Folding force-limiting wrench switching mechanism for deep cavity

A transfer mechanism and wrench technology, which is applied in the field of aero-engines, can solve the problems that the limit force wrench or ordinary adapter cannot meet the actual use requirements, and achieve the effect of improving the convenience of operation, accurate positioning, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better explain the present invention and facilitate understanding, the technical solutions and effects of the present invention will be described in detail below through specific implementation manners in conjunction with the accompanying drawings.

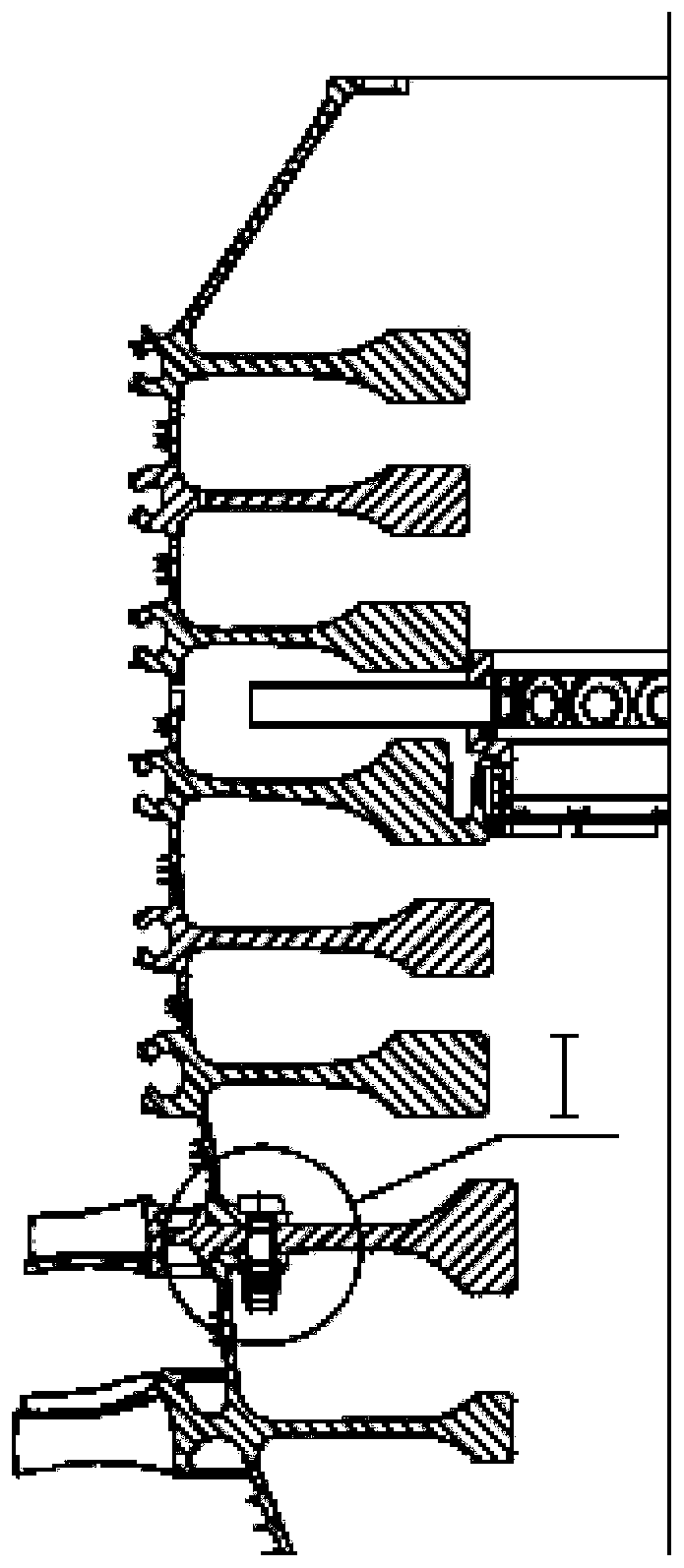

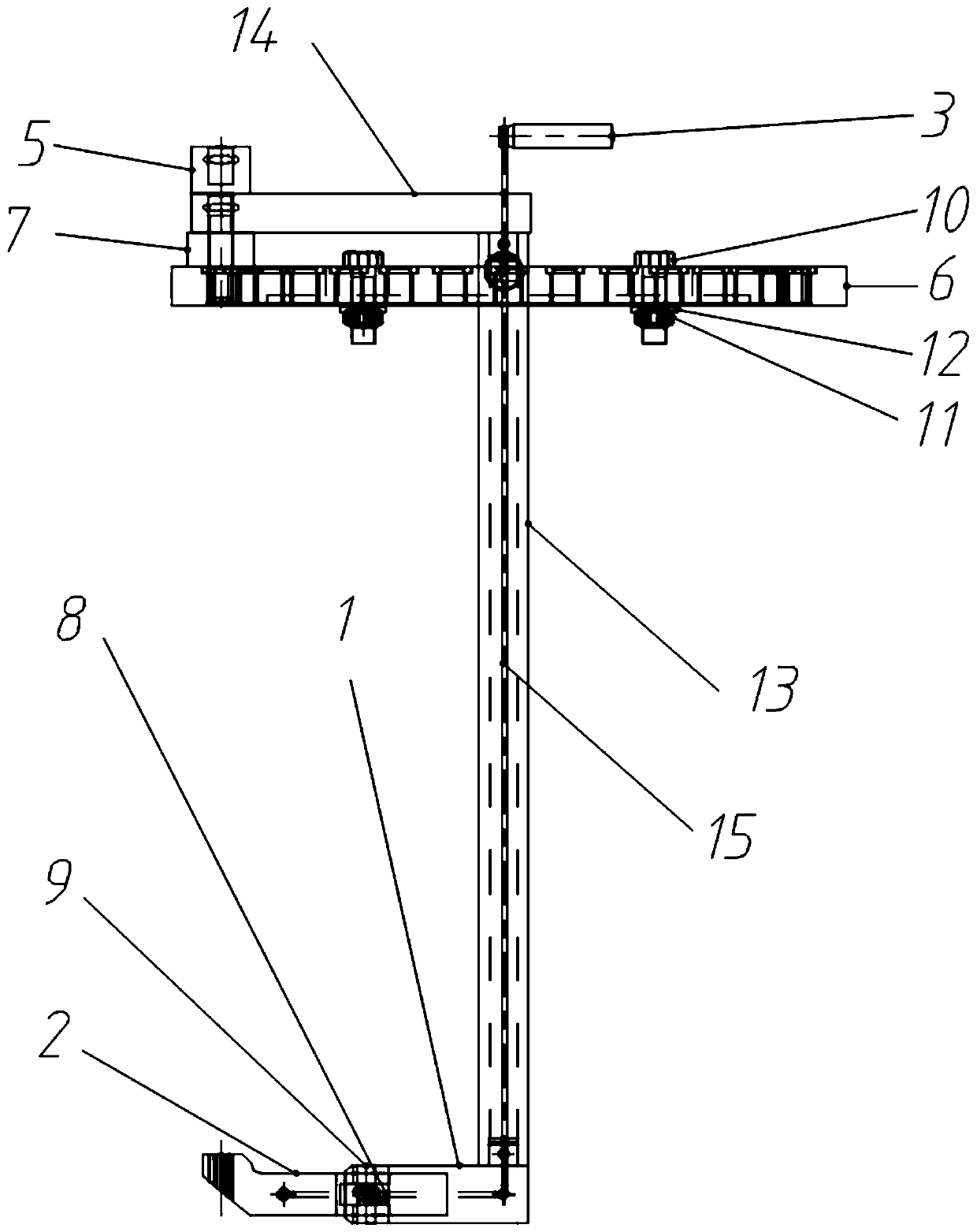

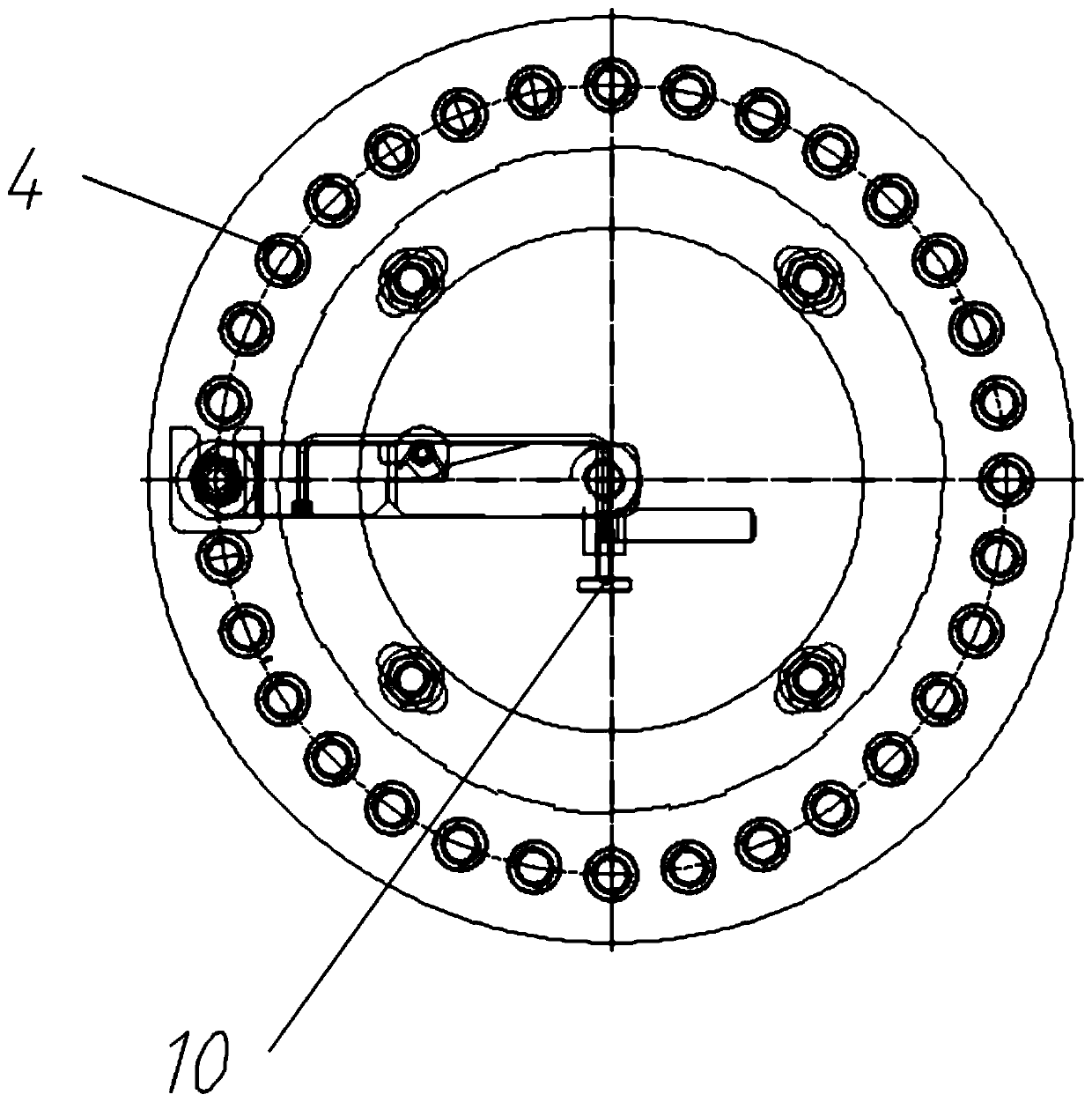

[0024] Such as Figure 2-3 As shown, a folding force limiting wrench transfer mechanism for a deep cavity includes a head folding part, a long arm part and a positioning part. The head folding part includes an adapter 2, an adapter 1 and a zipper assembly, such as Figure 4-7 As shown, the side of the adapter 2 and the adapter 1 are slotted, and the torsion spring 8 is built in. The adapter 2 and the adapter 1 are connected through the torsion spring 8 through the pin 9; the other end of the adapter 1 is connected to the long arm part. The long arm 13 is connected by a pin, and the top of the long arm 13 is connected with a positioning plate 14, and the end of the positioning plate 14 has a through hole; There ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com