Installation method of offshore equipment

一种安装方法、设备的技术,应用在海洋工程领域,能够解决海上风机安装设备建造难度与安装成本增加、吊臂力学结构可靠性低、制约海上风电发展等问题,达到船只利用率最大化、增强稳定性与可靠性、施工周期短的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means and creative features adopted in the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

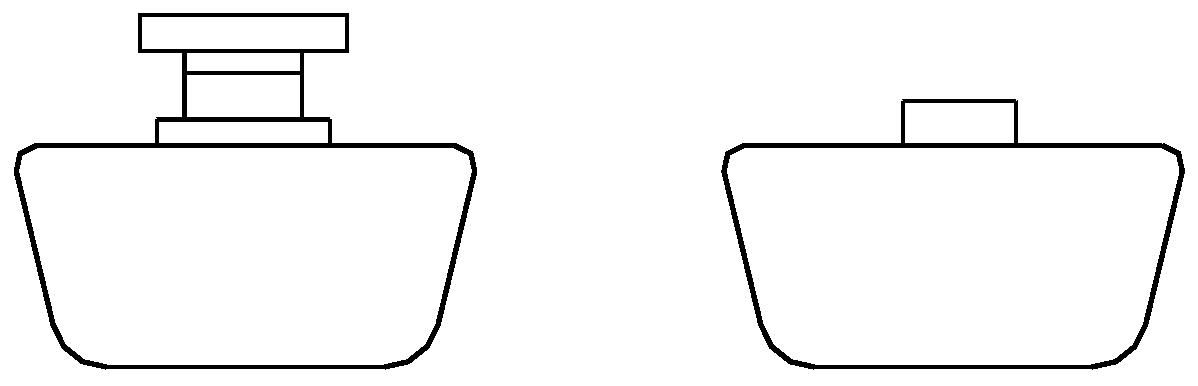

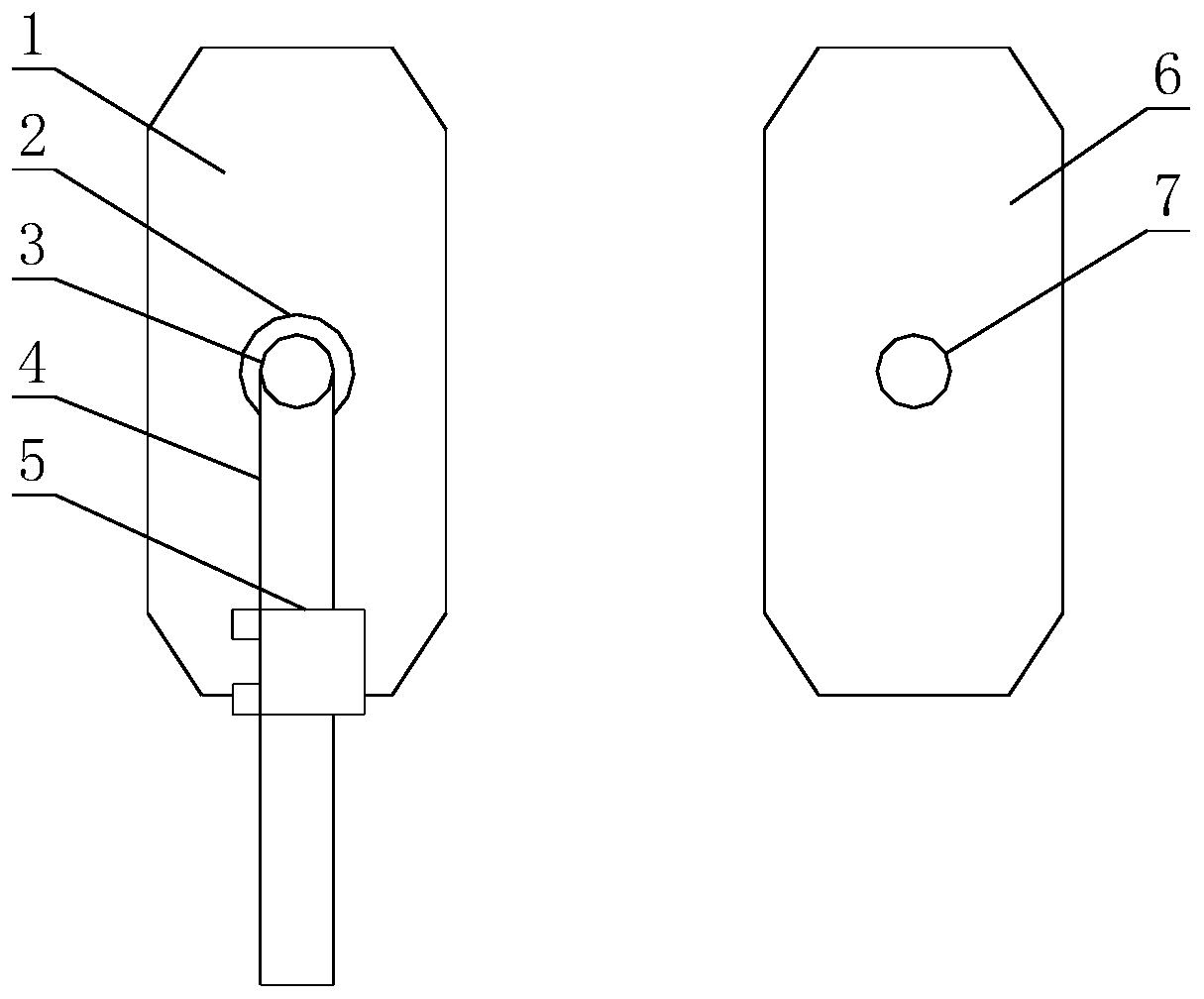

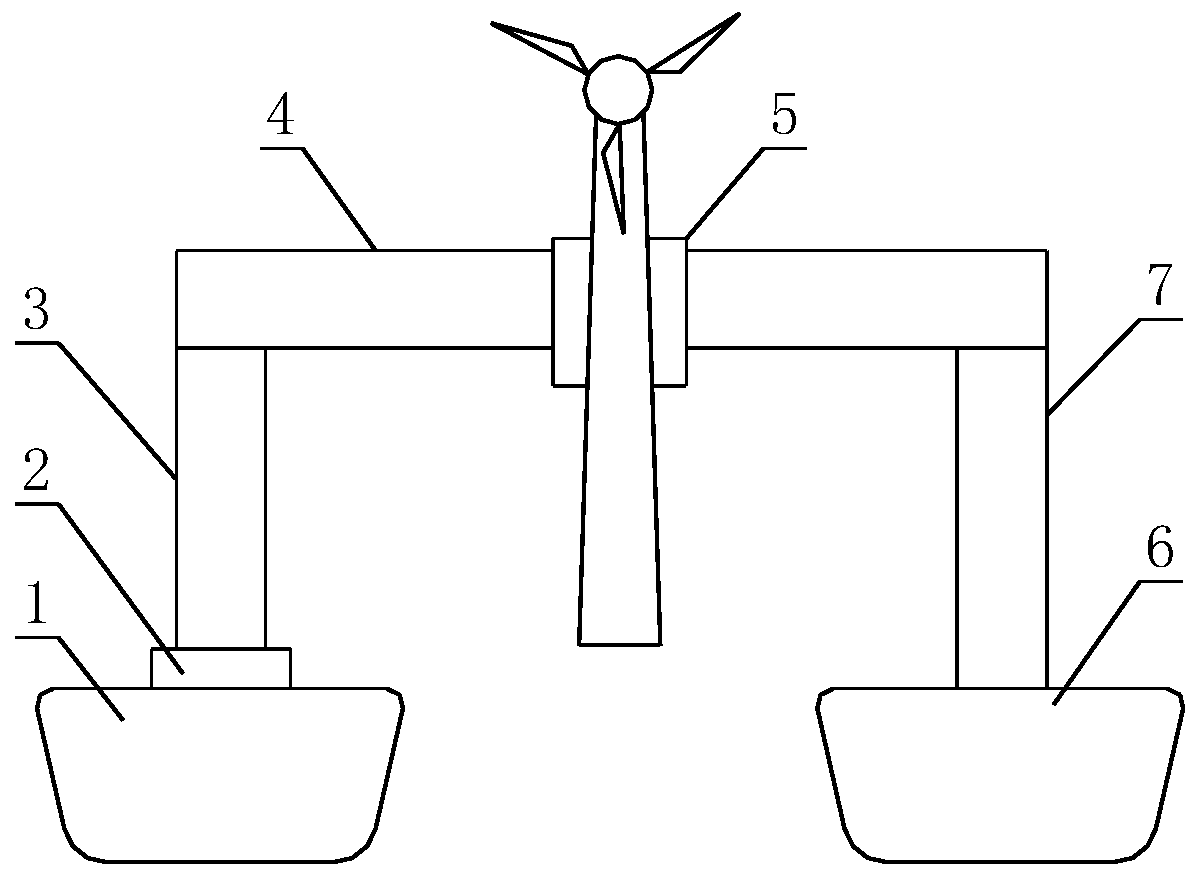

[0030] see Figure 1-4 As shown, the present invention is an installation method for offshore equipment. The main technical means is to use two ships to cooperate with each other. When the two ships sail to their destinations, a gantry crane-type hoisting operation platform with automatic lifting function is quickly built. After the operation is completed, the two ships will separate and return to work or continue to operate. The installation device for offshore equipment includes a main ship 1 , an auxiliary ship 6 , a lifting beam 4 , a rotating platform 2 , a foundation platform 3 , a lapping platform 7 , and lifting equipment 5 . Both the main ship 1 and the auxiliary ship 6 are self-propelled motor ships, the rotating platform 2 is fixed on the main ship 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com