Municipal well lid casting device

A manhole cover and municipal technology, applied in unloading devices, ceramic molding machines, manufacturing tools, etc., can solve the problems of accelerating concrete hardening, low work efficiency, cumbersome operation, etc., and achieve the effect of accelerating hardening and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

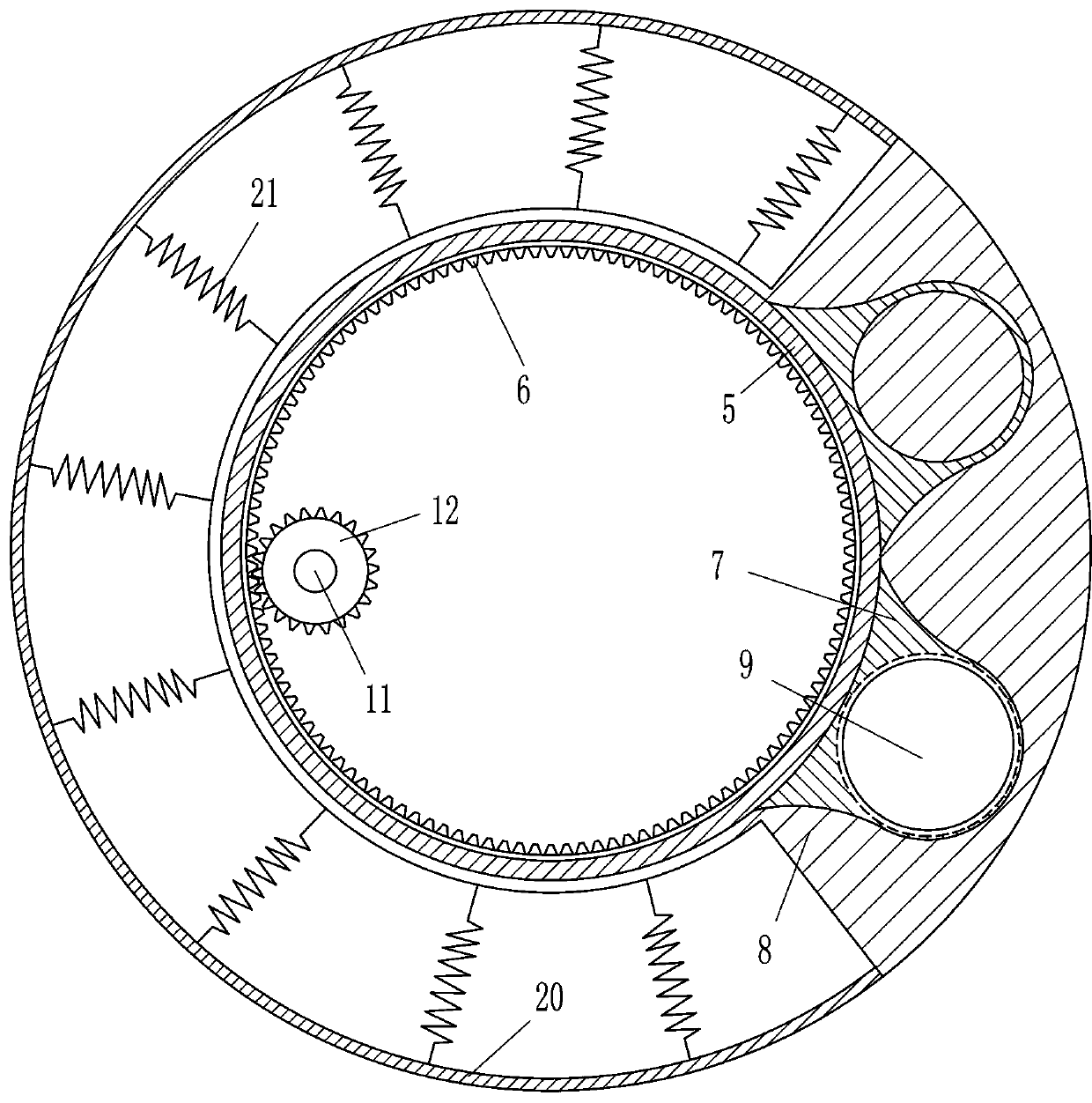

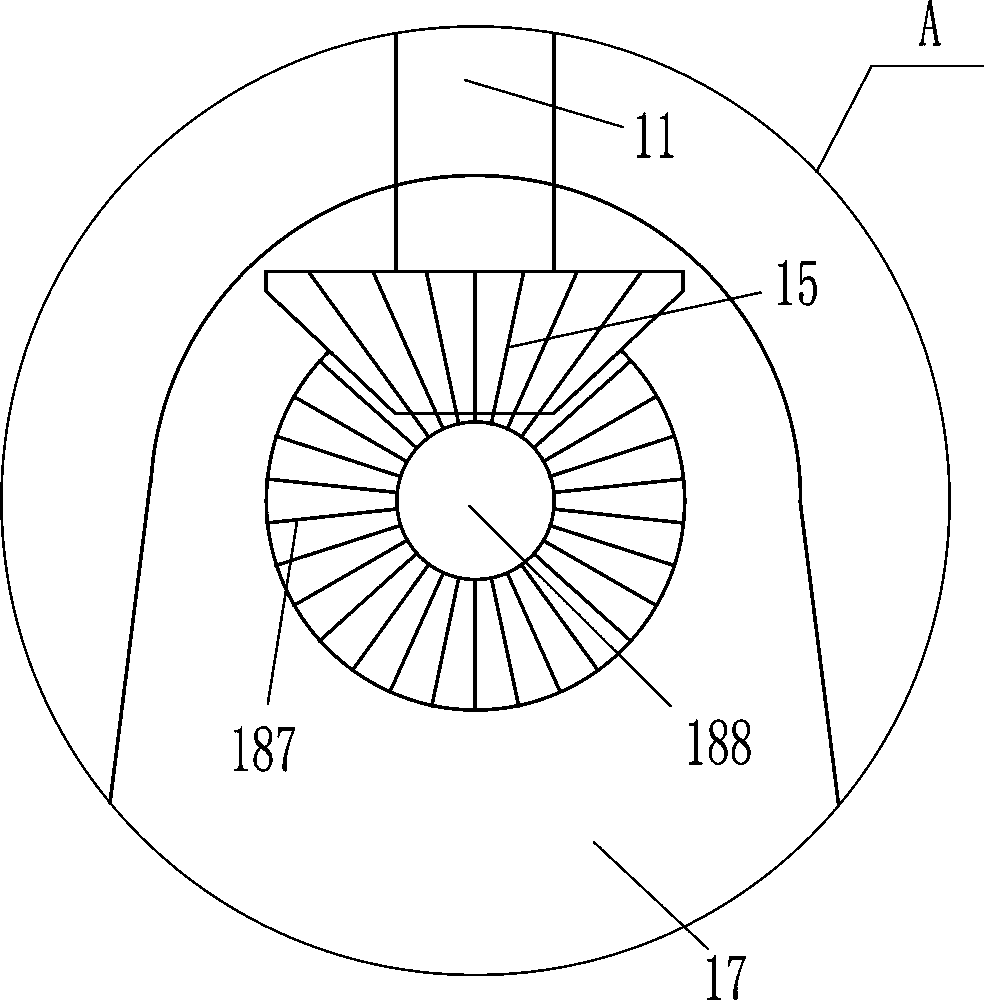

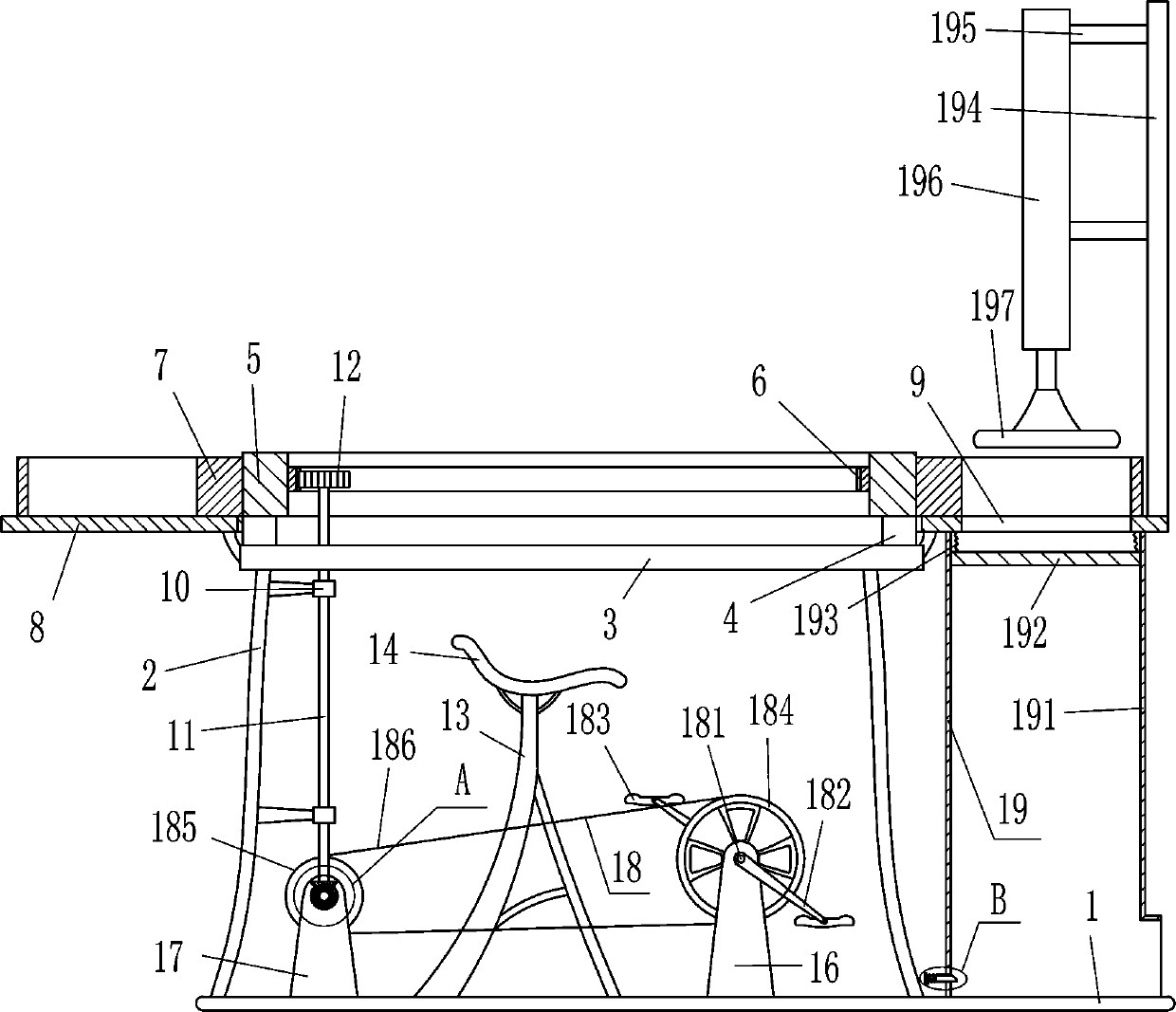

[0018] A municipal manhole cover pouring equipment, such as Figure 1-3 As shown, it includes a bottom plate 1, a pole 2, an annular slide rail 3, an annular slider 4, an annular block 5, an inner ring gear 6, an orifice plate 7, an annular plate 8, a bearing seat 10, a rotating shaft 11, and a first gear 12 , the support frame 13, the seat plate 14, the first bevel gear 15, the first support plate 16, the second support plate 17 and the driving mechanism 18, the left and right sides of the top of the base plate 1 are fixedly connected with poles 2, and the base plate 1 is connected by bolts The way to connect with the pole 2, the circular slide rail 3 that acts as a guide is installed between the tops of the poles 2 on the left and right sides, the annular slide rail 3 is connected to the pole 2 through bolt connection, the sliding type There is a ring slider 4, the ring slider 4 is slidingly matched with the ring slide rail 3, the ring block 5 is installed on the top of the ...

Embodiment 2

[0020] A municipal manhole cover pouring equipment, such as Figure 1-3 As shown, it includes a bottom plate 1, a pole 2, an annular slide rail 3, an annular slider 4, an annular block 5, an inner ring gear 6, an orifice plate 7, an annular plate 8, a bearing seat 10, a rotating shaft 11, and a first gear 12 , the support frame 13, the seat plate 14, the first bevel gear 15, the first support plate 16, the second support plate 17 and the driving mechanism 18, the left and right sides of the top of the base plate 1 are fixedly connected with the poles 2, and the ring-shaped rings that play a guiding role The slide rail 3 is installed between the tops of the support rods 2 on the left and right sides. The ring slide rail 3 is slidingly provided with a ring slider 4. The ring slider 4 is slidably matched with the ring slide rail 3. The ring block 5 is installed on the ring slider 4. On the top, an inner ring gear 6 is installed on the inner surface of the ring block 5, so that th...

Embodiment 3

[0023] A municipal manhole cover pouring equipment, such as Figure 1-3As shown, it includes a bottom plate 1, a pole 2, an annular slide rail 3, an annular slider 4, an annular block 5, an inner ring gear 6, an orifice plate 7, an annular plate 8, a bearing seat 10, a rotating shaft 11, and a first gear 12 , the support frame 13, the seat plate 14, the first bevel gear 15, the first support plate 16, the second support plate 17 and the driving mechanism 18, the left and right sides of the top of the base plate 1 are fixedly connected with the poles 2, and the ring-shaped rings that play a guiding role The slide rail 3 is installed between the tops of the support rods 2 on the left and right sides. The ring slide rail 3 is slidingly provided with a ring slider 4. The ring slider 4 is slidably matched with the ring slide rail 3. The ring block 5 is installed on the ring slider 4. On the top, an inner ring gear 6 is installed on the inner surface of the ring block 5, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com