Lifting device for automobile engine mechanical experiment

A lifting device and mechanical technology, which is applied in the direction of lifting devices, lifting frames, etc., can solve the problems of inconvenient operation, disassembly and observation of experimental parts, inconvenience, and inability to realize the rotation of experimental parts, so as to achieve convenient observation and operation. Simple, anti-autorotation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

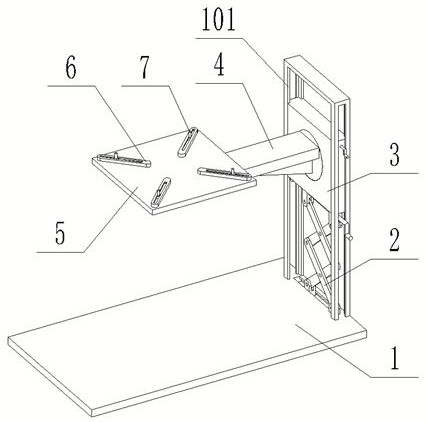

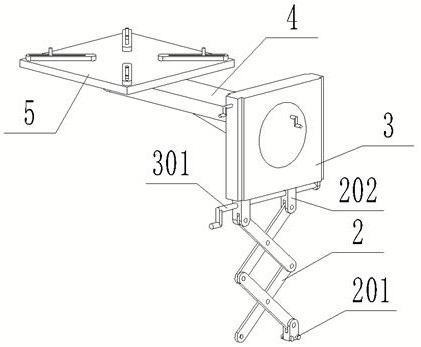

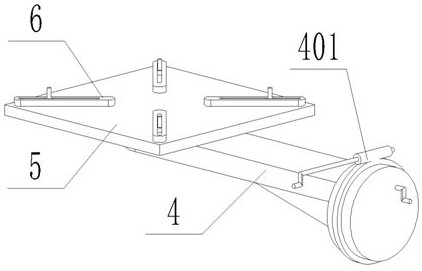

[0027] as attached figure 1 to attach Figure 8 Shown:

[0028] The present invention provides a lifting device for automobile engine mechanical experiments, including: a base 1, a lifting slide rail 101, a scissor mechanism 2, a roller 201, an upper sliding seat 202, a lifting block 3, a screw 301, a cantilever 4, a cantilever Turbine and worm transmission mechanism 401, swivel seat 5, swivel seat worm and worm transmission mechanism 501, connecting block 6, positioning teeth 601, T-shaped slot 602, fixing bolt 7 and T-shaped block 701; the right side of base 1 is slidingly connected with a set of lifting block 3; the lifting block 3 and the base 1 are connected through the scissors mechanism 2; the left end surface of the lifting block 3 is axially connected with a group of cantilever 4; the top of the cantilever 4 is axially c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com