A Type 2-8 High Pressure Loading Device for In Situ Neutron Diffraction

A loading device and neutron technology, applied in the direction of material analysis, measuring devices, instruments, etc. using wave/particle radiation, can solve problems such as inability to obtain experimental results, neutron signal attenuation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

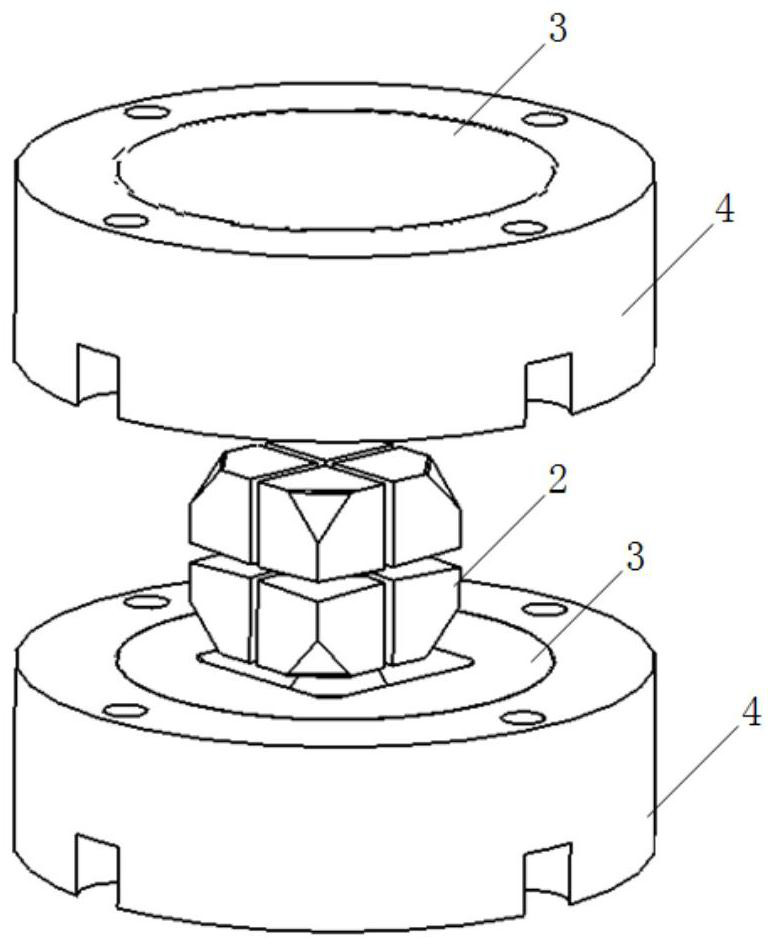

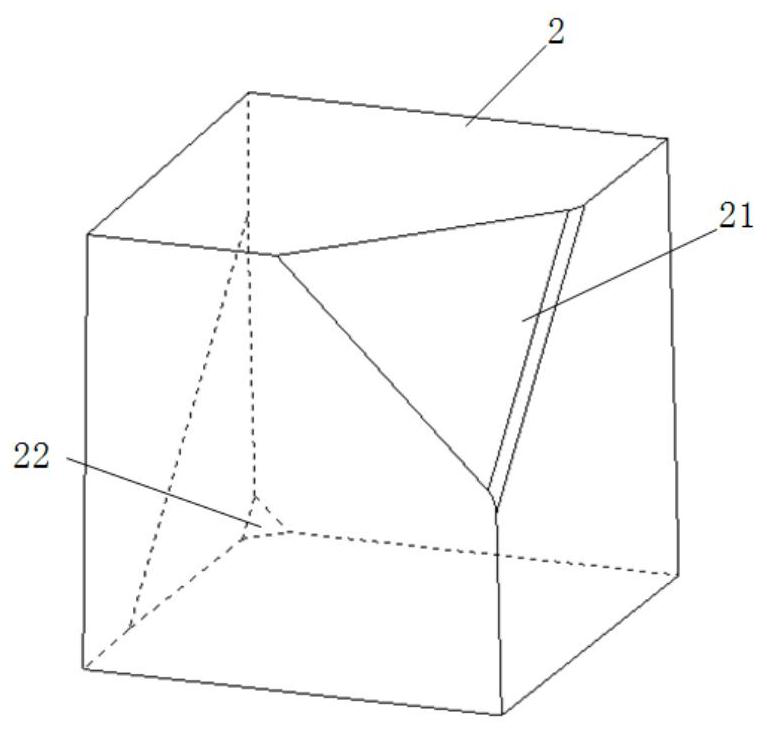

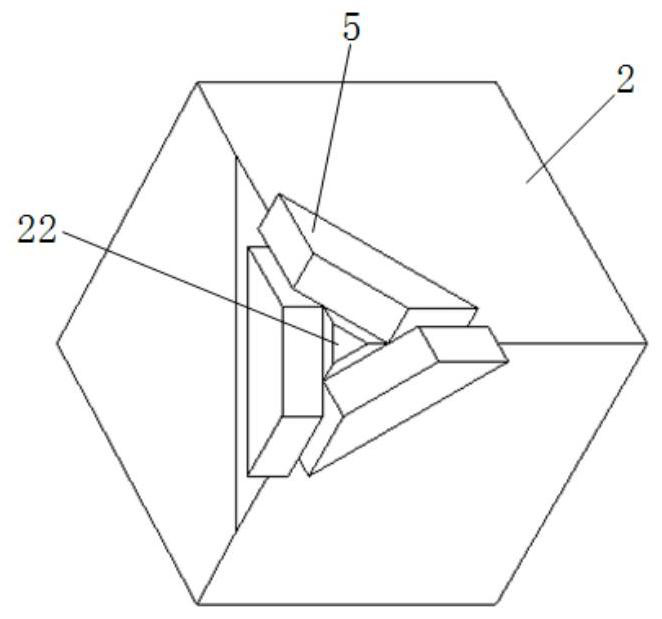

[0030] Such as figure 1 As shown, this embodiment provides a 2-8 type high-pressure loading device for in-situ neutron diffraction, including a pressure block, a guide block, a secondary anvil, and a pressure transmission medium arranged in sequence from the outside to the inside, wherein, As shown in 9, a pressure groove is provided in the middle of the pressure block, and the guide block is arranged in the pressure groove. One end of the guide block is provided with a square groove, and the inner wall of the groove is provided with an inclined guide surface. The square grooves of the two guide blocks are opposite to each other. Set to form a first-level cavity; one end of the pressurizing block is provided with a pressurizing groove matching the size and shape of the outside of the guide block, and the guide block is arranged in the pressurizing groove; figure 2 As shown, the secondary anvil is obtained by cutting off two corners that are symmetrical to the center point of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com