Universal multi-form fixed pipe coiling device

A hose reel and multi-form technology, applied in the field of universal multi-form fixed hose reels, can solve the problems of few usage scenarios, poor replacement, poor applicability, etc., and achieve the effect of wide application range and good bonding fastness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

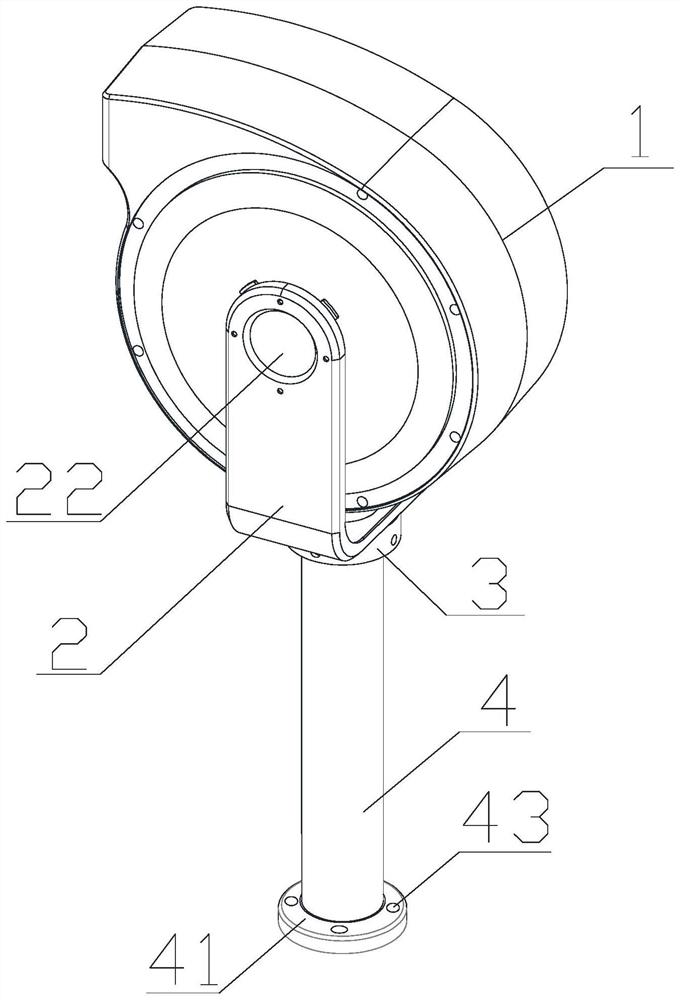

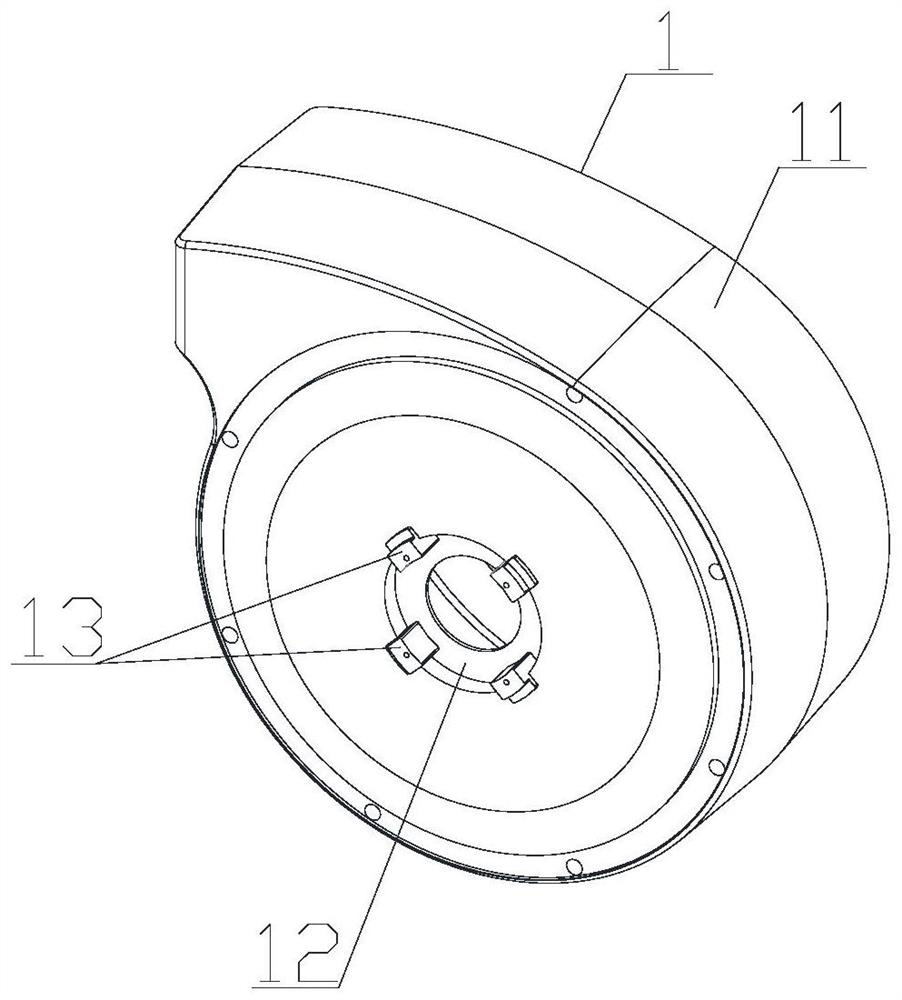

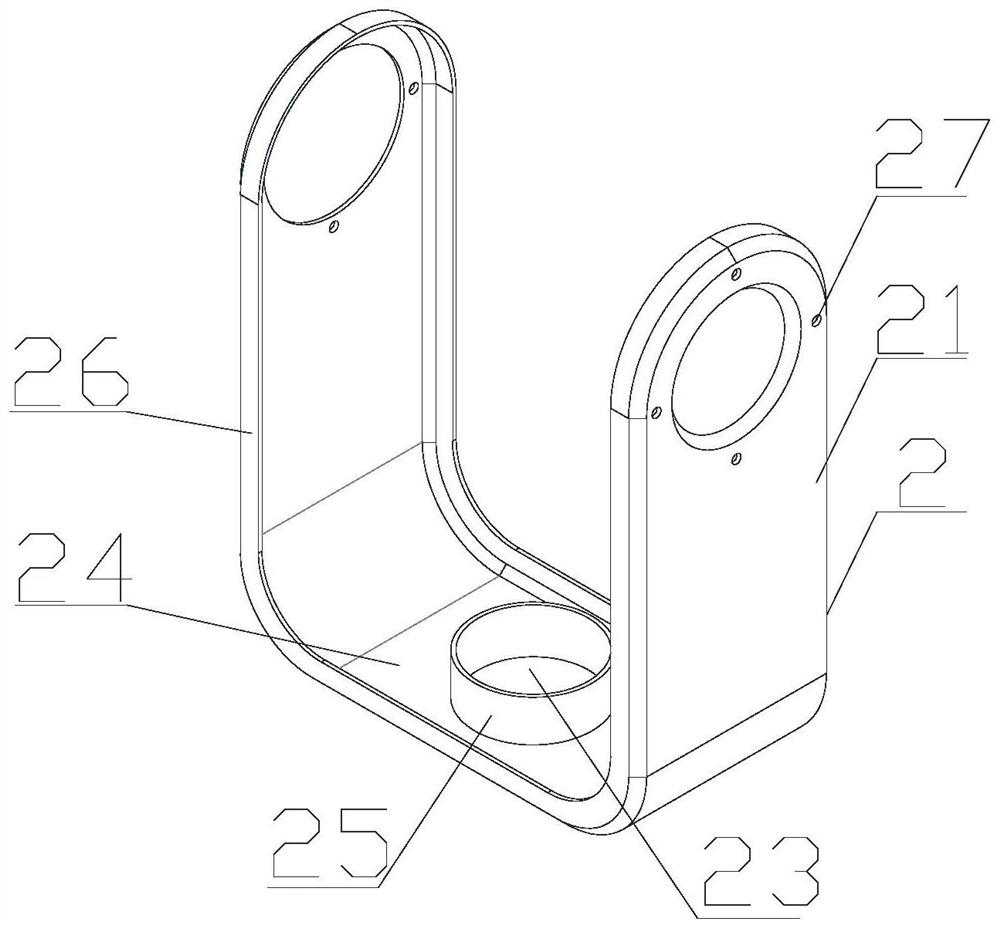

[0030] Example 1: refer to the attached Figure 1-Figure 15 . The universal multi-form fixed hose reel includes a hose reel 1, a hose reel turning base 2 and a hose reel rotating seat 3. The outer walls of the casing 11 in the hose reel 1 are concavely formed on both sides respectively. A circular shaft groove 12, two mounting plates 21 are oppositely provided on the upper end surface of the reel reversing base 2, and a circular shaft 22 is respectively installed on the inner wall surfaces of the two mounting plates 21. The circular shaft groove 12 is inserted and fitted with the corresponding circular shaft 22 and installed between the two mounting plates 21 . The end face is provided with an insertion hole 23 , and the reel reversing base 2 is installed on the reel rotating base 3 through the insertion hole 23 and the shaft head of the reel rotating base 3 by plug-fitting. The upper end surface of the bottom plate 24 in the reel turning base 2 is oppositely provided with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com