Self-hardening waterproof rubber sheath for ship electric wire

A rubber sheath, self-hardening technology, used in circuits, electrical components, insulated cables, etc., can solve problems such as safety hazards, leakage, and rubber sheaths are easily corroded and aged, so as to reduce safety hazards, reduce erosion, reduce The effect of corrosion and the rate of aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

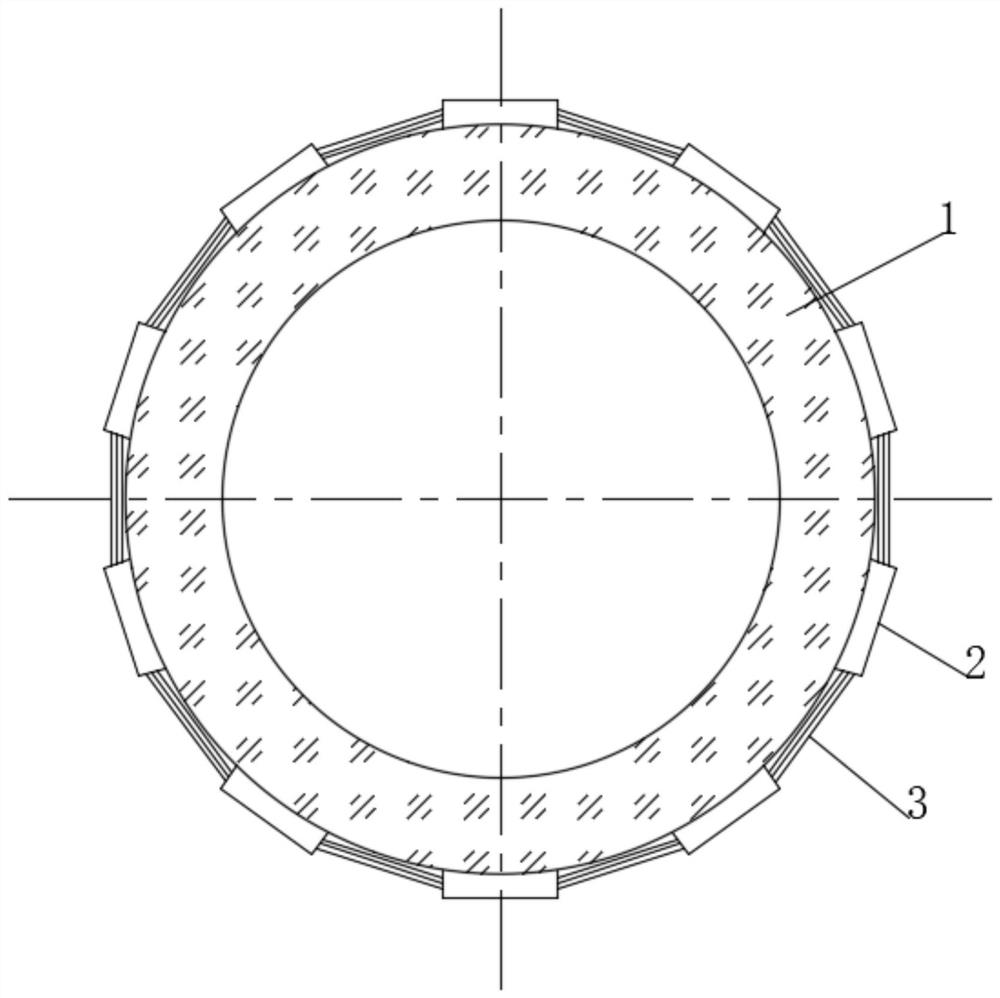

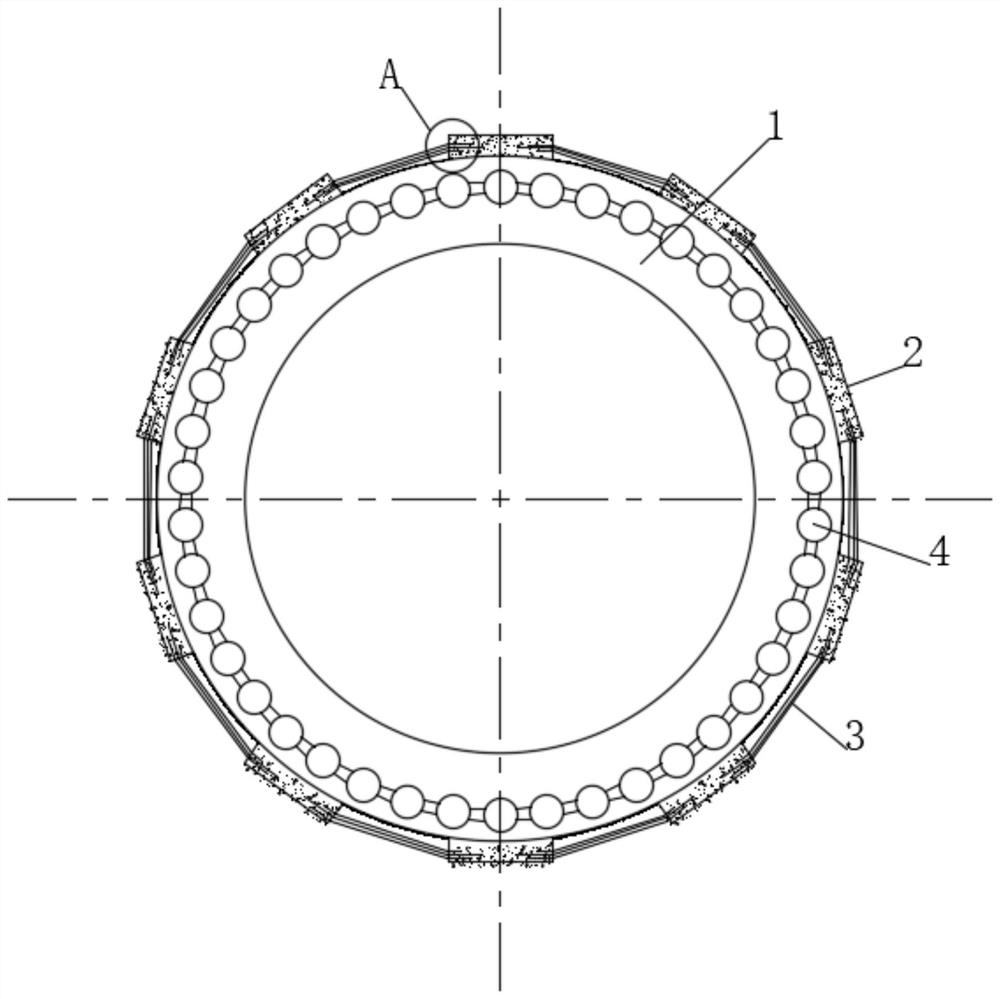

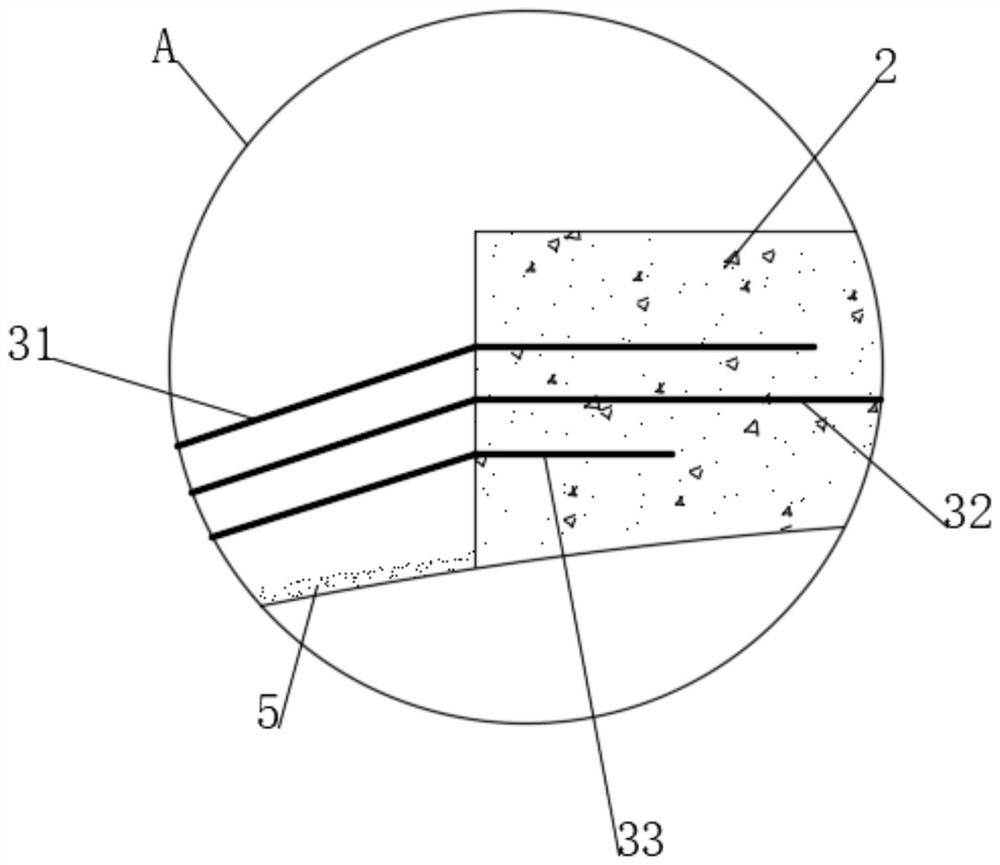

[0039] see figure 1 , a self-hardening waterproof rubber sheath for ship electric wires, comprising a sheath body 1, the outer end of the sheath body 1 is fixedly connected with a plurality of evenly distributed outer water resistance blocks 2, and the space between two adjacent outer water resistance blocks 2 Both are connected with an external water-blocking laminated net 3, and the external water-blocking block 2 is made of polymer water-absorbing resin material, which can absorb water hundreds or even thousands of times its own weight, and has a strong The water retention capacity makes it difficult for the water vapor to penetrate into the sheath body 1 after the water vapor is absorbed inside the outer resistance water block 2, so that it is not easy to affect the sheath body 1 while absorbing water, and the surface of the outer resistance water block 2 is coated with There is a nano-waterproof coating, which effectively prevents the air from penetrating directly into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com