Opposite-grinding type four-leg heat-insulating brick burr treatment device

A processing device and a technology of heat insulating bricks, which are applied in the direction of grinding drive devices, machine tools suitable for grinding the edge of workpieces, grinding machines, etc., can solve the problems of expensive equipment, difficulty in installing four-legged heat insulating brick grinding machines, and poor grinding effect. Issues such as less than guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

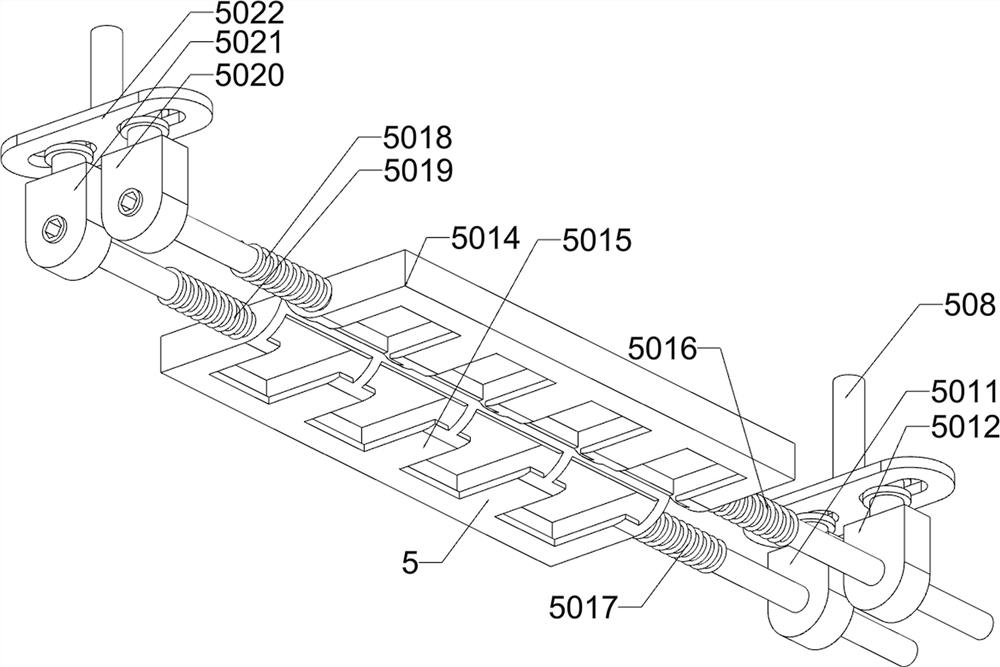

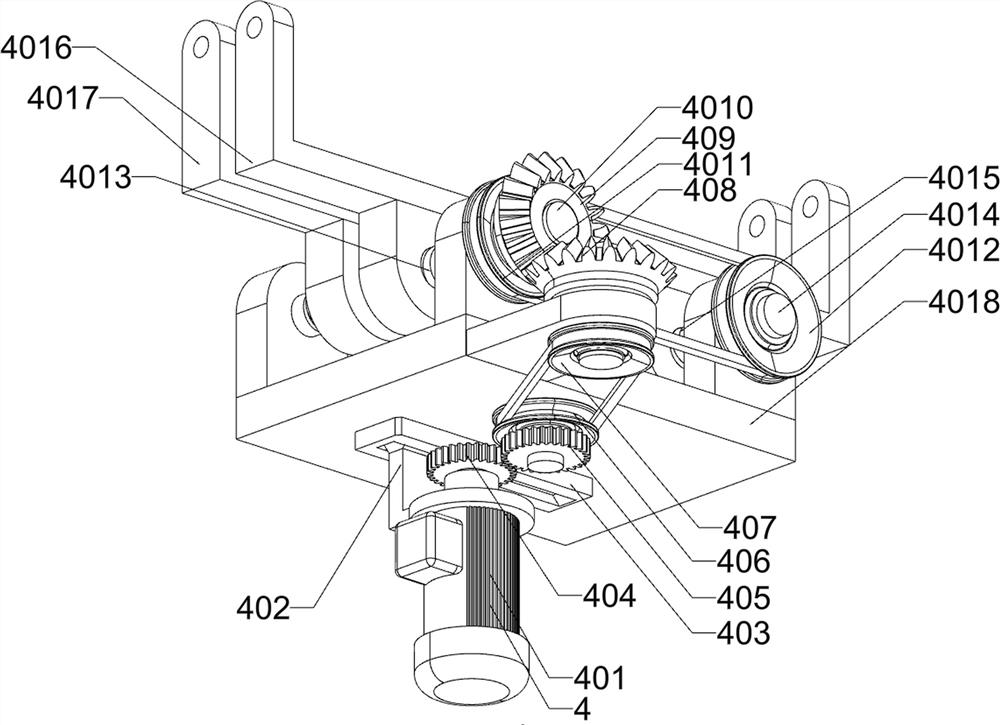

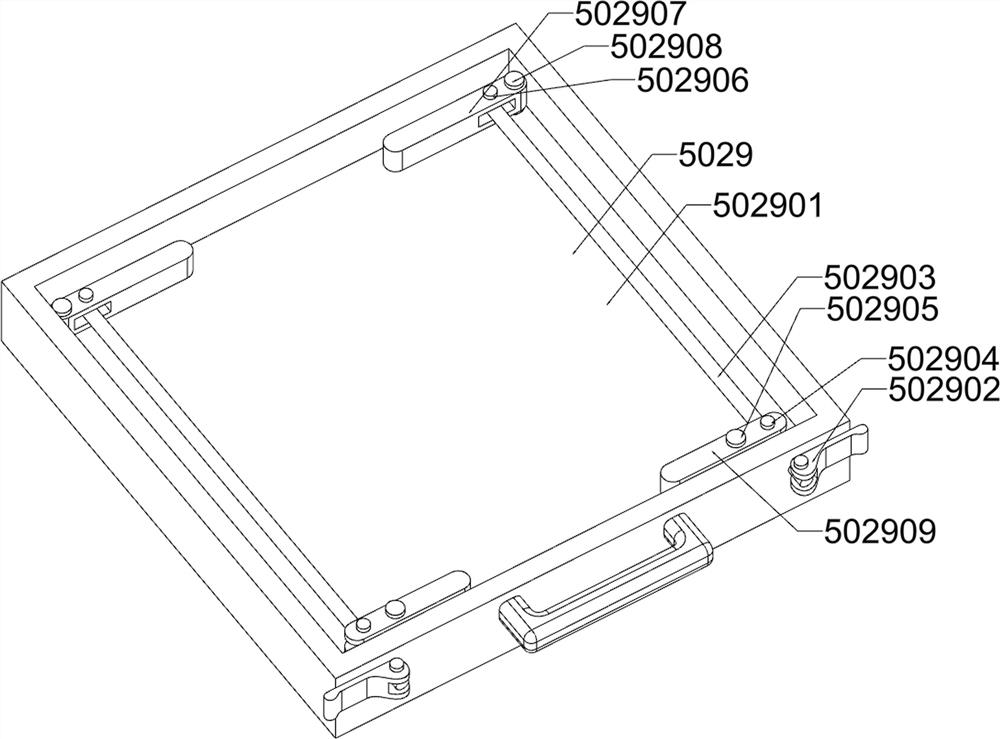

[0105] A pair of milling four foot insulation bricks, such as Figure 1-9 As shown, the bottom support plate 2; support the bottom plate 1, and the support bottom plate 1 is continuously fixed with the eight sets of bottom support plate 2; it is characterized in that the label transfer system 3 is connected to the support bottom plate 1; staple system 4 is connected to the support bottom plate 1; the fold system 5 is connected to the support bottom plate 1, and the fold system 5 is connected to the staple buckle system 4; the control display screen 6 is connected to the confinement system 5.

[0106] Working process: When using, the ground-type four-foot insulation brick clipping device is installed in place, external power supply, and place the four-legged inside the four-legged inside the four-legged four On both sides of the foot insulation brick wall, then control the starter by the control screen 2, first clamping the arranged four foot insulation bricks in the molar system 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com