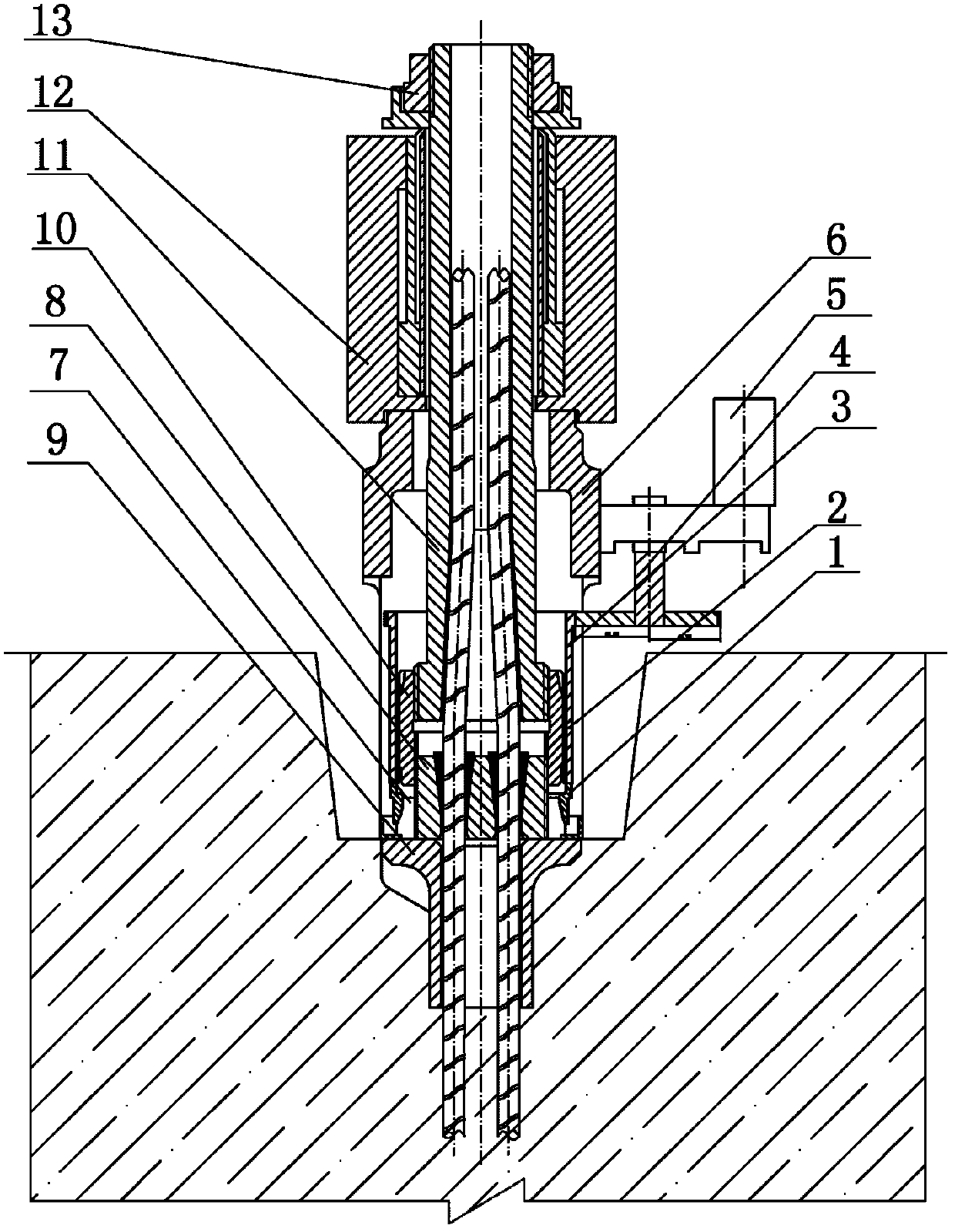

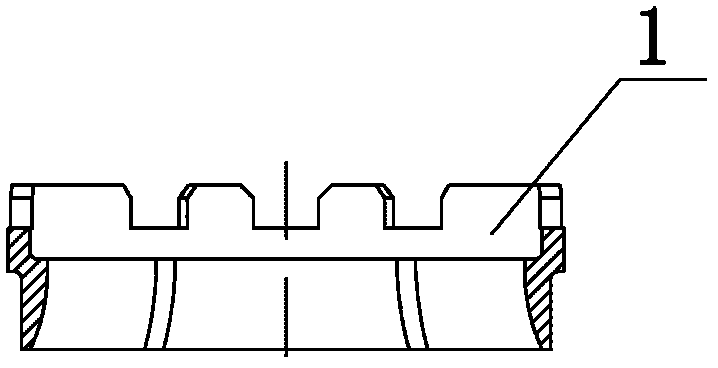

[0019] Example 1, see figure 1 , The present invention is mainly composed of the inner convex connecting sleeve 1, the transition sleeve 2, the passive rotating wheel 3, the active rotating wheel 4, the power machine 5 and the tension bracket 6, etc. The inner convex connecting sleeve 1 is sleeved in the secondary tension anchor On the support nut 7, one or more inner bosses can be designed in the inner cavity of the inner convex connecting sleeve 1. The inner bosses and the corresponding grooves on the outer periphery of the secondary tension anchor support nut 7 form a clearance fit. That is, the shape of the inner boss corresponds to the position of the outer circumferential groove of the support nut 7 and has the same shape, and the size of the inner boss is smaller than the groove size by 0.5-5 mm. Three or more grooves are provided on the upper end surface of the female-male connecting sleeve 1, and the lower end surface of the transition sleeve 2 is provided with three or...

Embodiment 2

[0020] Embodiment 2: The rotating device provided on the transition sleeve 2 of the present invention can also be a gear rotating mechanism. The upper end of the transition sleeve 2 is connected with the passive rotating wheel 3, and the passive rotating wheel 3 is connected with the manual rotating mechanism. When the secondary tension anchor completes the first tension and release, remove the jack and other tension tools, install the convex connecting sleeve 1 above the secondary tension anchor support nut 7, and install the tension connecting sleeve After 10 and the tension rod 11, the transition sleeve 2 and the passive rotating wheel 3 are installed on the outer periphery of the tension connection sleeve. At this time, there is a gap of 7-13 mm between the anchor ring 8 and the backing plate 9 for the second tension. At this time, the passive rotating wheel 3 can be driven by the manual rotating mechanism to drive the transition sleeve 2 to push the inner convex connecting ...

Embodiment 3

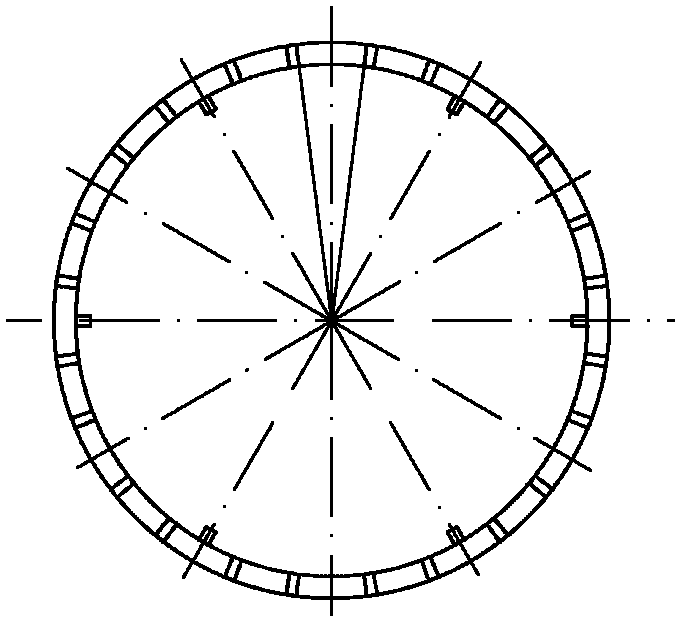

[0021] Embodiment 3: In addition to the manual operation mentioned above, the rotating device provided on the transition sleeve 2 of the present invention can also be driven by a power mechanism, see figure 1 , Connect the upper end of the transition sleeve 2 with the passive rotating wheel 3, and set a cylindrical gear on the outer periphery of the passive rotating wheel 3. The outer periphery of the driving rotating wheel 4 is set with a circular gear matched with the cylindrical gear on the outer periphery of the passive rotating wheel 3. The passive rotating wheel 3 The cylindrical gear on the outer circumference meshes with the circular gear on the outer circumference of the driving wheel 4 to transmit power; the center of the driving wheel 4 is designed with an inner shaft hole and a keyway and is connected to the output shaft of the power machine 5, which can be installed and fixed on the tension bracket On the side surface of 6, the shape and size of the tension support 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com