Rock confining pressure application device implemented by utilizing link mechanism

A link mechanism and application device technology, applied in the direction of measuring devices, test machinability, instruments, etc., can solve problems such as lack of confining pressure simulation capabilities, and achieve the effects of reduced test costs, high simulation range, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

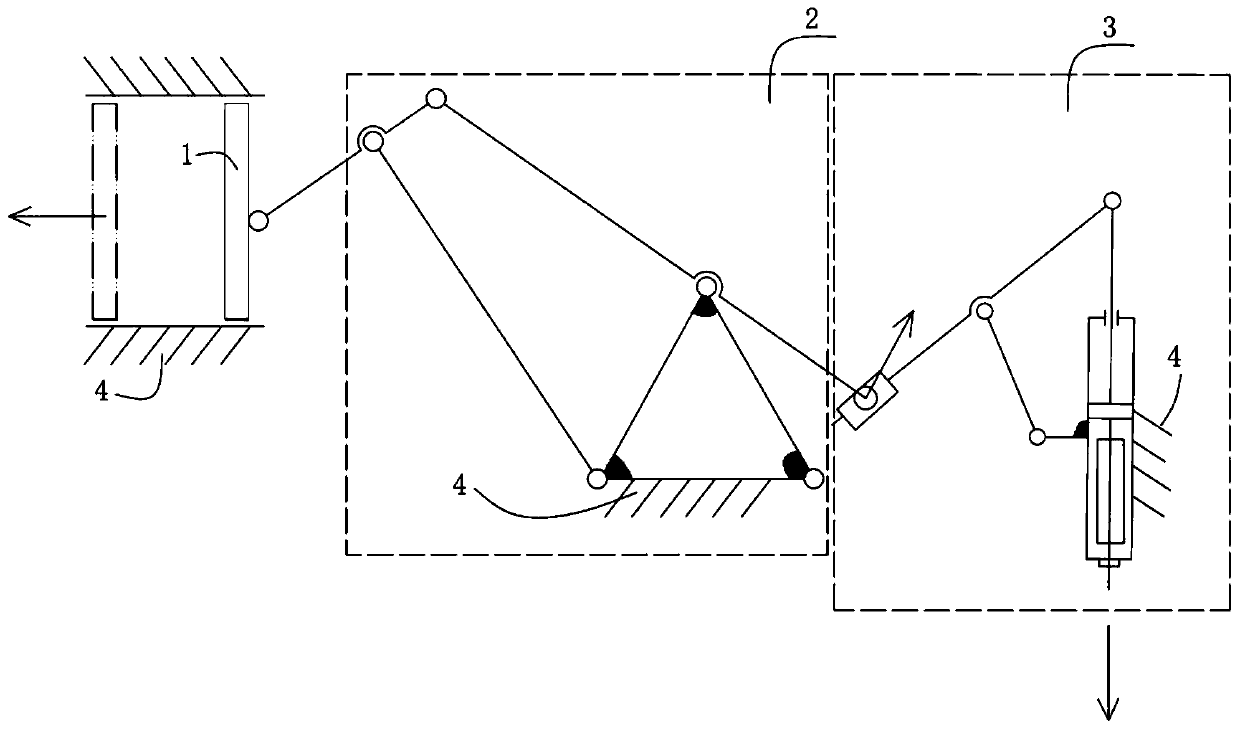

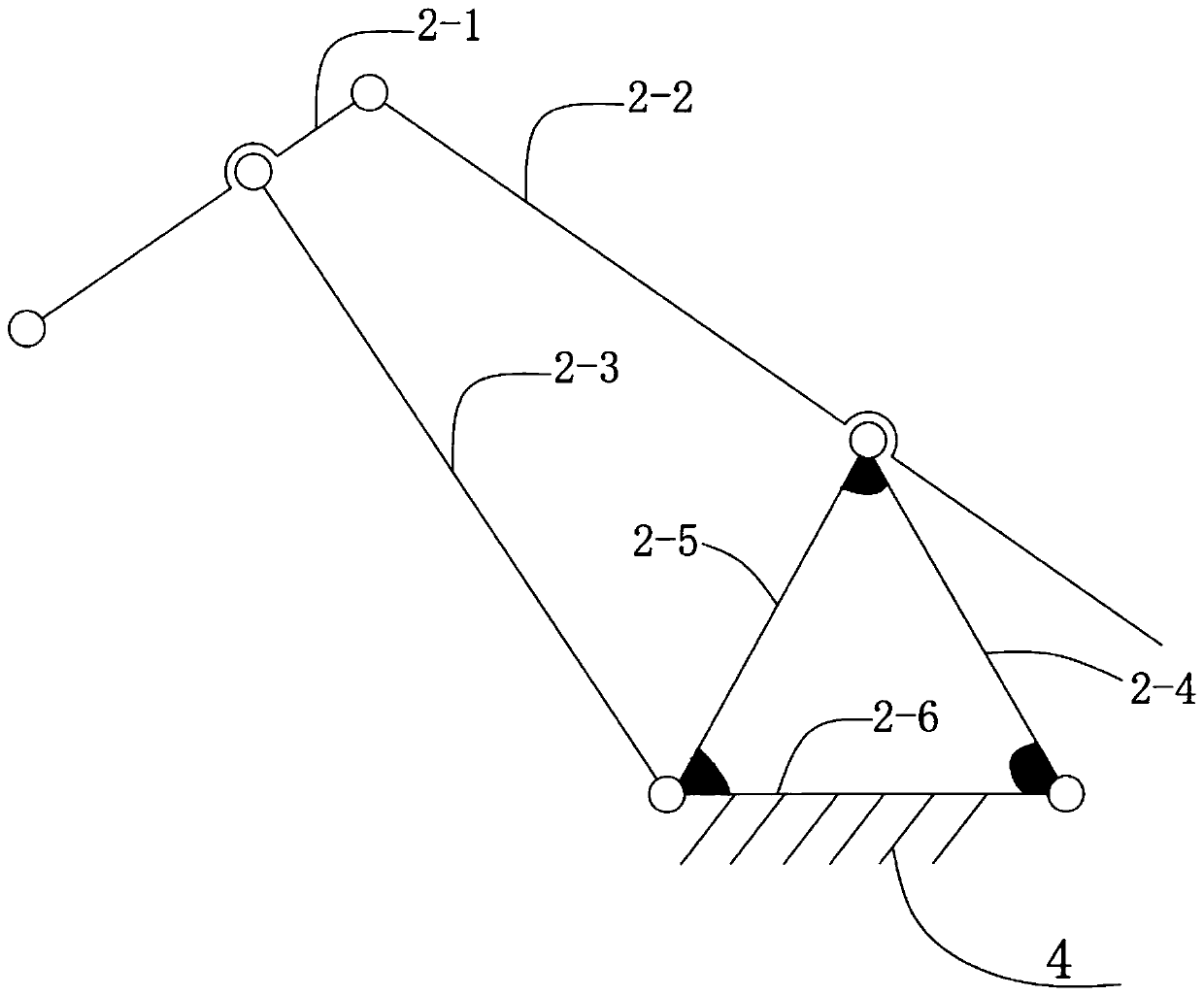

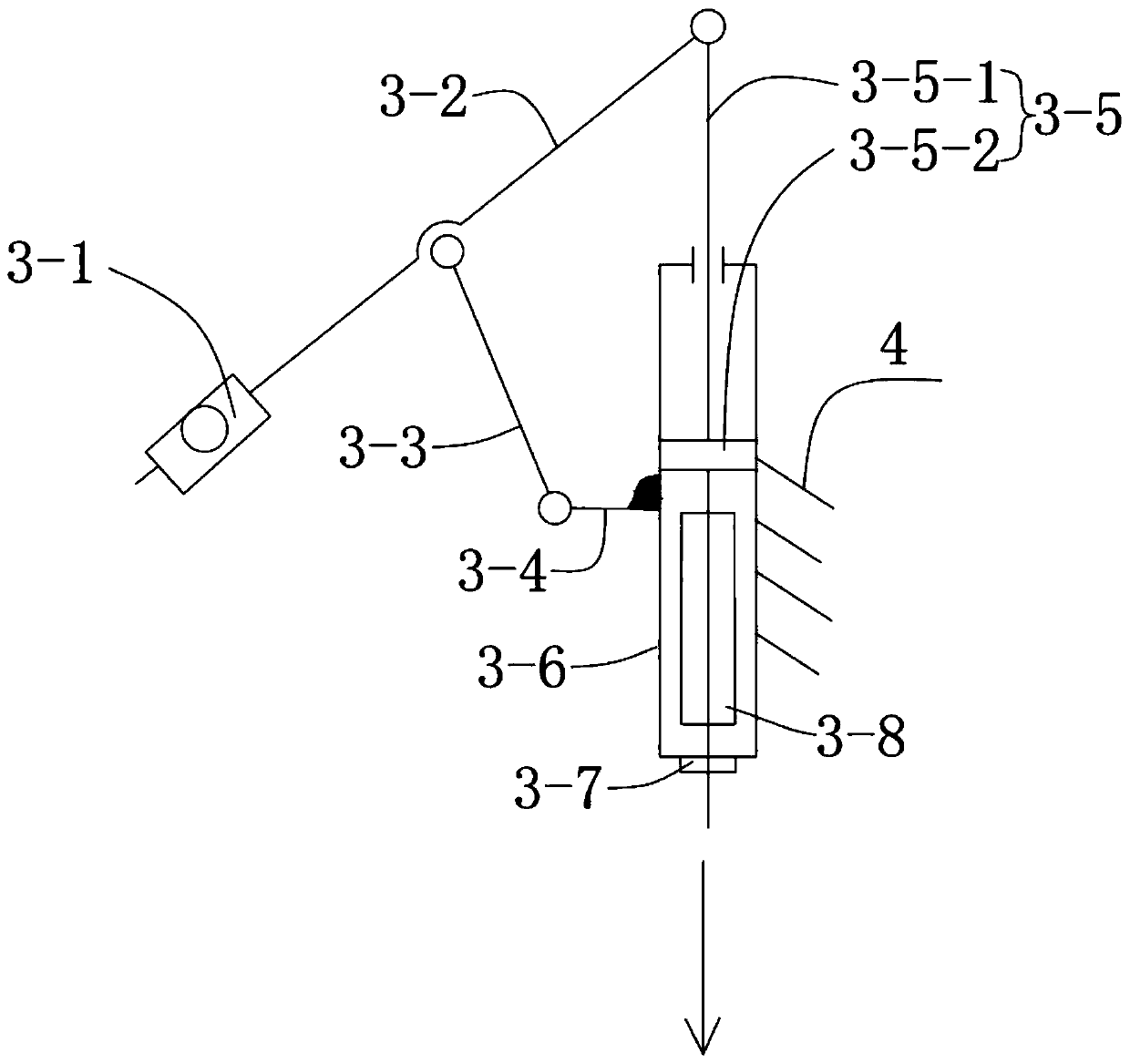

[0059] Such as Figure 1 to Figure 5 , Figure 10 Shown is a drawing of a specific embodiment 1 of a rock confining pressure applying device realized by a linkage mechanism of the present invention. Such as figure 1 As shown, it is a rock confining pressure application device realized by a linkage mechanism of the present invention, including a loading plate 1, a horizontal luffing mechanism 2, a fixed block mechanism 3, a heat collecting and conducting block 3-8, a heating element (not shown) ), characterized by:

[0060] The horizontal luffing mechanism includes the active rocker 2-2, the driven rocker 2-3 and the transition link 2-1; the active rocker 2-2 and the driven rocker 2-3 are connecting rods; the transition link 2-1 is a connecting rod; driven by the active rocker 2-2, the power passes through the transition connecting rod 2-1, so that the driven rocker 2-3 swings around the frame 4 with the active rocker 2-2 ;During this process, the rod end at the transition ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com