Manipulator capable of rotating in multiple directions

A manipulator and one technology, applied in the field of manipulators, can solve the problems of complex manipulator structure, inability to realize multi-directional rotation, inconvenient manipulator maintenance and installation, etc., to achieve the effect of simple structure and rapid loading and unloading of circular workpieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

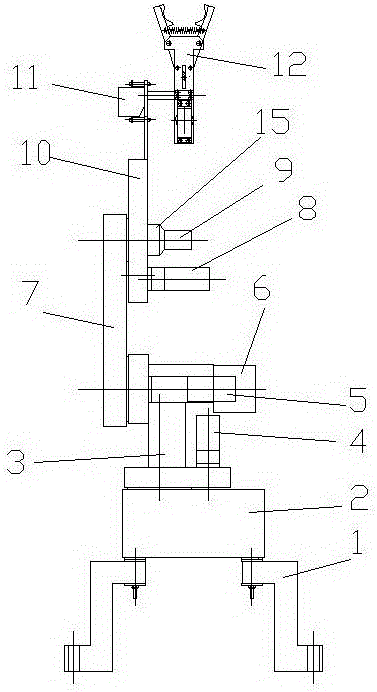

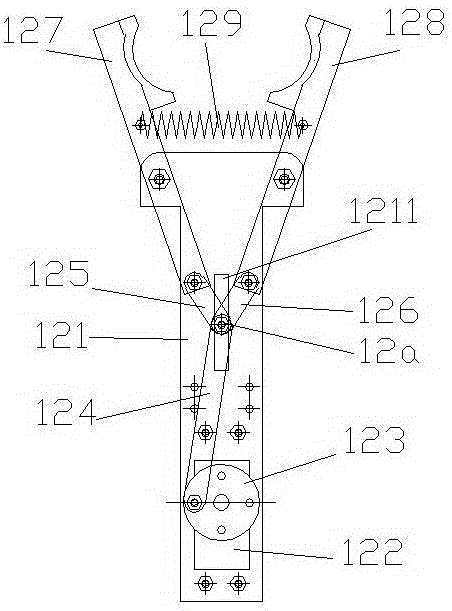

[0023] Example: see Figures 1 to 4 As shown, a manipulator that can rotate in multiple directions includes a first motor 4, a first reducer 3, a second motor 5 and a second reducer 6;

[0024] The junction box 2 is fixed on the base 1, the first reducer 3 is fixed on the junction box 2, the rotating shaft of the first motor 4 is fixed with the input shaft of the first reducer 3, and the output shaft of the first reducer 3 is fixed There is a second speed reducer 6, and the rotating shaft of the second motor 5 is fixed with the input shaft of the second speed reducer 6;

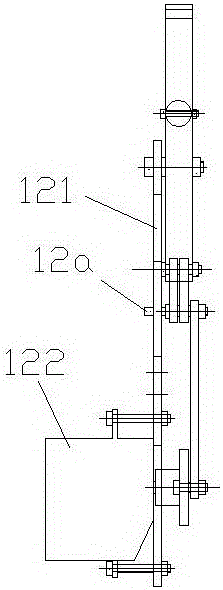

[0025] A boom 7 is fixed on the output shaft of the second speed reducer 6, and a hinge shaft 9 is formed or fixed on the boom 7. The small arm 10 is a hollow box, and the small arm 10 is inserted and sleeved on the hinge shaft 9. The third motor 8 is fixed on the small arm 10, a drive gear 13 is fixed on the rotating shaft of the third motor 8, a fixed gear 14 is fixed on the hinge shaft 9, the drive gear 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com