Combined Serpentine Torque Wrench

A torque wrench, combined technology, applied in the direction of wrenches, screwdrivers, manufacturing tools, etc., can solve the problems of inconvenient disassembly and assembly, poor flexibility, limited torque of the built-in motor, etc., to achieve the effect of convenient disassembly and assembly, simple operation and accurate transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] specific implementation plan

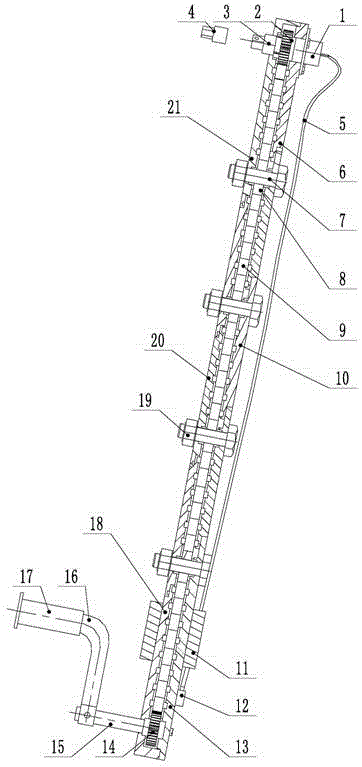

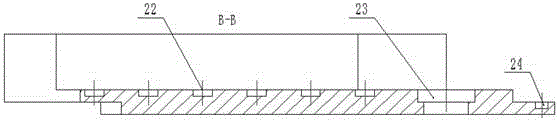

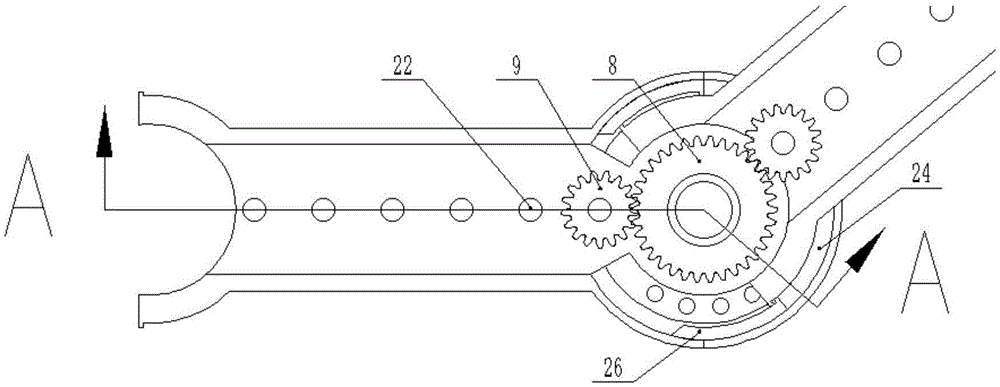

[0029] exist figure 1 In the schematic diagram of the combined serpentine torque wrench shown, the wrench mainly includes a torque input device, a torque output device and a torque transmission device. The torque transmission device is a plurality of coupling rods with the same structure, and each coupling rod includes: a pinion , connecting rod bottom groove and cover plate, central gear and studs, such as figure 2 , image 3 and Figure 4 As shown, one end of the groove bottom plate of the connecting rod bottom groove 20 is a circular plate, and the center of the circular plate is provided with a through hole 23, and five slotted holes 25 are respectively arranged symmetrically along the central plane of the circular plate, and the center lines of these slotted holes are at On a circle, be provided with the limit bead 28 in this groove, as Figure 5 As shown; the other end of the above-mentioned groove bottom plate is a concave arc-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com