Intercooling separation device and process for catalytic cracking product gas

A technology of catalytic cracking and product gas, which is applied in cold treatment separation, liquefaction, ethylene production, etc. It can solve the problems of energy loss, reduce power consumption, avoid excessive oxygen content, and save investment related to deoxygenation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solution of the present invention will be clearly and completely described below. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments that are improved or adjusted by those skilled in the art belong to the protection scope of the present invention.

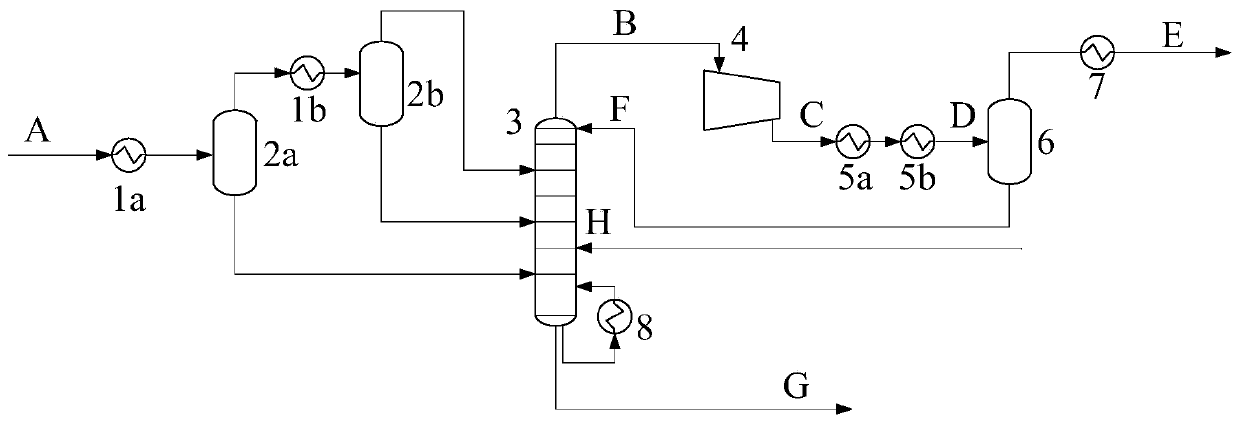

[0039] by figure 1 Describe the intercooling separation device and process of the catalytic cracking product gas provided by the present invention as an example, wherein, multiple precooling heat exchangers, separator tanks, and condensers can be set according to requirements, and in this embodiment, it is set as precooling heat exchange Two liquid separator tanks and two condensers:

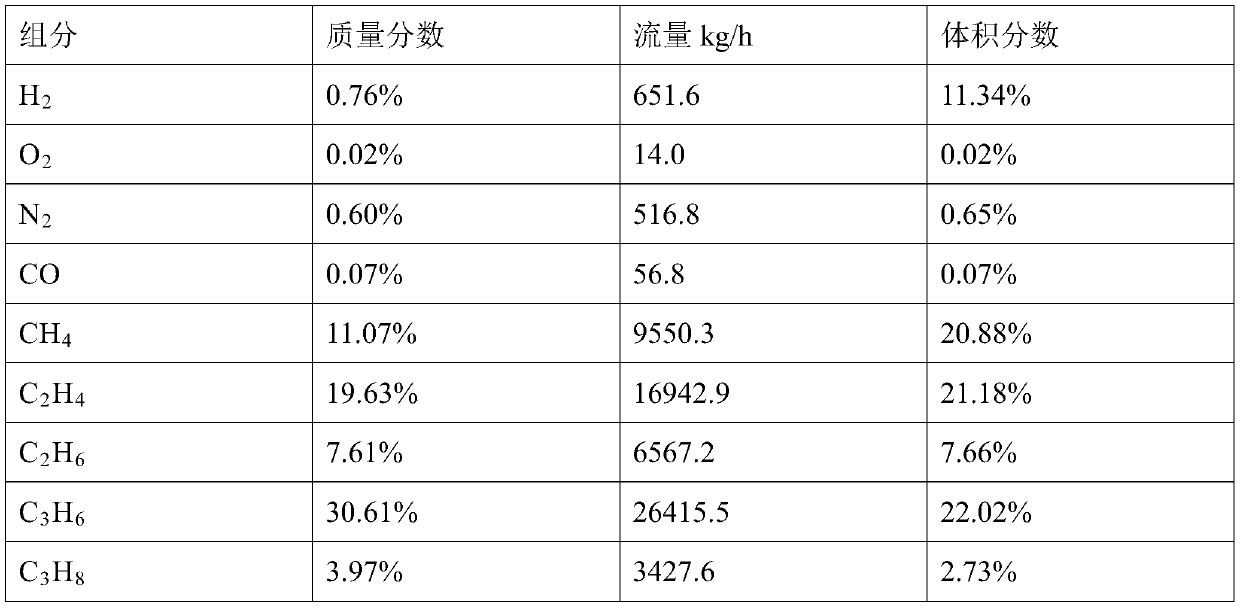

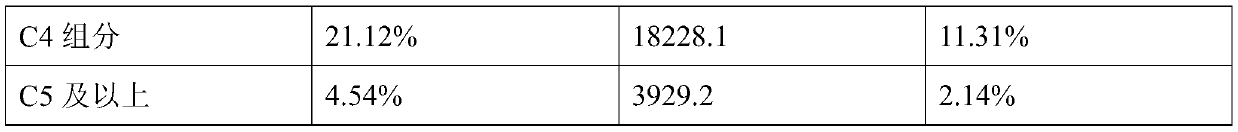

[0040] After the catalytic cracking product gas A after the upstream treatment enters the intercooling separation unit provided by the present invention, the specific flow is as follows: the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com