Fuel tank assembly and automobile

A fuel tank and assembly technology, applied in the field of fuel tank assemblies and automobiles, can solve the problem of high production costs, and achieve the effects of reducing weight requirements, reducing production costs, and high anti-corrosion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

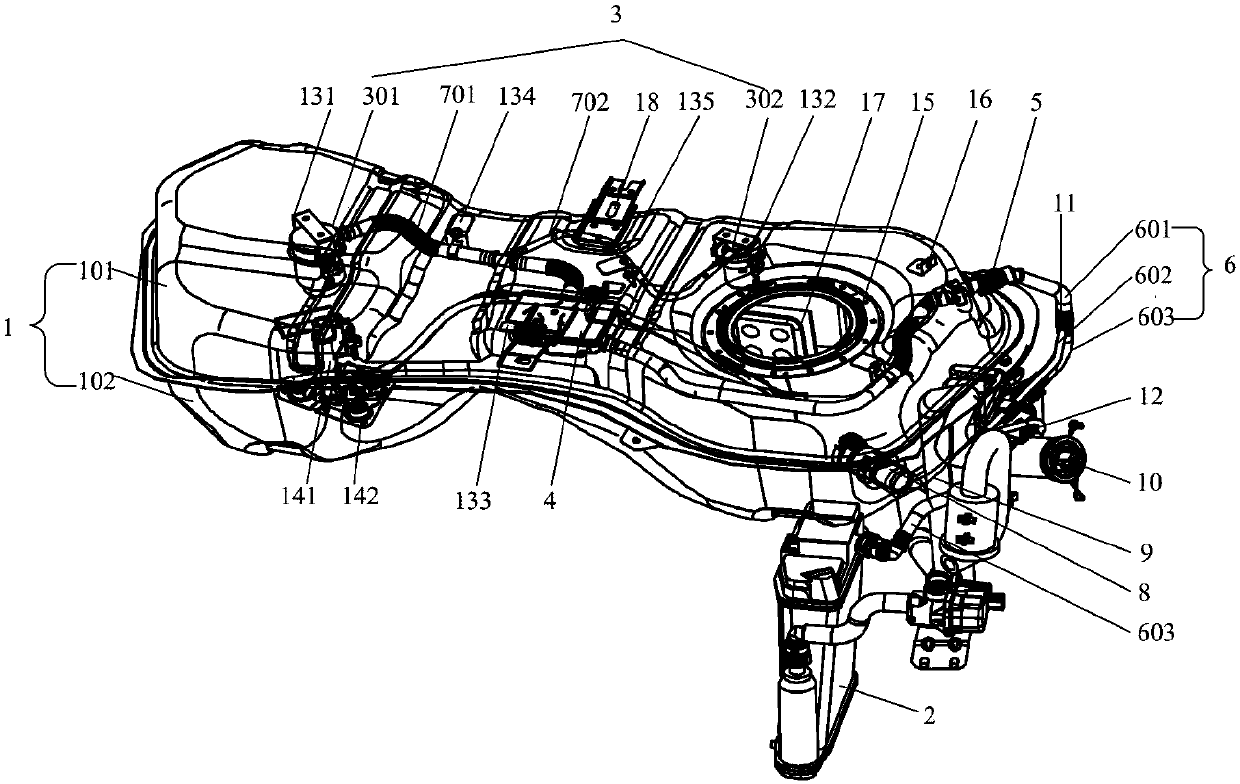

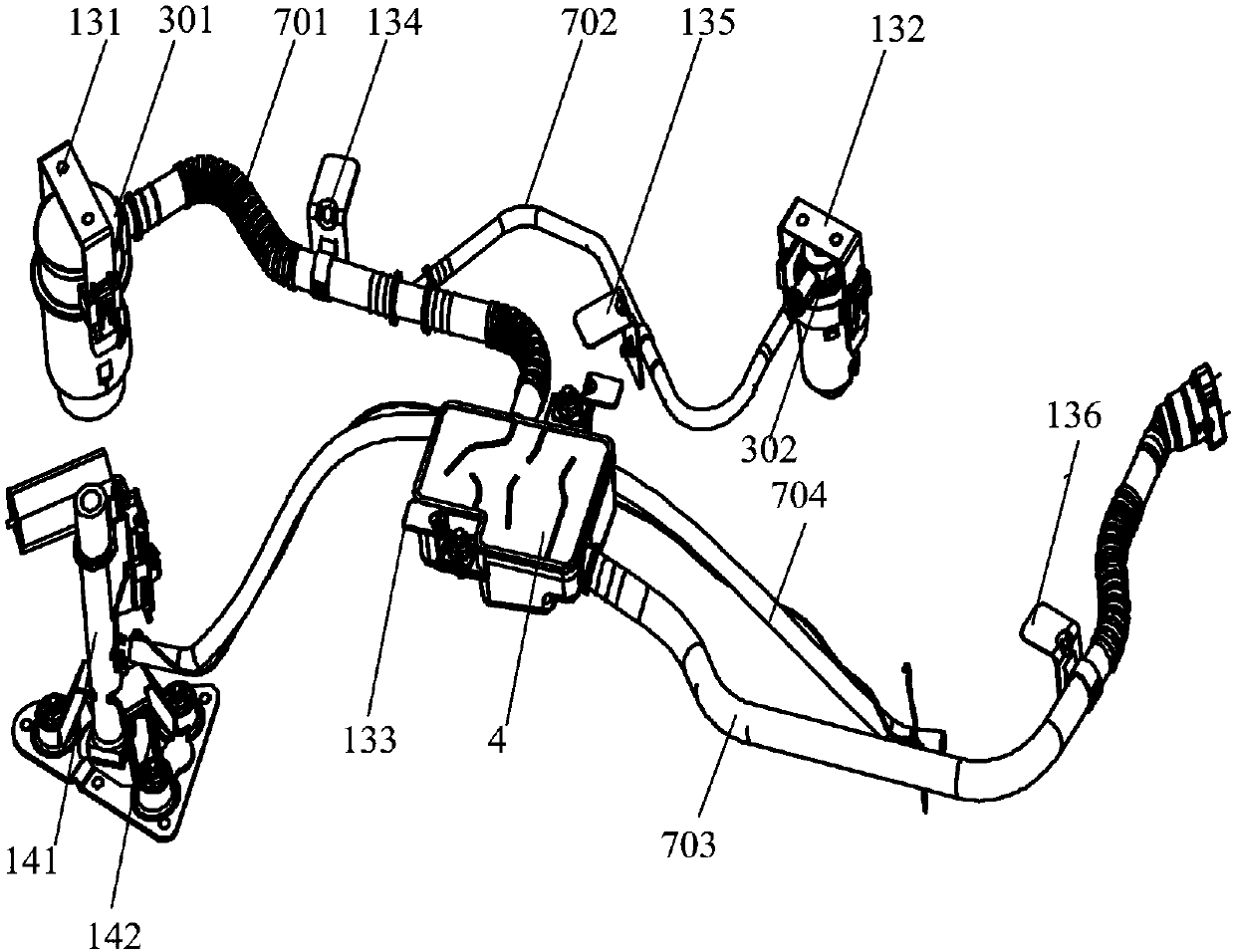

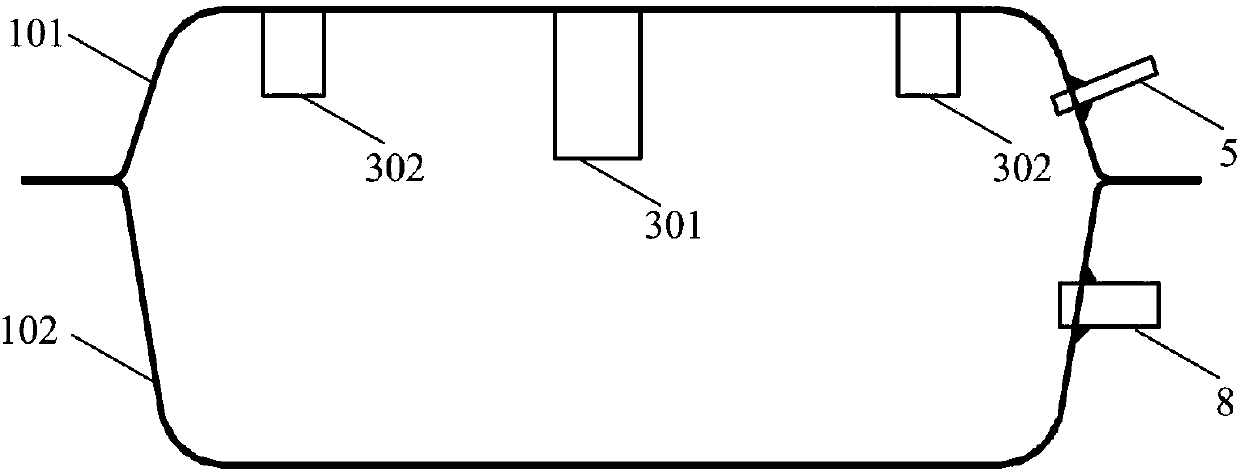

[0036] see figure 1 , in order to facilitate understanding, the external structure and internal structure of the fuel tank are shown in figure 1 , but the specific positions of each structure may be subject to the actual description.

[0037] This embodiment provides a fuel tank assembly, including: a stainless steel shell 1 and a carbon tank 2, the top of the stainless steel shell 1 is provided with a valve body 3 and a liquid vapor separator (Liquid vapor separator, referred to as LVS) 4, stainless steel The housing 1 is also provided with an exhaust pipe joint 5, the outlet of the valve body 3 communicates with the inlet of the liquid collector 4 through a pipeline, and the outlet of the liquid collector 4 communicates with one end of the exhaust pipe joint 5 through a pipeline. The other end of the air pipe joint 5 communicates with the carbon canister 2 through an exhaust pipeline 6 .

[0038] In the above-mentioned fuel tank assembly, the stainless steel shell 1 is inc...

Embodiment 2

[0079] This embodiment provides an automobile, which includes the fuel tank assembly in the above embodiment.

[0080] see figure 1 , the above-mentioned fuel tank assembly is applied in automobiles, including a stainless steel shell 1, which is used as a fuel tank body. Compared with the low-carbon steel shell in the prior art, the stainless steel plate material When the thickness reduction rate reaches 10%, the yield strength increases from the original 280MPa to 480MPa, that is, through work hardening, under the same strength requirements, the plate thickness of the low carbon steel shell needs to be 1.4mm ~ 1.7mm, while the stainless steel shell The plate thickness of the body 1 only needs to be 0.8mm~1.2mm, so that the thickness of the shell plate can be reduced. Taking a fuel tank with a rated volume of 50L as an example, the weight of the assembly can be reduced to about 12.5Kg, realizing the lightness of the fuel tank. Quantification, thereby reducing the weight requi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com