Giant hydraulic power plant state maintenance model construction method and system

A construction method and technology of hydropower plants, applied in the direction of instruments, etc., can solve the adverse effects of safe and stable operation of equipment, reduce equipment life cycle, less maintenance and other issues, to save equipment purchase and installation funds, increase availability factor and power generation capacity, The effect of improving operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with drawings and embodiments.

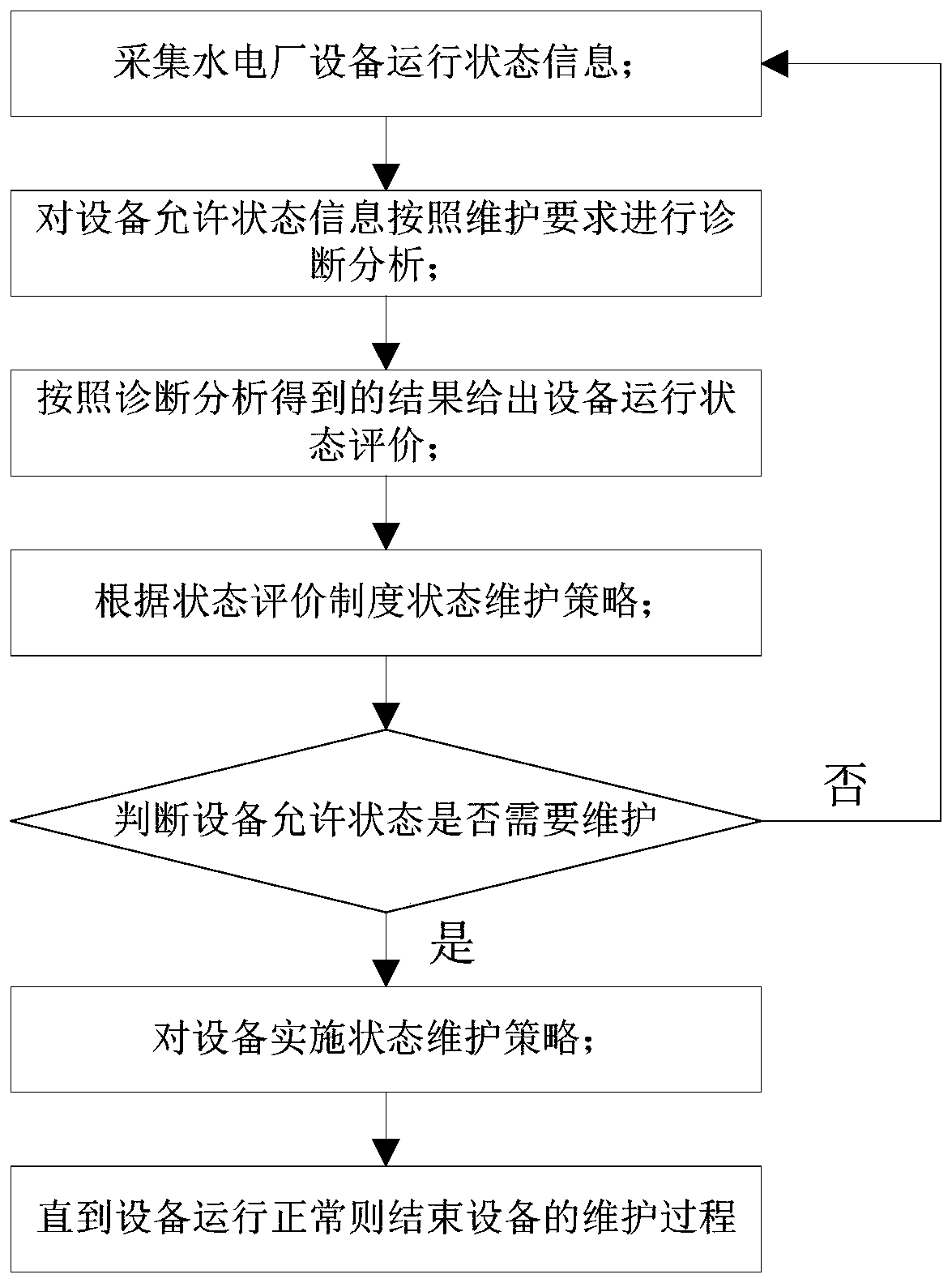

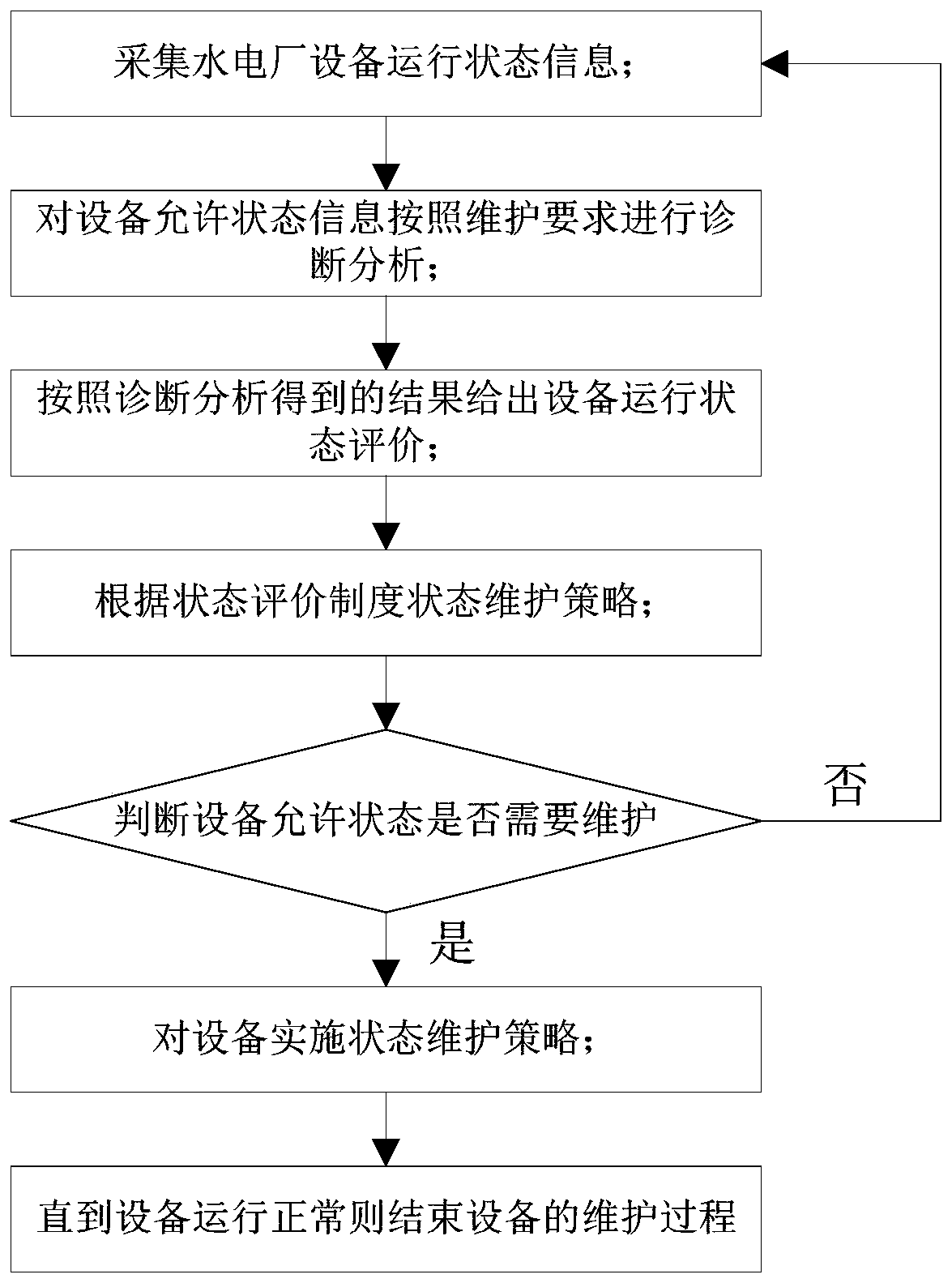

[0052] The method for constructing the condition maintenance model of a giant hydropower plant provided in this embodiment includes the following steps:

[0053] Collect information on the operation status of hydropower plant equipment;

[0054] Carry out diagnostic analysis on equipment permission state information according to maintenance requirements;

[0055] According to the results obtained from the diagnostic analysis, the equipment operation status evaluation is given;

[0056] According to the state evaluation system state maintenance strategy;

[0057] Judging whether the equipment permit status needs to be maintained, if not, return to re-collect the operation status information of the hydropower plant equipment;

[0058] If yes, implement a condition maintenance strategy for the device;

[0059] The maintenance process of the equipment is ended until the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com